Patents

Literature

43results about How to "No manual mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

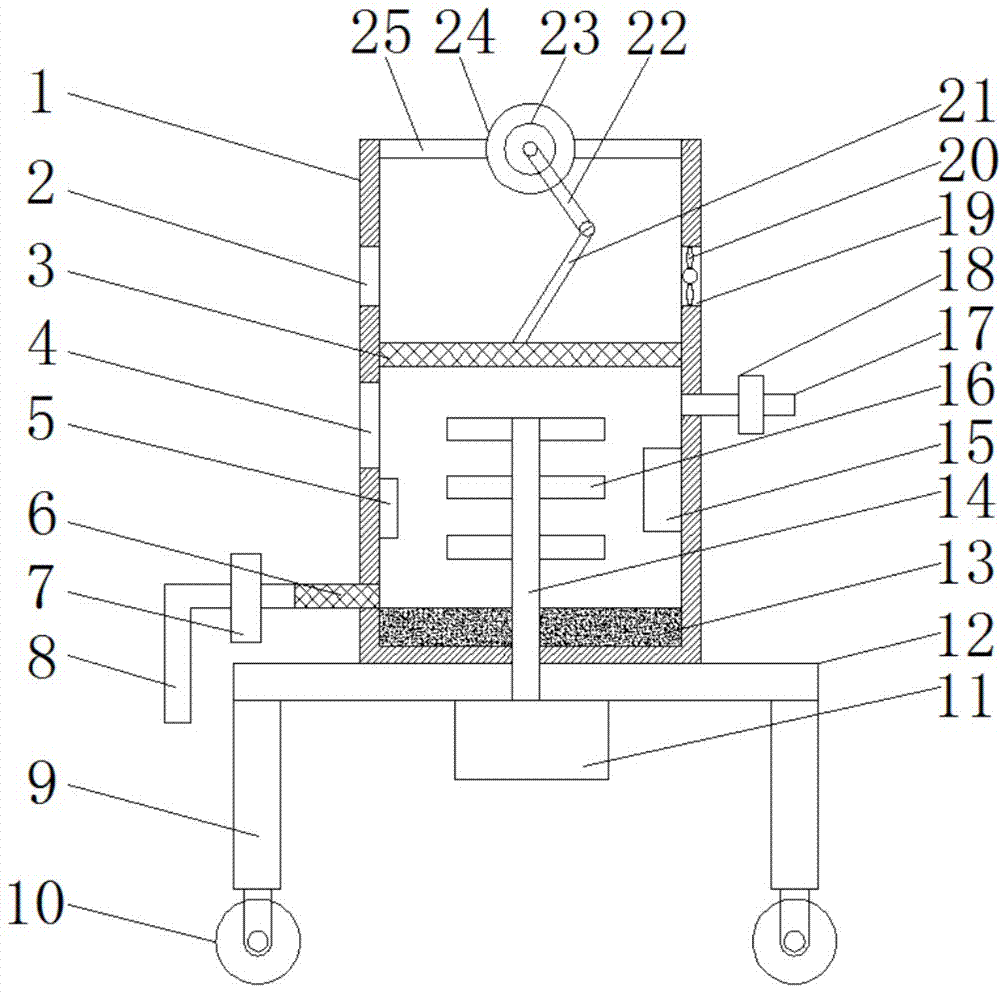

Conductive silver adhesives stirring equipment for electronic products manufacturing

InactiveCN106914176ANo manual mixingEasy to operateRotary stirring mixersTransportation and packagingAdhesiveEngineering

