Feed proportioning and feeding system

A feed and hopper technology, applied in the field of feed batching and feeding system, can solve the problem of high cost, achieve precise batching, reduce the number of workers, and design reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

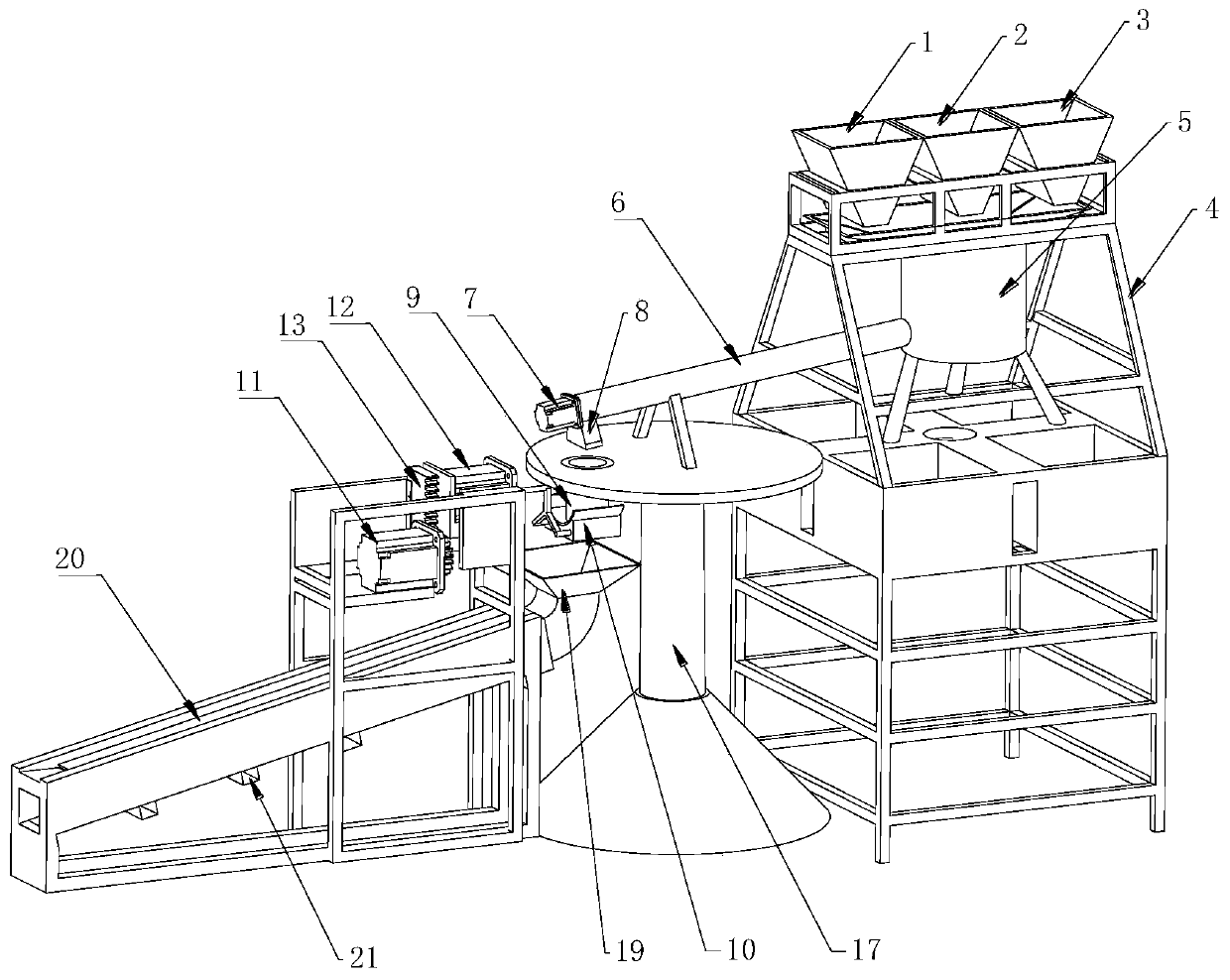

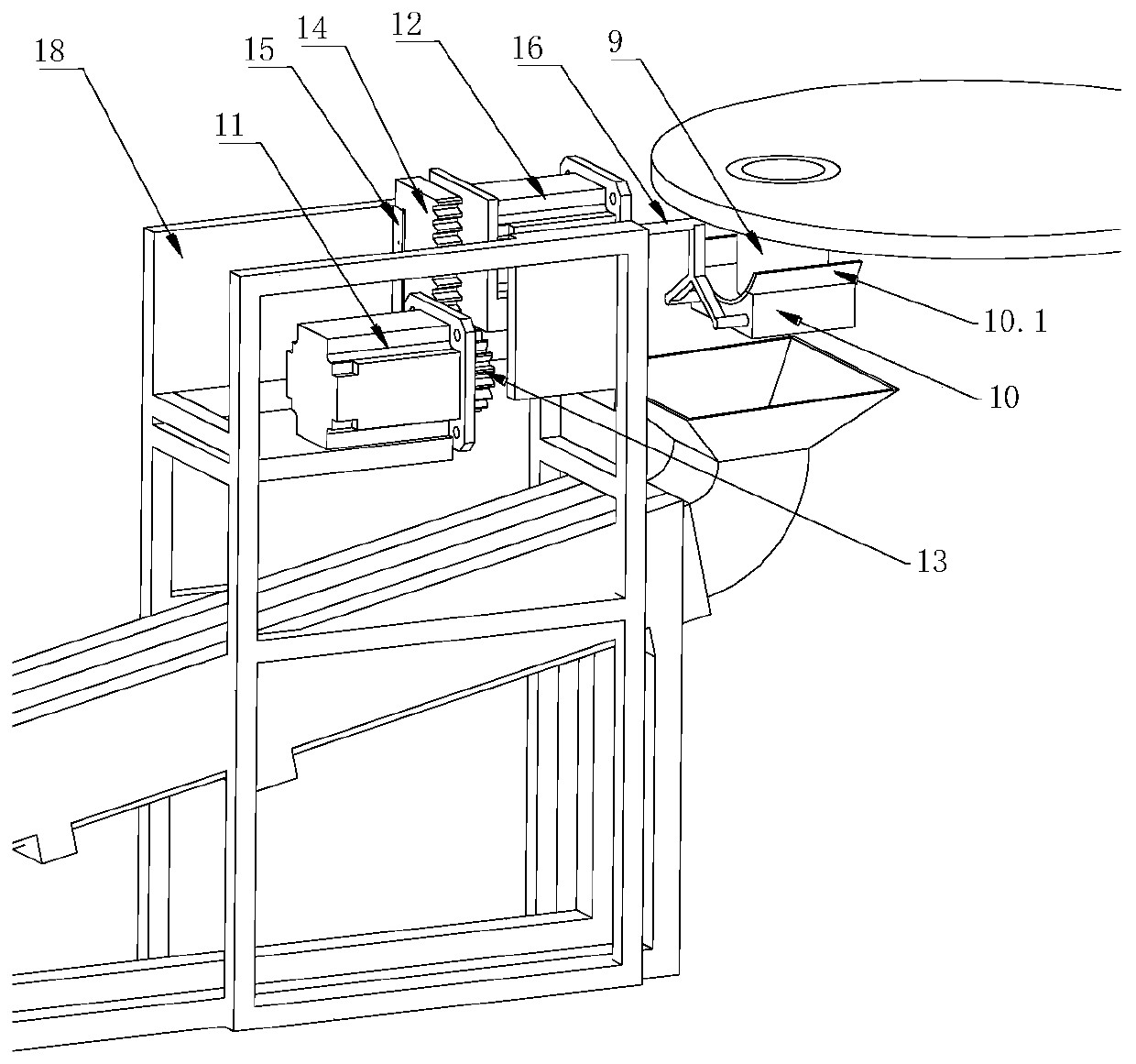

[0035] Referring to the accompanying drawings, a feed ingredient feeding system includes a batching device, a feeding device, a weighing device and a positioning feeding device.

[0036] The batching device includes a first hopper 1, a second hopper 2, a third hopper 3, a first bracket 4 and a mixing bin 5, and the first hopper 1, the second hopper 2, and the third hopper 3 are arranged in a straight line On the first bracket 4, the mixing bin 5 is also fixed on the first bracket, and the mixing bin 5 is positioned under the first hopper 1, the second hopper 2, and the third hopper 3, so that the first hopper 1, the second hopper The feed discharged from the