Steel for hot stamping forming, hot stamping forming process and hot stamping forming component

A technology of hot stamping forming and hot stamping, which is applied in the direction of hot-dip plating process, metal material coating process, substructure, etc., and can solve the problems of difficult control, low ductility, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

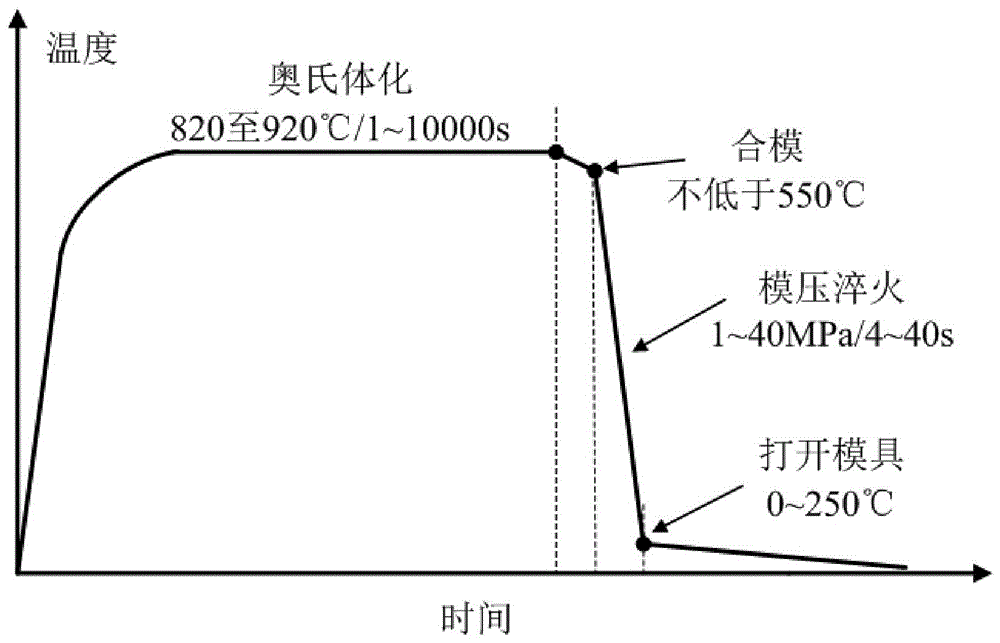

[0023] The present invention will be described in more detail below with reference to exemplary embodiments. The following examples or experimental data are intended to illustrate the present invention, and it should be clear to those skilled in the art that the present invention is not limited to these examples or experimental data.

