Aluminum powder precise distribution device

A technology of feeding device and aluminum powder, which is applied in the direction of sales of raw material supply device, batching weighing instrument, clay preparation device, etc., can solve the problems of low degree of automation, time-consuming and laborious, backward technology, etc., and achieve high degree of automation and batching effect Good, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

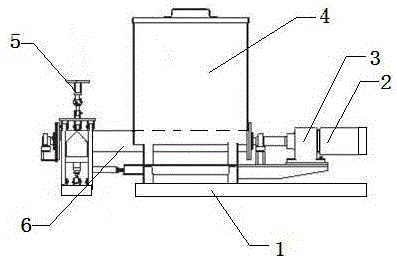

[0012] This embodiment provides an accurate batching device for aluminum powder. ), feeding cylinder (6);

[0013] Among them: including the base (1), the aluminum powder feeding device is fixedly installed on the base (1). Driven by the driving mechanism (2), the hopper (4) is installed on the support of the base (1), and a weighing scale (5) is designed at the output end of the feeding cylinder (6).

[0014] The driving mechanism (2) is an air cylinder.

Embodiment 2

[0016] This embodiment provides an accurate batching device for aluminum powder. ), feeding cylinder (6);

[0017] Among them: including the base (1), the aluminum powder feeding device is fixedly installed on the base (1). Driven by the driving mechanism (2), the hopper (4) is installed on the support of the base (1), and a weighing scale (5) is designed at the output end of the feeding cylinder (6).

[0018] The drive mechanism (2) is a private server motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com