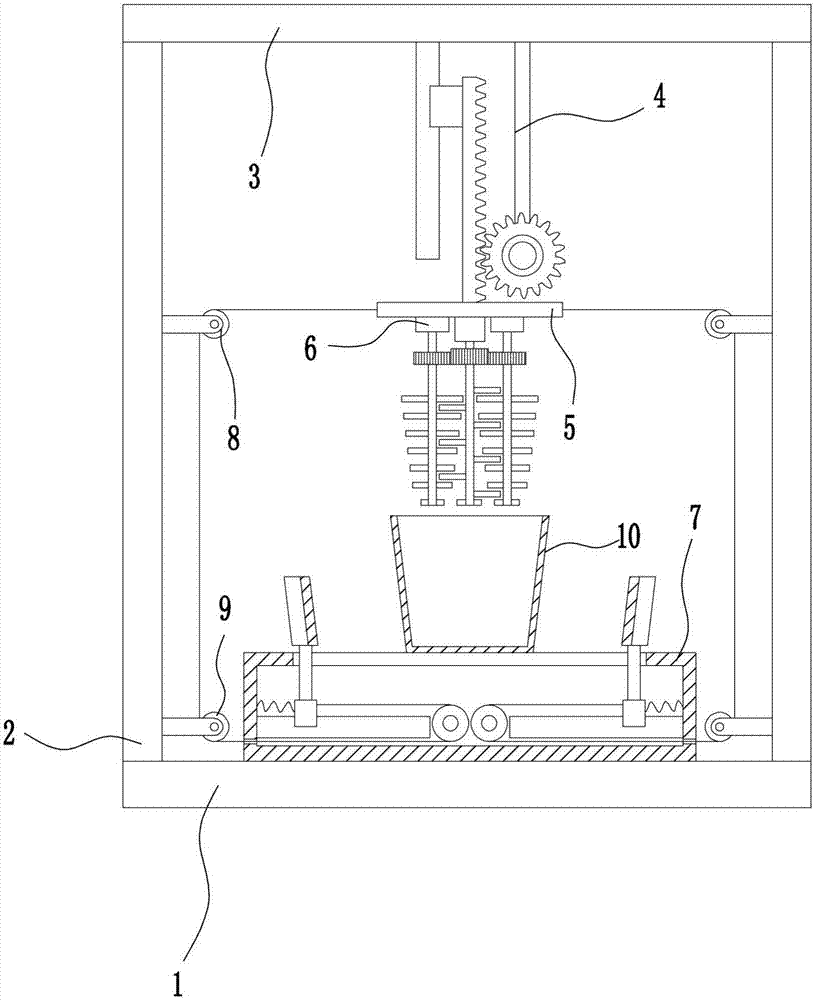

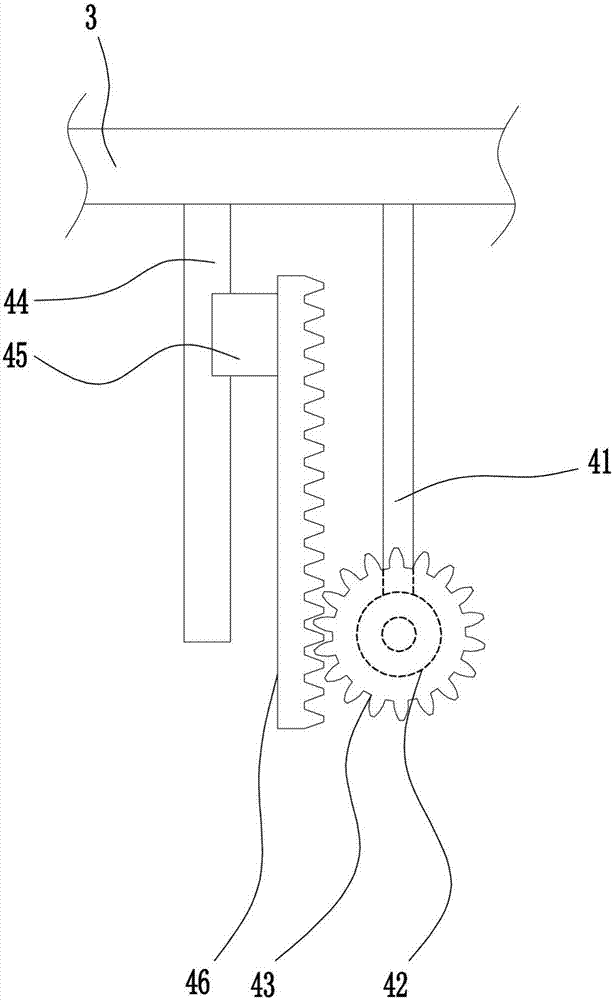

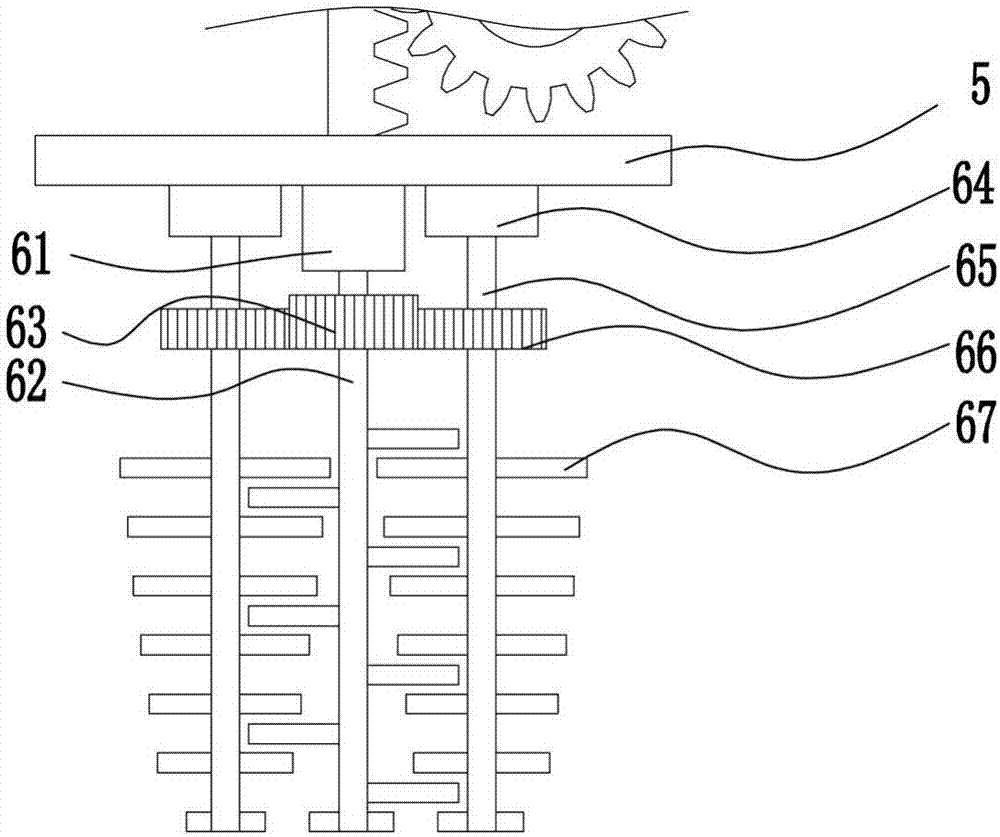

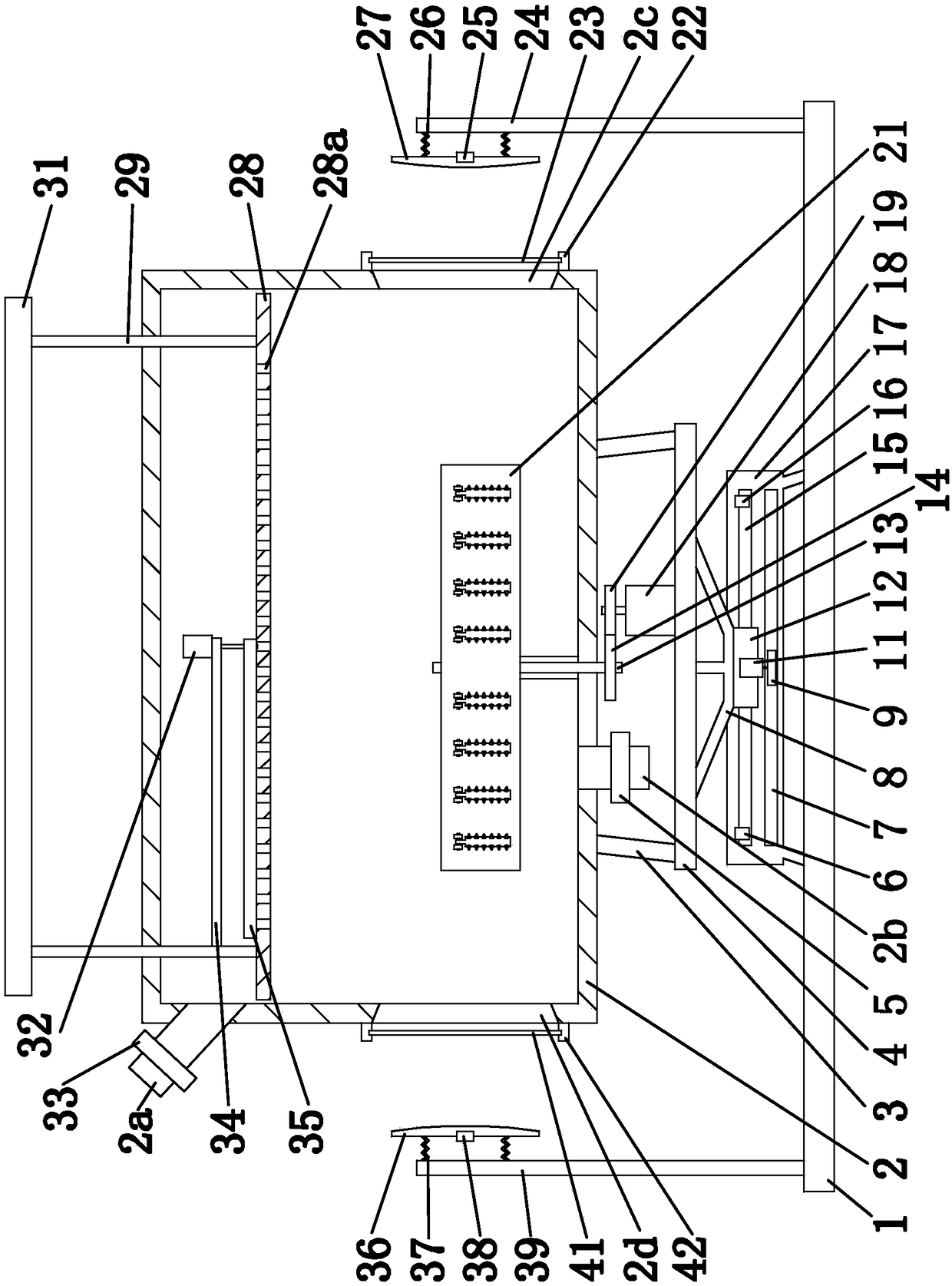

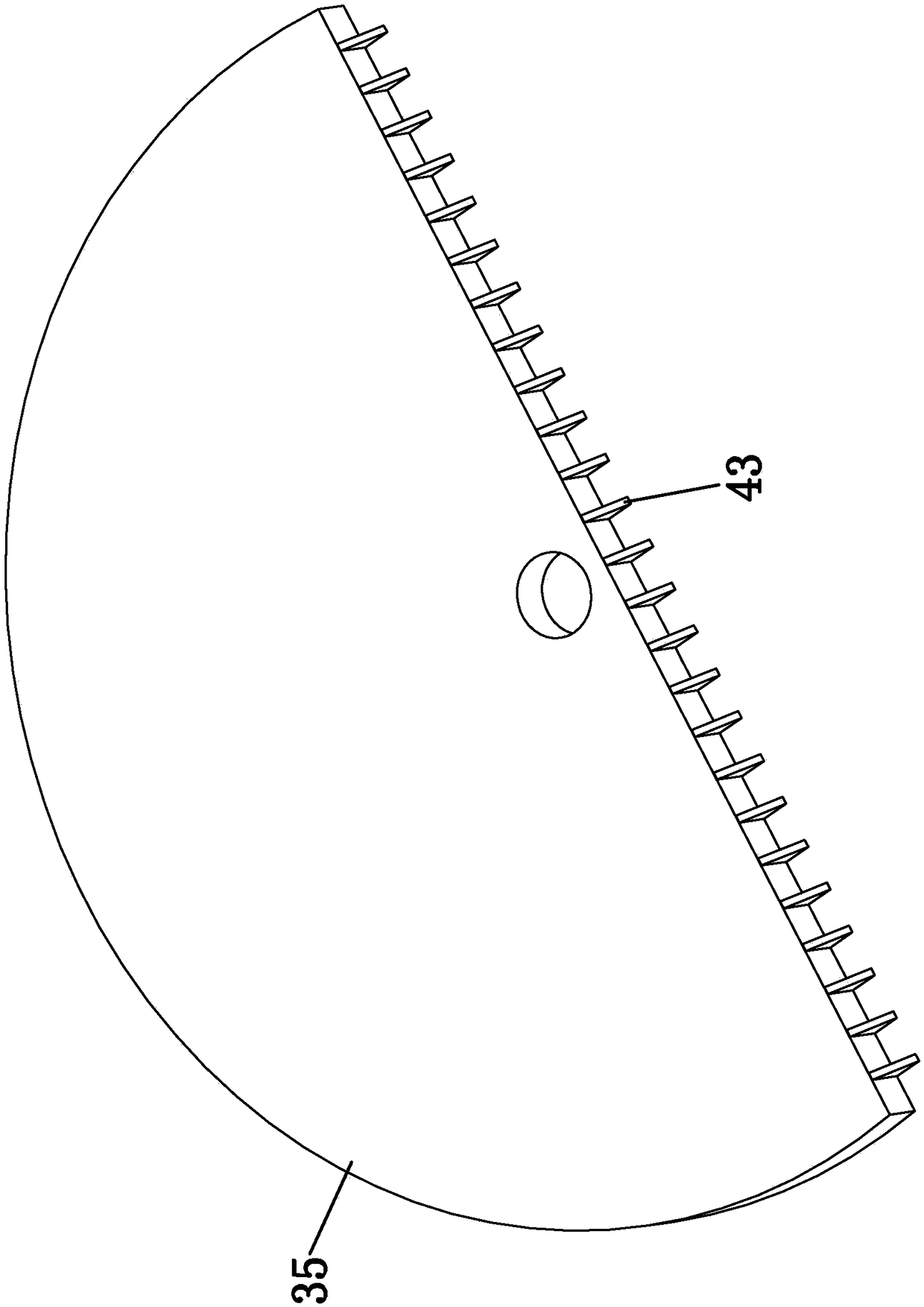

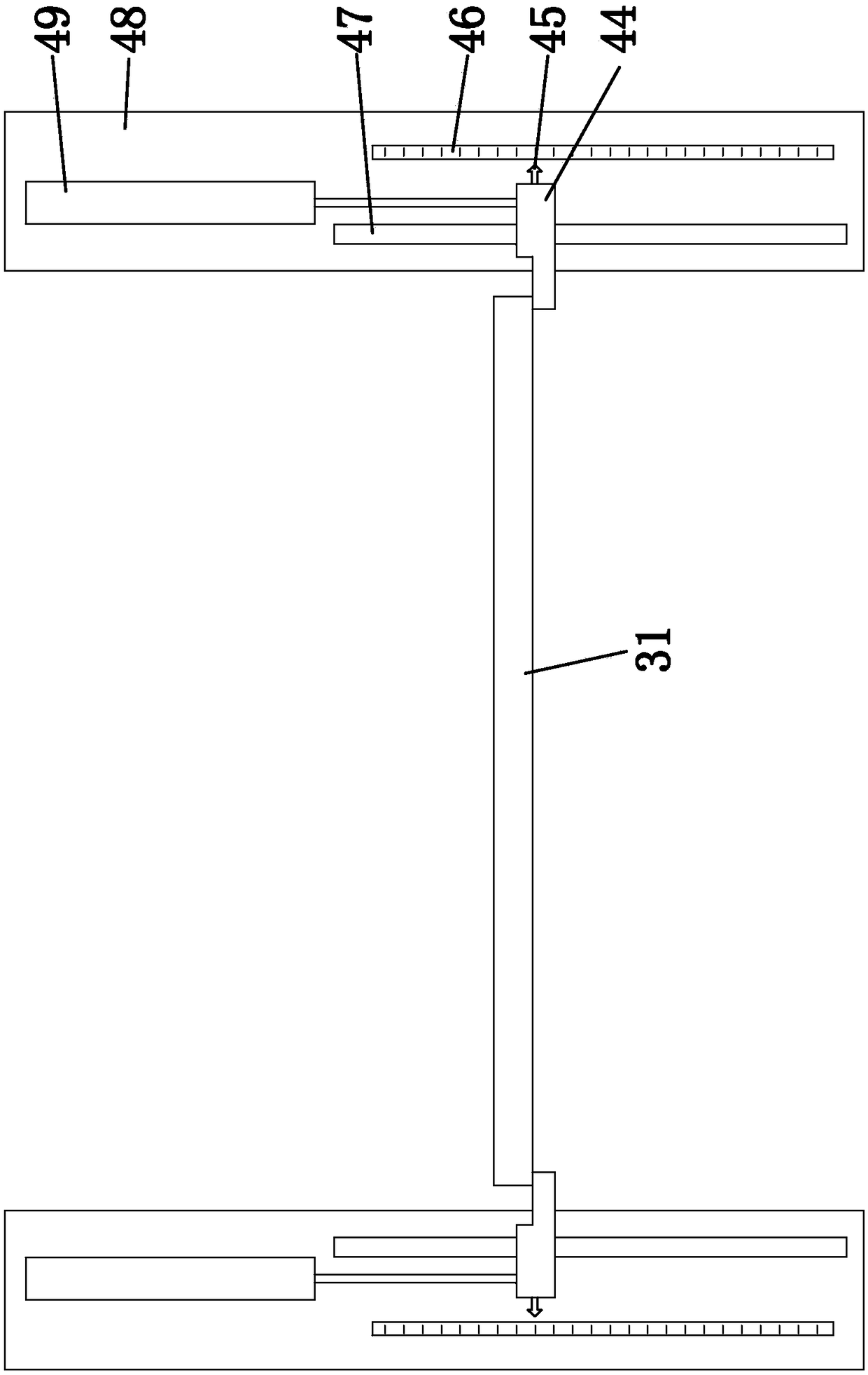

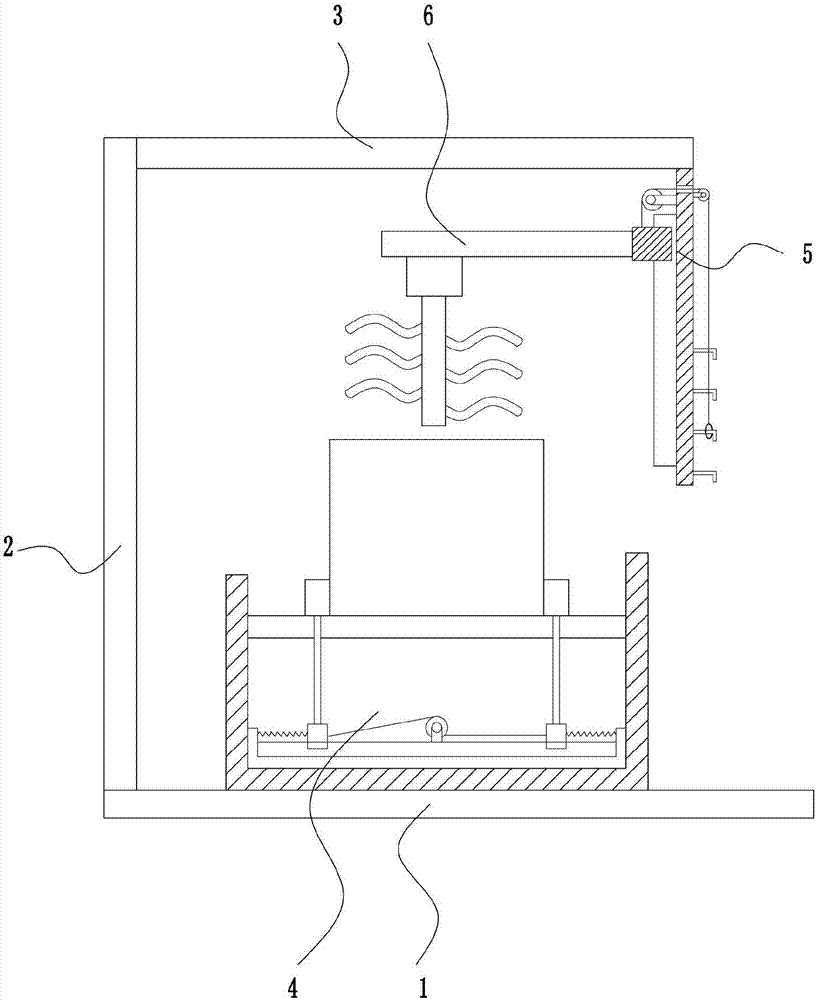

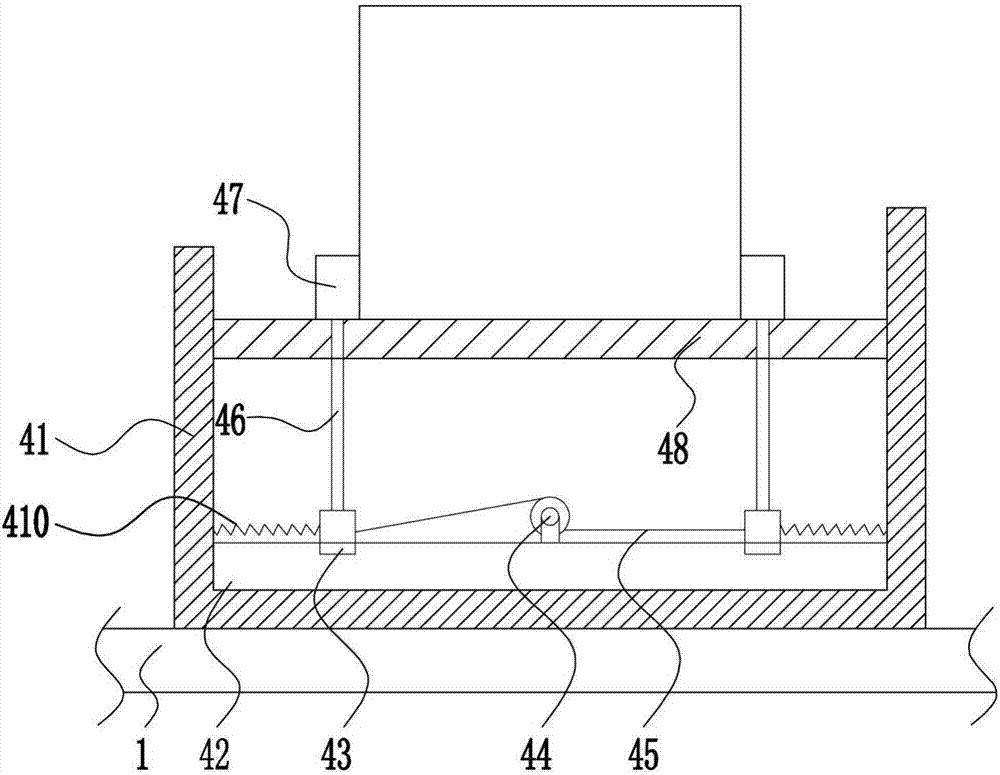

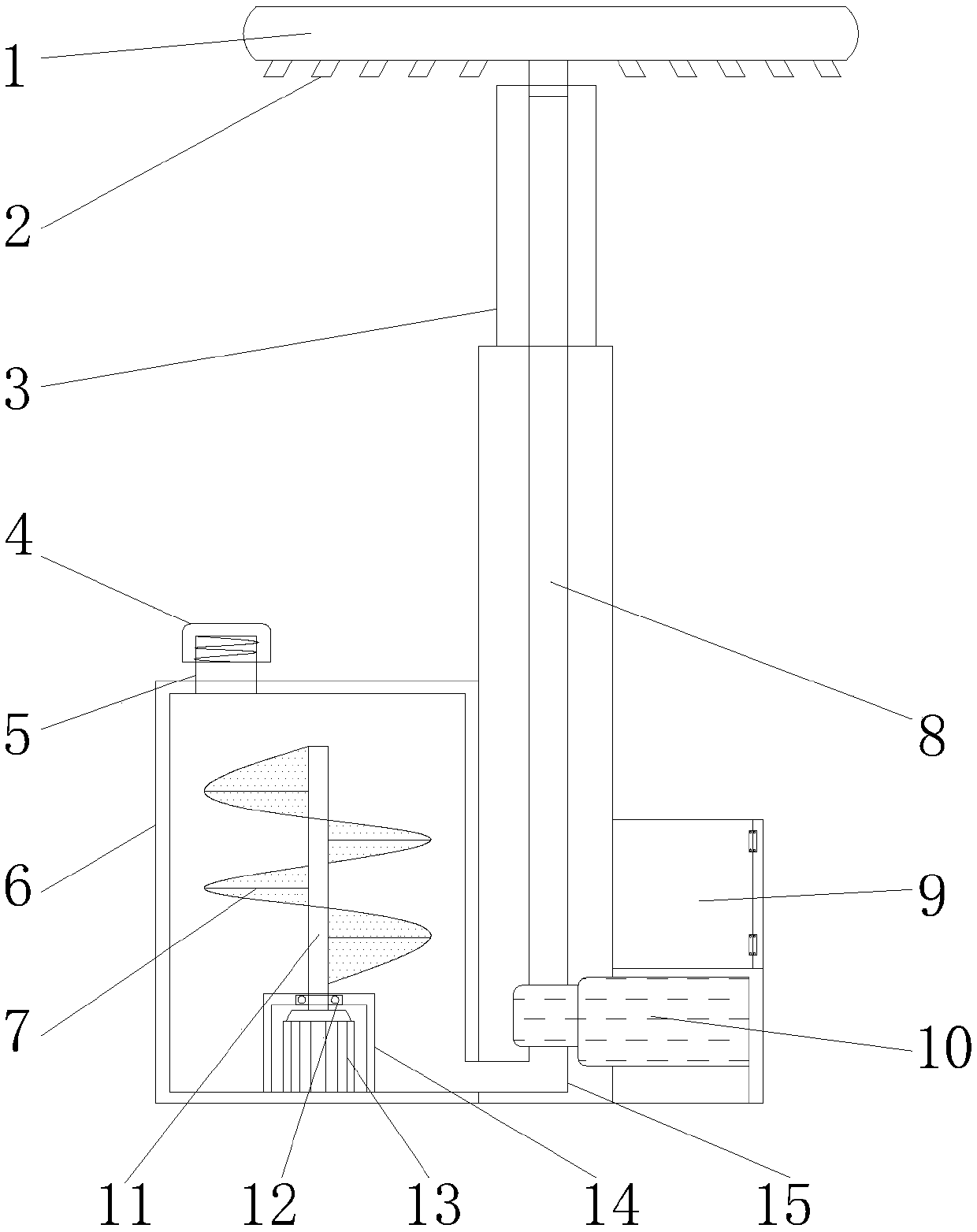

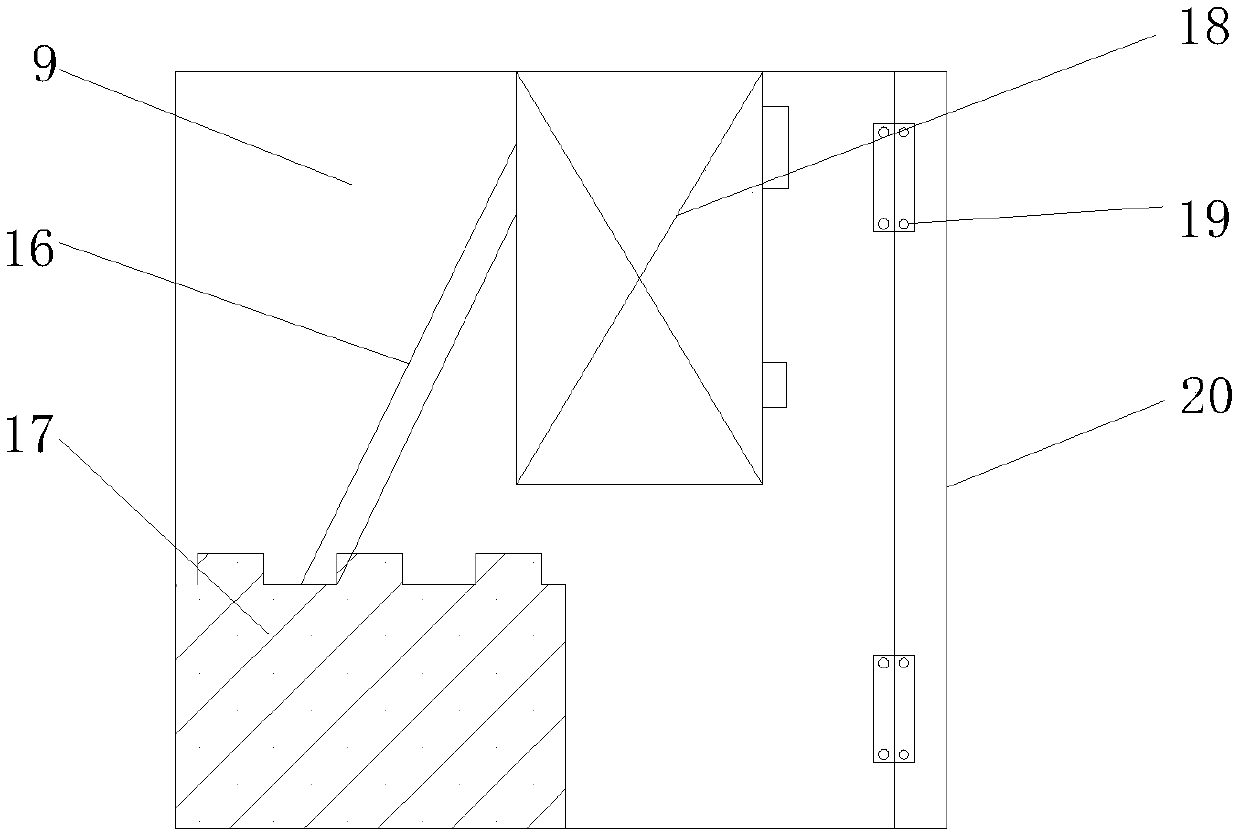

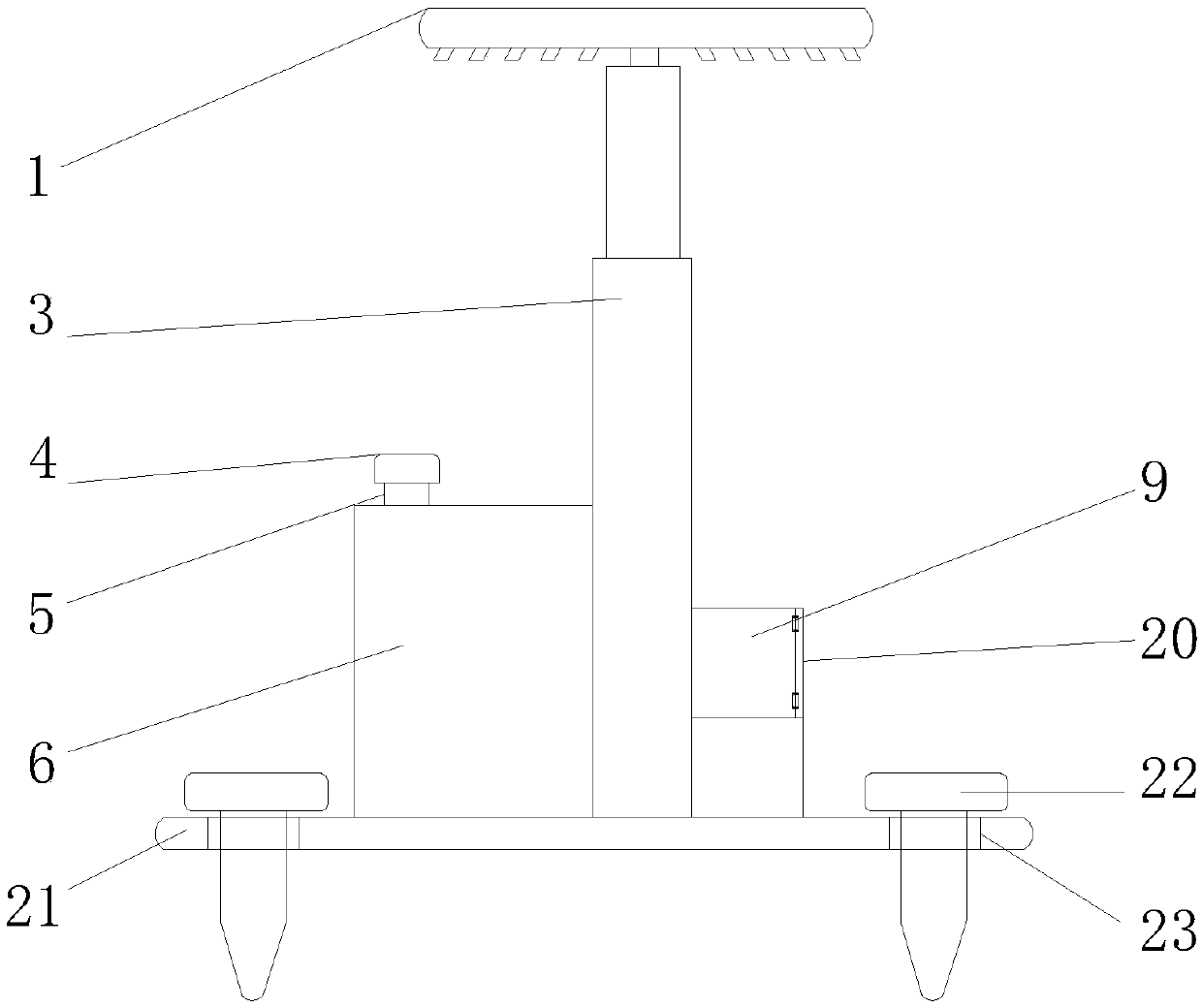

The invention relates to stirring equipment, especially to conductive silver adhesives stirring equipment for electronic products manufacturing. The invention provides the conductive silver adhesives stirring equipment for electronic products manufacturing. The stirring equipment requires no manual stirring, is simple to operate, and has high stirring efficiency. To solve the above technical problem, the invention provides the conductive silver adhesives stirring equipment for electronic products manufacturing. The stirring equipment comprises a base plate, supports, a top board, an elevating mechanism, a fixed plate, a stirring mechanism, a clamping mechanism, etc. the supports are installed at left and right sides of the top of the base plate. The top of the supports is provided with the top board. The elevating mechanism is installed at the middle of the bottom of the top board. The bottom of the elevating mechanism is connected to the fixed plate, the bottom of which is provided with the stirring mechanism. The top of the base plate is provided with the clamping mechanism. A first fixed pulley is installed in the middle at the inner side of each support. The stirring equipment achieves the following effects: no manual stirring is required; operation is simple; and stirring efficiency is high.

