Centralized supply control method and system of liquid feeding for pig farms

A control method and technology of feeding system, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of large investment in feed supply equipment, easily polluted feed supply, and high feed loss, and achieve intelligentization. The effect of precise delivery, reducing hardware investment costs, and reducing drug use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

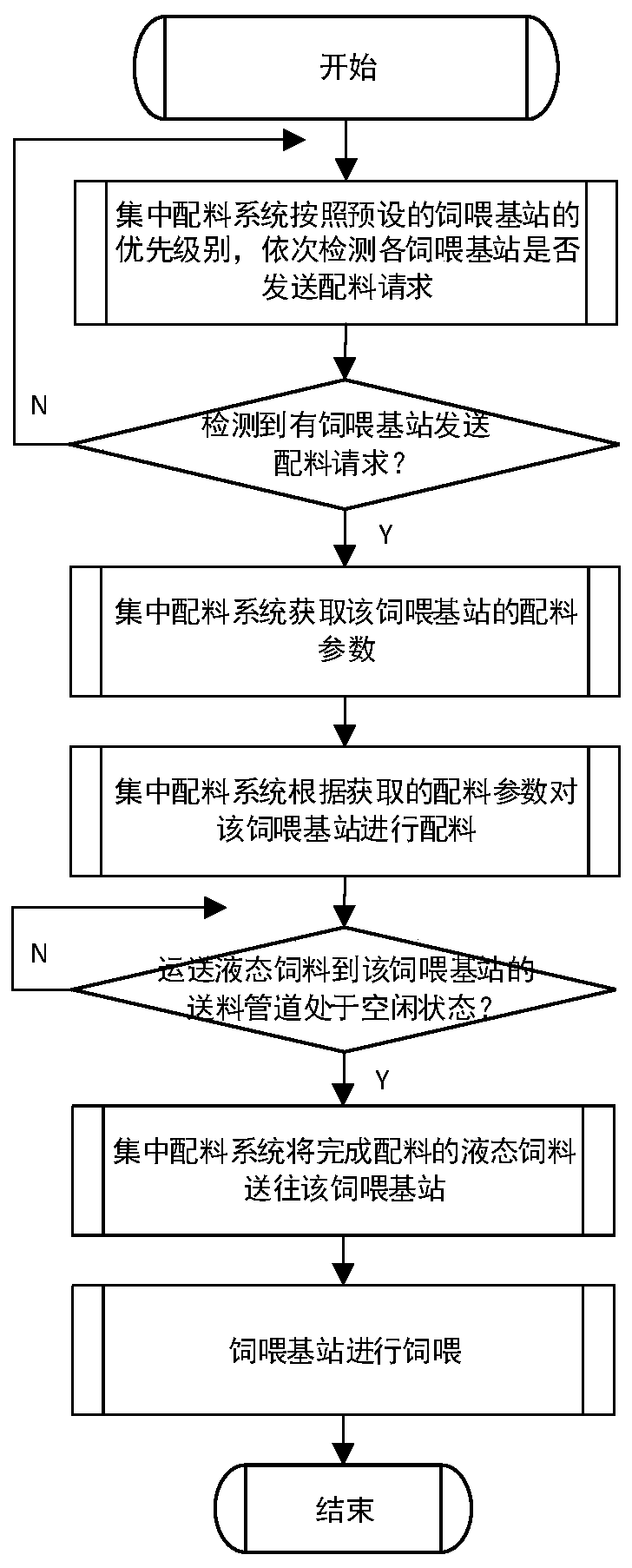

Method used

Image

Examples

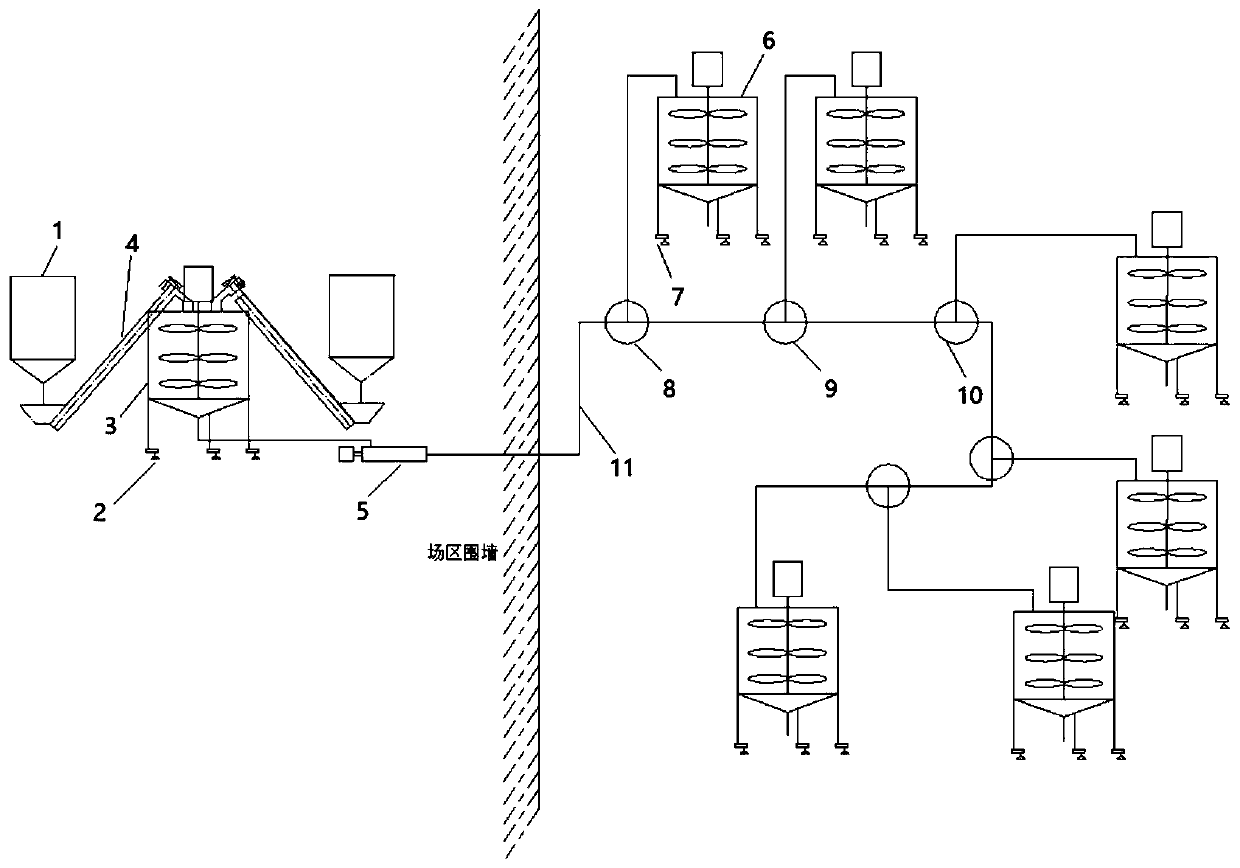

Embodiment 1

[0062] A centralized batching system is set in the centralized feeding area. The centralized batching system includes a mixing batching device and a material tower 1. Each material tower 1 is equipped with a hoist 4 for conveying the dry feed in the material tower 1 through the hoist 4. to the mixing device. If the semi-finished feed that is not prepared according to the standard of full-price feed is used, a silo 1 is set up for each raw material, such as silo 1 for storing corn, silo 1 for storing soybean meal, silo 1 for storing bran, etc., when not in use In the case of a centralized batching system, breeding enterprises can only invest in feed factories for mixing and preparation, but the present invention only needs to set up a feeding tower 1 and a hoist 4 for each raw material in the centralized feeding area, which greatly reduces cost input. For example: corn, soybean meal, bran and other raw materials, each raw material provides a material tower 1, and only needs to ...

