A universal connecting pipe fitting

A technology for connecting pipe fittings and pipe fittings, applied in the direction of pipe components, pipes/pipe joints/fittings, threaded connections, etc., can solve problems such as leakage, rubber ring aging, loss of elasticity, etc., to eliminate temperature stress, ensure gaps, and seal effects reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

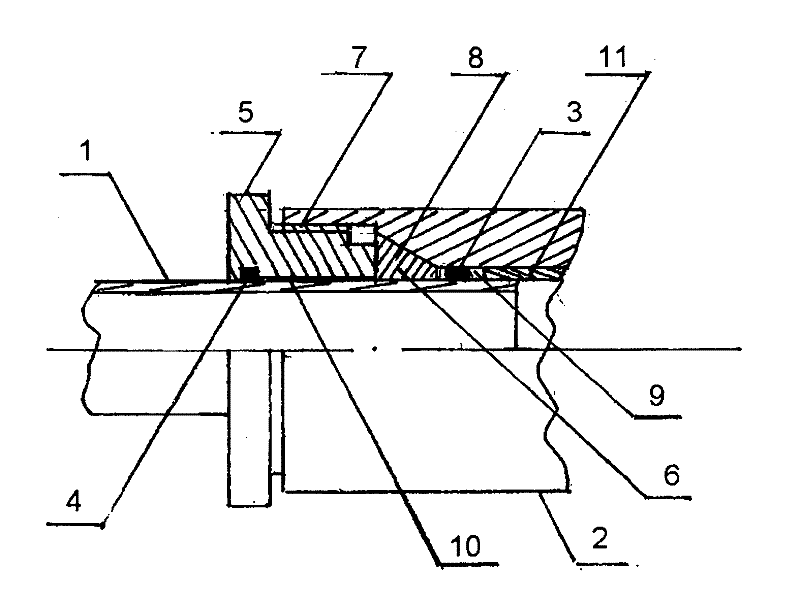

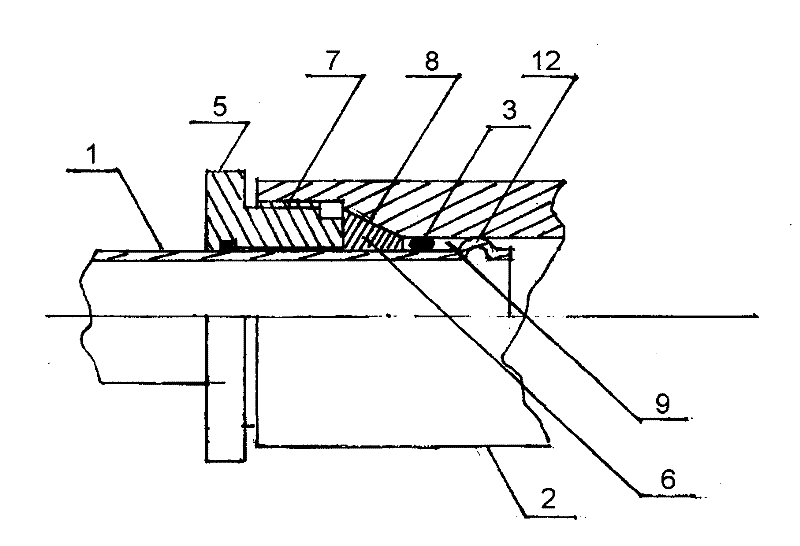

[0017] 1. Universal connecting pipe fittings are used for fixed pipe connection

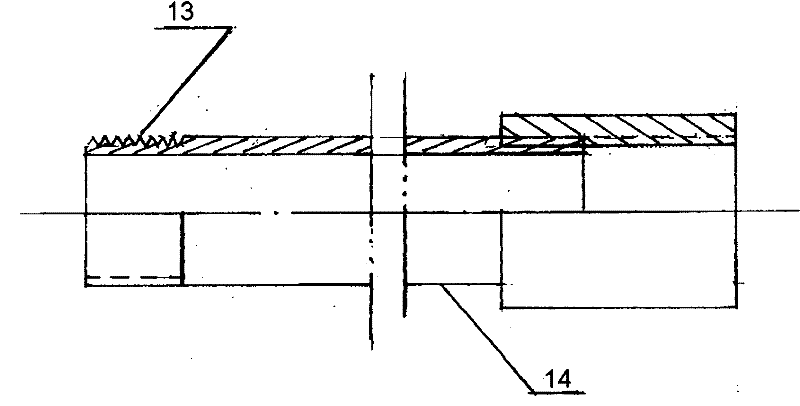

[0018] Put the screw plug 5, the radial tightening ring 6, and the O-shaped sealing rubber ring 3 into the pipe 1 to be connected in sequence, and put the O-shaped sealing rubber ring 3 on the end of the pipe 1, and apply the adhesive on the pipe 1 and the pipe fitting to be connected, the pipe 1 and the screw plug 5 are first inserted and screwed into the pipe fitting housing 2 a little, and then the pipe 1 is pushed into the pipe fitting housing 2. At this time, the O-shaped sealing rubber ring 3 will enter the sealing cavity 9 in the form of rolling, and the radial size of the solid rubber of the rubber ring will be compressed by the working inclined surface 8 of the pipe fitting, so that the real rubber of the O-shaped sealing rubber ring 3 can radially The compression ratio of the cross-section is greater than 25%, so that the interface has good sealing performance, and then the screw plug 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com