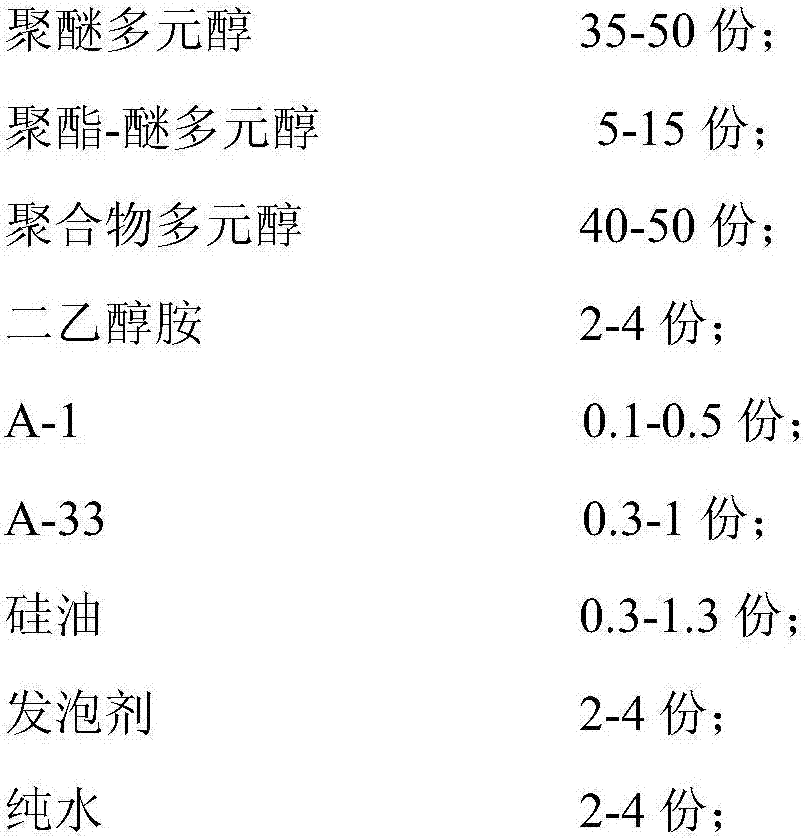

Polyester-polyether polyol, preparation method thereof as well as prepared high-resilience polyurethane foamed plastic and preparation method thereof

A polyester polyol and ether polyol technology, which is applied in the field of polyurethane high-resilience foam, can solve the problems of product use and storage effects, material properties are not stable enough, and the color value of synthetic products is deep. Excellent hydrolysis resistance and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

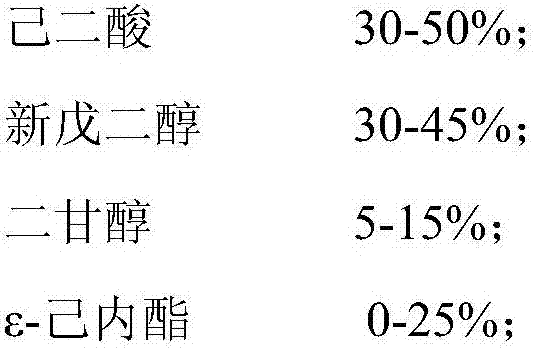

[0041] (1) The preparation method of polyester polyol is as follows:

[0042] The raw materials and proportioning are shown in Table 1;

[0043] Put adipic acid, neopentyl glycol, diethylene glycol, ε-caprolactone and catalyst tetrabutyl titanate into the reaction kettle, replace the air in the kettle with nitrogen, start stirring, raise the temperature to 120°C for 1 hour, and then , heat up to 230°C, keep warm until the acid value is less than 20mgKOH / g, start vacuuming, and gradually increase the vacuum degree. When the acid value is less than 1mgKOH / g and the hydroxyl value is 122mgKOH / g, the temperature is lowered to obtain the polyester multi-component alcohol.

[0044] (2) The preparation method of polyester-ether polyol is as follows:

[0045] Add 920g of polyester polyol (hydroxyl value 122mgKOH / g) and 0.0707g of double metal cyanide complex (DMC catalyst) prepared in step (1) to the pressure-resistant reactor, then heat up to 130°C and vacuumize To -0.09MPa, blow ...

Embodiment 2

[0048] (1) The preparation method of polyester polyol is as follows:

[0049] The raw materials and proportioning are shown in Table 1;

[0050]Put adipic acid, neopentyl glycol, diethylene glycol, ε-caprolactone and catalyst tetrabutyl titanate into the reaction kettle, replace the air in the kettle with nitrogen, start stirring, raise the temperature to 125°C for 1 hour, and heat up to 230°C, keep warm until the acid value is less than 20mgKOH / g, start vacuuming, gradually increase the vacuum degree, and when the acid value is less than 1mgKOH / g and the hydroxyl value is 122mgKOH / g, lower the temperature to obtain the polyester polyol.

[0051] (2) The preparation method of polyester-ether polyol is as follows:

[0052] Add polyester polyol 736g (hydroxyl value 122mgKOH / g) prepared by step (1), polytetrahydrofuran diol 132g (hydroxyl value 170mgKOH / g), double metal cyanide complex (DMC catalyst) in the pressure-resistant reactor 0.0606g, then heated up to 140°C, evacuated ...

Embodiment 3

[0055] (1) The preparation method of polyester polyol is as follows:

[0056] See Table 1 for raw materials and proportioning;

[0057] Put adipic acid, neopentyl glycol, diethylene glycol, ε-caprolactone and catalyst tetrabutyl titanate into the reaction kettle, replace the air in the kettle with nitrogen, start stirring, raise the temperature to 130°C for 1 hour, and then heat up to 230°C, keep warm until the acid value is less than 20mgKOH / g, start vacuuming, gradually increase the vacuum degree, and when the acid value is less than 1mgKOH / g and the hydroxyl value is 125mgKOH / g, lower the temperature to obtain the polyester polyol.

[0058] (2) The preparation method of polyester-ether polyol is as follows:

[0059] Add polyester polyol 673.2g (hydroxyl value 125mgKOH / g) prepared by step (1), polytetrahydrofuran diol 165g (hydroxyl value 170mgKOH / g), double metal cyanide complex (DMC catalyst) in the pressure-resistant reactor ) 0.106g, then heated up to 150°C, evacuated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com