Embodiment 2

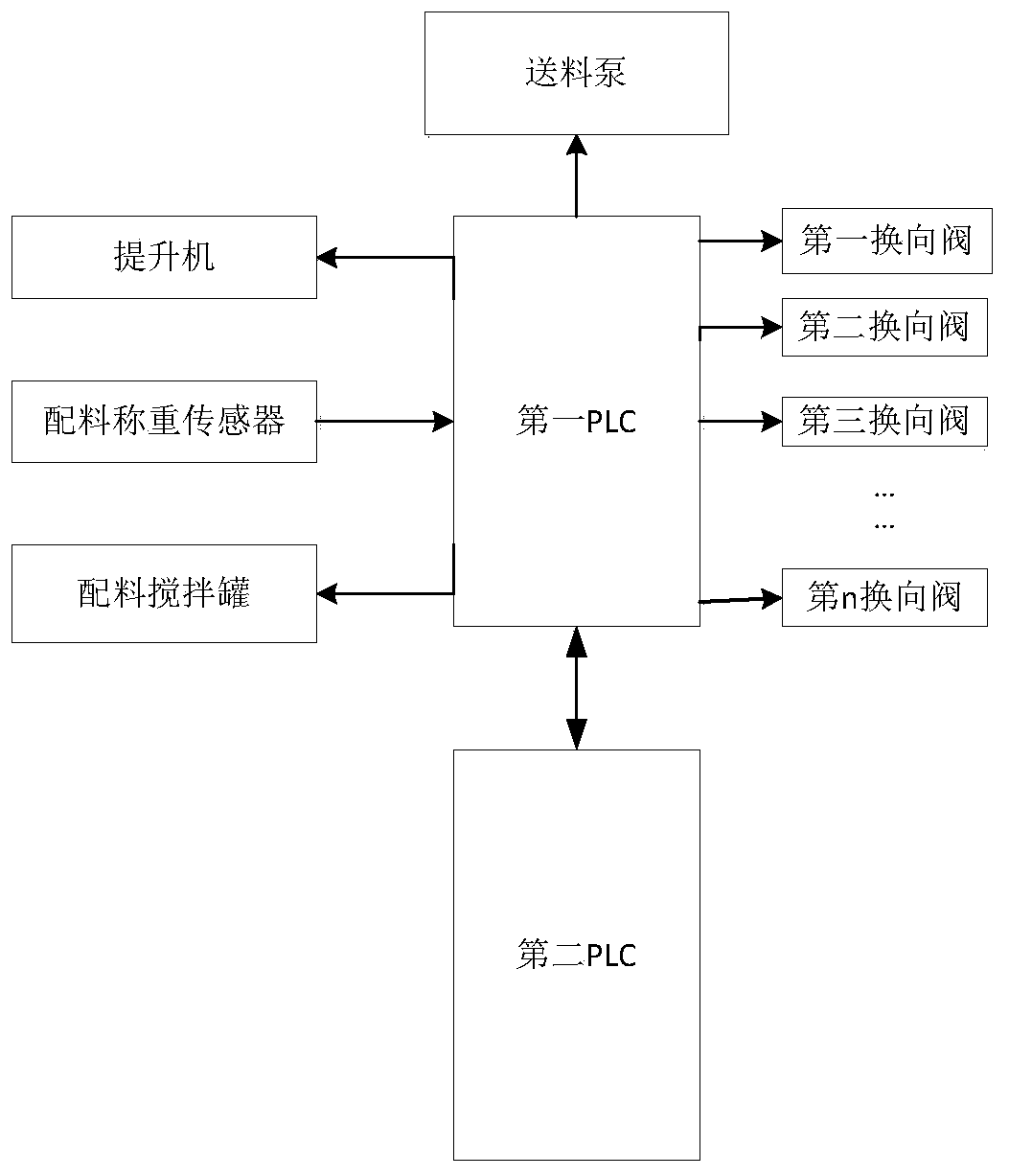

[0074] In this embodiment 2, on the basis of the embodiment 1, a high-pressure vortex blower for cleaning the feeding pipeline and a flushing device for cleaning the ingredient mixing tank 3 are further provided in the centralized feeding area.

[0075] Wherein, the flushing device includes a flushing pipeline and a flushing valve, the flushing pipeline is arranged above the batching mixing tank 3, and the water outlet is connected to the batching mixing tank 3, the flushing valve is installed on the flushing pipeline, and the blowing port of the high-pressure vortex fan It communicates with the feeding pipeline, and a purge valve is arranged on the pipeline between the blowing port of the high-pressure vortex blower and the feeding pipeline. The first PLC controls the connection of the high-pressure vortex blower and the flushing valve.

[0076] In this embodiment, in the feed delivery process, the first PLC determines the weight of the remaining feed in the mixing tank accor...

Embodiment 3

[0079] Embodiment 3 On the basis of Example 1, multiple stirring and batching devices are set, and the multiple stirring and batching devices are connected by the first PLC control, for example: two stirring and batching devices are set, and one stirring and batching device can be corresponding to the More than one material tower 1, and another stirring and batching device corresponds to the remaining several feeding towers 1, so that the efficiency of feed preparation can be improved through multiple stirring and batching devices working at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com