Micropore polyurethane elastomer material and preparation method and use thereof

A technology of polyurethane elastomer and microporous, which is applied in the direction of track, building, fixed rail, etc., and can solve the problems of not meeting practical requirements and poor shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Component A: polyether polyol P1 (2-functionality polytetrahydrofuran ether polyol with a number average molecular weight of 2000) 55kg, polyether polyol P2 (3-functionality polyoxyethylene-oxypropylene copolyether with a number average molecular weight of 4800) Polyhydric alcohol, terminal and primary hydroxyl content greater than 70%) 25kg, ethylene glycol 6kg, foam stabilizer 0.3kg, water 0.4kg, tertiary amine catalyst 0.6kg, 3000 mesh hollow glass microspheres 10kg.

[0034] B component: the same as the comparative example.

Embodiment 2

[0036] Component A: polyether polyol P1 (2-functionality polytetrahydrofuran ether polyol with a number average molecular weight of 2000) 75kg, polyether polyol P2 (3-functionality polyoxyethylene-oxypropylene copolyether with a number average molecular weight of 4800) Polyhydric alcohol, terminal primary hydroxyl content is greater than 70%) 5kg, ethylene glycol 9kg, foam stabilizer 0.7kg, water 0.5kg, tertiary amine catalyst 1.0kg, 5000 mesh hollow glass microspheres 25kg.

[0037] Component B: 90kg of diphenylmethane diisocyanate, 10kg of dimethyl biphenyl diisocyanate, 77kg of polyether polyol P1 (2-functional polytetrahydrofuran ether polyol with a number average molecular weight of 2000), and an NCO group content of 23 %.

Embodiment 3

[0039] Component A: polyether polyol P1 (2-functionality polytetrahydrofuran ether polyol with a number average molecular weight of 3000) 75kg, polyether polyol P2 (3-functionality polyoxyethylene-oxypropylene copolyether with a number average molecular weight of 3000) Polyhydric alcohol, terminal primary hydroxyl content greater than 70%) 5kg, 1,4-butanediol 8kg, foam stabilizer 0.7kg, water 0.45kg, tertiary amine catalyst 0.8kg, 4000 order hollow glass microspheres 18kg.

[0040] Component B: 70kg of diphenylmethane diisocyanate, 30kg of dimethyl biphenyl diisocyanate, 164.3kg of polyether polyol P (2-functionality polytetrahydrofuran ether polyol with a number average molecular weight of 3000), the content of NCO groups is 20%.

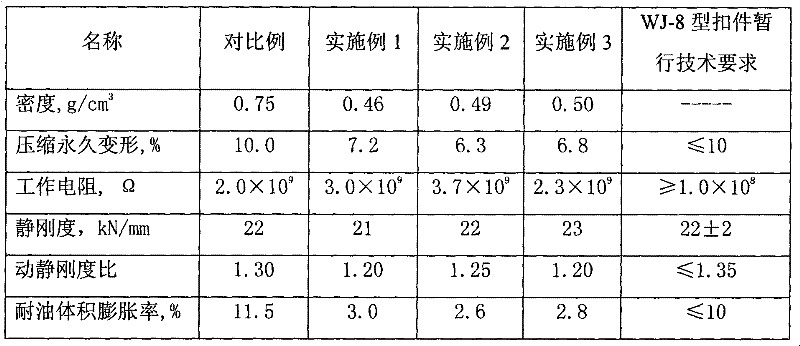

[0041] The results of the examples show that after the hollow glass microsphere filler is added, the product density is significantly reduced, and the oil resistance is significantly improved. The performance of the product meets the requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com