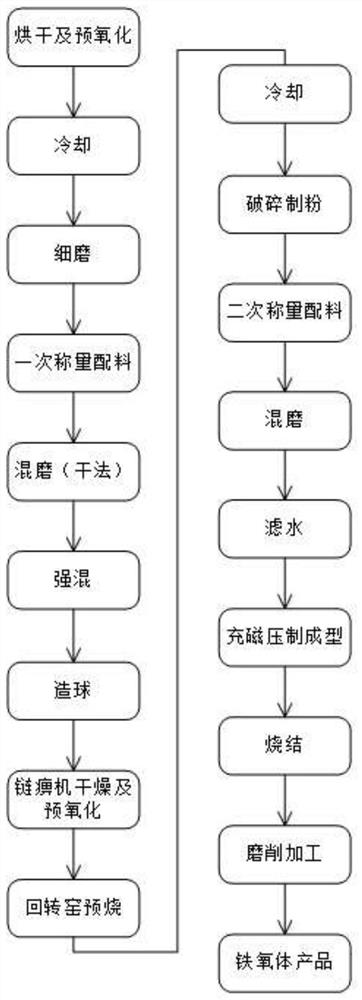

Process for preparing permanent magnetic ferrite in short process

A permanent magnet ferrite and short-process technology, which is applied in the direction of inorganic material magnetism, can solve the problems of lengthy process and low production efficiency, and achieve the effects of accurate ingredients, stable product performance, consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

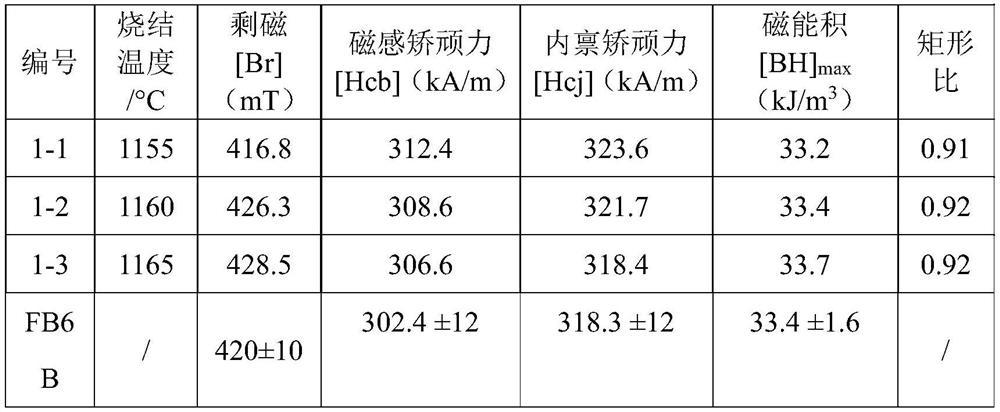

[0036] Embodiment 1 (this embodiment is to have carried out three groups of parallel tests, and sintering temperature is respectively 1155 ℃, 1160 ℃ and 1165 ℃):

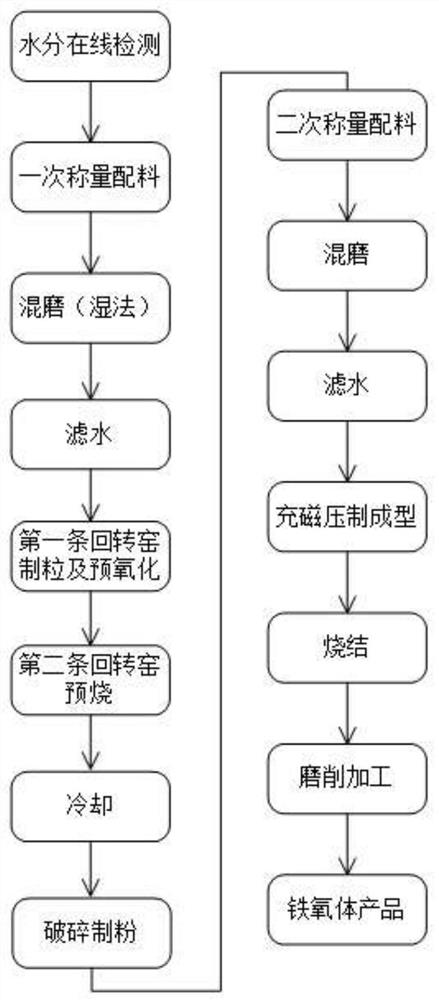

[0037] A short flow process of the present invention prepares the technique of permanent magnet ferrite, and its flow chart is as figure 2 shown, including the following steps:

[0038] (1) the ultra-pure magnetite concentrate with a purity of 99.6%, a Si impurity content of 0.08%, an Al impurity content of 0.09%, a Fischer average particle size of 9 microns, and a water content of 9% is transported into the batching bin by a belt, The water content of the material is detected by the microwave on-line detection probe, and the analysis value of the water content of the material is fed back to the primary batching system in real time; referring to the real-time detection of the water content of the ultra-pure magnetite concentrate, according to the chemical formula SrO 5.85Fe 2 o 3 , adding strontium carbonate with...

Embodiment 2

[0046] Example 2 (in this example, three groups of parallel tests were carried out at the same time, and the highest temperatures of the second rotary kiln head were 1280°C, 1290°C and 1300°C respectively):

[0047] A short flow process of the present invention prepares the technique of permanent magnet ferrite, and its flow chart is as figure 2 shown, including the following steps:

[0048] (1) be 99.5% with purity, Si impurity content be 0.07%, Al impurity content be 0.08%, Fisherman's average particle diameter is 10 microns, and water content is that the ultra-pure magnetite concentrate of 8% is transported into batching bin by belt, The moisture content of the material is checked by the microwave on-line detection probe, and the analysis value of the moisture content of the material is fed back to the primary batching system in real time; referring to the real-time detection of the moisture content of the ultra-pure magnetite concentrate, according to the chemical formula...

Embodiment 3

[0057] A short flow process of the present invention prepares the technique of permanent magnet ferrite, and its flow chart is as figure 2 shown, including the following steps:

[0058] (1) The ultra-pure magnetite concentrate with a purity of 99.6%, Si impurities and Al impurities of 0.08%, a Fischer average particle size of 10 microns, and a water content of 10% is transported into the batching bin by a belt, and the material is passed through microwave On-line detection probe, the analysis value of material moisture content is fed back to the primary batching system in real time; refer to the moisture content detected in real time by ultra-pure magnetite concentrate, according to the chemical formula SrO nFe 2 o 3 , n=5.95, add strontium carbonate (purity 98%, average particle size 1.5 microns);

[0059] (2) Add water to the material after step (1) and carry out wet mixing and grinding. After wet mixing and grinding, the average particle size of the primary slurry is 3 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com