AGV integrated full-intelligent batching control system

An intelligent batching and control system technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of low automation and difficult to avoid manual misoperation, so as to reduce labor costs, accurate batching, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

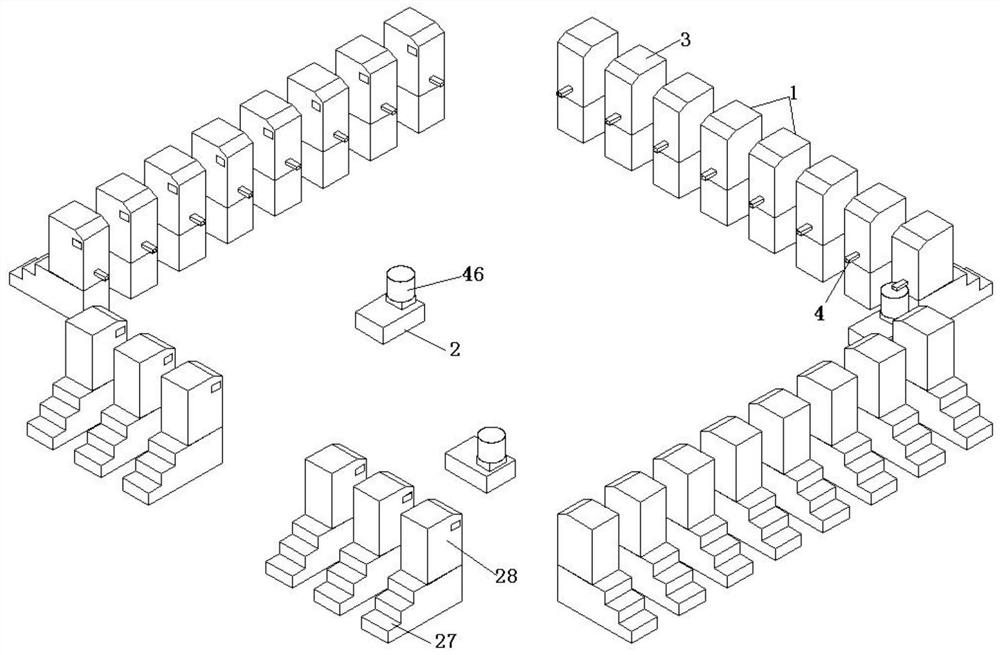

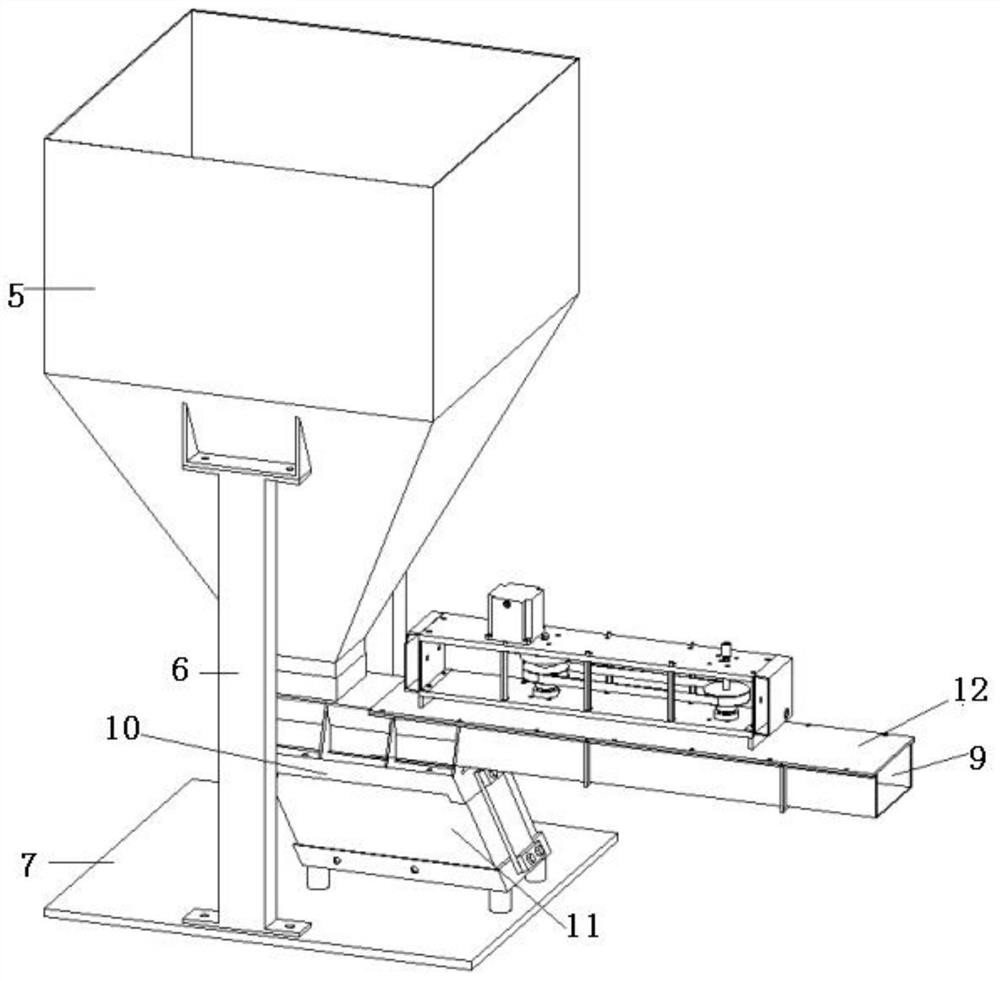

[0022] Such as Figure 1-Figure 4 The shown a kind of AGV overall intelligent batching control system includes a batching unit 1 and a batching AGV trolley 2, the batching unit 1 is provided with multiple, the batching unit 1 includes a protective shell 3 and a placement table 27, the protective The casing 3 is fixed on the placement table 27, and the side of the protective casing 3 is hinged with a chamber door 28, and a material flow control device and a controller are installed inside the protective casing 3, and the material flow control device is connected to the controller. The output end of the material flow control device is connected to the discharge port 4, the discharge port 4 is fixed on the protective shell 3, the controller is connected to the upper computer control center by telecommunication, and the ingredient AGV trolley 2 is connected to the upper computer control center by telecommunication;

