Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

A technology of epoxy resin and polyurethane, applied in modified epoxy resin adhesives, polyurea/polyurethane adhesives, adhesives, etc., can solve the problem of slow curing speed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

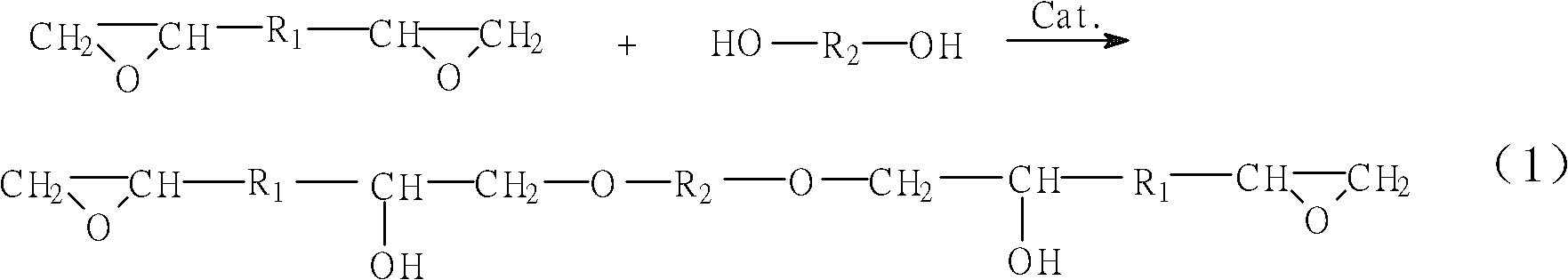

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 polyurethane-acrylic acid-epoxy resin photosensitive prepolymer (A)

[0027] 1) Preparation of low-viscosity epoxy acrylate prepolymer

[0028] In a clean 500ml three-necked flask, add epoxy resin E-54, ethylene glycol, N, N-dimethylbenzylamine and a certain amount of toluene under electric stirring, wherein, E-54 and ethylene glycol The equivalent ratio of N,N-dimethylbenzylamine accounts for 0.25wt% of the amount of E-54. The reaction was carried out at 110° C. for 3 hours. Cool to 80° C., remove the solvent under a vacuum of 2 to 5 kPa, and weigh the intermediate product after cooling to room temperature.