Owner:苍南博雅科技有限公司

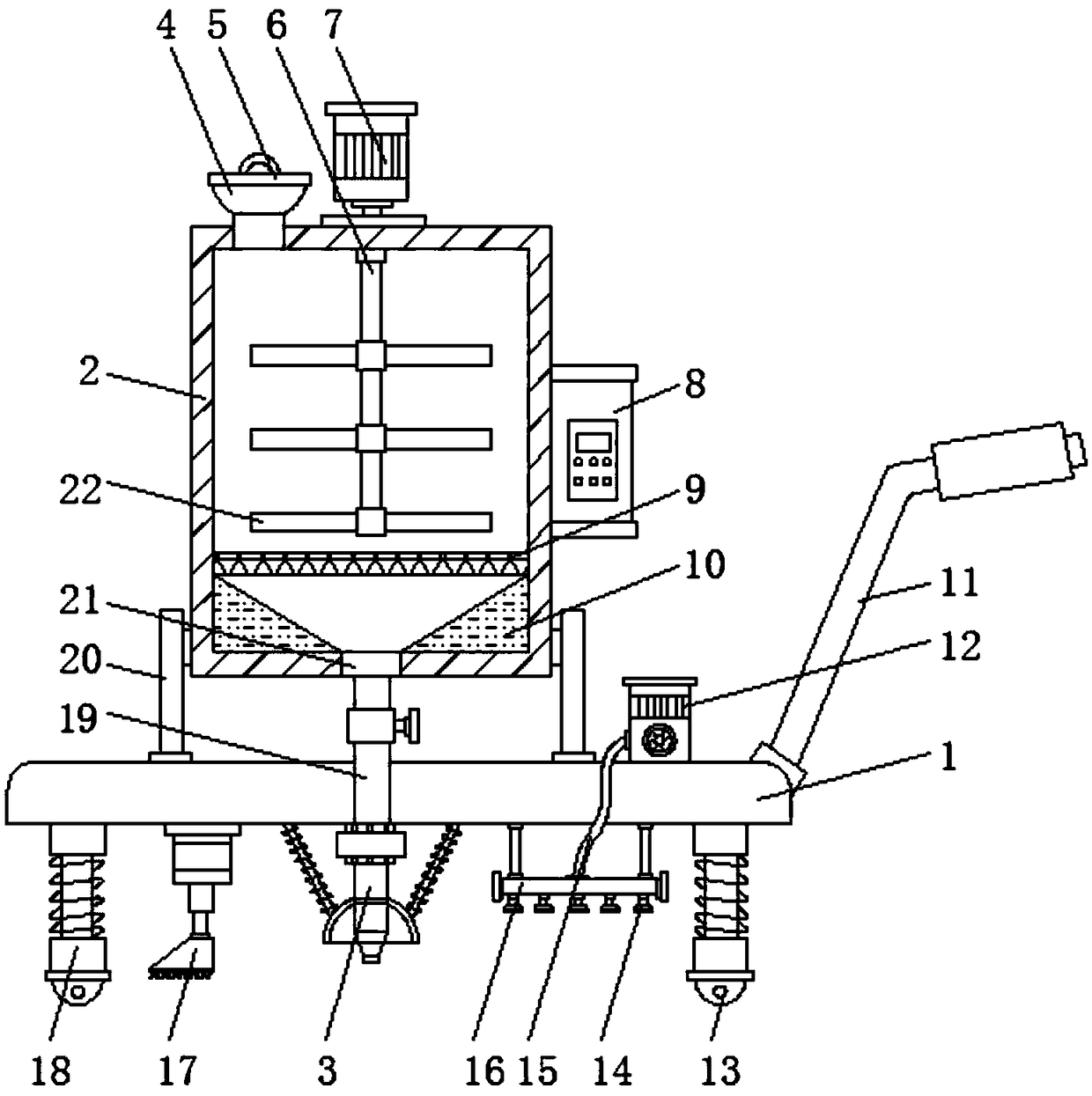

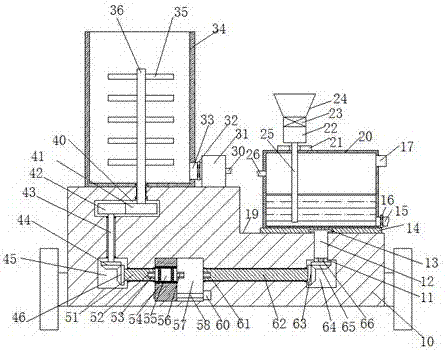

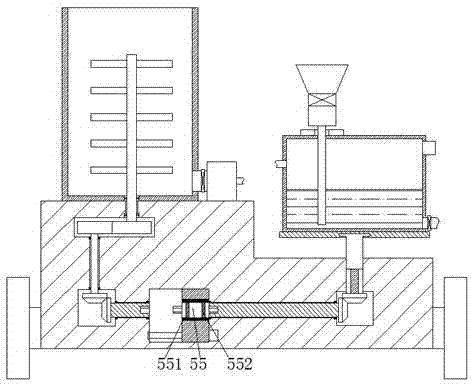

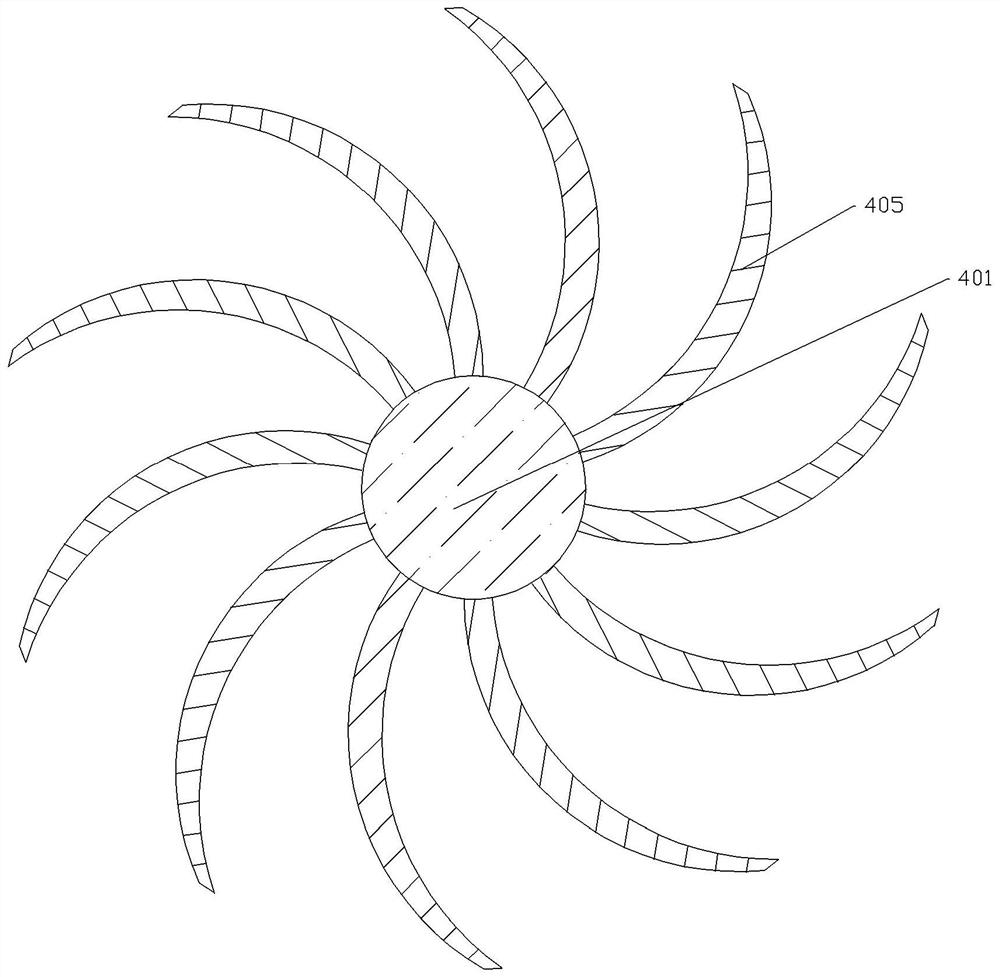

Burdening equipment

InactiveCN108097135AEasy to viewStir wellShaking/oscillating/vibrating mixersTransportation and packagingEngineeringElectromagnetic valve

The invention provides burdening equipment and aims at solving the technical problems that the existing burdening device is too simple in structure, needs to expend a great quantity of waiting time, is low in burdening speed and the like. The burdening equipment comprises a base; the base is provided with a moving seat; the moving seat is connected with a moving structure which can drive the moving seat to move back and forth and is fixed with a burdening tank through supporting legs; the upper part of the burdening tank is provided with a charging hole; the charging hole is provided with a first electromagnetic valve; the lower part of the burdening tank is provided with a discharge hole; the discharge hole is provided with a second electromagnetic valve; the lower part of the burdening tank is provided with a stirring shaft; the stirring shaft is vertically arranged; the lower end of the stirring shaft extends out of the burdening tank and is connected with a drive structure which can drive the stirring shaft to rotate; the upper end of the stirring shaft is connected with a stirring blade; the stirring blade is provided with a plurality of swinging components. The burdening equipment provided by the invention has the advantage of rapidness in burdening.

