Multi-component rare earth raw material sampling method

A multi-component, rare earth technology, applied in sampling devices, thermal excitation analysis, material excitation analysis, etc., can solve the problems of raw material failure and unrepresentative samples, and achieve the effect of accurate batching and true and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

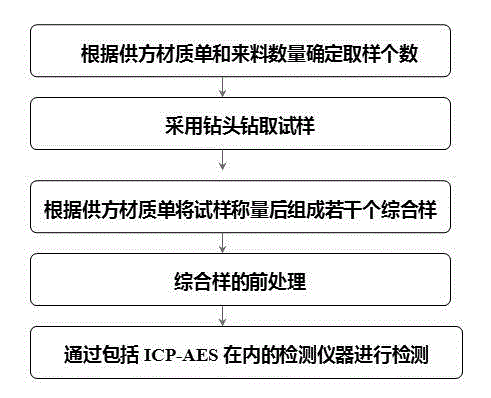

[0016] Example 1: A kind of sampling method of lanthanum cerium rare earth metal raw material, such as figure 1 As shown; a batch of lanthanum-cerium rare earth metal raw materials weighs 10 tons, and there are a total of 10 small batches, that is, each small batch is 1 ton, and each 1 ton is packed in 4 barrels. The supplier's material list is as follows: 10 sets of detection data. Take 3 barrels per 1 ton, that is, each small batch, and take one sample per barrel. For each small batch of three alloy ingot samples, use a 7mm drill to drill the samples, and discard the 0.5-1.0mm from the surface. Drilling cuttings, and then put the drilled samples into the sampling bag immediately; then weigh the samples according to the ratio of 1:1:1 to form a comprehensive sample, a total of 10 comprehensive samples. After comprehensive sample pretreatment, it was detected by ICP-AES spectrometer.

[0017] In order to prove the practicability and reliability of the method, the conventio...

Embodiment 2

[0020] Example 2: A kind of sampling method of lanthanum cerium rare earth metal raw material, such as figure 1 As shown; if one incoming material is 5 tons, and 5 tons of raw materials are a batch, at least 4 barrels are used for each 1 ton, and only one set of test data is displayed on the material list of the supplier; 6 barrels of incoming materials are randomly selected, Take one sample per barrel, drill the sample with an 8mm drill bit for 6 alloy ingot samples, discard the drill cuttings 0.5-1.0mm from the surface, and then immediately put the drilled sample into the sampling bag; every two samples Weigh the samples according to the ratio of 1:1 to form a comprehensive sample, a total of 3 comprehensive samples. After comprehensive sample pretreatment, it was detected by ICP-AES spectrometer.

Embodiment 3

[0021] Embodiment 3: A kind of sampling method of lanthanum cerium rare earth metal raw material, such as figure 1 As shown; if one incoming material is 12 tons, and the 12 tons of raw materials are a batch, at least 4 barrels are used for each 1 ton, and only one set of test data is displayed on the material list of the supplier; then 8 barrels of incoming materials are randomly selected, Take one sample per barrel, drill samples with a 9mm drill bit for 8 alloy ingot samples, discard the drill cuttings 0.5-1.0mm from the surface, and then immediately put the drilled samples into the sampling bag; every two samples Weigh the samples according to the ratio of 1:1 to form a comprehensive sample, a total of 6 comprehensive samples. After comprehensive sample pretreatment, it was detected by ICP-AES spectrometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com