A grouting construction method for rapidly tensioning anchor cables

A construction method and anchor cable technology, which is applied in the direction of earth drilling, bolt installation, mining equipment, etc., can solve problems such as tunnel instability, tunnel scrapping, and long grouting time, and achieve good grouting effect, quality, and operation The process is simple and practical, and the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

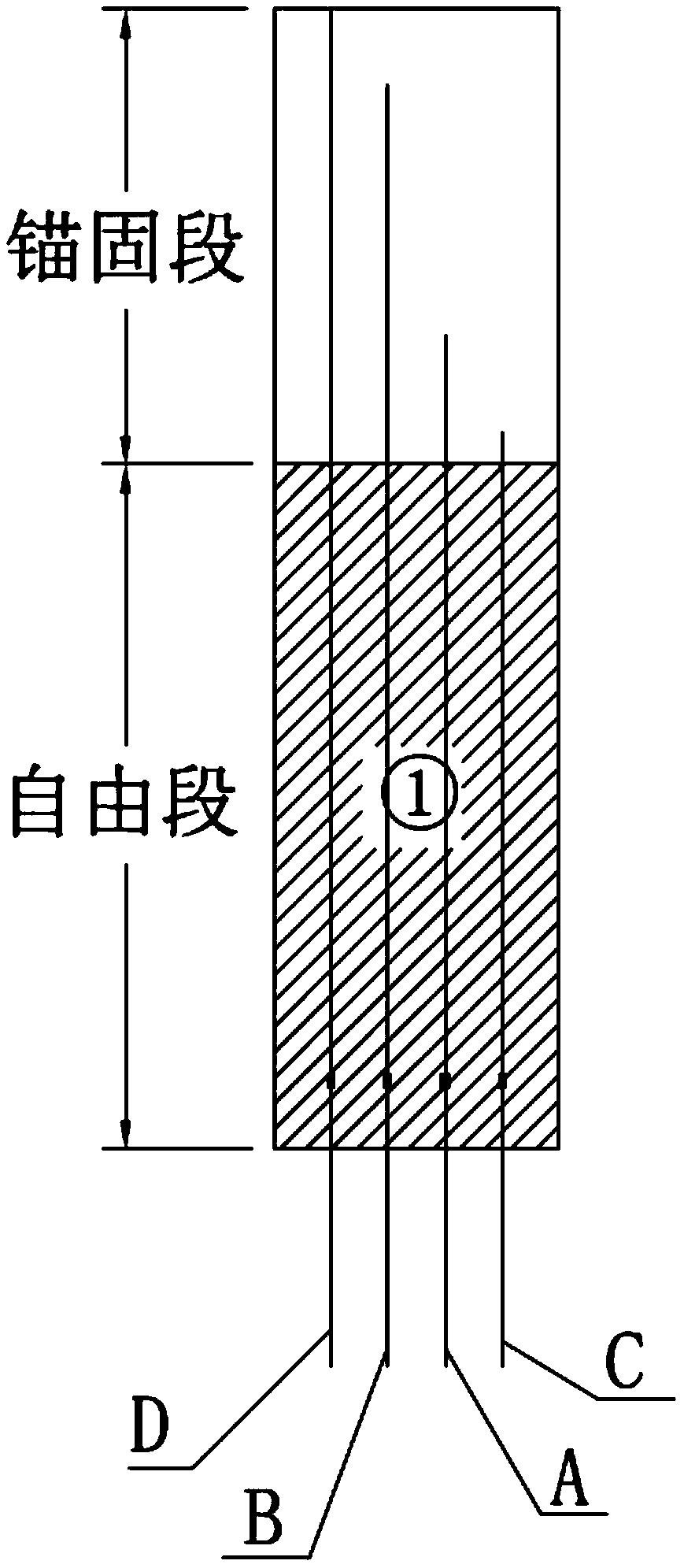

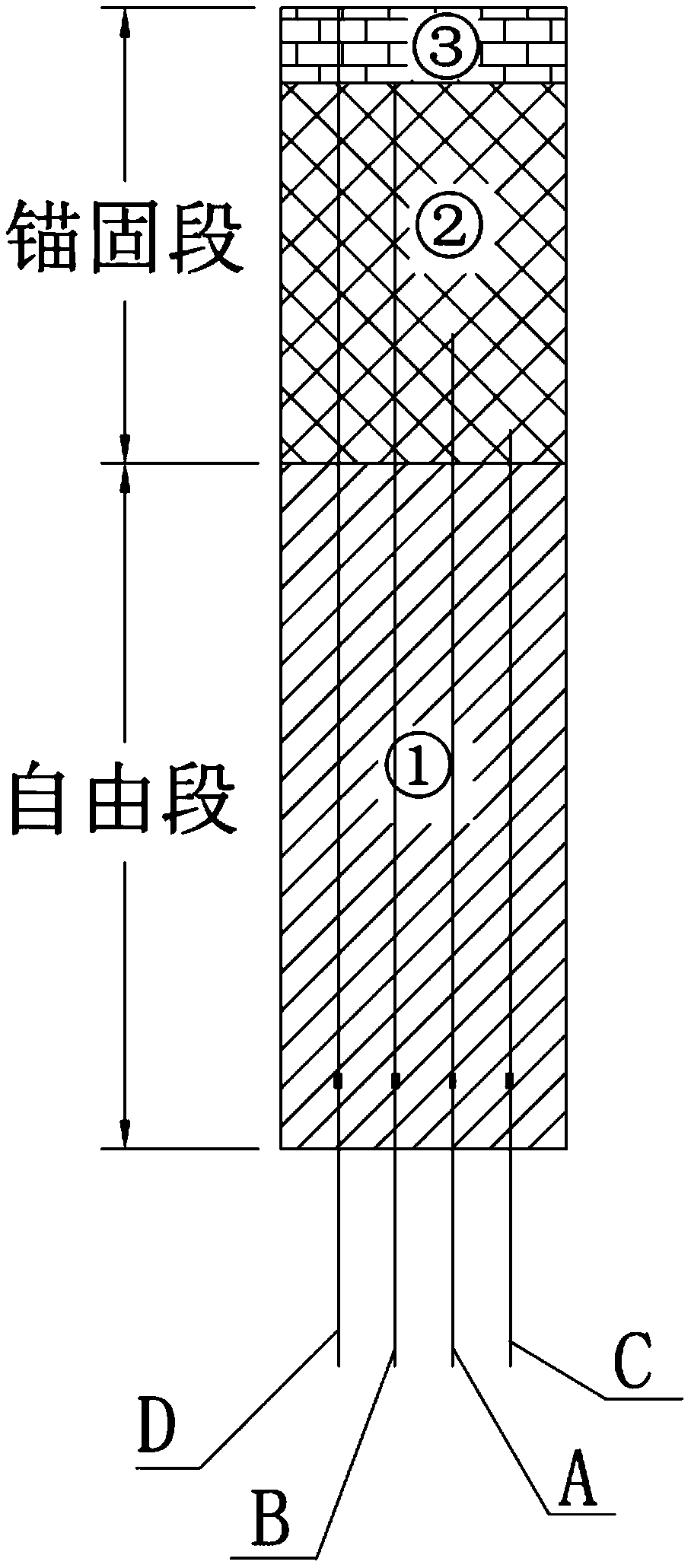

[0031] see figure 1 and figure 2 , the grouting construction method of the fast-setting high-strength fast-tensioning anchor cable provided by the invention comprises the following steps:

[0032] 1. Anchor cable drilling: Drill anchor cable holes at the position where the surrounding rock of the tunnel needs to be reinforced.

[0033] 2. Anchor cable installation: install the anchor cable in the anchor cable hole, specifically: bind the first grouting pipe A, the second grouting pipe B, the first exhaust pipe C and the second exhaust pipe D The anchor cable bundle is advanced into the anchor cable hole, and the anchor section and the free section are determined.

[0034] The first grouting pipe A, the second grouting pipe B, the first exhaust pipe C and the second exhaust pipe D are all arranged in the anchor cable hole and communicated with the outside. Wherein, the first grouting pipe A, the second grouting pipe B and the first exhaust pipe C all pass through the free s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com