Owner:海宁迪万沃浦建材科技有限公司

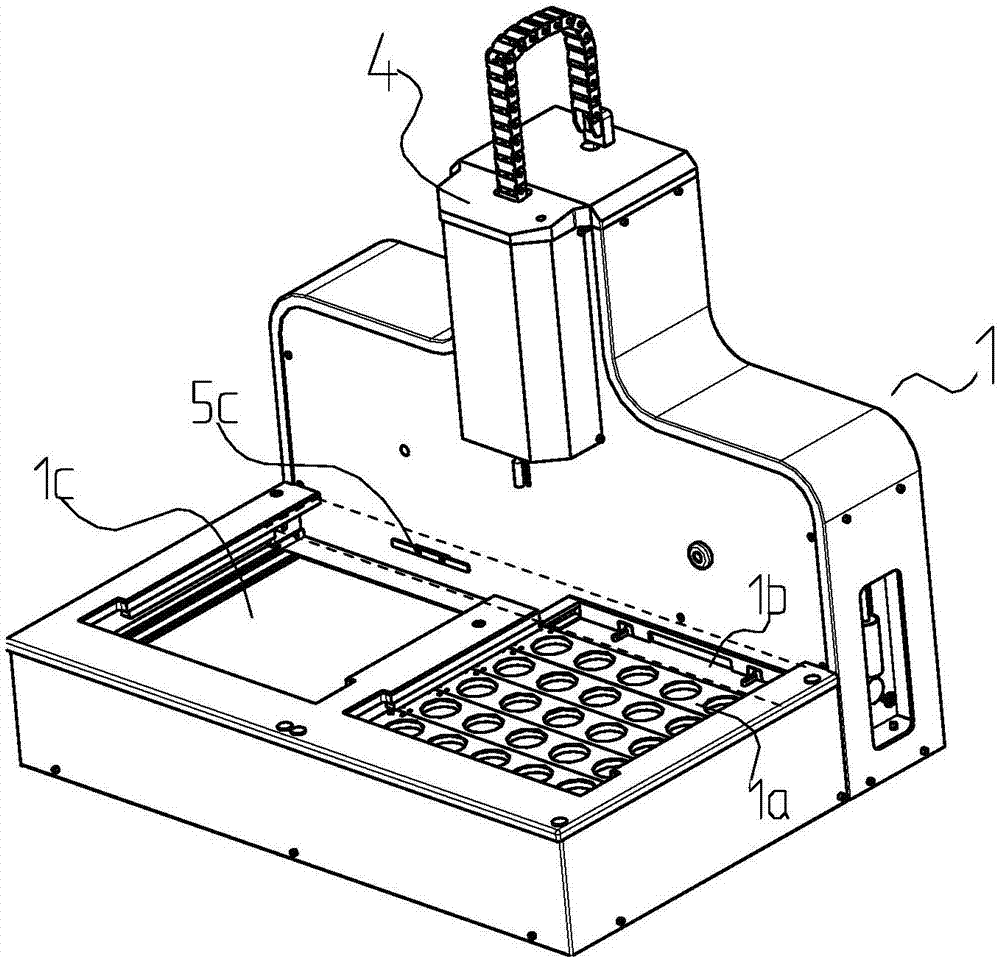

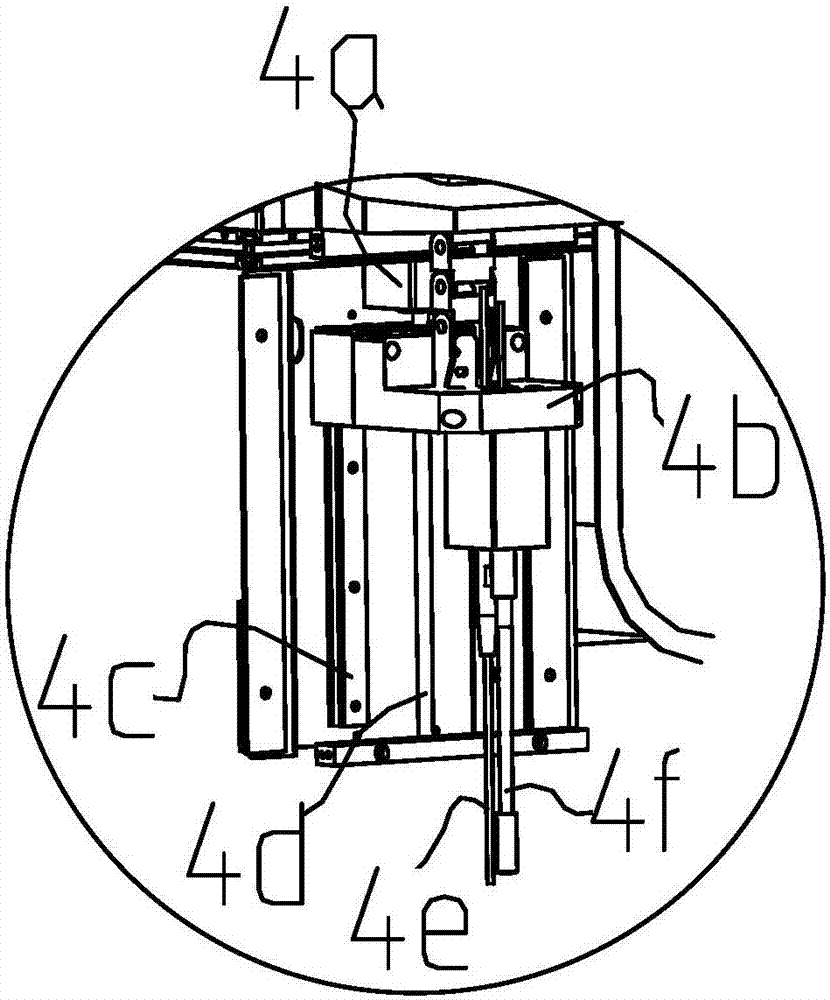

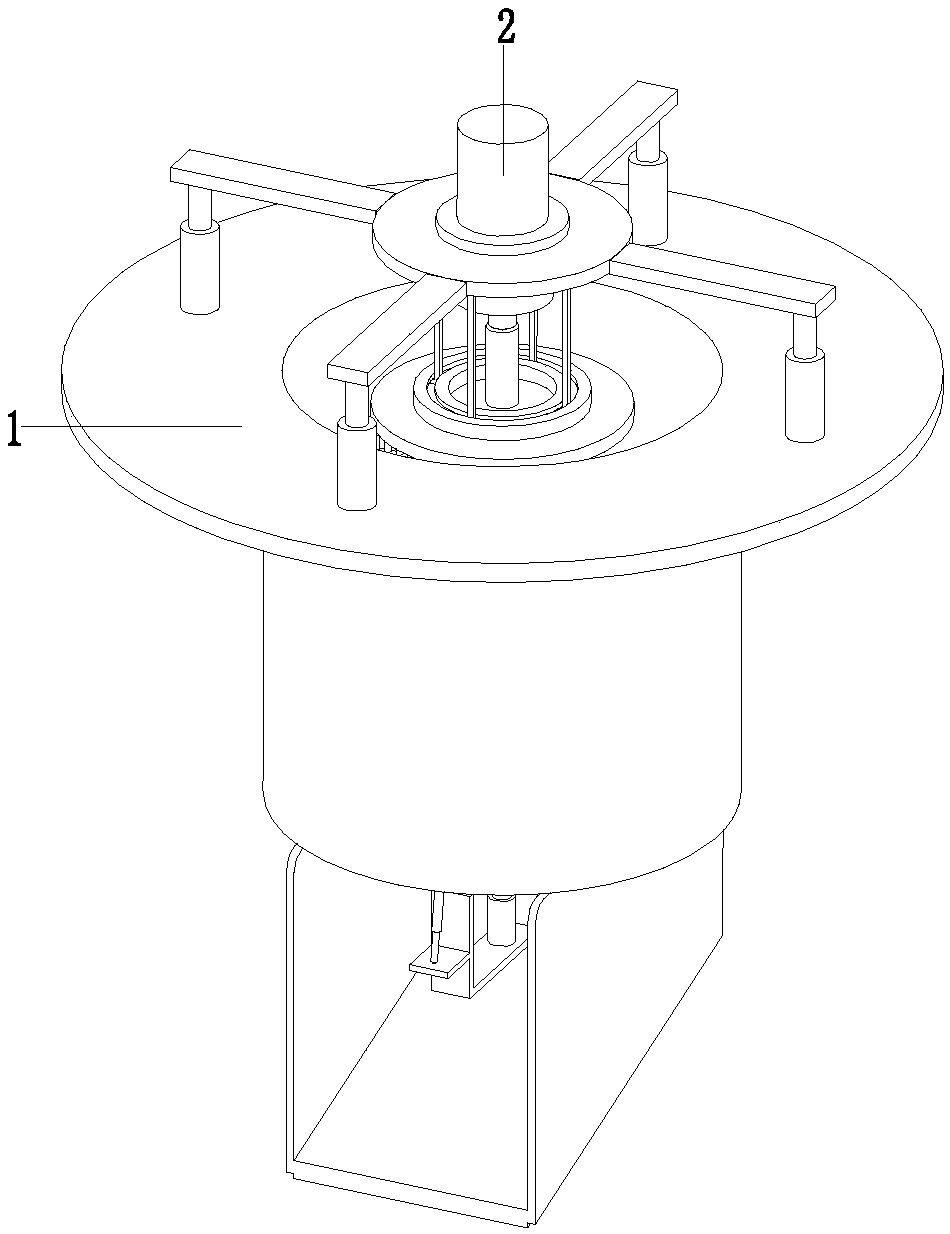

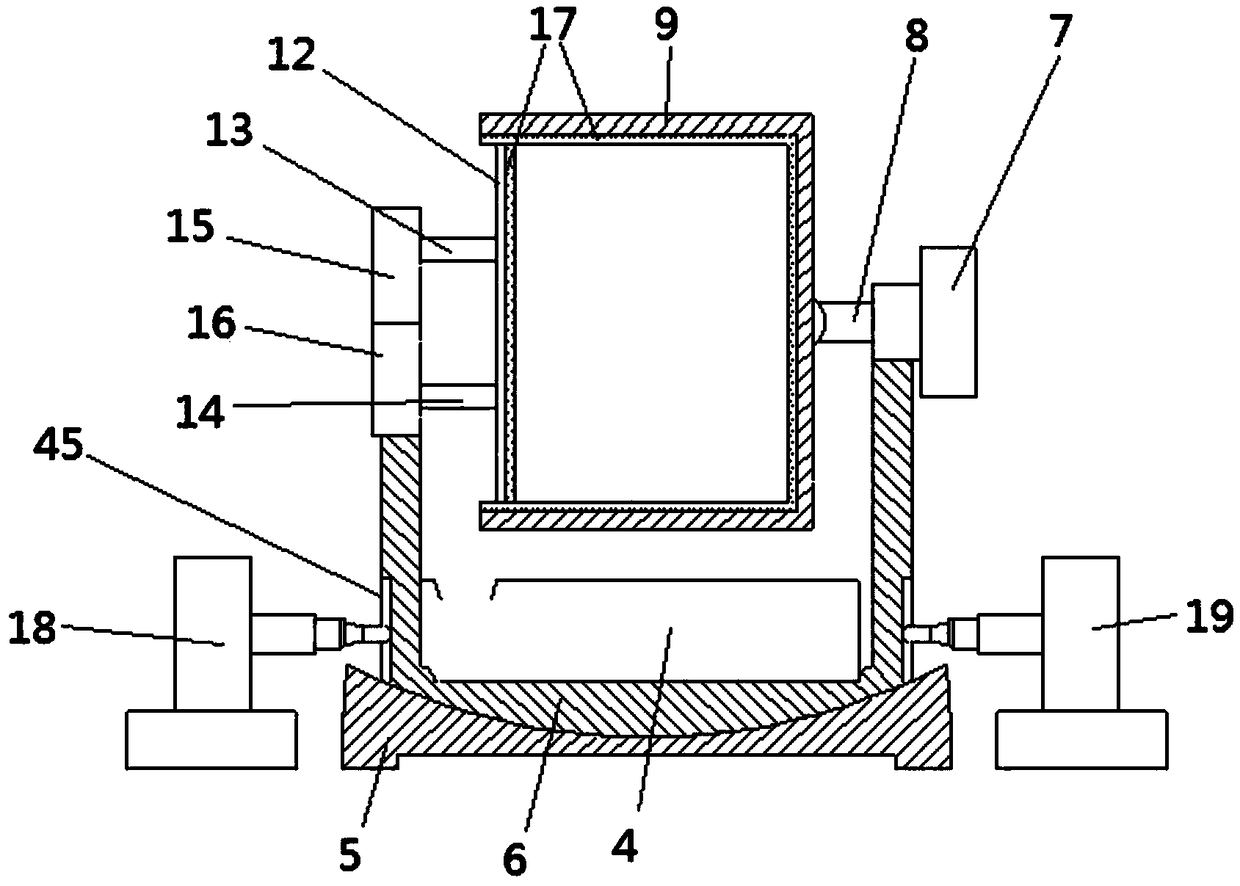

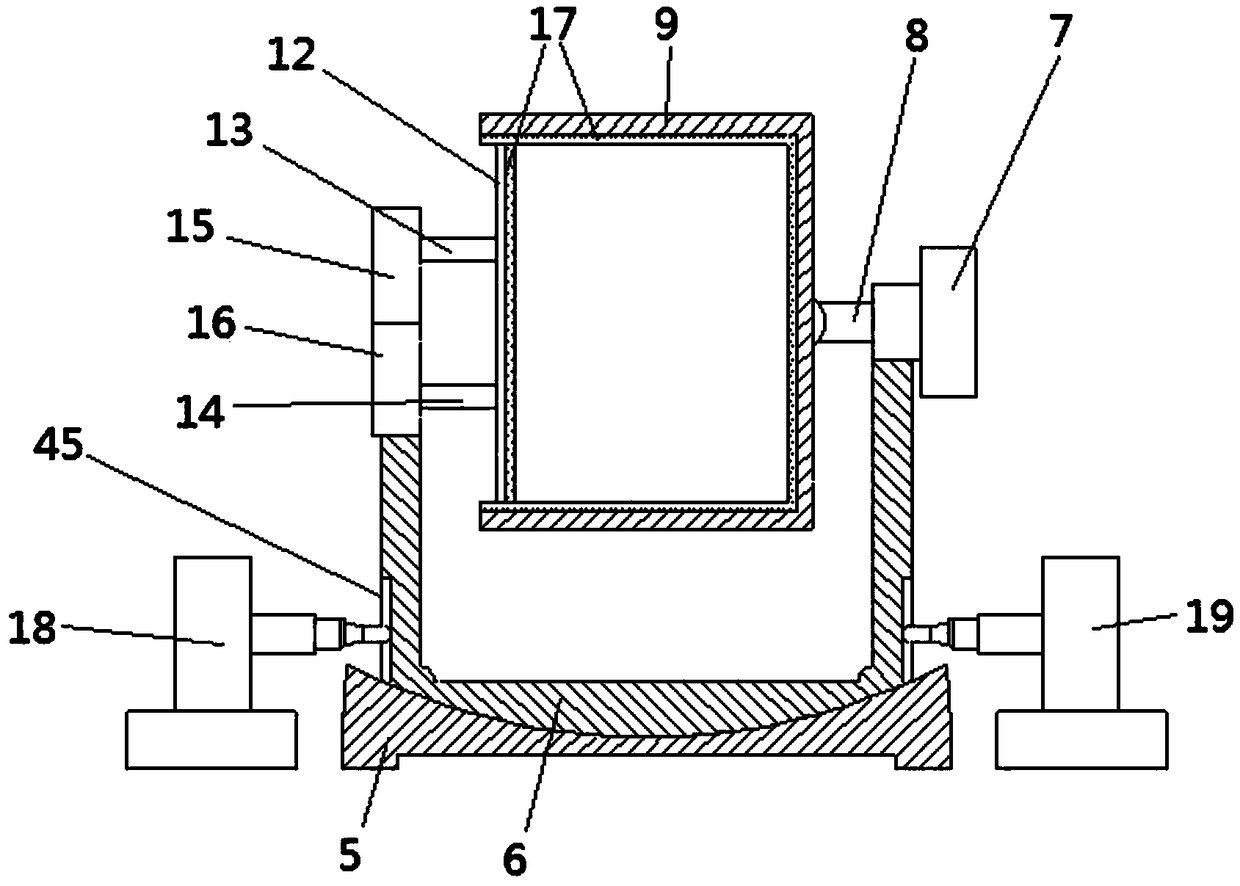

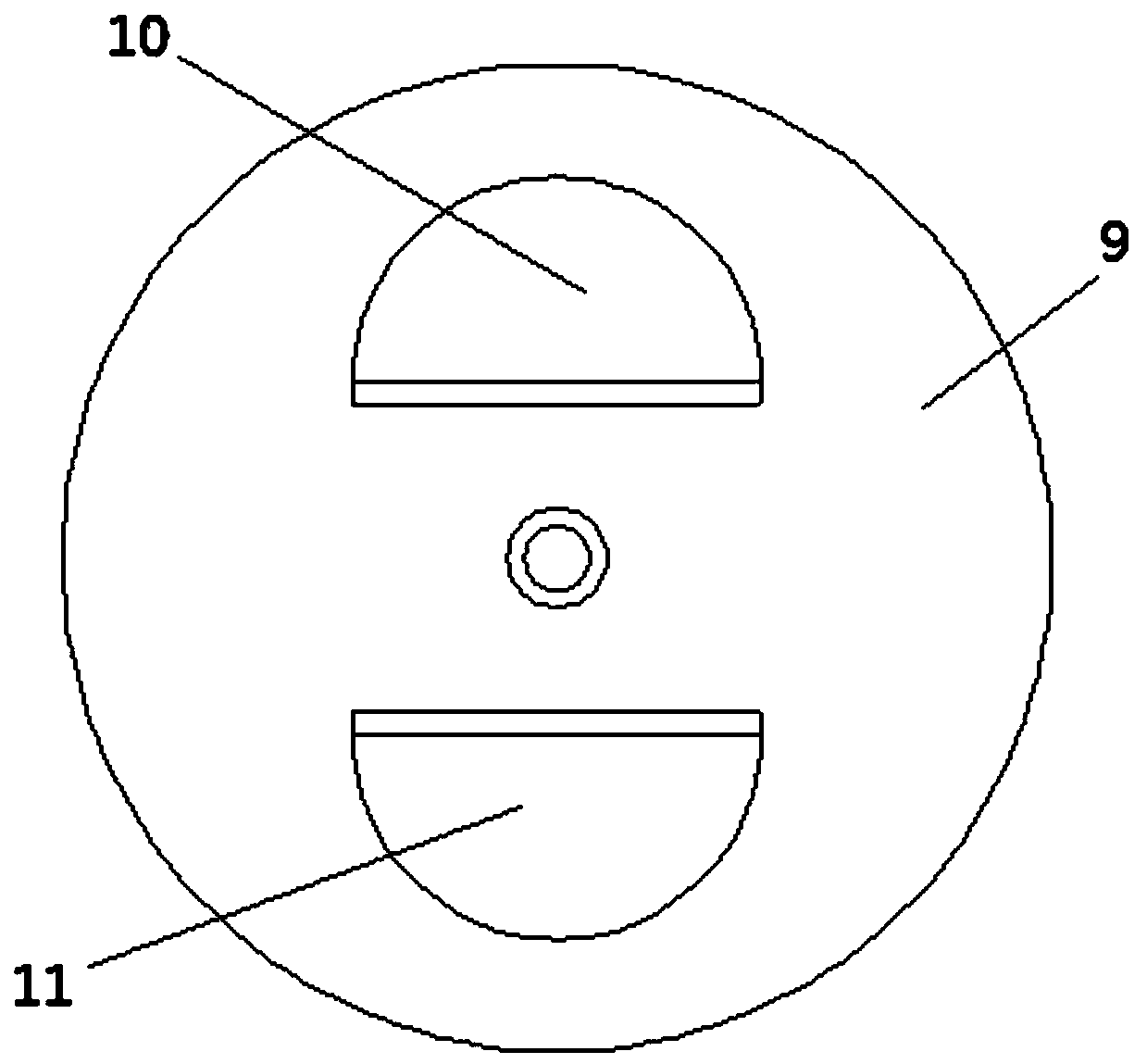

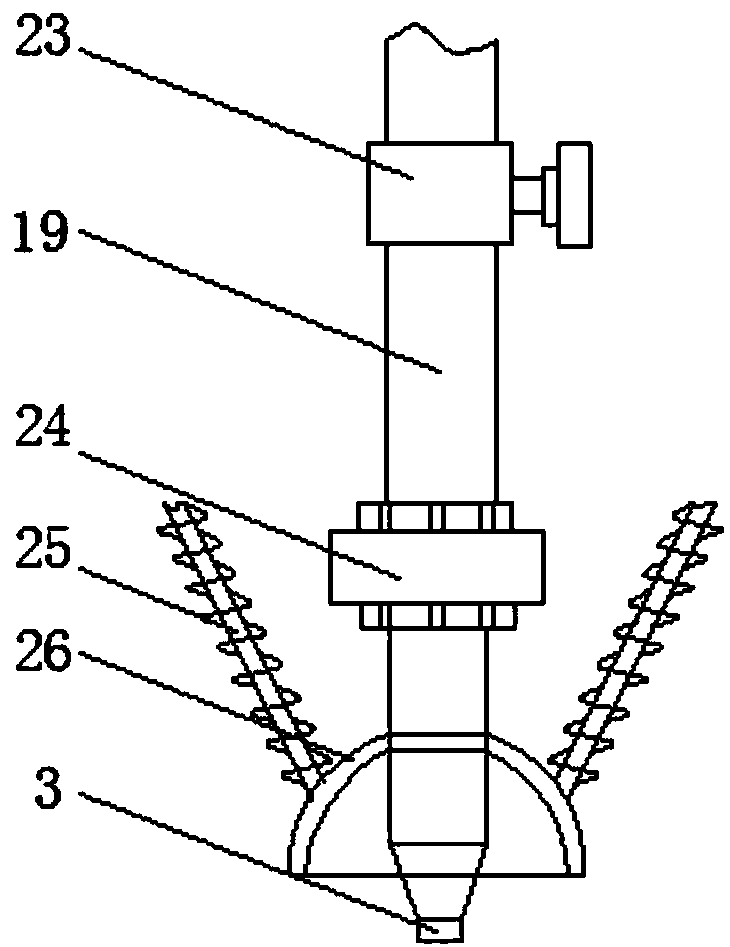

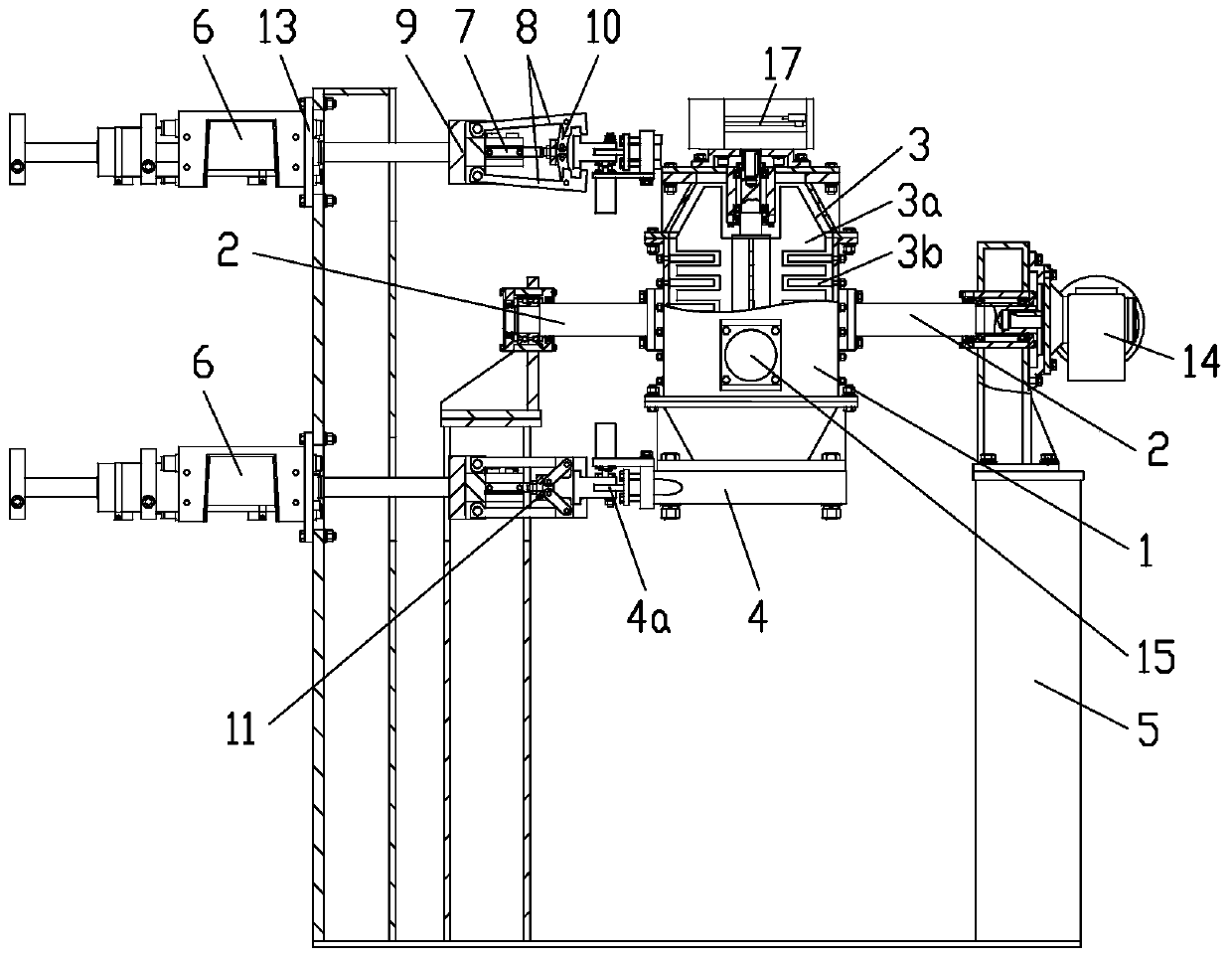

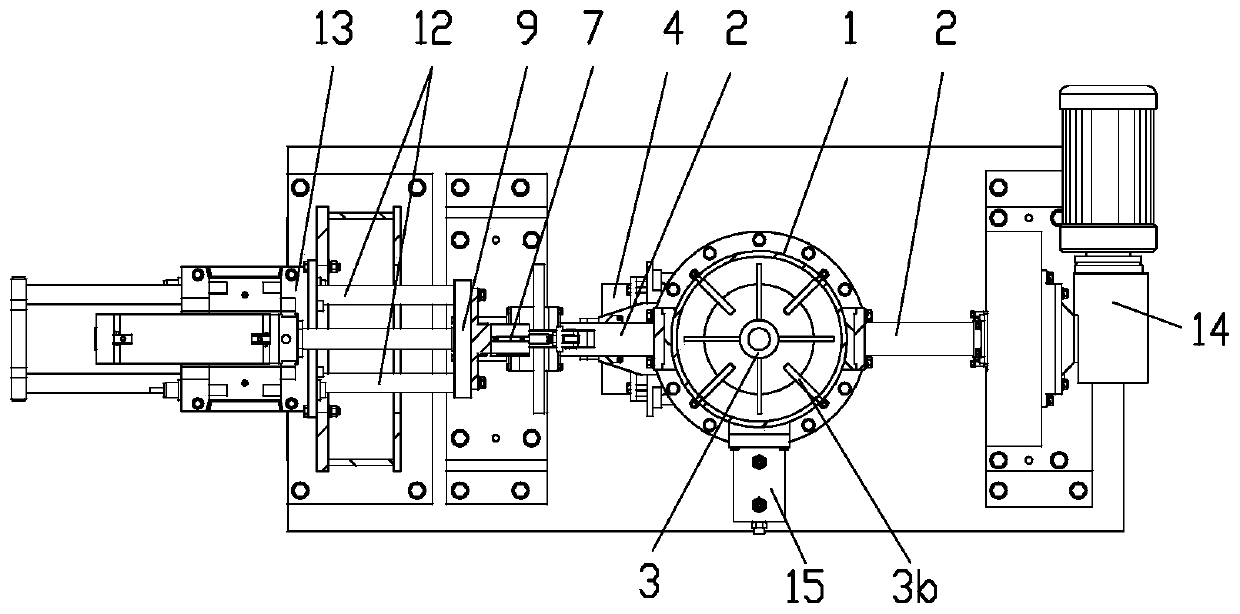

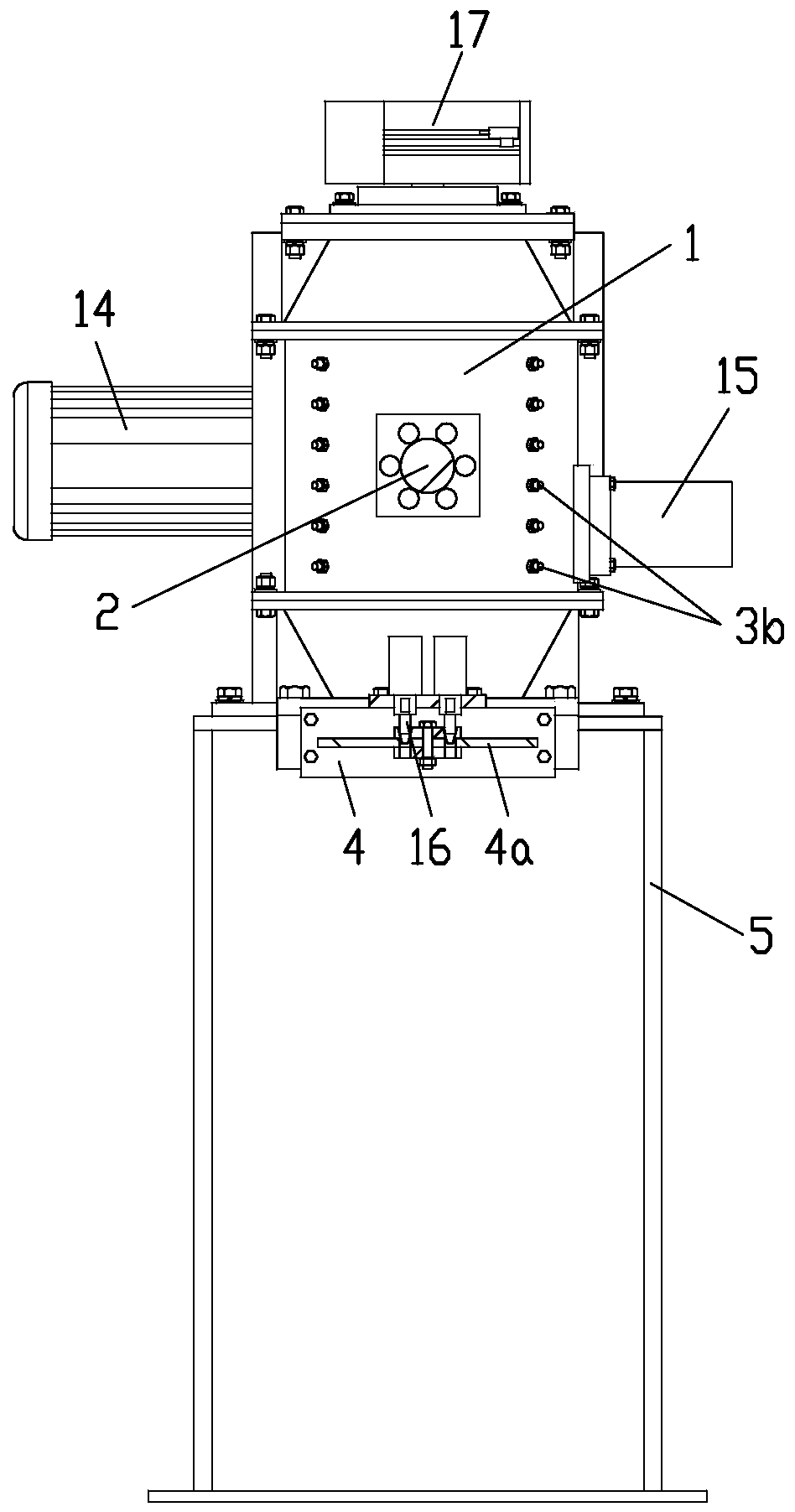

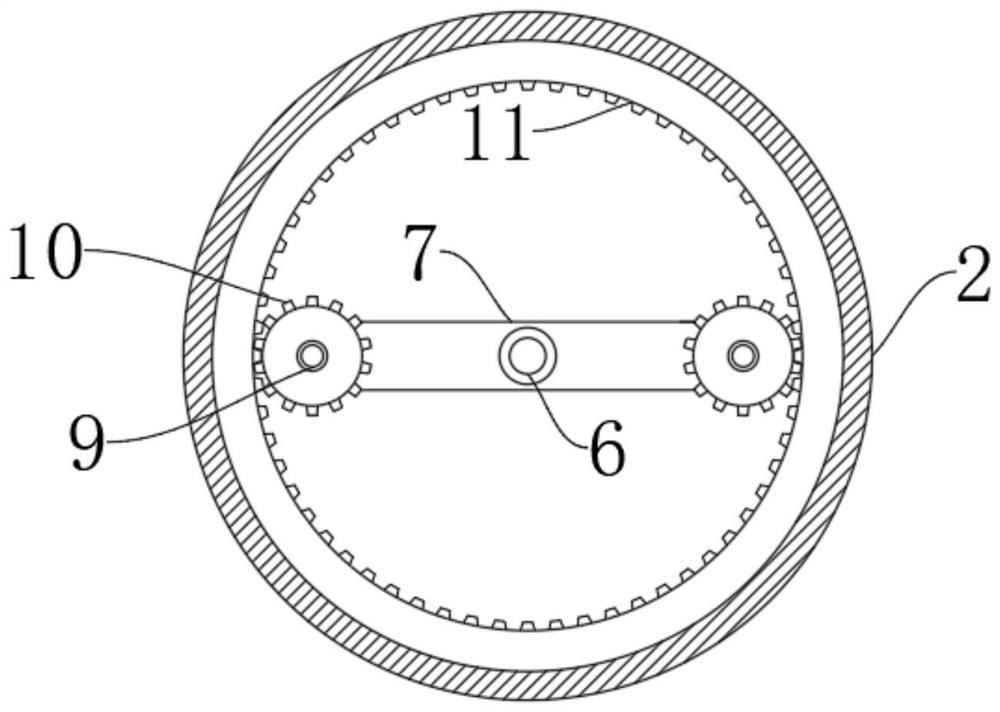

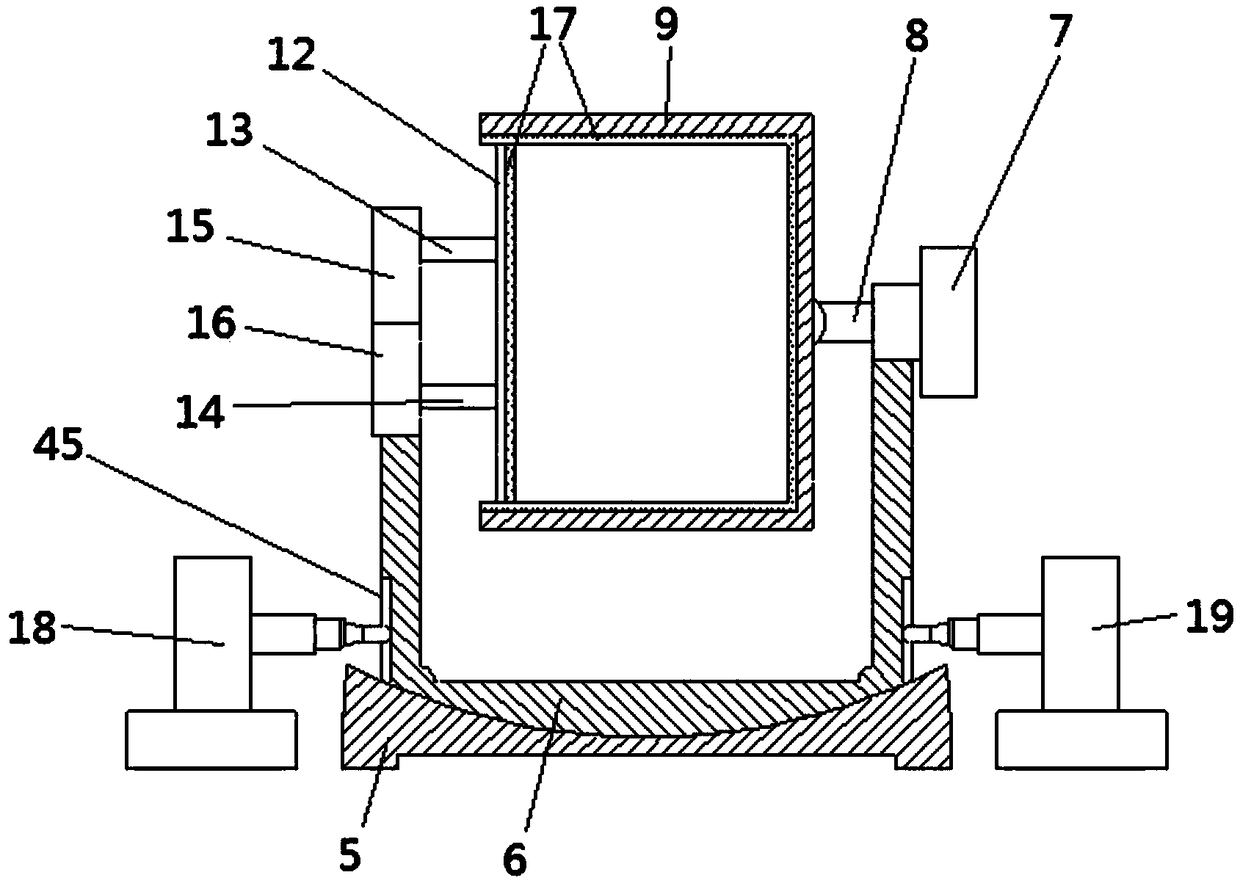

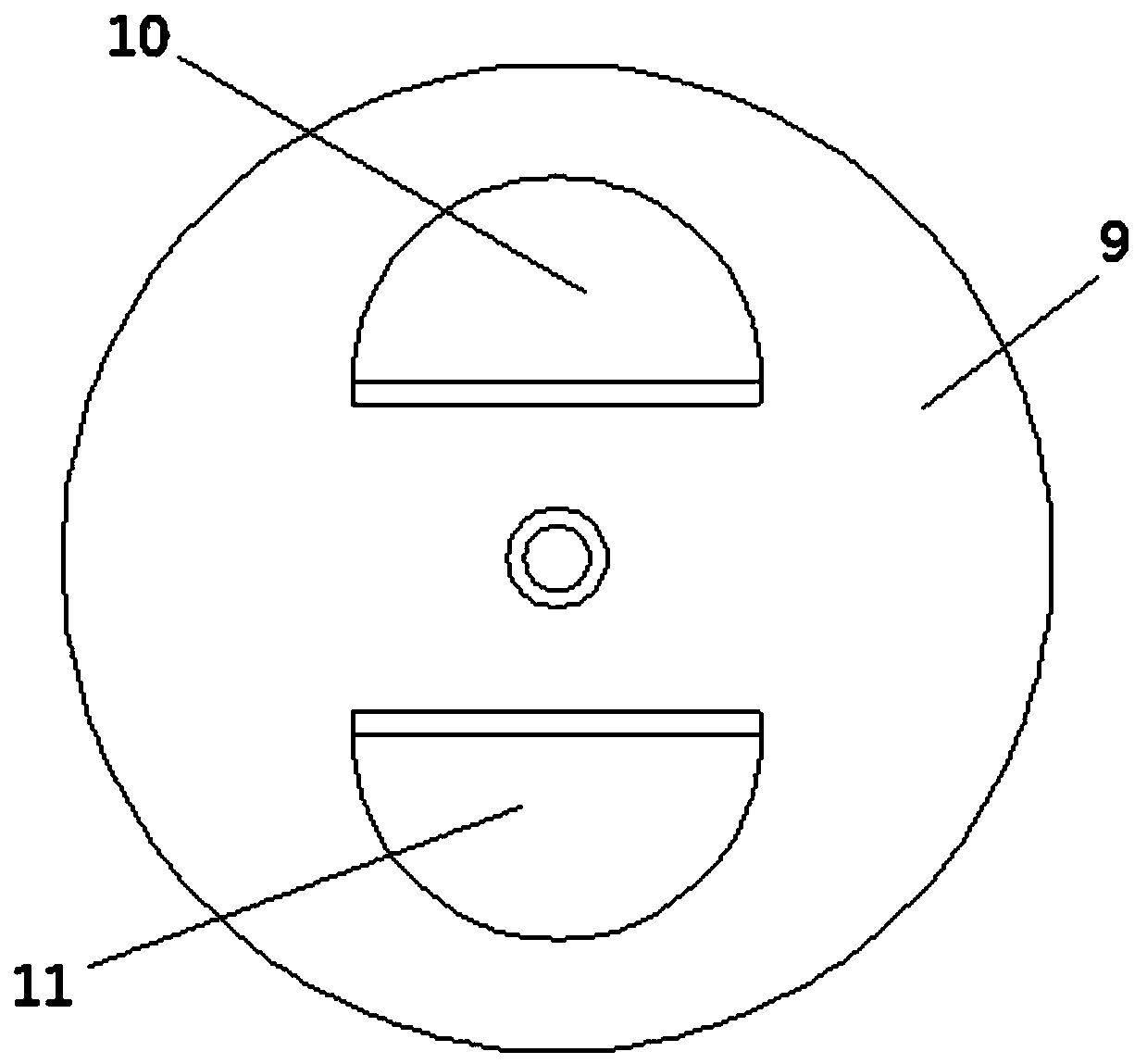

Solder paste stirring equipment for electronic product manufacturing

InactiveCN106881044AEasy to operateImprove stirring efficiencyRotating receptacle mixersTransportation and packagingSolder pasteArchitectural engineering

The invention relates to stirring equipment, in particular to solder paste stirring equipment for electronic product manufacturing. The invention solves the technical problems by providing the solder paste stirring equipment for electronic product manufacturing, which is simple in operation and high in stirring efficiency. In order to solve the technical problems, the invention provides such the solder paste stirring equipment for electronic product manufacturing. The solder paste stirring equipment for electronic product manufacturing comprises a bottom plate, a left frame, a top plate, a clamping mechanism, a lifting mechanism, a stirring mechanism and the like, wherein the clamping mechanism is mounted at the middle part of the top of the bottom plate; the left frame is mounted on the left side of the top of the bottom plate; the top plate is connected to the upper part of the right side of the left frame; the lifting mechanism is mounted on the right side of the bottom of the top plate; the stirring mechanism is connected to the left side of the lifting mechanism. Through synchronous rotation of the stirring mechanism and a solder paste barrel, the stirring efficiency is improved, manual stirring is not required, and the effects of simple operation and high stirring efficiency are achieved.

