Nanosilicon dioxide modified polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomer and nano-silica, which is applied in the field of polyurethane elastomer materials, can solve the problems of the system that is difficult to uniformly disperse nanoparticles, poor compatibility, high viscosity of polymer matrix, and high surface activity of nanoparticles, so as to achieve improvement Compatibility, improvement of mechanical properties and heat resistance, effects of avoiding migration and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

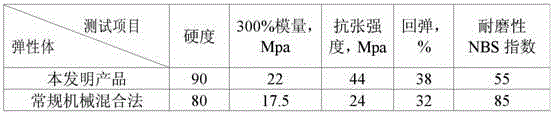

Image

Examples

Embodiment 1

[0027] Component A includes the following raw materials:

[0028] Polytetrahydrofuran ether polyol (molecular weight: 2000) 100 g,

[0029] Butanediol 0.9 g,

[0030] Toluene diisocyanate 19.0 g,

[0031] Component B includes the following raw materials:

[0032] Ethyl silicate 8 g,

[0033] γ-Aminopropyltriethoxysilane 2.4 g,

[0034] MOCA 40 g.

[0035] The specific preparation steps of nano-silica modified polyurethane elastomer are as follows:

[0036] (1) Preparation of component A of the polyurethane prepolymer: Weigh 100 g of polytetrahydrofuran ether glycol and add it to a four-neck flask equipped with a stirrer, a thermometer, a feeding tube, a nitrogen connection, a vacuum connection and a dry filter tube. Remove trace moisture under reduced pressure, add 19g of toluene diisocyanate, heat up to 85°C and keep it warm for 1.5 hours, then add 1.2g of butanediol and continue the reaction for 3 hours to prepare component A of polyurethane prepolymer;

[0037] (2) P...

Embodiment 2

[0040] Component A includes the following raw materials:

[0041] Polytetrahydrofuran ether polyol 100 g,

[0042] Butanediol 1.2 g,

[0043] Diphenylmethane diisocyanate 27.5 g;

[0044] Component B includes the following raw materials:

[0045] N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane 1.2 g,

[0046] Ethyl silicate 8 g,

[0047] MOCA 40 g.

[0048] The specific preparation steps of nano-silica modified polyurethane elastomer are as follows:

[0049] (1) Preparation of component A of polyurethane prepolymer: Weigh 100g of polytetrahydrofuran ether glycol and add it into a four-necked flask equipped with a stirrer, a thermometer, a feeding tube, a nitrogen connection, a vacuum connection and a dry filter tube, and reduce Press to remove trace moisture, add 27.5g diphenylmethane diisocyanate, heat up to 85°C and keep it warm for 1.5 hours, then add 0.5g butanediol and continue the reaction for 3 hours to prepare polyurethane prepolymer component A;

[0050] (2) ...

Embodiment 3

[0053] Component A includes the following raw materials:

[0054] Polycaprolactone diol (molecular weight is 2000) 100 g,

[0055] Butanediol 0.5 g,

[0056] Diphenylmethane diisocyanate 27.5 g;

[0057] Component B includes the following raw materials:

[0058] γ-Aminopropyltriethoxysilane 2.4 g,

[0059] Ethyl silicate 8.0 g,

[0060] MDA 40 g.

[0061] The specific preparation method is as follows:

[0062] Preparation of component A of polyurethane prepolymer: Weigh 100g of polycaprolactone diol and add it to a four-necked flask equipped with a stirrer, a thermometer, a feeding tube, a nitrogen connection, a vacuum connection and a dry filter tube, and decompress and decompress. Remove trace moisture, add 27.5 g of diphenylmethane diisocyanate, heat up to 85 ° C for 1.5 h, and then add 0.5 g of butanediol to continue the reaction for 3 h to prepare component A of polyurethane prepolymer;

[0063] B: Preparation of chain extender component B: Add 40g MDA to 8g ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com