Optically thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and polyurethane elastomer technology, applied in the field of optical grade thermoplastic polyurethane elastomer and its preparation, can solve the problems of large difference in thermal expansion coefficient, poor bonding performance, fogging, etc., and achieve good bonding performance and matching characteristics , Wide adjustable range of performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

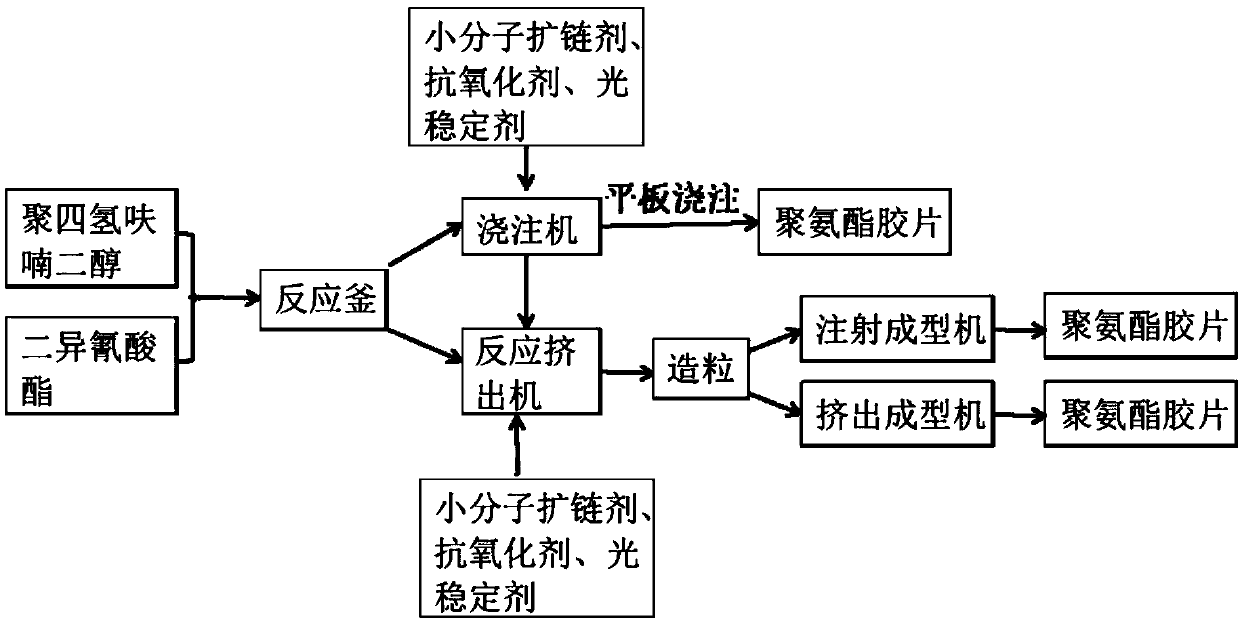

Method used

Image

Examples

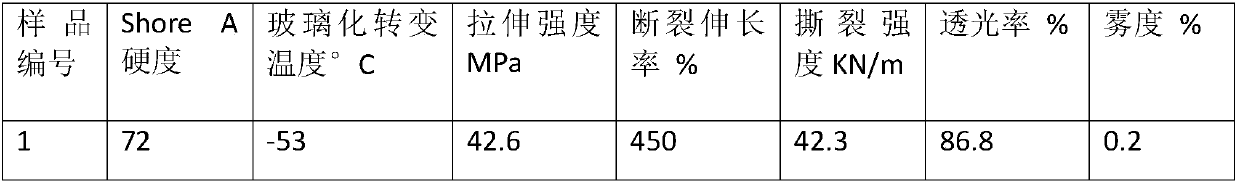

Embodiment 1

[0033] In a 5L reactor, add 1400g polytetrahydrofuran diol (molecular weight 1000) and 490g H 12 MDI, 0.2g dibutyltin dilaurate (DBTDL) as a catalyst, heat and stir at 95°C for 3 hours to synthesize a prepolymer, and place it in the A barrel of the pouring machine, weigh and place 80g of butanediol in the B barrel as a chain extender , and add 10g antioxidant and 20g light stabilizer. After mixing the materials evenly in proportion with a pouring machine, pour directly into the flat mold, level the flat mold by tape casting method, place the flat mold in a blast oven at 95°C for reaction chain extension, and obtain a transparent polyurethane film with a thickness of about 1.5mm . The obtained polyurethane film was tested for tensile properties and tear strength, and its optical properties were tested after being compounded with two pieces of 2mm thick chemically strengthened inorganic glass.

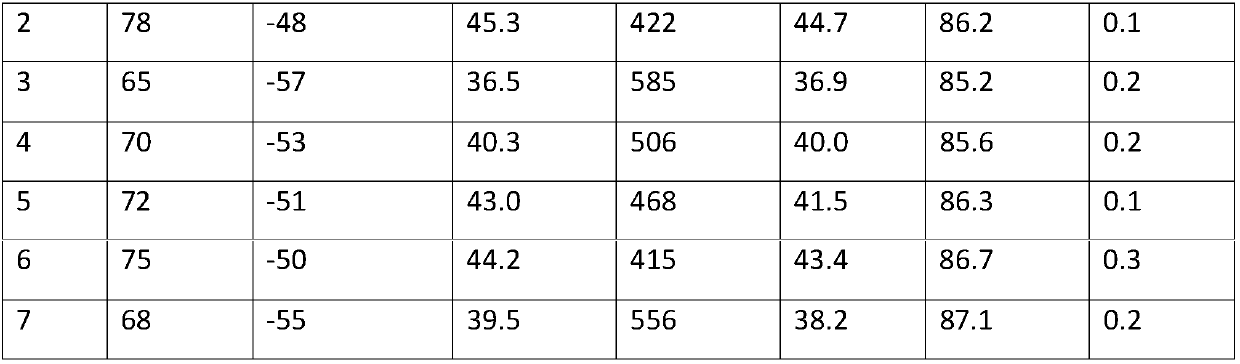

Embodiment 2

[0035] Adjust the ratio of monomers, that is, adjust the ratio of soft and hard segments of polyurethane elastomers. Use 1300g polytetrahydrofuran diol (molecular weight 1000) and 590g H in the synthetic process of prepolymer 12 MDI. Other components are unchanged, according to the method and equipment of Example 1, the synthesis of polyurethane elastomer material and film preparation are carried out, and its performance is tested;

Embodiment 3

[0037] Adjust the ratio of hard and soft segments again. Use 1500g polytetrahydrofuran diol (molecular weight 1000) and 390g H in the synthetic process of prepolymer 12 MDI. Other components are unchanged, according to the method and equipment of Example 1, the synthesis of polyurethane elastomer material and film preparation are carried out, and its performance is tested;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com