Owner:苍南博雅科技有限公司

Automatic titrator

ActiveCN107505430AGuaranteed uptimeGuaranteed stabilityChemical analysis using titrationPollutionTitration

The invention discloses an automatic titrator. The automatic titrator comprises a main body casing, wherein a pushing-in groove, a horizontal moving channel and a pushing-out groove are formed in the main body casing, and the pushing-in groove and the horizontal moving channel are sequentially connected to form a right-angle bent channel; a conveying part capable of sliding along a given straight line is arranged in each of the pushing-in groove and the horizontal moving channel, and each conveying part is connected with a corresponding linear driving device. By adopting four actions of entering, exiting, traversing and extending-in, namely, the setting of four displacement directions, the effects of mutual non-overlap between front and back reagent bottles as well as automatic stirring, detection and titration are realized, and no person participates in the whole process, so that the automation degree is high, and pollution is prevented. Step motors cooperate with null electrodes, and the null electrodes divide the whole platform into a pushing-in area, a pushing-out area, a horizontal sliding area and a titration range area corresponding to the pushing-in groove, the horizontal sliding groove and the pushing-out groove, and titration is performed at the mutual overlapped and staggered position of the four areas. Therefore, the error rate is low, and the efficiency is high.

Owner:河北德润厚天科技股份有限公司

Rice steamed sponge cake production process

The invention mainly relates to the technical field of rice steamed sponge cake production and discloses a rice steamed sponge cake production process. The process comprises the steps as follows: (1)material selection for primary fermentation; (2) powder mixing; (3) pulp mixing; (4) primary resting; (5) material