Electrode material for TiNiFe alloy vacuum consumable smelting and preparation thereof

A technology for vacuum consumable smelting and electrode materials, which is applied in the direction of improving energy efficiency and process efficiency, can solve problems such as difficult preparation, poor welding performance, and smelting failure, and achieves simple preparation method, improved reliability, and improved The effect of composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

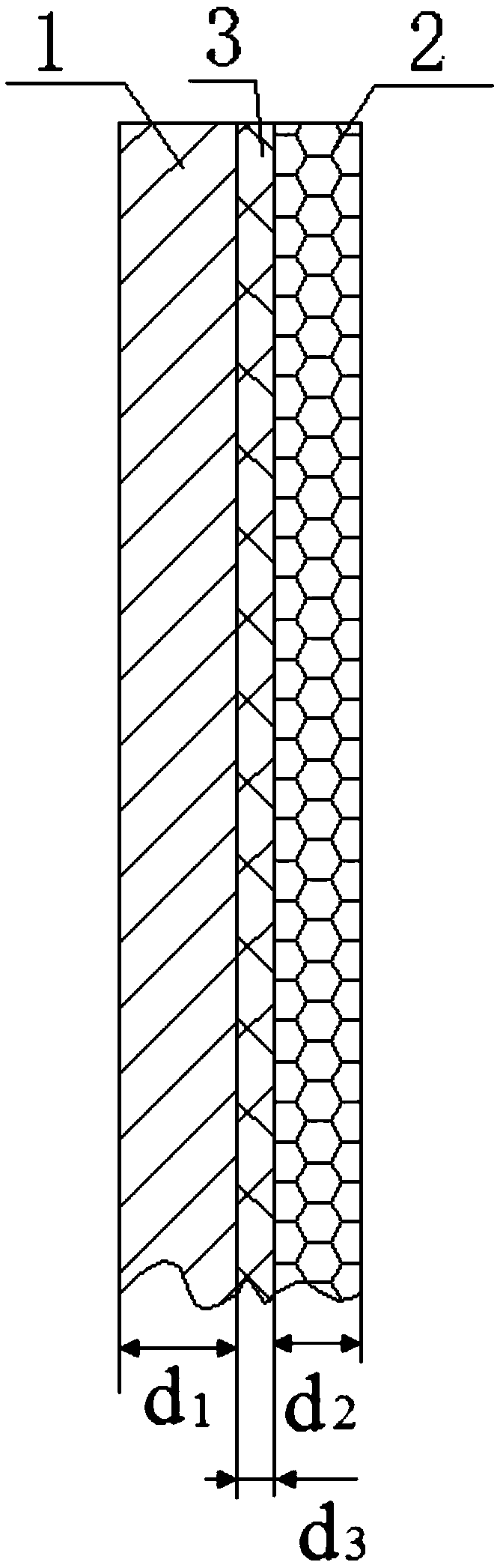

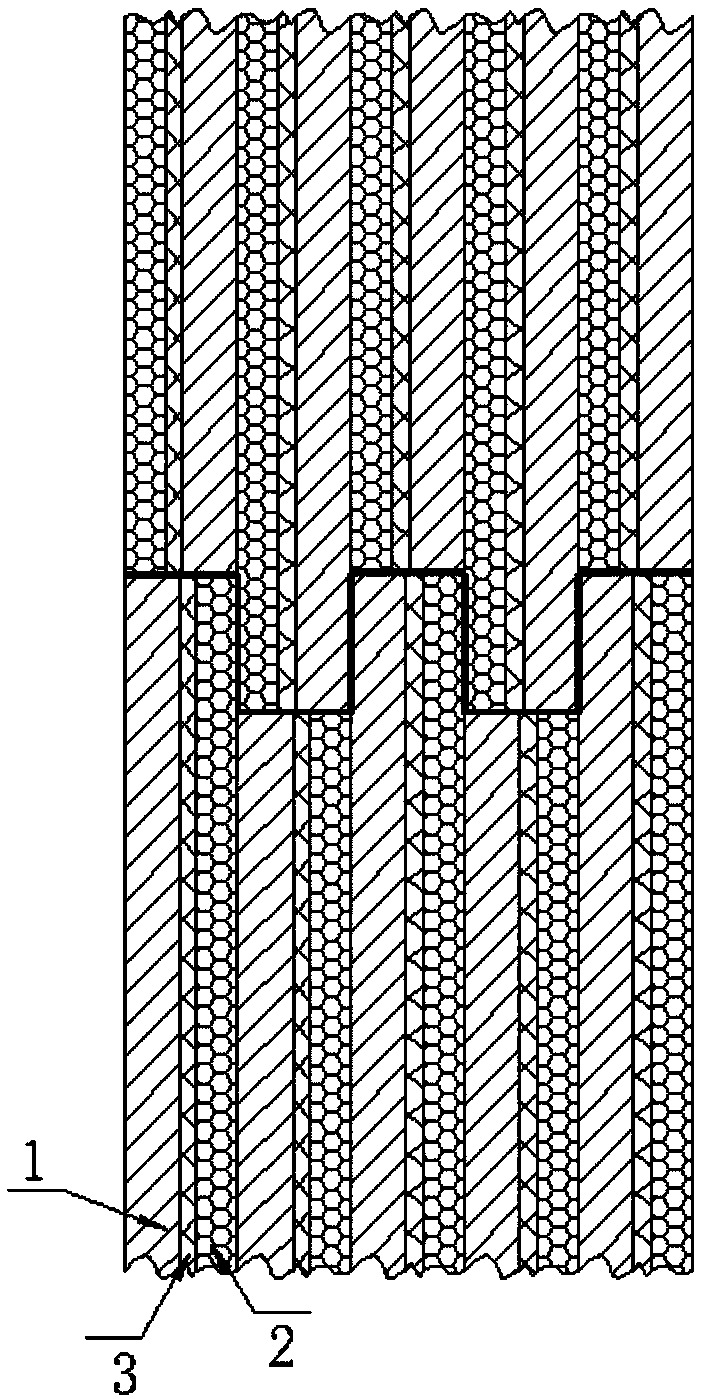

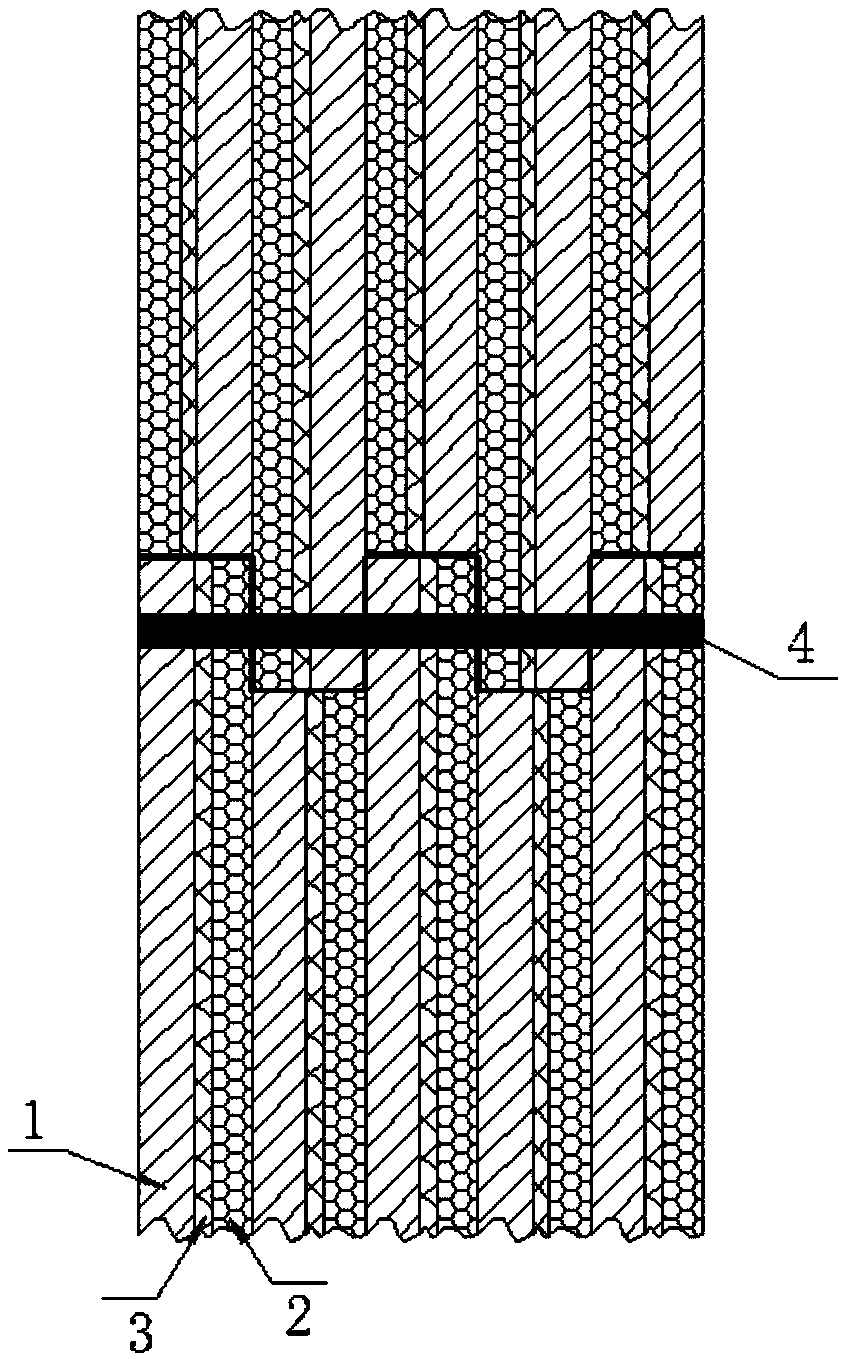

[0031] The electrode material of Ti50Ni47Fe3 alloy (atomic percentage content) was prepared by the following steps, and the diameter of the vacuum consumable melting crucible was 160mm.

[0032] (1) According to the composition requirements of TiNiFe alloy, the thickness and dimensional tolerance of high-purity titanium plate, high-purity nickel plate and high-purity iron plate are designed as follows: thickness of high-purity titanium plate: 2.47±0.02mm; thickness of high-purity nickel plate: 1.45±0.02mm; high-purity iron plate Plate thickness: 0.10±0.01mm; High-purity titanium plate, high-purity nickel plate, and high-purity iron plate are cold-rolled and deformed, and cut into slabs with a length of 800mm and a width of 100mm according to the size of the vacuum consumable melting crucible.

[0033] (2) According to the ingredient distribution requirements of the TiNiFe alloy, the weight error of various sheet materials is ≤0.03%. The high-purity titanium plate, high-purity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com