PTMG (polyoxytetramethylene glycol) modifying moisture curing polyurethane melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, moisture-curing technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor hydrolysis resistance, low peel strength, and poor flexibility, and achieve hydrolysis resistance. Good performance, overcoming the effects of low peel strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

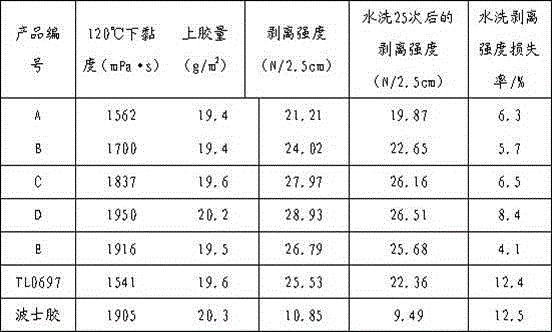

Examples

Embodiment 1

[0043] A PTMG modified moisture-curing polyurethane hot-melt adhesive, the following components are taken in parts by mass: 35 parts of polypropylene glycol, 15 parts of polytetrahydrofuran diol, 8 parts of polyadipate-1,6-hexanediol ester diol, 0.5 parts of antioxidant, 15.99 parts of tackifying resin, 25 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.01 part of catalyst, and 0.5 part of white carbon black.

[0044] The preparation steps are as follows:

[0045] (1) Selection of raw materials;

[0046] (2) Stir and mix polypropylene glycol, polytetrahydrofuran diol, polyhexamethylene adipate diol, and antioxidant, heat up to about 120°C, and dehydrate at a vacuum degree of less than 100Pa at 0.5 h;

[0047] (3) Add tackifying resin, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0048](4) Cool down to 87°C, add 4,4'-diphenylmethane diisocyanate (MDI) and catalyst, stir, and react for 2 hours at a vacuum degree of less...

Embodiment 2

[0053] A PTMG modified moisture-curing polyurethane hot-melt adhesive, the following components are taken in parts by mass: 30 parts of polypropylene glycol, 20 parts of polytetrahydrofuran diol, 8 parts of polyadipate-1,6-hexanediol ester diol, 0.5 parts of antioxidant, 15 parts of tackifying resin, 24 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.01 part of catalyst, 2 parts of silane coupling agent, and 0.49 parts of white carbon black.

[0054] The preparation steps are as follows:

[0055] (1) Selection of raw materials;

[0056] (2) Stir and mix polypropylene glycol, polytetrahydrofuran diol, polyhexamethylene adipate diol, and antioxidant, heat up to about 120°C, and dehydrate at a vacuum degree of less than 100Pa at 0.5 h;

[0057] (3) Add tackifying resin, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0058] (4) Cool down to 87°C, add 4,4'-diphenylmethane diisocyanate (MDI) and catalyst, stir, and react for ...

Embodiment 3

[0064] A PTMG modified moisture-curing polyurethane hot-melt adhesive, the following components are taken in parts by mass: 18.99 parts of polypropylene glycol, 30 parts of polytetrahydrofuran diol, 8 parts of poly-1,6-hexanediol adipate, 0.5 parts of antioxidant, 15 parts of tackifying resin, 25 parts of 4,4'-diphenylmethane diisocyanate (MDI), 0.01 part of catalyst, 2 parts of silane coupling agent, and 0.5 parts of white carbon black.

[0065] The preparation steps are as follows:

[0066] (1) Selection of raw materials;

[0067] (2) Stir and mix polypropylene glycol, polytetrahydrofuran diol, polyhexamethylene adipate diol, and antioxidant, heat up to about 120°C, and dehydrate at a vacuum degree of less than 100Pa at 0.5 h;

[0068] (3) Add tackifying resin, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0069] (4) Cool down to 87°C, add 4,4'-diphenylmethane diisocyanate (MDI) and catalyst, stir, and react for 2 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com