selection for secondary fermentation; (6) secondary resting; and (7) steaming. The secondary resting process is adopted, through secondary resting of the primarily rested rice steamed sponge cake, the surface of the rice steamed sponge cake is flatter, the uniformity of pores in the rice steamed sponge cake is improved, starch is added during material selection for secondary fermentation, so that the elasticity of the rice steamed sponge cake can be guaranteed, the taste of the rice steamed sponge cake can be improved, besides, the rice steamed sponge cake pulp is more stable, has long fermentation time, cannot become thin easily and is not prone to aging cracking during storage, a mechanical mechanism is used for uniformly stirring raw materials of the rice steamed sponge cake, and the fermentation time of the raw materials of the rice steamed sponge cake can be saved.

Owner:杭州普罗星淀粉有限公司

Chinese herbal medicine decoction device

ActiveCN107088160AGood cooking effectAvoid mixingPharmaceutical product form changeMedicinal herbsImpurity

The invention discloses a Chinese herbal medicine decoction device. The device comprises a first motor, a casing, a filtering net, a foam fishing plate, a base and a blower, wherein the first motor rotates to drive stirring blades on a rotary stirring shaft to rotate, so that medicines in the casing can be stirred, manual stirring is not required, convenience and rapidness are realized, and the medicine decoction effect is improved; a medicine liquid is filtered through the filtering net, and the situation that medicine dregs and impurities are mixed in the medicine liquid and the quality of the medicine liquid is affected is avoided; the foam fishing plate is arranged to be used for fishing out foam produced when the medicines are decocted in the casing; the blower is used for blowing foam on the foam fishing plate out of the casing via a foam outlet, the medicine decoction effect is improved, and the equipment practicability is improved.