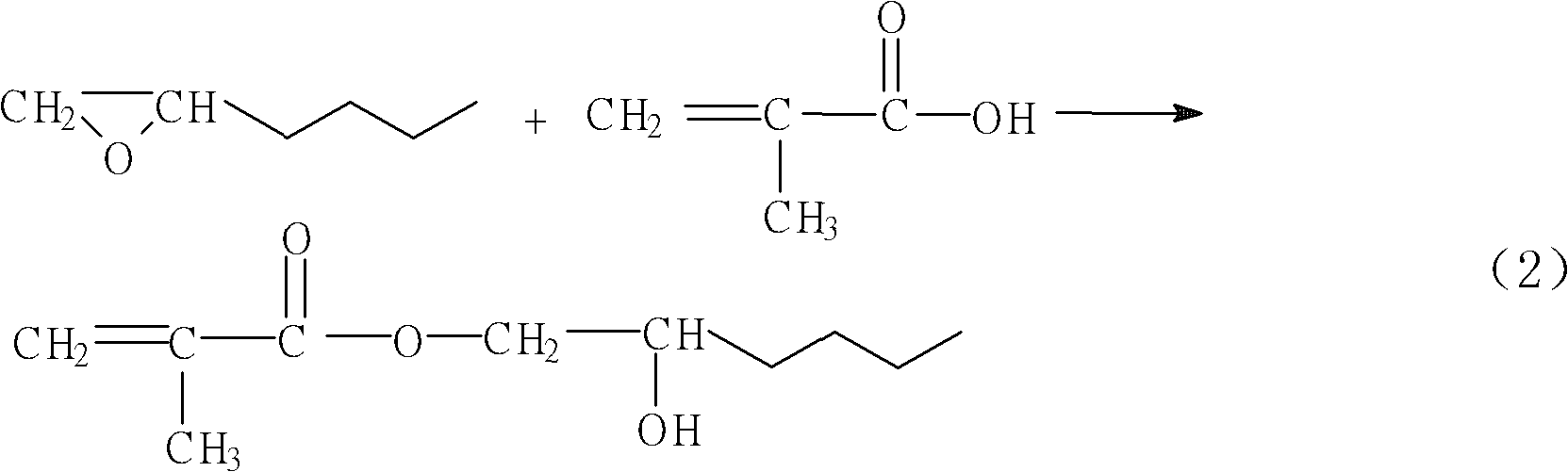

[0029] Under continuous stirring, add 0.02wt% p-hydroxyanisole and a certain amount of toluene to the above-mentioned reaction product mixture, gradually heat up to 105-110°C, add dropwise the mixed solution of tetrabutylammonium bromide and acrylic acid, at 30 Added in minutes. Wherein, tetrabutylammonium bromide accounts for 1...

Embodiment 2

[0033] The preparation of embodiment 2 polyurethane-acrylic acid-epoxy resin photosensitive prepolymer (B)

[0034] 1) Preparation of low-viscosity epoxy acrylate prepolymer

[0035] Replace E-54 in Example 1 with epoxy resin F-51, replace ethylene glycol with 1,3-propanediol, replace N,N-dimethylbenzylamine with triethanolamine, and react at 110° C. for 2.5 hours.

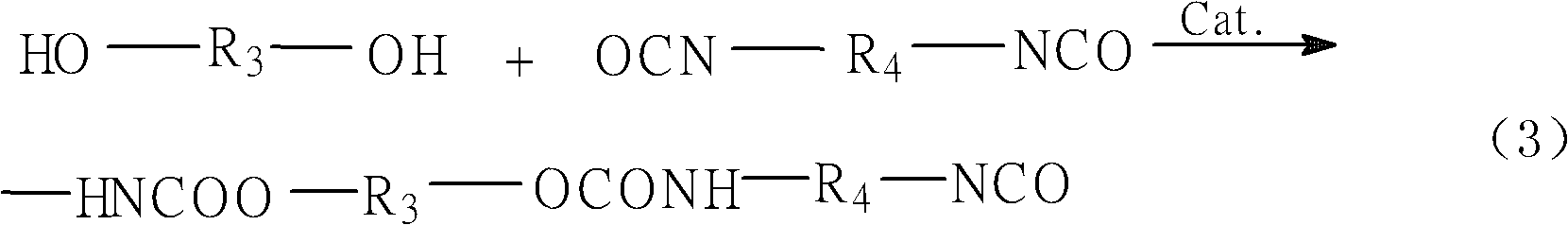

[0036] 2) Preparation of prepolymer of polyurethane acrylate resin

[0037] Replace polyethylene glycol (200) in embodiment 1 with dipropylene glycol, replace TDI with HDI, other conditions are with embodiment 1.

Embodiment 3

[0038] The preparation of embodiment 3 polyurethane-acrylic acid-epoxy resin photosensitive prepolymer (C)

[0039] 1) Preparation of low-viscosity epoxy acrylate prepolymer

[0040] Epoxy resin 711 (Tianjin Institute of Synthetic Materials) was used to replace E-54 in Example 1, and other conditions were the same as Example 1.

[0041] 2) Preparation of prepolymer of polyurethane acrylate resin

[0042] Replace TDI in embodiment 1 with HMDI, replace hydroxyethyl acrylate with hydroxypropyl acrylate, and other conditions are the same as embodiment 1.

[0043] Preparation of Polyurethane-Acrylic-Epoxy Resin Photocuring Adhesive (UV Adhesive) Composition

[0044] The prepolymers of the above-mentioned examples 1 to 3 were added with 0.3wt% of "1173", 0.1wt% of "819", 0.1wt% of "EHA" (N, N-dimethyl 4-dimethylaminobenzene 2-ethylhexyl formate), 15wt% of 1,6-hexanediol diacrylate, 0 to 15wt% of n-hexyl acrylate (the amount added depends on the viscosity of the prepolymer mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com