Process for preparing water-soluble copolyester

A copolyester, water-soluble technology, applied in the field of high polymer synthesis, can solve the problems of adverse effects in the production process of sea-island fibers and poor crystallization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

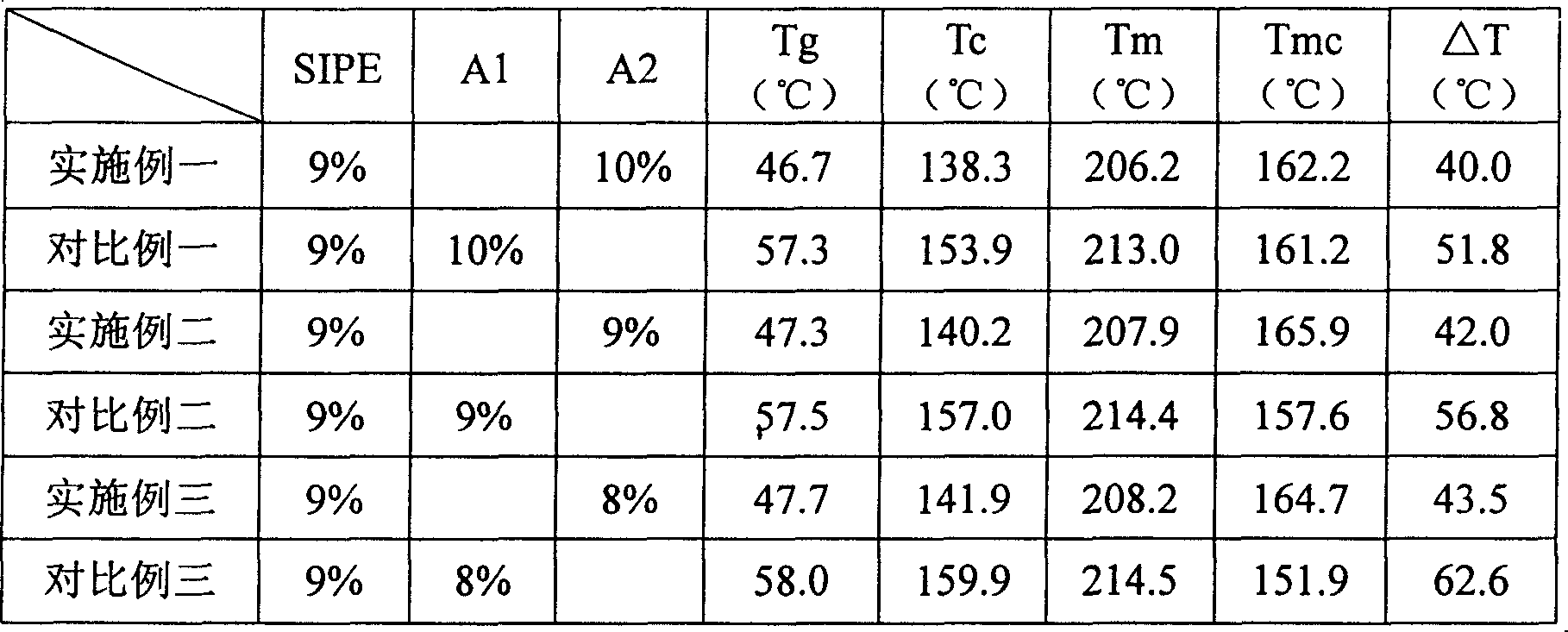

Embodiment 1

[0021] 91.26 kg of PTA (purified terephthalic acid), 10.14 kg of isophthalic acid, 65.3 kg of EG (ethylene glycol), 80 grams of antimony acetate, 50 grams of sodium acetate, and 30 grams of phosphoric acid were successively put into a 300L stainless steel reactor. use N 2 Pressurize after several replacements, use the valve at the top of the fractionation column to adjust the pressure in the kettle to 0.2-0.25MPa (gauge pressure), stir at 65rpm, and raise the temperature to 220°C-260°C for esterification. Release the pressure when the water output reaches 21 kilograms, end the esterification, then drop into 53.7 kilograms of ES-40 (weight percent concentration is the ethylene glycol solution of 40% bishydroxyethyl isophthalate-5-sodium sulfonate) 15 kilograms of polytetrahydrofuran (accounting for 10% of copolyester gross weight) that the number average molecular weight is 5500, heat up and reduce pressure, the stirring speed is adjusted to 40~55rpm, carry out under 280~295 ℃,...

Embodiment 2

[0026]92.35 kg of PTA, 10.25 kg of isophthalic acid, 66 kg of EG, 80 g of antimony acetate, 50 g of sodium acetate, and 30 g of phosphoric acid were successively put into a 300L stainless steel reactor. After replacing with N2 for several times, pressurize, use the valve at the top of the fractionating column to adjust the pressure in the kettle to 0.2-0.25MPa (gauge pressure), stir at 65rpm, and raise the temperature to 220-260°C to carry out the esterification reaction. Release the pressure when the water output reaches 21 kilograms, end the esterification, then drop into 54.2 kilograms of ES-40 (weight percent concentration is the ethylene glycol solution of 40% bishydroxyethyl isophthalate-5-sodium sulfonate) , 13.5 kilograms of polytetrahydrofuran (accounting for 9% of copolyester gross weight) that the number average molecular weight is 5500, heat up and reduce pressure, the stirring speed is adjusted to 40~50rpm, carry out under 282~290 ℃, absolute pressure 30~300Pa cond...

Embodiment 3

[0031] 92.22 kg of PTA, 11.38 kg of isophthalic acid, 66.7 kg of EG, 80 g of antimony acetate, 50 g of sodium acetate, and 30 g of phosphoric acid were successively put into a 300L stainless steel reactor. use N 2 Pressurize after several replacements, use the valve at the top of the fractionation column to adjust the pressure in the kettle to 0.2-0.25MPa (gauge pressure), stir at 65rpm, and raise the temperature to 220°C-260°C for esterification. Release the pressure when the water output reaches 21 kilograms, end the esterification, then drop into 54.9 kilograms of ES-40 (the concentration by weight is the ethylene glycol solution of 40% bishydroxyethyl isophthalate-5-sodium sulfonate) 12 kilograms of polytetrahydrofuran (accounting for 8% of copolyester gross weight) that the number-average molecular weight is 5500, heat up and reduce pressure, the stirring speed is adjusted to 40~50rpm, carry out under 283~291 ℃, absolute pressure 30~300Pa conditions condensation reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com