Owner:LUOYANG NINGZHU PHARMA

Grinding device with waste scrap recovery function

InactiveCN108274383AChange volumeGrind fullyEdge grinding machinesPolishing machinesDischarge efficiencyEngineering

The invention discloses a grinding device with a waste scrap recovery function. The grinding device comprises a grinding machine, and a discharging device is arranged in the grinding machine. The grinding machine comprises a lower base. An upper base is arranged above the lower base and is connected with a first rotary motor. The first rotary motor is connected with a cover-free grinding cavity through a rotary shaft. The grinding cavity is provided with a workpiece inlet and a flowing grinding material inlet. A grinding cover is arranged on one side of the grinding cavity and is symmetricallyprovided with a first telescopic rod and a second telescopic rod. The first telescopic rod is connected with a first push rod motor, and the second telescopic rod is connected with a second push rodmotor. Fixed grinding materials are embedded on the inner surface of the grinding cavity and the grinding cover. A first electric-hydraulic push rod and a second electric-hydraulic push rod are arranged on the two sides of the upper base correspondingly. The grinding device has the advantages that the size of the grinding cavity can be adjusted according to the machined workpiece quantity, the workpiece grinding effect is good, the discharging efficiency is high, and waste scraps generated by grinding can be recycled.

Owner:湖州铭之远研磨科技有限公司

Line drawing device for building construction

InactiveCN108952189AWell mixedProcess stabilityBuilding material handlingCause blockageArchitectural engineering

The invention discloses a line drawing device for building construction. The device comprises a base and a paint box, universal wheels are connected with the four corners of the bottom of the base through shock absorbing supporting legs, the paint box is fixed to the base through the supporting frame, the top of the paint box is provided with an feeding hopper and a stirring motor, an impurity removing net is horizontally arranged in the paint box, a discharging port is formed in the bottom of the paint box, the bottom of the discharging port is communicated with a line drawing pipe through adischarging pipe, the line drawing pipe is vertically arranged below the base, and the two sides of the line drawing pipe are provided with a cleaning push plate and a hot wind spraying pipe respectively. By means of the device, the structure is simple, the use is convenient, paint in the paint box can be fully and uniformly stirred and mixed, manual stirring is not needed, the labor intensity ofworkers is reduced, an impurity removing net is arranged in the paint box, and large particle impurities in the paint can be effectively filtered to prevent the impurities from entering the line drawing pipe to cause blockage.