[0023] The material flow control device includes a hopper 5, the...

Embodiment 2

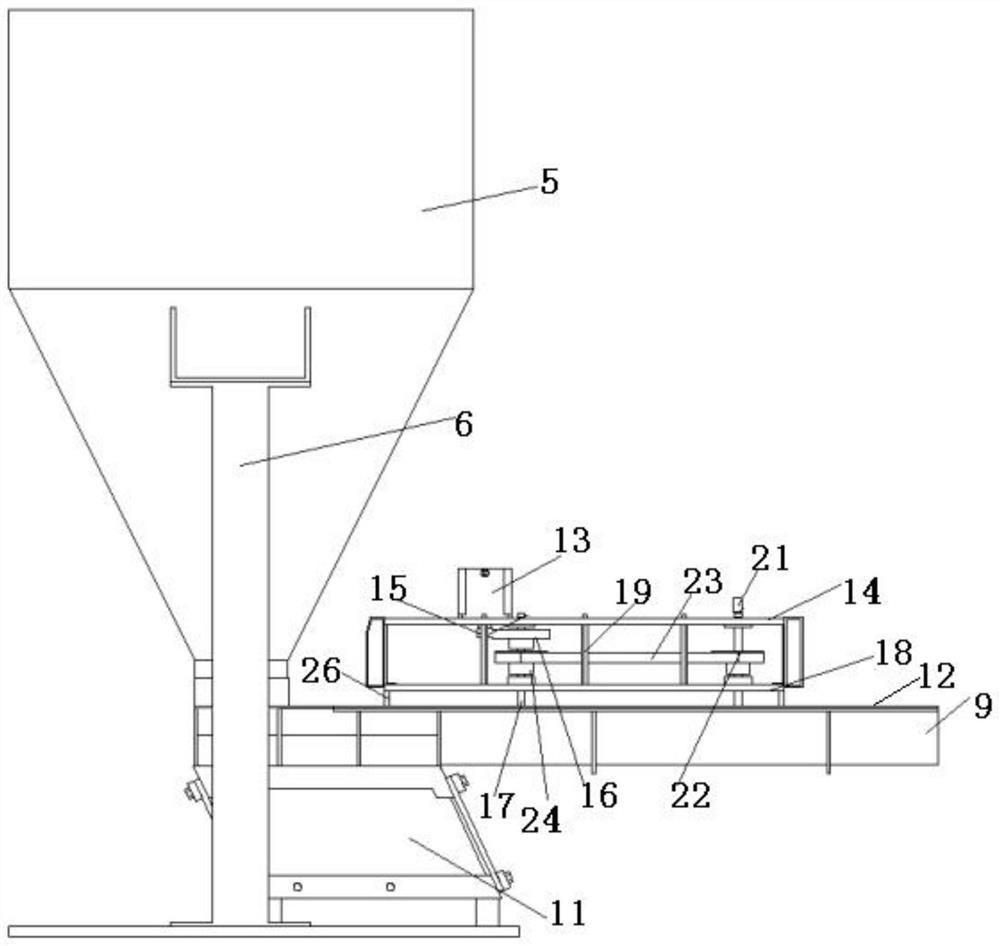

[0026] Such as Figure 1-Figure 6 The shown a kind of AGV overall intelligent batching control system includes a batching unit 1 and a batching AGV trolley 2, the batching unit 1 is provided with multiple, the batching unit 1 includes a protective shell 3 and a placement table 27, the protective The casing 3 is fixed on the placement platform 27, and a chamber door 28 is hinged on the side of the protective casing 3, and a material flow control device and a controller are installed inside the protective casing 3, and the material flow control device can be fed into the material flow control device at regular intervals through the chamber door 28. Add raw materials, the material flow control device is connected to the controller, the output end of the material flow control device is connected to the discharge port 4, the discharge port 4 is fixed on the protective shell 3, and the controller is connected to the upper computer for control by telecommunication In the center, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com