Novel precision batching device for fertilizer production

A fertilizer and precise technology, which is applied in the field of precise batching devices for the production of new fertilizers, can solve the problems of inability to guarantee the conveyor belt, low batching accuracy, and inaccurate batching, and achieve the effects of simple structure, simple batching, and fast batching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

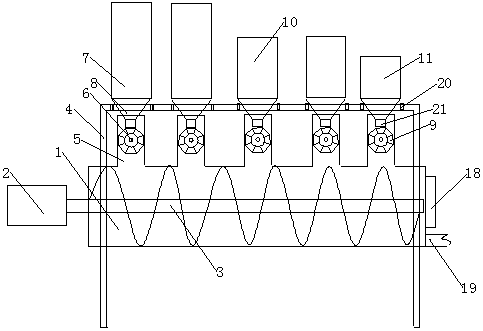

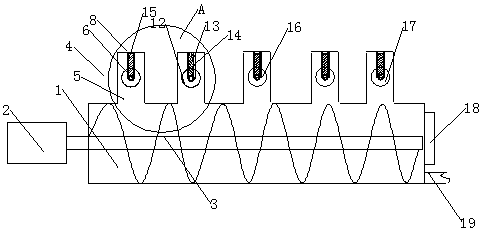

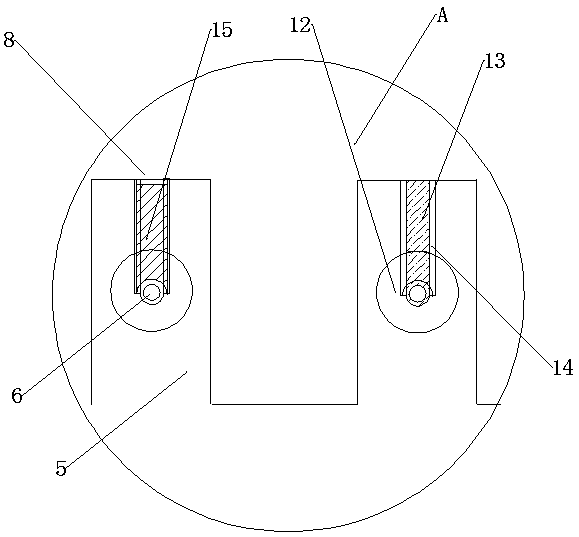

[0018] Such as Figure 1-3 As shown, a new type of precise batching device for fertilizer production includes a support frame 4, a plurality of partition bars 20 are arranged on the support frame 4, and a card seat is arranged between two adjacent partition bars 20, A first hopper 7, a second hopper 10, and a third hopper 11 are arranged in order from left to right above the holder. The first hopper 7, the second hopper 10, and the third hopper 11 The bottom of the hopper 11 is provided with a guide port 8, the said guide port 8 is provided with a solenoid valve 21, below the support frame 4 is provided with a batching dragon 1, the left side of the batching dragon 1 A motor 2 is provided, and the motor 2 is connected with a guide roller 3, and a feeding trough 5 opposite to the card seat is provided above the batching dragon 1, and the rear wall of the feeding trough 5 is opened There is a U-shaped groove 13, and sliding grooves 14 are provided on both left and right sides of...

Embodiment 2

[0021] Such as Figure 1-3 As shown, a new type of precise batching device for fertilizer production includes a support frame 4, a plurality of partition bars 20 are arranged on the support frame 4, and a card seat is arranged between two adjacent partition bars 20, A first hopper 7, a second hopper 10, and a third hopper 11 are arranged in order from left to right above the holder. The first hopper 7, the second hopper 10, and the third hopper 11 The bottom of the hopper 11 is provided with a guide port 8, the said guide port 8 is provided with a solenoid valve 21, below the support frame 4 is provided with a batching dragon 1, the left side of the batching dragon 1 A motor 2 is provided, and the motor 2 is connected with a guide roller 3, and a feeding trough 5 opposite to the card seat is provided above the batching dragon 1, and the rear wall of the feeding trough 5 is opened There is a U-shaped groove 13, and sliding grooves 14 are provided on both left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com