A kind of 1860mpa grade prestressed steel strand and its manufacturing method

A technology of prestressed steel strands and manufacturing methods, applied in the field of prestressed steel strands, which can solve the problems of uneven stress on thin steel wires and difficulty in improving the breaking force level of steel strands, and achieve the effect of uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

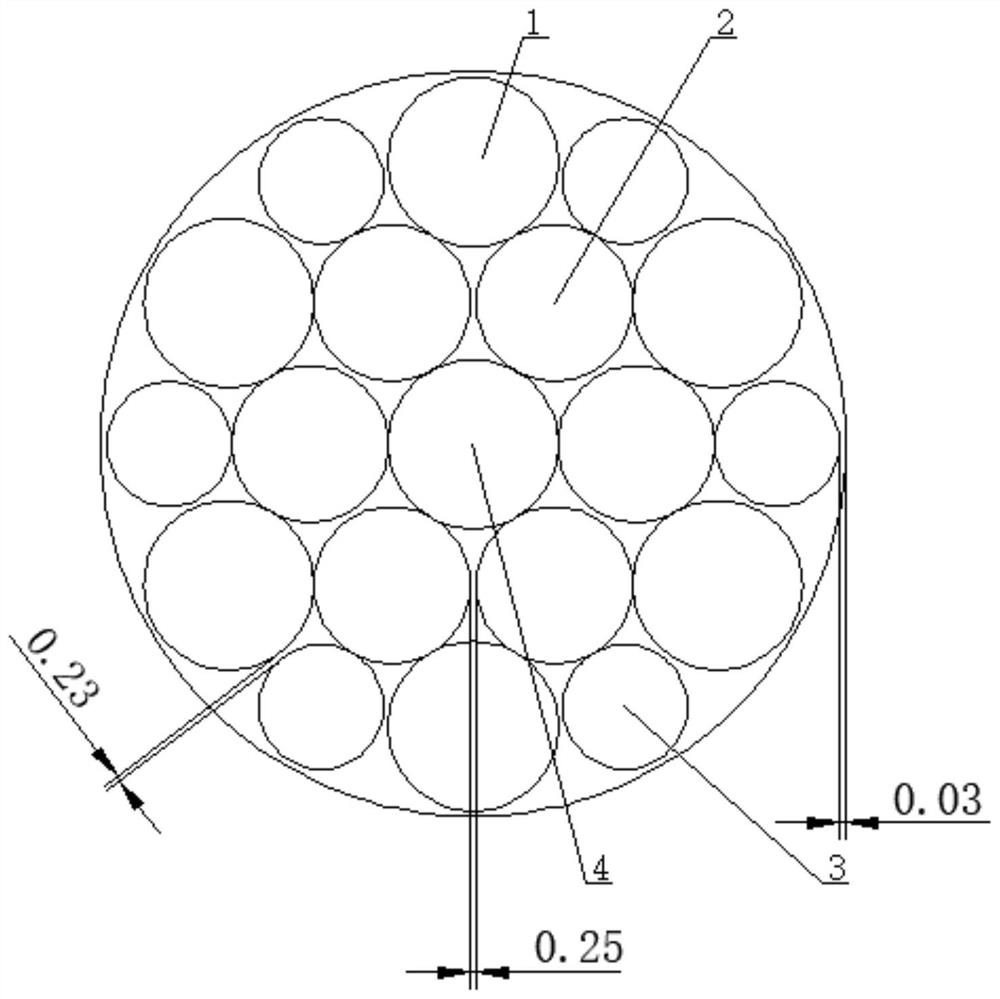

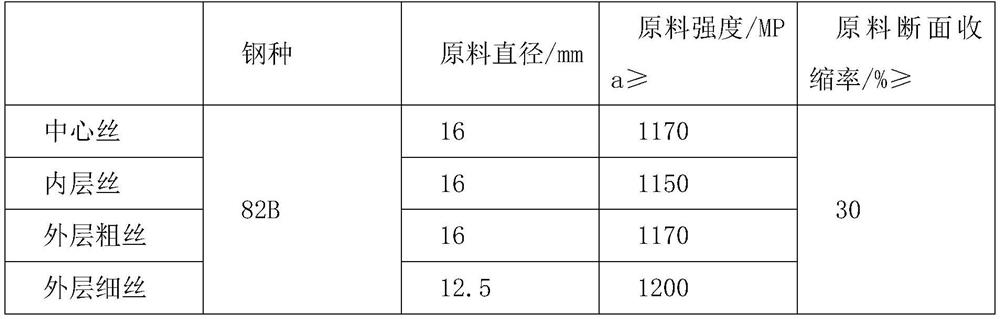

[0021] 1×19W-Φ28.6mm 1860MPa prestressed steel strand, including one central wire 4, six inner wires 2, six outer thick wires 1 and six outer thin wires 3, the innovation of the present invention lies in that 19 wires At the same time, it is twisted into shape at the same time, the twist direction is left twist, the lay length is 386 mm, the diameter of the central filament is 6.62-6.68 mm, the diameter of the inner layer filament is 6.12-6.18 mm, and the diameter of the outer thick filament is 6.62 mm. -6.68 mm, the diameter of the outer filament is 4.88-4.94 mm, and the nominal diameter Φ after twisting is 28.6 mm.

[0022] In this embodiment, for the prestressed steel strand, the gap between adjacent inner layer wires is 0.20-0.25 mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com