Automatic supply device and method of corn steep liquor in production of microbial fermentation

A technology for microbial fermentation and automatic supply, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of easy rancidity and inconvenient feeding of corn steep liquor, and achieve convenient storage and use, Good environmental benefits and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

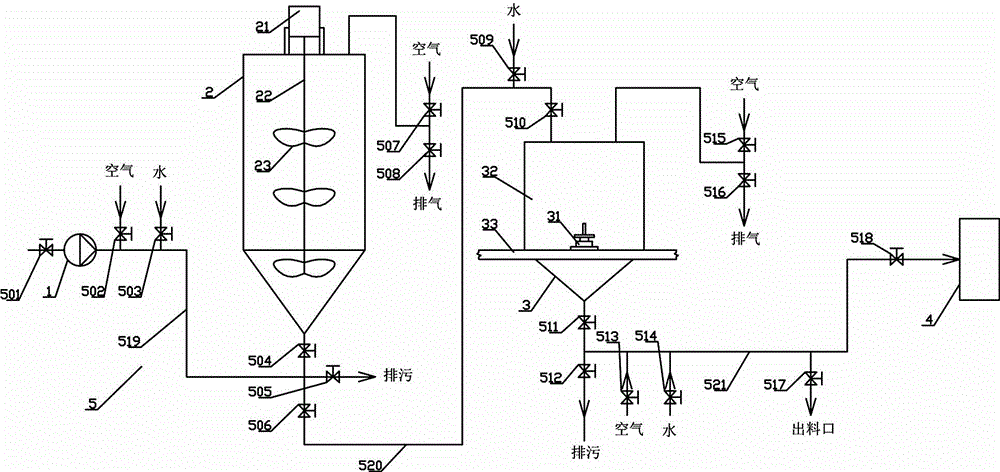

[0034] Such as figure 1 In, an automatic supply device for corn steep liquor in microbial fermentation production. Pump 1 is connected to storage tank 2 through feed pipe 519, storage tank 2 is connected to weighing tank 3 through weighing pipe 520, and weighing tank 3 passes ingredients The pipeline 521 is connected to the batching tank 4;

[0035] The storage tank 2 and the weighing tank 3 have a sealed structure. The storage tank 2 and the weighing tank 3 are provided with air inlet pipes, and the feed pipe 519, the weighing pipe 520, the batching pipeline 521 and the air inlet pipe are provided There are multiple valves. With this structure, accurate ingredients of corn steep liquor are realized, the quality of fermentation ingredients is improved, and labor intensity is also reduced. And because of the closed batching and transportation, the probability of corn steep liquor pollution is reduced.

[0036] In a preferred solution, the storage tank 2 is also provided with a co...

Embodiment 2

[0043] A method for batching using the above-mentioned automatic corn steep liquor supply device in microbial fermentation production includes the following steps:

[0044] 1. Use pump 1 to send corn steep liquor into storage tank 2;

[0045] 2. Use the air intake pipe of the storage tank 2 to pass compressed air into the weighing tank 3;

[0046] 3. After accurate weighing, use the air inlet pipe of the weighing tank 3 to pass compressed air into the corn steep liquor into the batching tank 4;

[0047] Through the above steps, the automatic supply of corn steep liquor in microbial fermentation production is realized.

[0048] In a preferred solution, the stirring device in the storage tank 2 is started every 4 to 8 hours and stirred for 10-20 minutes. After laboratory verification, the corn steep liquor solution will not produce precipitation and stratification within 8 hours. Therefore, the above-mentioned stirring scheme is adopted to avoid the precipitation and stratification of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com