Two-stage work metal energy dissipation device

An energy dissipator and work technology, applied in bridge parts, building components, bridges, etc., can solve the problems of economic loss, single energy consumption form, and seismic action amplification of the additional stiffness of energy consumption devices, so as to attenuate seismic response and protect safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

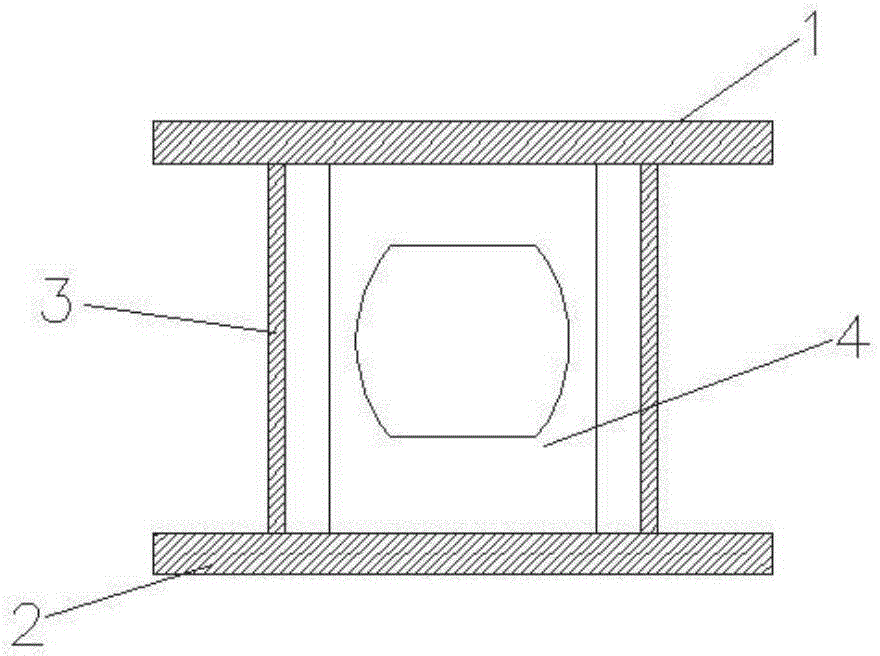

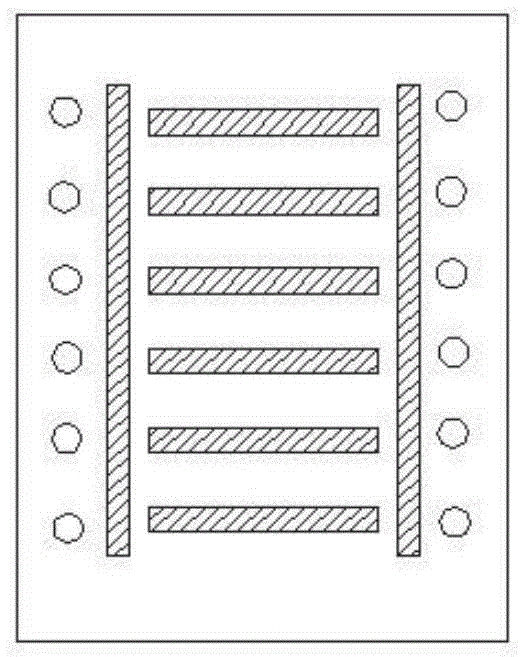

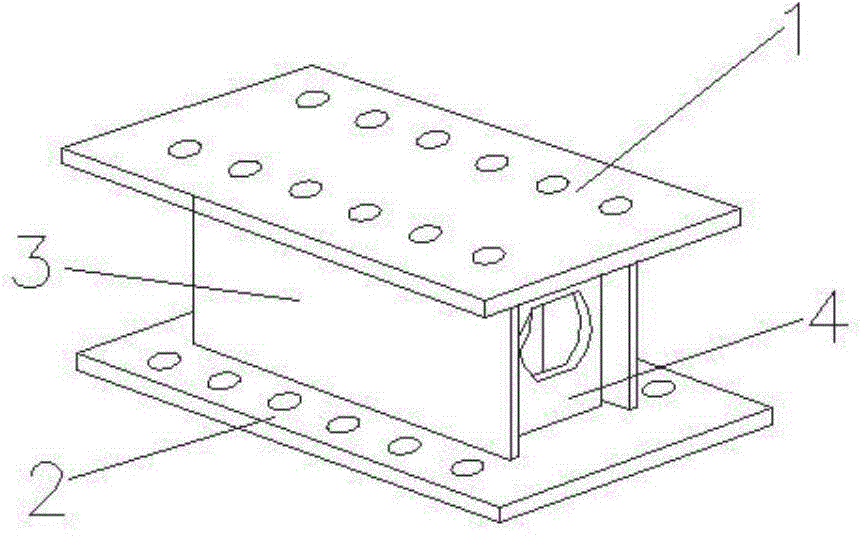

[0020] Such as Figure 1-4 Shown: a two-stage working energy dissipator, including upper top plate 1, lower bottom plate 2 and core energy dissipation components. The core energy-dissipating components include shear-type energy-dissipating components and bending-type energy-dissipating components. The shear-type energy dissipation component includes two rectangular low-yield point steel sheets 3 fixedly connected with the upper top plate 1 and the lower bottom plate 2, and the two rectangular low-yield point steel sheets 3 are arranged parallel to each other. The curved energy-dissipating component includes 6 rectangular curved energy-dissipating steel sheets 4 fixedly connected to the upper top plate 1 and the lower bottom plate 2, and the 6 rectangular curved energy-dissipating steel sheets 4 are arranged parallel to each other and spaced between two rectangular low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com