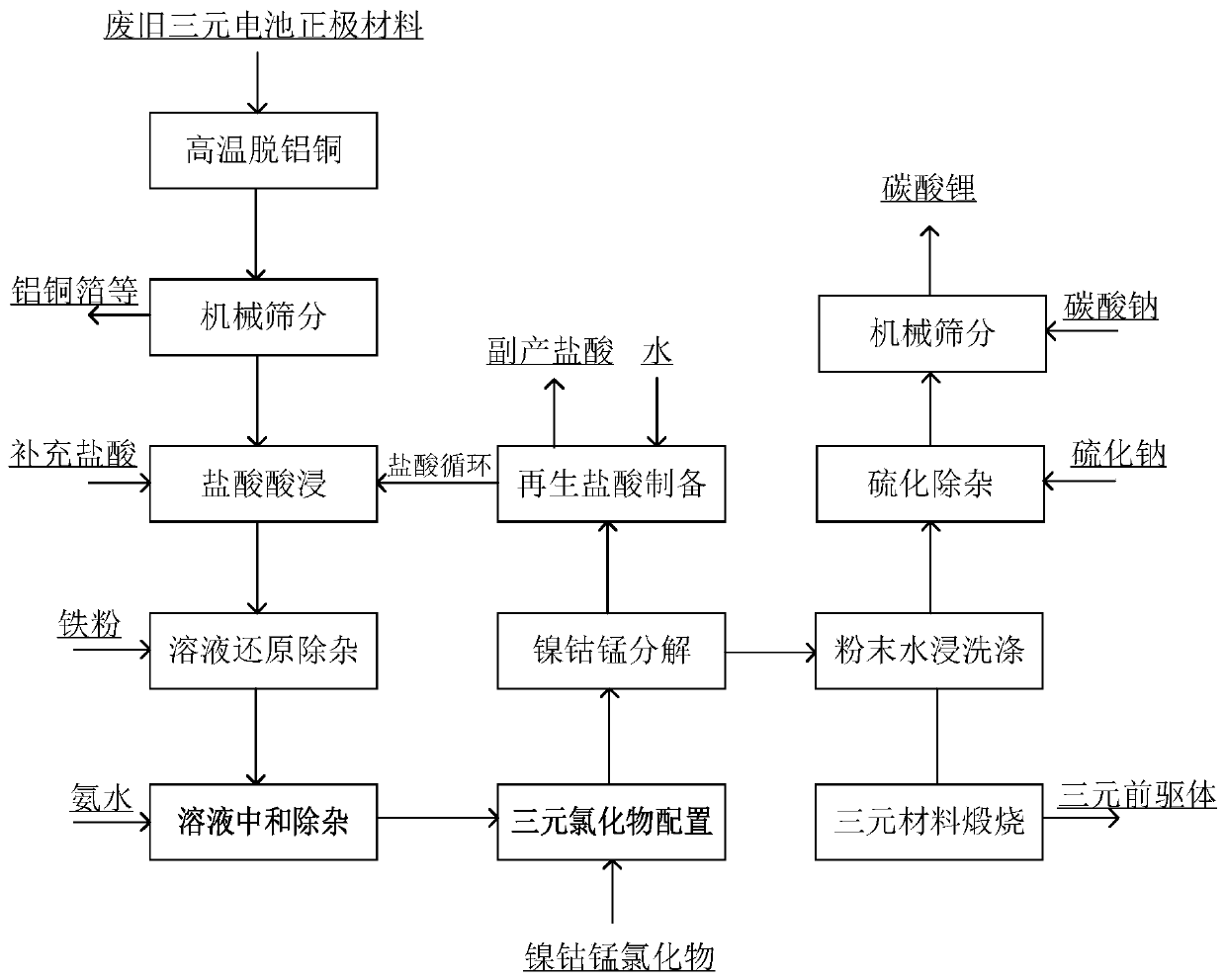

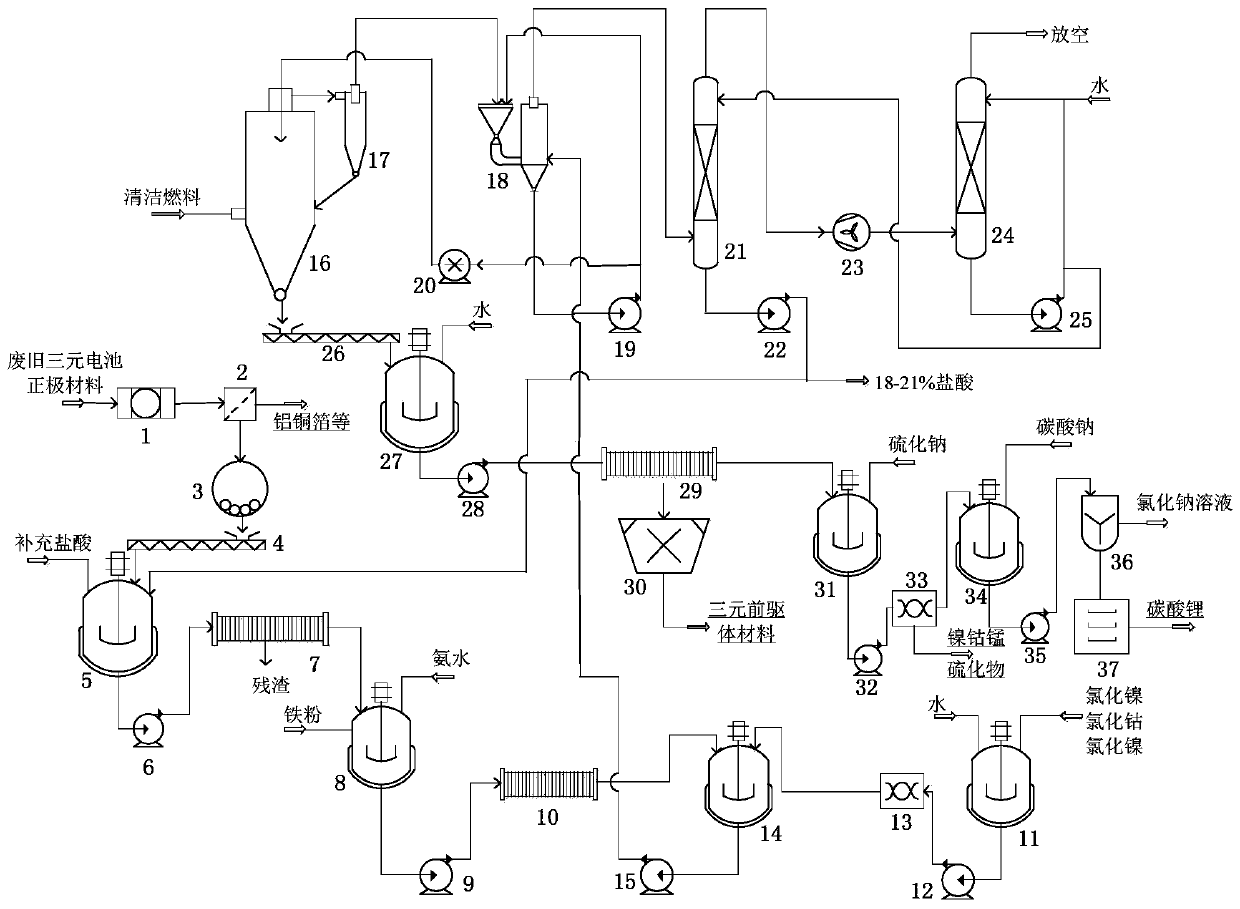

Method and system for recycling waste ternary battery positive electrode material based on hydrochloric acid regeneration cycle

A ternary battery and cathode material technology, applied in battery recycling, waste collector recycling, chemical instruments and methods, etc., can solve the problems of environmental hazards, excessive waste liquid, and waste liquid, and achieve no environmental risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] Recycling method of waste ternary battery cathode material:

[0145] (1') High-temperature dealuminated copper: Add the waste ternary battery positive electrode material into a natural gas heating rotary high-temperature furnace for activation. The activation temperature is 500°C and the activation time is 90 minutes. During this process, the binder in the waste Remove and decompose organic matter, so that lithium, nickel, cobalt, manganese, etc. are separated from aluminum foil, copper foil and copper wire;

[0146] (2') mechanical sieving: the activation product obtained in step (1') is reclaimed aluminum foil, copper foil and copper wire in the sieving machine, and obtains the solid powder containing lithium, nickel, cobalt, manganese; The waste ternary battery positive electrode material after removing aluminum foil, copper foil and copper wire is ground to more than 200 mesh;

[0147] (3') hydrochloric acid pickling: the ball mill product in step (2') is sent into...

Embodiment 2

[0155] Recycling method of waste ternary battery cathode material:

