Waterborne polyurethane emulsion, coating and preparation method and application of waterborne polyurethane emulsion

A technology of water-based polyurethane and emulsion, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of chemical reagent corrosion, limit the application of water-based polyurethane, poor stability and water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

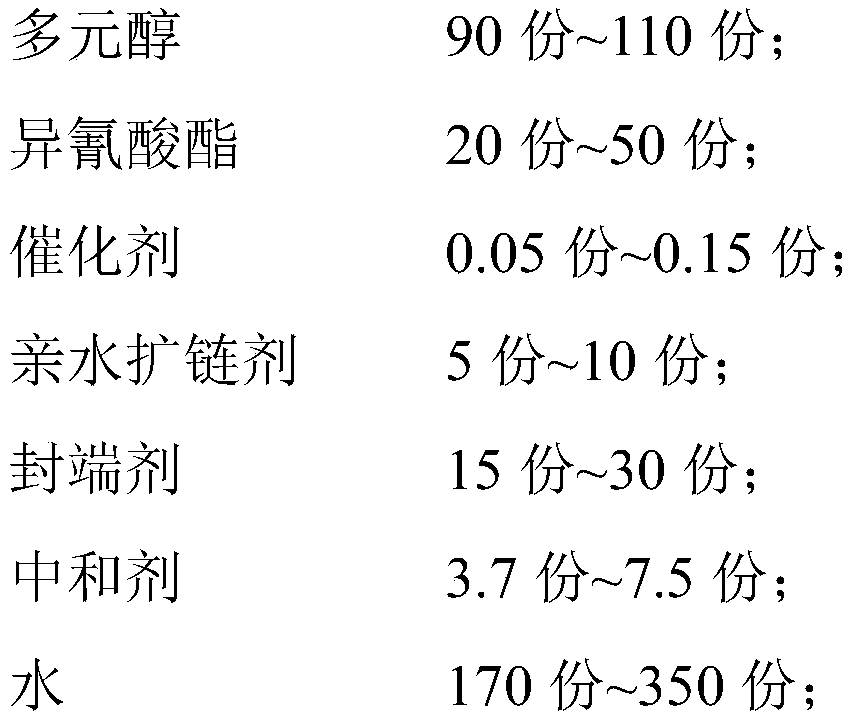

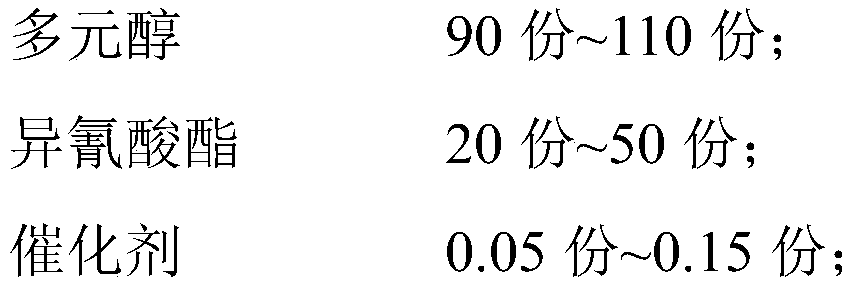

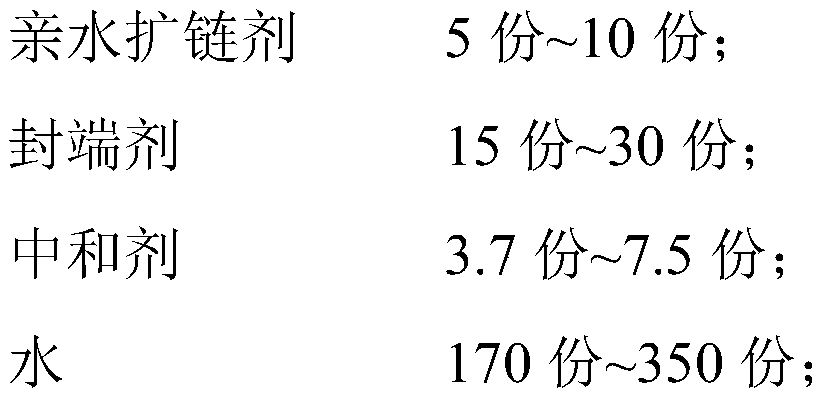

[0054] Another embodiment of the present invention also provides a kind of preparation method of aqueous polyurethane emulsion, and this preparation method comprises the steps:

[0055] Compounding polyol, isocyanate, catalyst, hydrophilic chain extender, end-capping agent, neutralizing agent and water according to the mass parts in the above-mentioned aqueous polyurethane emulsion;

[0056] Mix polyol, isocyanate and catalyst, and stir at a temperature of 70°C to 95°C for 2h to 5h;

[0057] Cool down to 60°C-70°C, add hydrophilic chain extender, and stir at 60°C-75°C for 1h-3h;

[0058] Add an end-capping agent, and stir at a temperature of 60°C to 75°C for 0.1h to 0.5h, then add a neutralizing agent;

[0059] Cool down to 40°C-60°C, add 95-105 parts by mass of solvent, and stir for 0.1h-1h to obtain a prepolymer;

[0060] Disperse the prepolymer in water at 8°C to 12°C to obtain a pre-finished product of water-based polyurethane emulsion;

[0061] Removal of solvents from...

Embodiment 1

[0077] In this embodiment, the polyol A is a carbon dioxide copolymer polyol, the number average molecular weight of the carbon dioxide copolymer polyol is 3000 g / mol, and the hydroxyl functionality is 2.

[0078] In this embodiment, the polyol B is a mixture of polycarbonate diol, polybutylene adipate diol and polytetrahydrofuran diol. Wherein the number average molecular weight of polycarbonate diol is 2000g / mol, and the hydroxyl functionality is 2; The number average molecular weight of polybutylene adipate diol is 3000g / mol, and the hydroxyl functionality is 2; Polytetrahydrofuran diol has a number average molecular weight of 2000 g / mol and a hydroxyl functionality of 2.

[0079] The isocyanate in this embodiment is isophorone diisocyanate. The catalyst is an organic bismuth catalyst. The hydrophilic chain extender is dimethylolpropionic acid. The capping agent is trimethylolpropane. The neutralizing agent is triethylamine. Water is deionized water. The solvent is ac...

Embodiment 2

[0089] In this embodiment, the polyol A is a carbon dioxide copolymer polyol, the number average molecular weight of the carbon dioxide copolymer polyol is 3000 g / mol, and the hydroxyl functionality is 2.

[0090] In this embodiment, the polyol B is a mixture of polycarbonate diol, polybutylene adipate diol and polytetrahydrofuran diol. Wherein the number average molecular weight of polycarbonate diol is 2000g / mol, and the hydroxyl functionality is 2; The number average molecular weight of polybutylene adipate diol is 3000g / mol, and the hydroxyl functionality is 2; Polytetrahydrofuran diol has a number average molecular weight of 2000 g / mol and a hydroxyl functionality of 2.

[0091] The isocyanate in this embodiment is isophorone diisocyanate. The catalyst is an organic bismuth catalyst. The hydrophilic chain extender is dimethylolbutyric acid. The capping agent is trimethylolpropane. The neutralizing agent is triethylamine. Water is deionized water. The solvent is acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com