Preparation method of antibacterial polyurethane

A technology of polyurethane and antibacterial activity, which is applied in the field of preparation of antibacterial polyurethane, which can solve the problems such as the degree of quaternization of polyurethane and the difficulty of controlling the reaction, and achieve strong sterilization, mildew and moth resistance, easy control of reaction conditions, and antibacterial effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

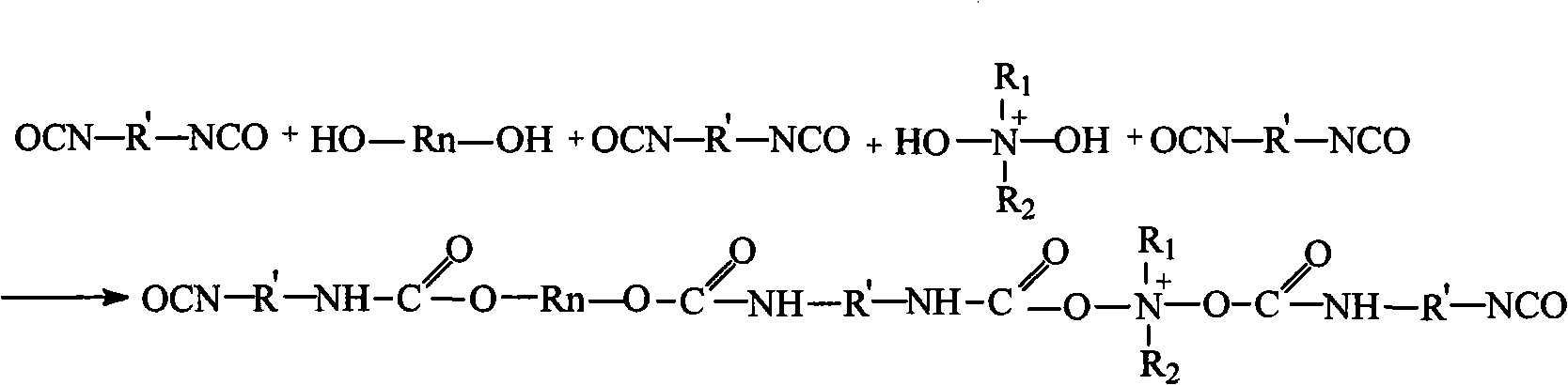

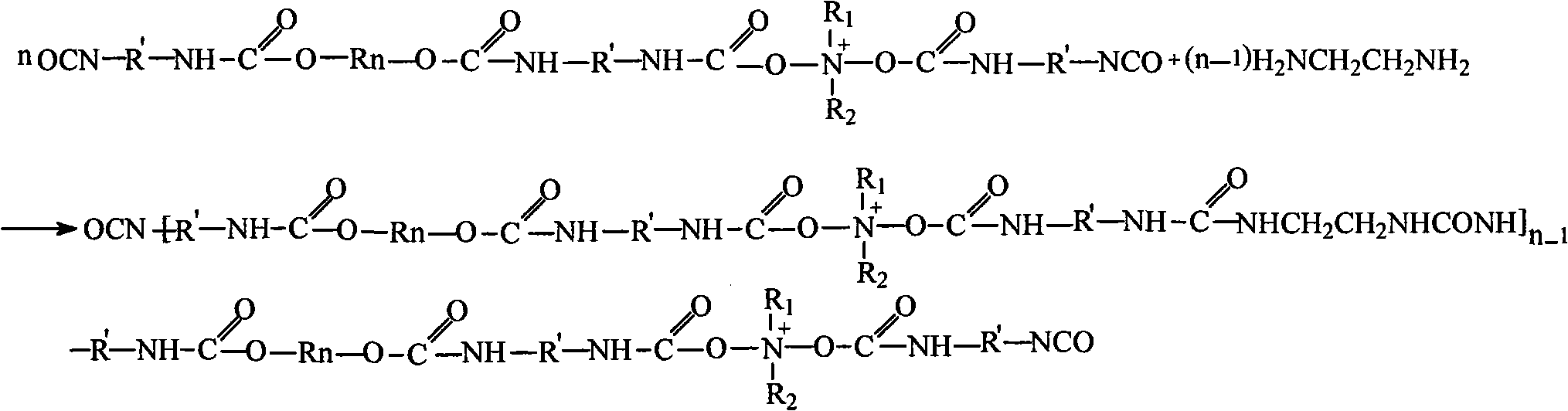

Method used

Image

Examples

Embodiment 1

[0029] Example 1: In the prepolymerization stage, accurately weigh 1 mole of polytetrahydrofuran (molecular weight: 1800) in a three-necked flask, heat and vacuum dehydrate, add 2.2 moles of MDI after cooling to about 30°C, stir continuously and raise the temperature to 60-70°C, maintain this temperature for about 30 minutes, add 2500ppm (relative to the amount of 1 mole of polytetrahydrofuran) N-methyl-N-dodecyl-N, N-dihydroxyethylammonium bromide, and react for 10 minutes, the prepolymer is obtained. In the chain extension reaction stage, first dilute the prepolymer with N,N-dimethylamide to a concentration of about 50%, then raise the temperature to 70°C, add 0.8 moles of chain extender ethylenediamine, and wait until the reaction liquid is glycerol-like, Enter the termination reaction stage, then add 0.2 moles of terminator diethylamine in several times, the sum of the amount of chain extender ethylenediamine and terminator diethylamine is 1 mole, cool the reaction solutio...

Embodiment 2

[0030] Example 2: In the prepolymerization stage, accurately weigh 1 mole of polytetrahydrofuran (molecular weight: 1800) in a three-necked flask, heat and vacuum dehydrate, and add 2.2 moles of diphenylmethane-4,4' after cooling to about 30°C Diisocyanate, keep stirring and raise the temperature to 60-70°C, maintain this temperature for 30 minutes, add 5000ppm (relative to the amount of 1 mole of polytetrahydrofuran) N-methyl-N-n-butyl-N, N dihydroxyethyl ammonium bromide and react for 10 minutes to obtain the prepolymer. In the chain extension reaction stage, first dilute the prepolymer with N,N-dimethylamide to a concentration of about 50%, then raise the temperature to 70°C, add 0.8 moles of chain extender ethylenediamine, and wait until the reaction liquid is glycerol-like, Enter the termination reaction stage, then add 0.2 mole of terminator diethylamine in several times, the sum of the amount of chain extender ethylenediamine and terminator diethylamine is 1 mole, cool ...

Embodiment 3

[0031] Example 3: In the prepolymerization stage, accurately weigh 1 mole of polytetrahydrofuran (molecular weight: 1800) in a three-necked flask, heat and vacuum dehydrate, and add 2.2 moles of diphenylmethane-4,4' after cooling to about 30°C Diisocyanate, keep stirring and raise the temperature to 60-70°C, maintain this temperature for 30 minutes, add 10000ppm (relative to the amount of 1 mole of polytetrahydrofuran) N-methyl-N-benzyl-N, N-dihydroxyethyl ammonium chloride and react for 10 minutes to obtain the prepolymer. In the chain extension reaction stage, first dilute the prepolymer with N,N-dimethylamide (DMF) to a concentration of about 50%, then heat up to 70°C, add 0.8 moles of chain extender ethylenediamine, and wait until the reaction liquid is glycerol After that, enter the termination reaction stage. At this time, add 0.2 mole of terminator diethylamine in multiple times, the sum of the amount of chain extender ethylenediamine and terminator diethylamine is 1 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com