[0156] (1') High-temperature dealuminated copper: Add the waste ternary battery positive electrode material into an electric heating box-type high-temperature furnace for activation. The activation temperature is 520°C and the activation time is 80 minutes. During this process, the binder in the waste Remove and decompose organic matter, so that lithium, nickel, cobalt, manganese, etc. are separated from aluminum foil, copper foil and copper wire;

[0157] (2') mechanical sieving: the activation product in step (1') is reclaimed aluminum foil, copper foil and copper wire in the sieving machine, and obtains the solid powder containing lithium, nickel, cobalt, manganese; The waste ternary battery positive electrode material after removing aluminum foil, copper foil and copper wire is ground to more than 200 mesh;

[0158] (3') hydrochloric acid pickling: the powder obtained in step (2') is sent into hydrochlor...

Embodiment 3

[0166] Recycling method of waste ternary battery cathode material:

[0167] (1') High-temperature dealuminated copper: Add the waste ternary battery positive electrode material into an electric heating box-type high-temperature furnace for activation. The activation temperature is 540°C and the activation time is 70 minutes. During this process, the binder in the waste Remove and decompose organic matter, so that lithium, nickel, cobalt, manganese, etc. are separated from aluminum foil, copper foil and copper wire;

[0168] (2') mechanical sieving: the activation product in step (1') is reclaimed aluminum foil, copper foil and copper wire in the sieving machine, and obtains the solid powder containing lithium, nickel, cobalt, manganese; The waste ternary battery positive electrode material after removing aluminum foil, copper foil and copper wire is ground to more than 200 mesh;

[0169] (3') hydrochloric acid pickling: the ball mill product that step (2') obtains is sent int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com