Refractory matter batching equipment

A technology of batching equipment and refractory materials, which is applied in clay preparation devices, mixing plants, mixing operation control devices, etc. Reliable, easy to debug, and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

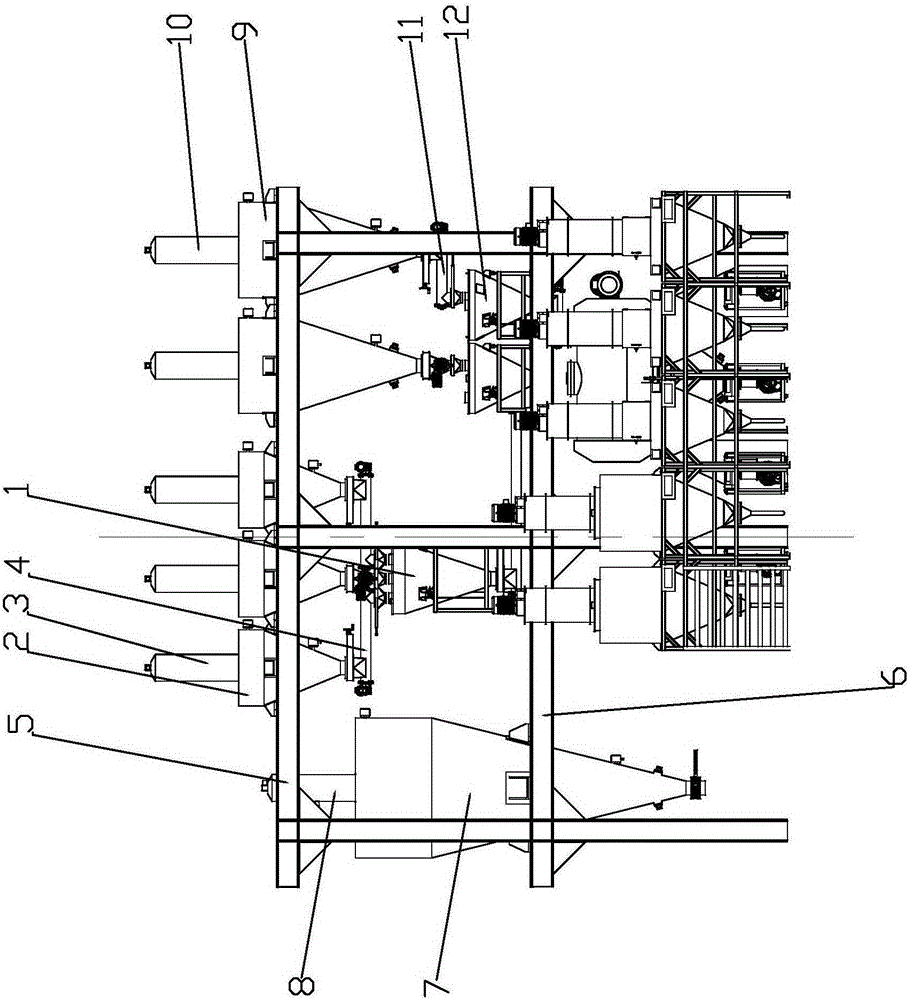

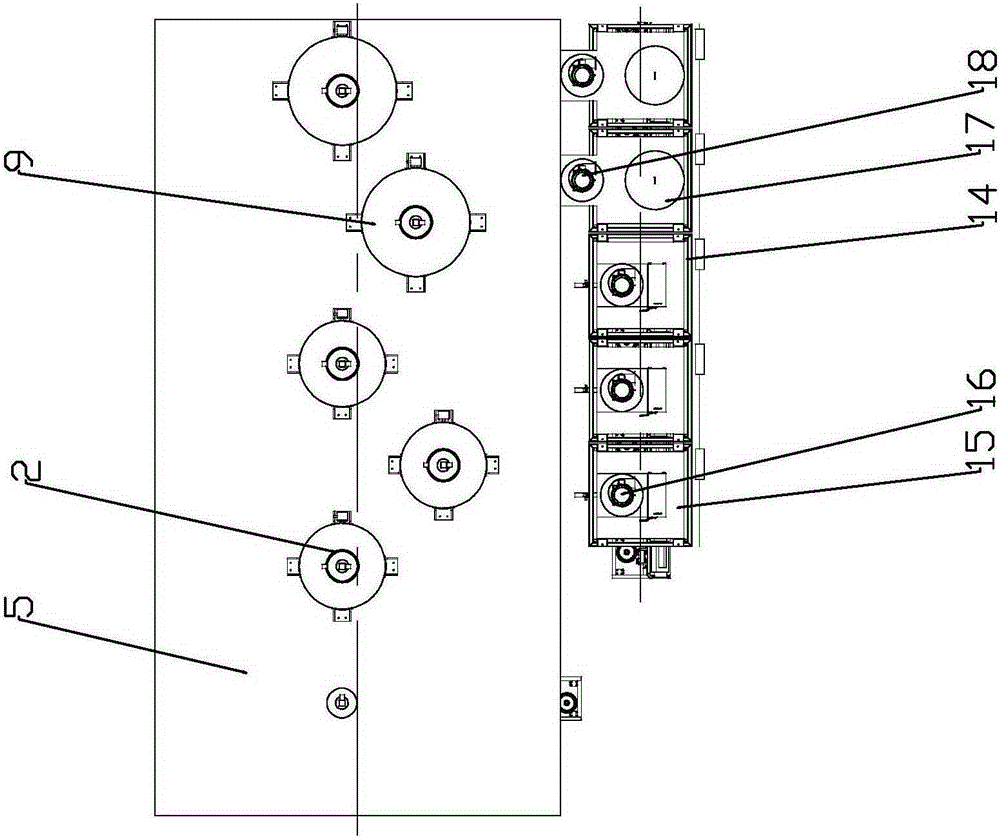

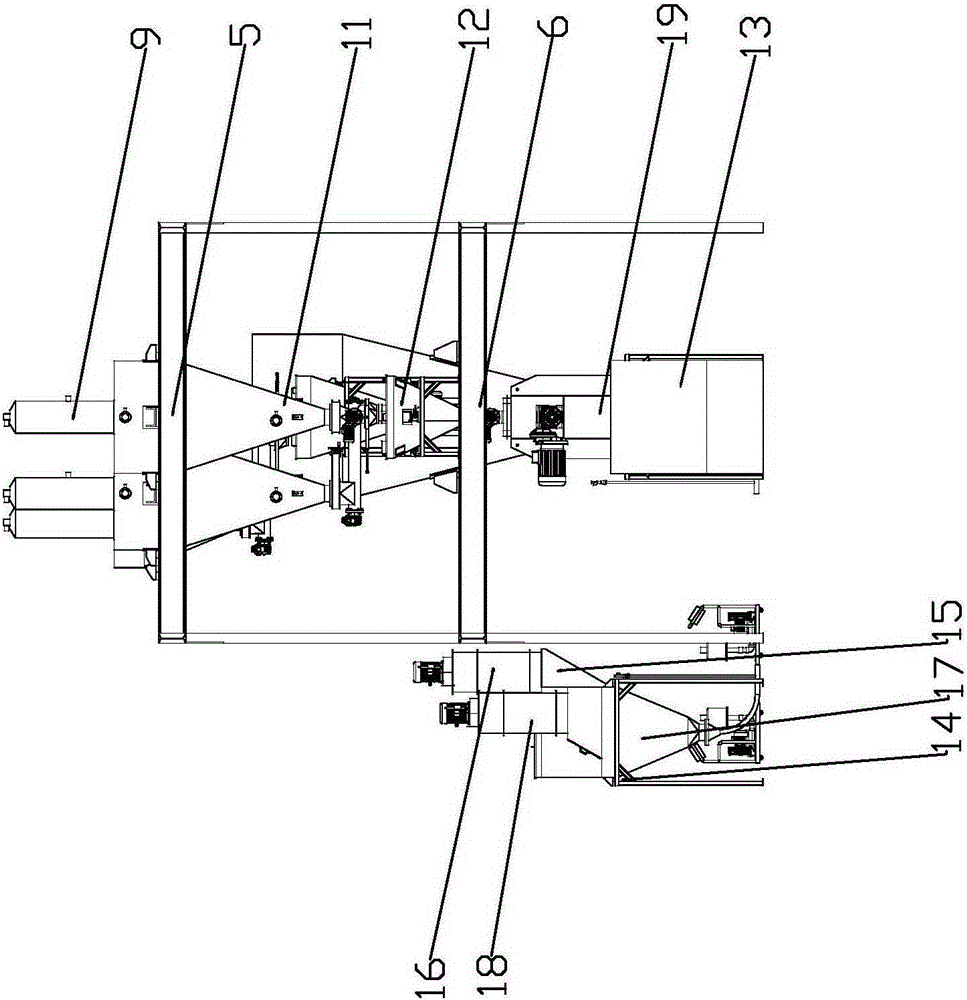

[0017] Such as Figure 1~3 As shown, the present invention mainly comprises the first metering hopper 1, the first silo 2, the first vacuum suction machine 3, the first screw conveyor 4, the upper platform 5, the middle platform 6, the storage bin 7, the storage bin Vacuum suction machine 8, second silo 9, second vacuum suction machine 10, second screw conveyor 11, second weighing hopper 12, silo screw conveyor 13, loading platform 14, ton bag loading silo 15. Big bag dust collector 16, small bag feeding bin 17, small bag dust collector 18 and mixer 19.

[0018] The upper platform 5 and the middle platform 6 are connected up and down as a whole. A plurality of first material bins 2 are fixed on the upper platform 5, a first vacuum suction machine 3 is provided at the feed end of each first material bin 2, and a first vacuum suction machine 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com