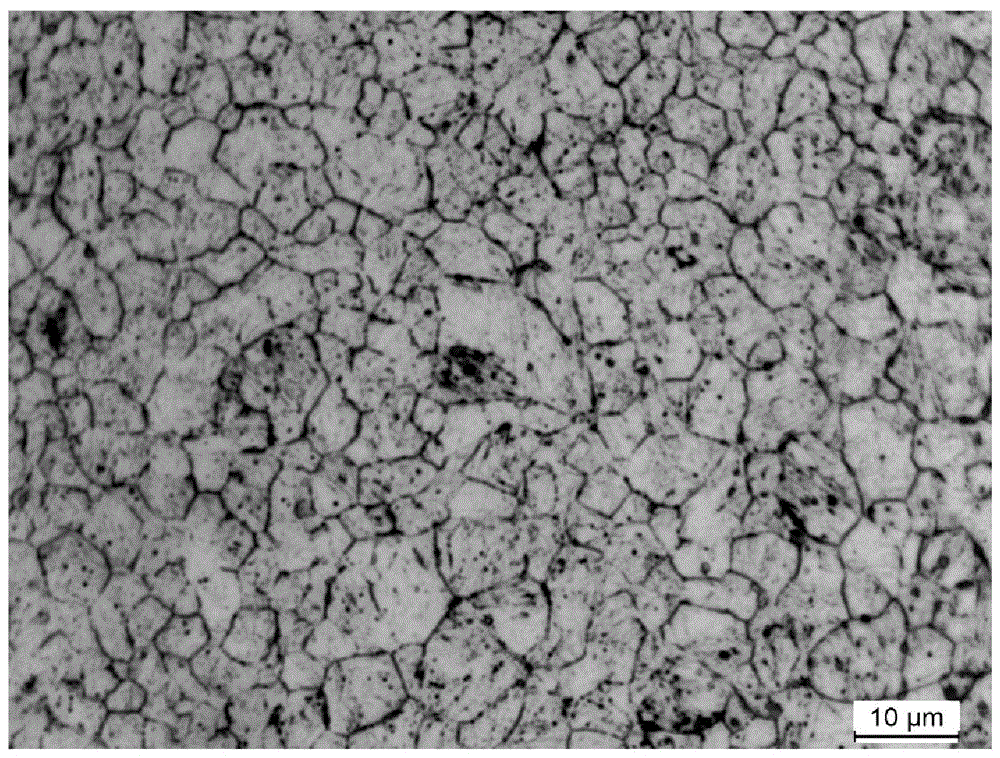

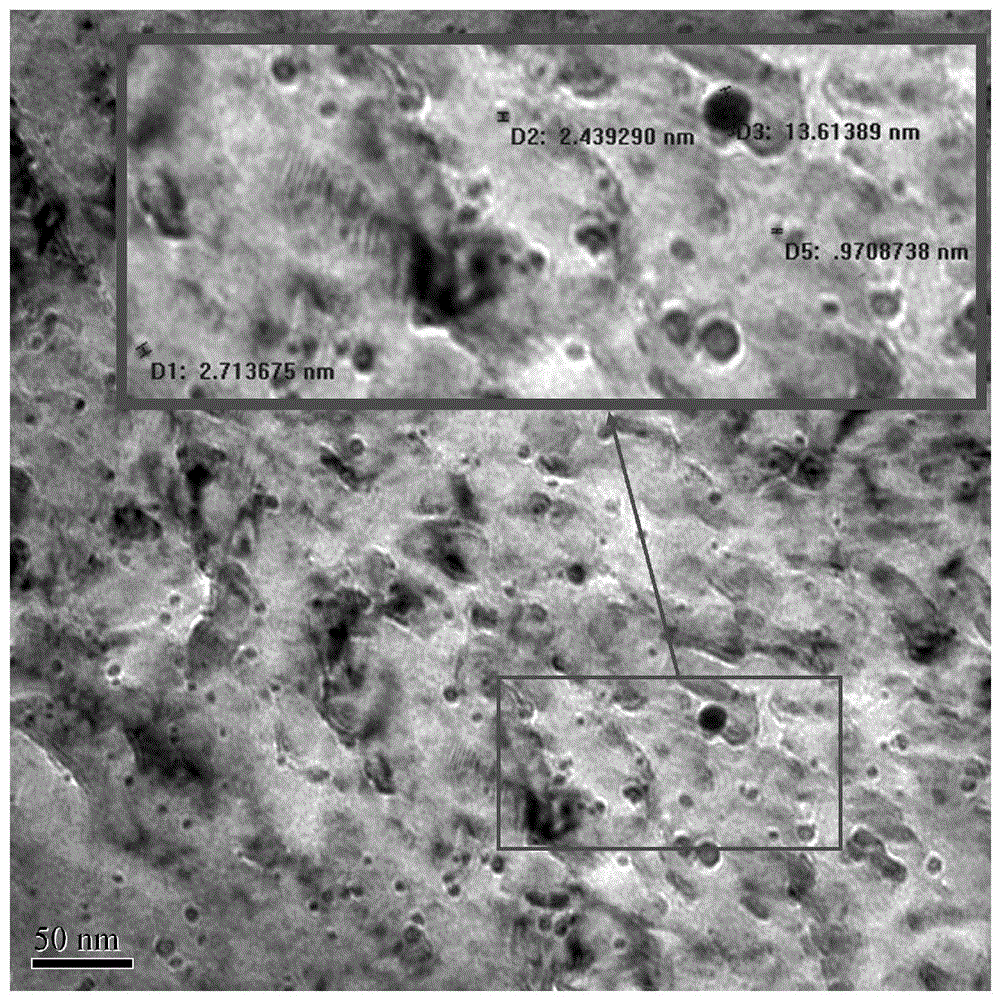

[0024] According to one embodiment of the present invention, there is provided a steel for hot stamping, which comprises the following components by weight: 0.27-0.40% C; 0.2-3.0% Mn; 0.11-0.4% V; 0-0.8 % Si; 0-0.5% Al; 0-2% Cr; 0-0.15% Ti; 0-0.15% Nb; 0-0.004% B; the total content of Mo, Ni, Cu less than 2% And other alloying elements that are beneficial to improve its hardenability, as well as other impurity elements.

[0025] The strength of martensite increases with the increase of carbon content, but high carbon content leads to the formation of twin martensite, which reduces the toughness of the material. Twin martensite must be tempered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com