outlets at the bottom of the second hopper 2 and the third hopper 3 can all fall into the mixing bin 5. The first hopper 1, the second hopper 2 and the third hopper 3 are respectively equipped with different feeds, each The bottom outlets of each hopper are respectively provided with electromagnetic valves, and the batchin...

Embodiment 2

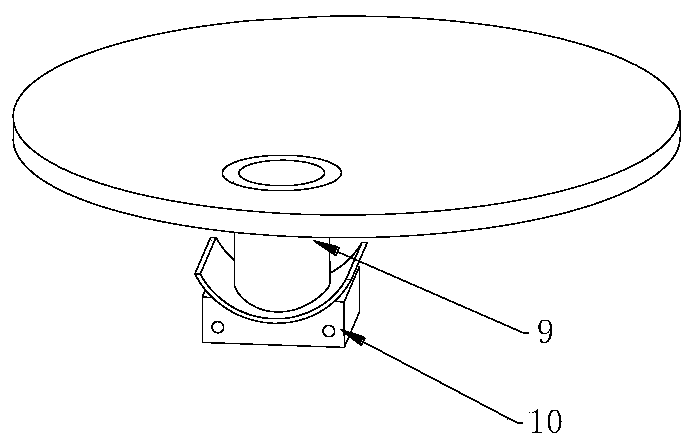

[0043] On the basis of Embodiment 1, further speaking, a limit switch is set at the bottom end of the outer wall of the barrel 9. When the weighing base 10 rises to trigger the limit switch, the weighing base 10 stops. At this time, the weighing base 10 The position is the weighing working position (the distance between the weighing pan and the bottom of the barrel is 1mm).

Embodiment 3

[0045] On the basis of Embodiment 1, further speaking, the number of hoppers of the batching device is not limited to three, but may be multiple, and the specific number is determined according to actual needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com