Method for extracting precious metal from spent automobile catalyst by concentration smelting-wet separation process

An auto catalyst and wet separation technology, applied in the field of precious metal recovery, can solve the problems of low precious metal recovery rate, large consumption of reagents, decreased consumption, etc., achieve significant economic and environmental benefits, improve metal recovery rate and acid consumption falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

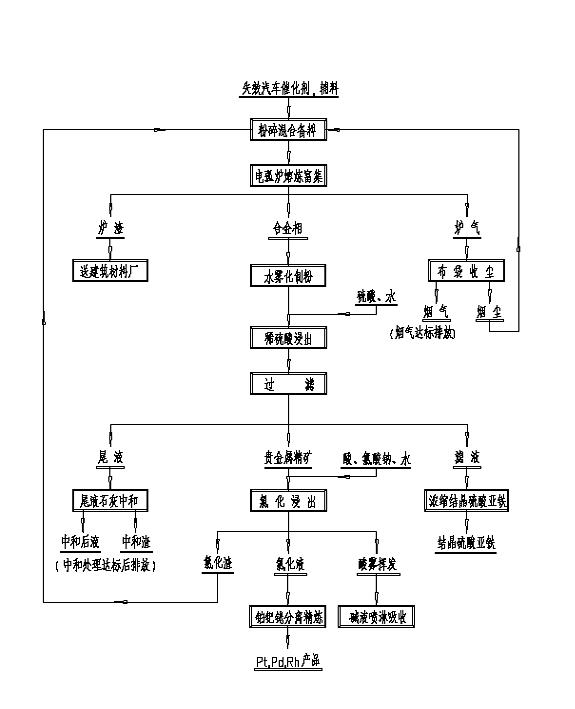

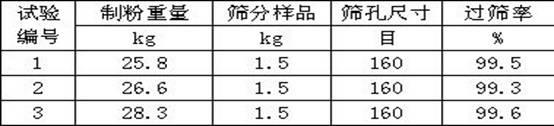

Method used

Image

Examples

Embodiment Construction

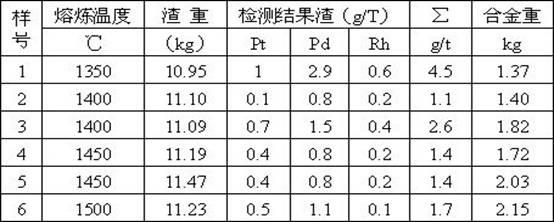

[0030] 1. Enrichment smelting

[0031] After the exhausted automobile catalyst is crushed and pulverized, according to the weight ratio of catalyst and auxiliary materials: catalyst: collector: flux: reducing agent = 10: 1~6: 3~9: 0.5~0.8, mix evenly, granulate, bake Dried and used as a furnace charge. The sample ratio is:

[0032] 1) Catalyst: iron ore powder: borax powder: coke powder = 10:3:4:0.5

[0033] 2) Catalyst: Pyrite powder: Fluorite powder: Charcoal powder=10:1:6:0.6

[0034] 3) Catalyst: iron ore powder: soda powder: raw coal powder=10:5:3:0.6

[0035] 4) Catalyst: iron ore powder: lime powder: coke powder = 10:6:5:0.7

[0036] 5) Catalyst: pyrite powder: quartz sand: coke powder = 10:5:9:0.8

[0037] 6) Catalyst: pyrite powder: lime powder: raw coal powder = 10:6:8:0.6

[0038] During smelting, the charge is put into the electric arc furnace and smelted at high temperature for 1-3 hours until the precious metal and the carrier are effectively and complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com