Owner:德清县三中交通工程有限公司

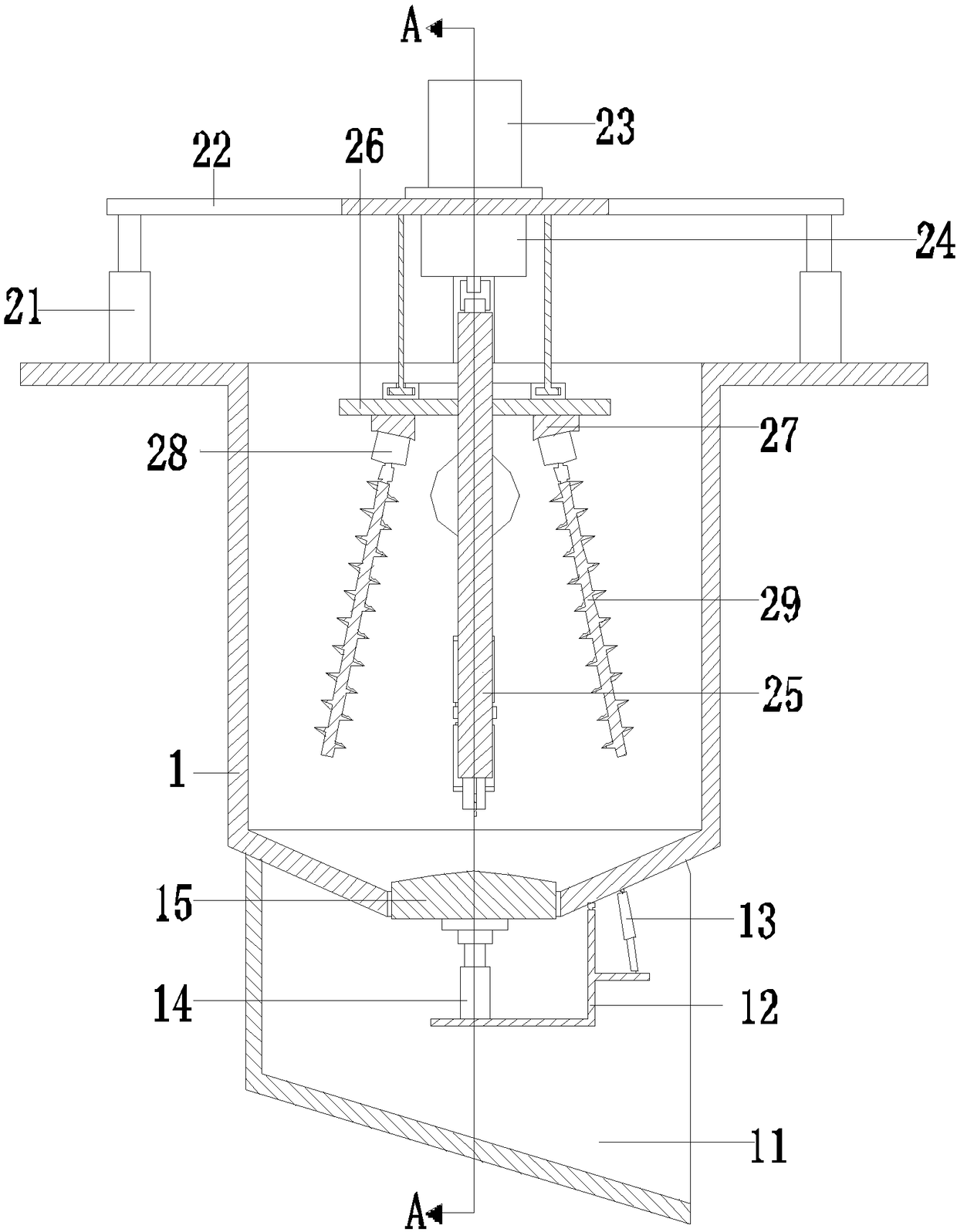

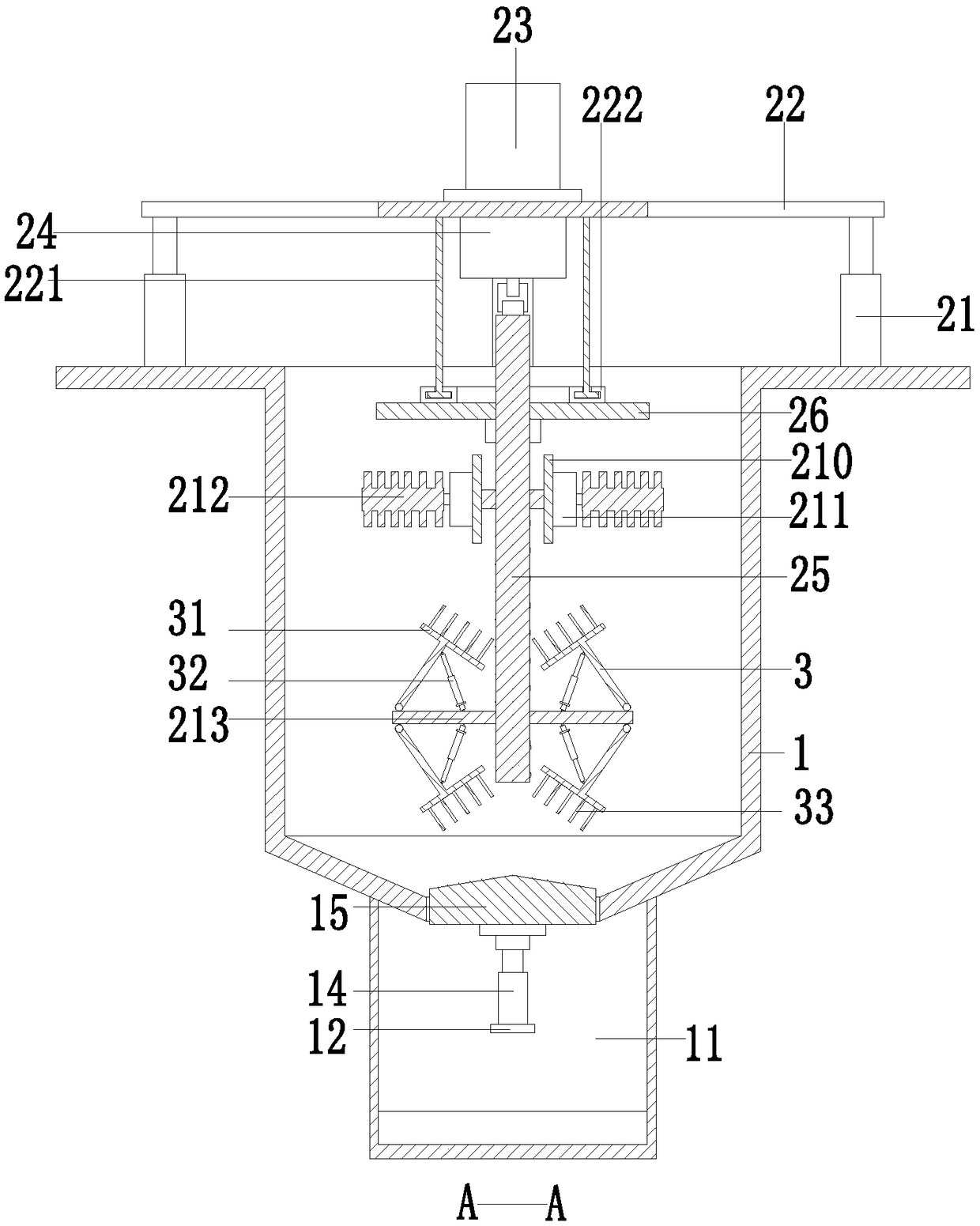

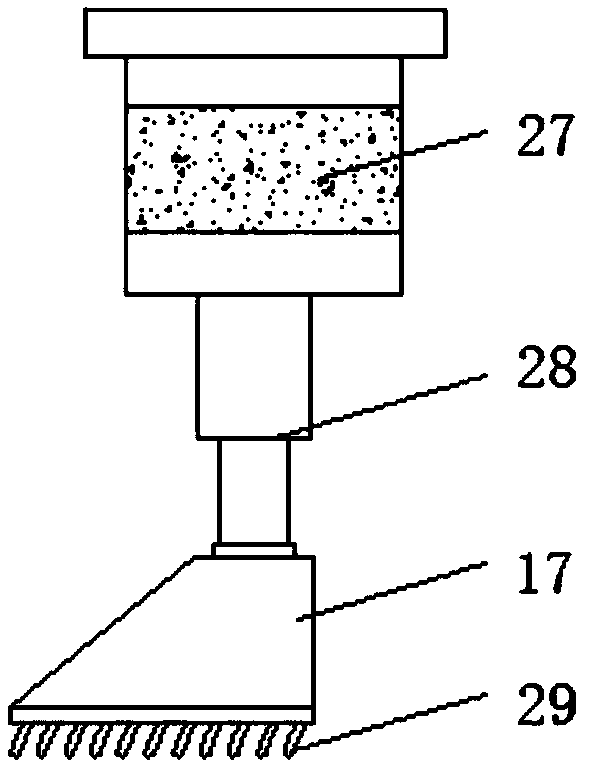

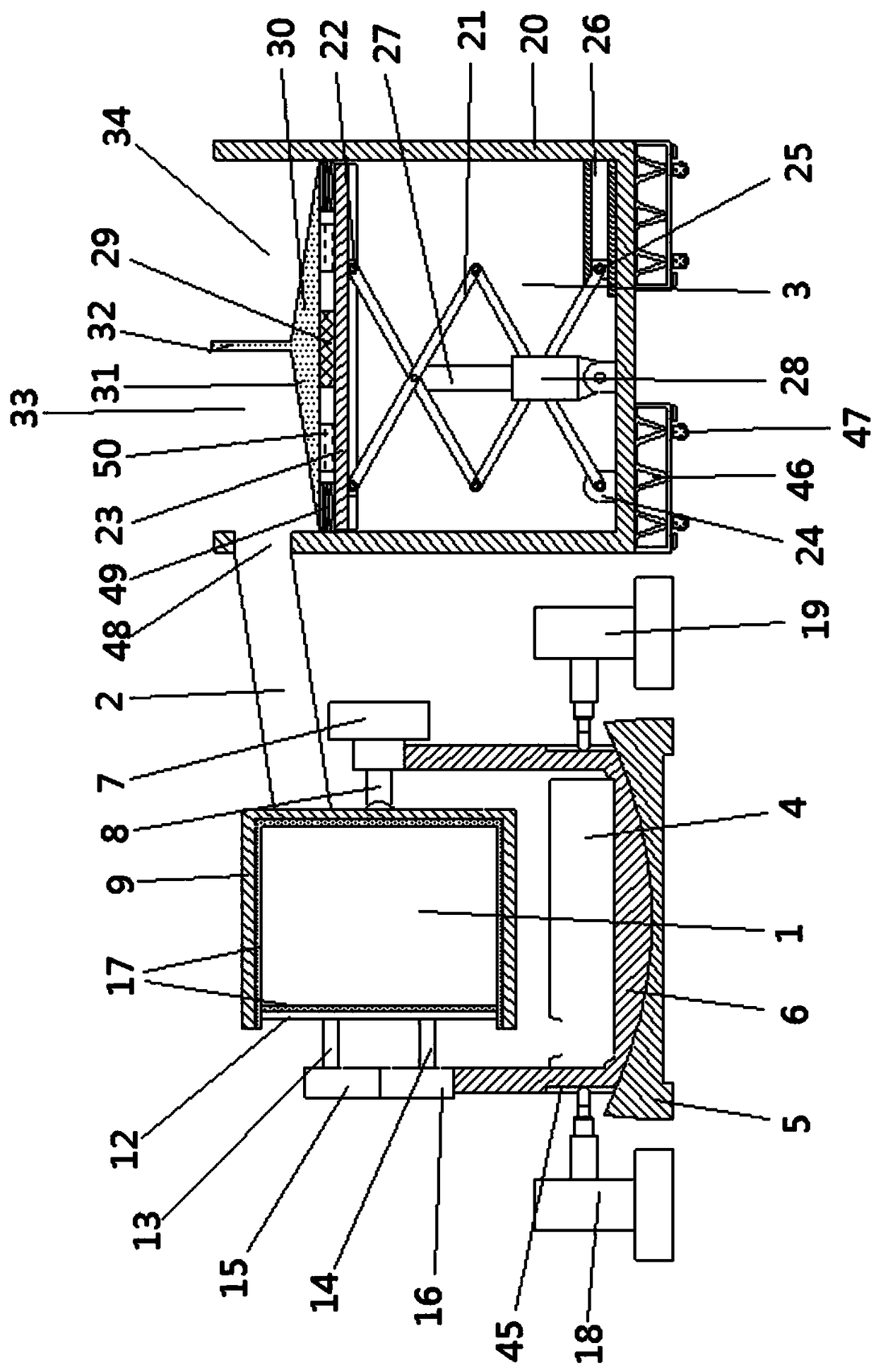

Intelligent cement stirring treatment equipment

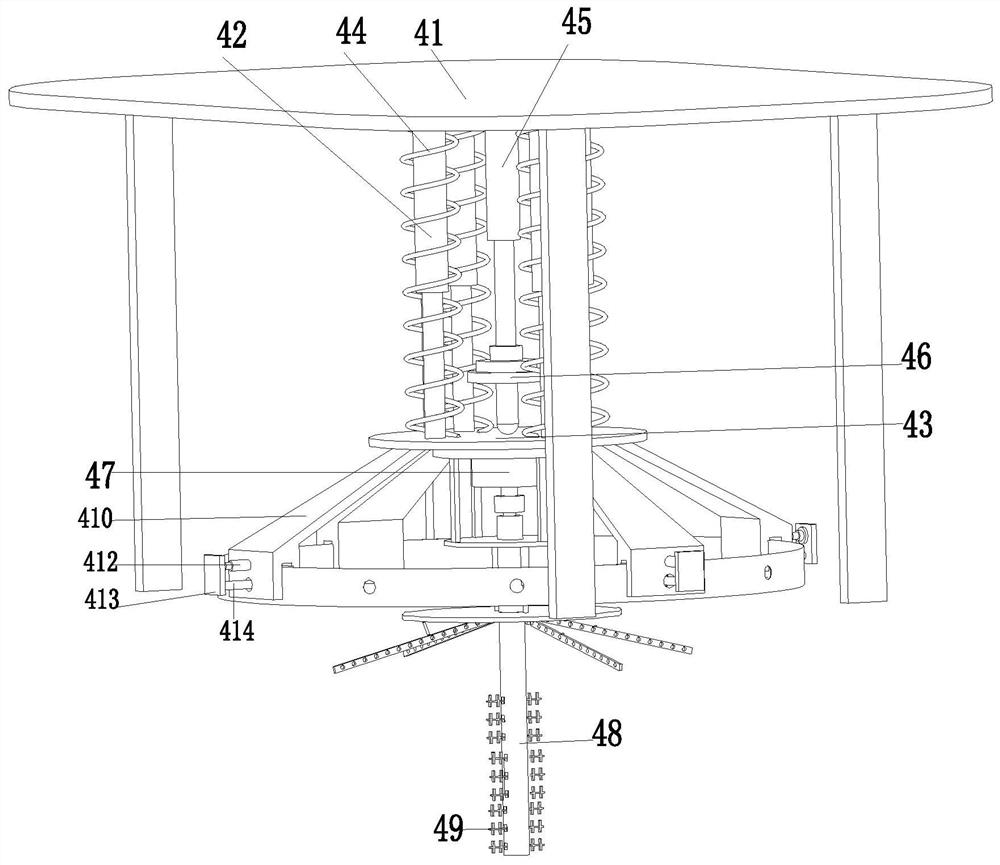

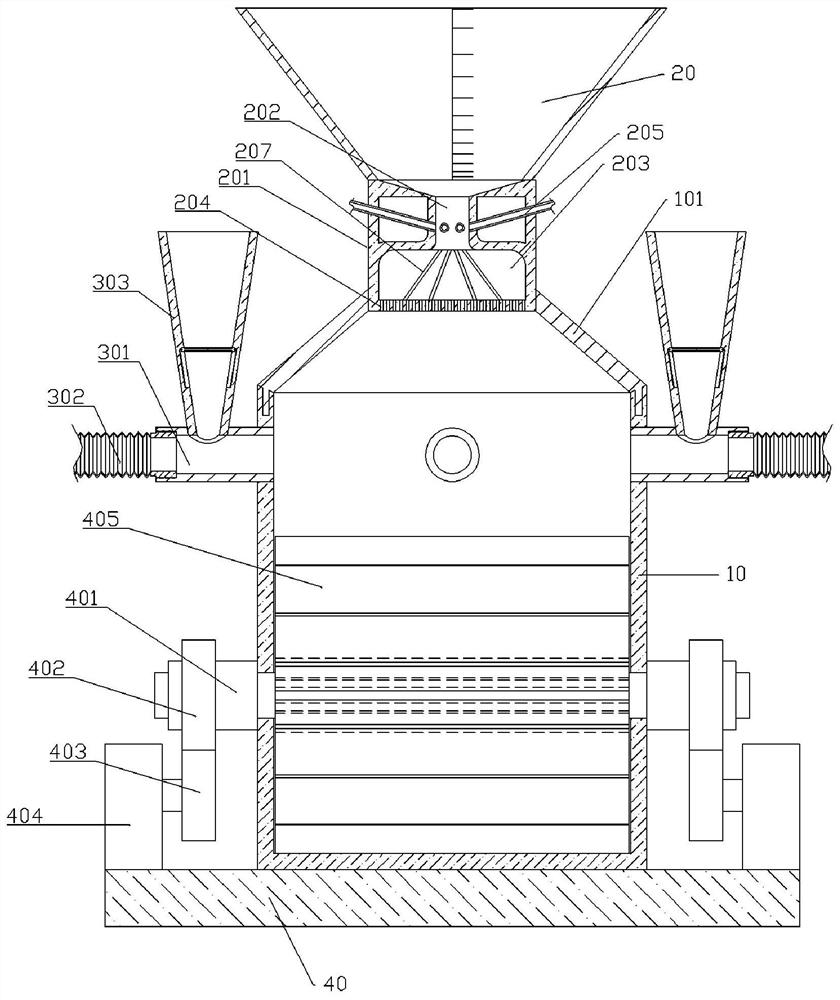

InactiveCN108501204APrevent many disadvantages such as uneven fillingReduce stirring speedDischarging apparatusMixing operation control apparatusDrive shaftEngineering

The invention aims at providing intelligent cement stirring treatment equipment. According to the technical scheme provided by the invention, the intelligent cement stirring treatment equipment is composed of an operation platform, a first bearing seat, a first driving supporting platform, a first driving auxiliary bracket, a first driving transmission shaft, a first driving motor bracket, a firstdriving motor, a feeding buffering cabin, a feeding opening, an induction triggering device, a stirring tank, a stirring rotary shaft, a second bearing seat, a second driving supporting platform, a second driving auxiliary bracket, a rotary speed regulation motor, a second driving motor bracket, a second driving motor and a master control cabinet. The equipment has better sealing performance andis more environmentally friendly and more reliable; automatic monitoring is realized; the intelligent cement treatment equipment is used for stirring a series of building solvent solid materials including cement, concrete and the like and can realize gradual condensation of the materials when the materials are not stirred for a long time, so that the stirring speed is reduced to carry out data analysis and the rotary speed power is improved; a stirring rotary speed also can be controlled so that output cement materials can be directly ensured.

Owner:杨金梅 +4

Concrete mixing equipment for maintaining municipal road surfaces and roadbeds

InactiveCN107794825ARealize the function of automatic stirringStir wellRoads maintainenceScreedEngineering

The invention relates to a concrete mixing equipment for roadbed maintenance of municipal roads. The mixing device includes a leveling plate, a traction cylinder, a traction telescopic rod, a stirring mechanism, a connecting rod, and a lifting electric push rod auxiliary device. A base plate is installed, and a traveling wheel is installed at the lower end of the base plate. The invention can solve the problems of high labor intensity, high labor cost, low work efficiency, potential safety hazards, unsatisfactory repair effect and waste of raw materials in the process of repairing the cement concrete pavement just poured after the rain, and can realize the automation of the cement concrete pavement Patched functionality.

Owner:储田生

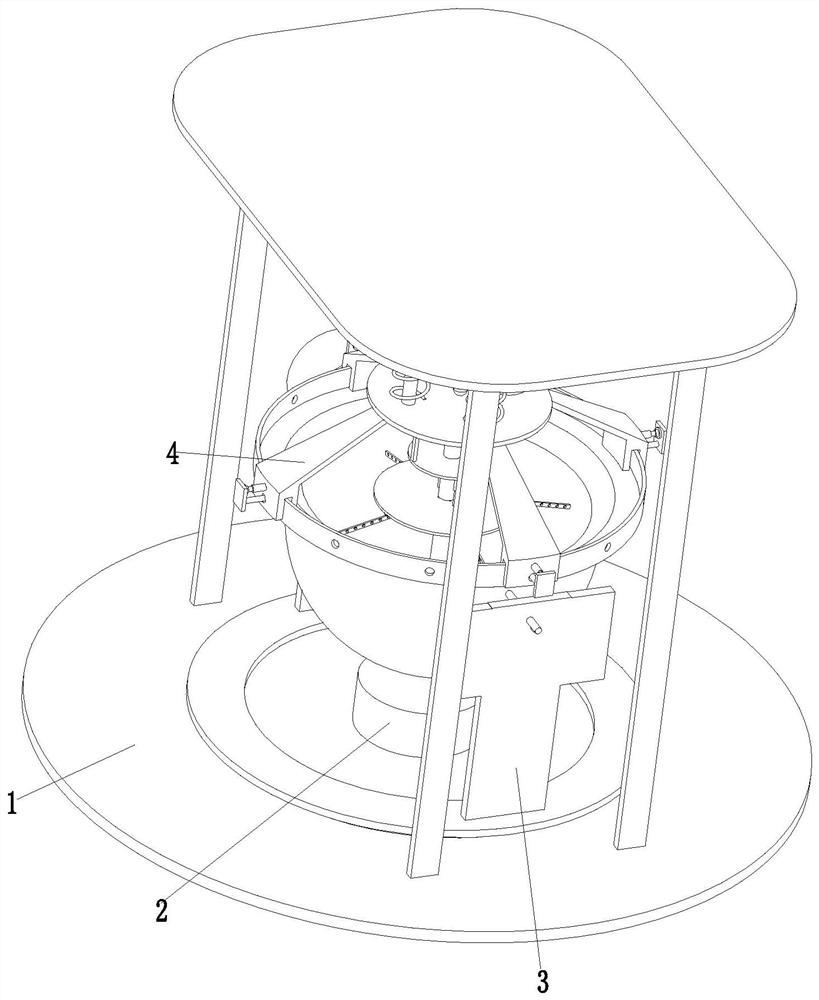

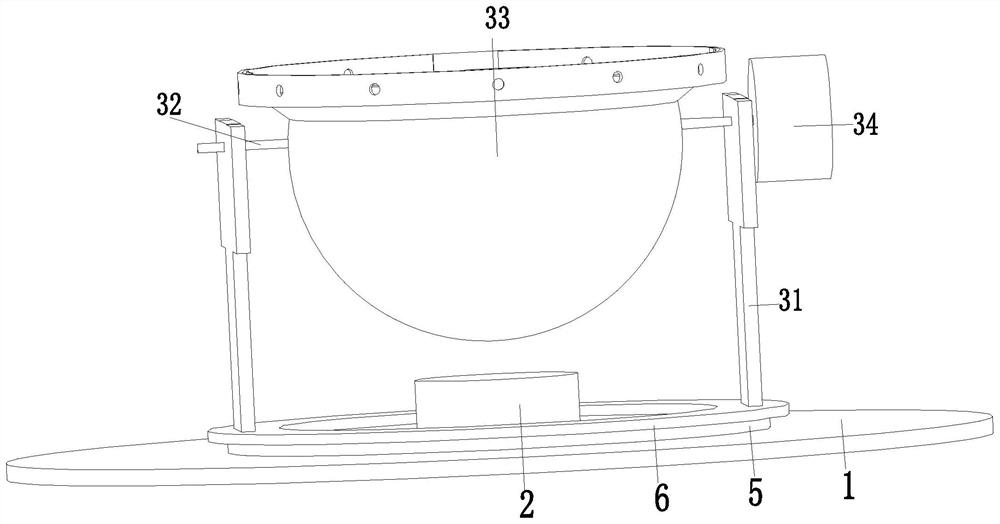

Automatic blender mixer

InactiveCN109806799AStirring intensity is moderateEnsure safetyShaking/oscillating/vibrating mixersBLENDER/MIXERValve opening

The invention discloses an automatic blender mixer, which includes a mixing pot with a sealable pot mouth. The mixing pot is supported by two half shafts arranged on the side wall of a pot body and driven by a gear motor to rotate, the mixing pot is provided with a stirring paddle, and the stirring paddle is driven by a rotating air cylinder arranged at the pot bottom of the mixing pot to swing atthe amplitude of 180 degrees; and preferably, a stirring blade is arranged on the stirring paddle, a fixed blade is arranged on the inner wall of the pot body of the mixing pot, the stirring blade isprovided with a gap for avoiding the fixed blade, a vibrator is arranged on the pot body of the mixing pot, the pot mouth of the mixing pot is provided with a gate valve, and a rack is provided withtwo valve opening and closing devices for corresponding to the pot mouth in upward and downward states correspondingly. The automatic blender mixer has the beneficial effects that automatic mixing andstirring of inflammable and explosive materials are realized through a way of combination of shaking and stirring, the mixing effect is good, the efficiency is high, manual stirring is not required,and the physical and mental health of operators can be effectively guaranteed.

Owner:重庆航天工业有限公司

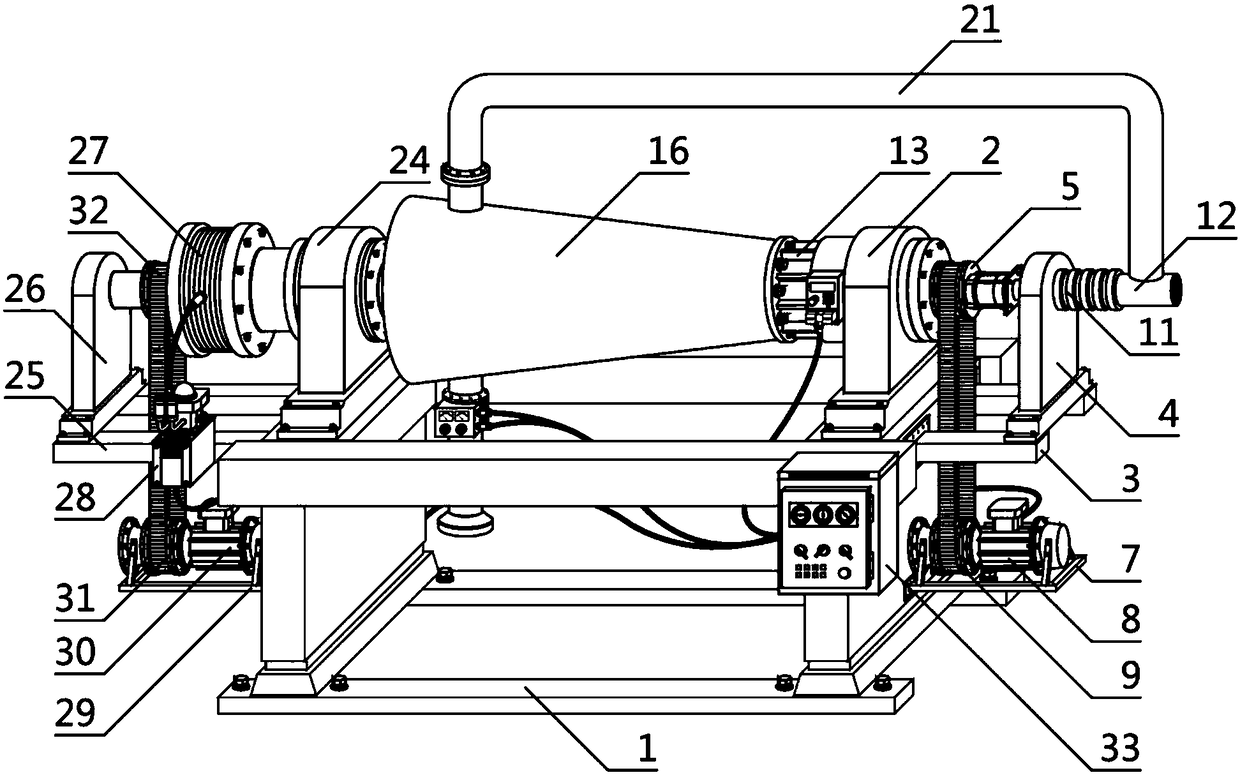

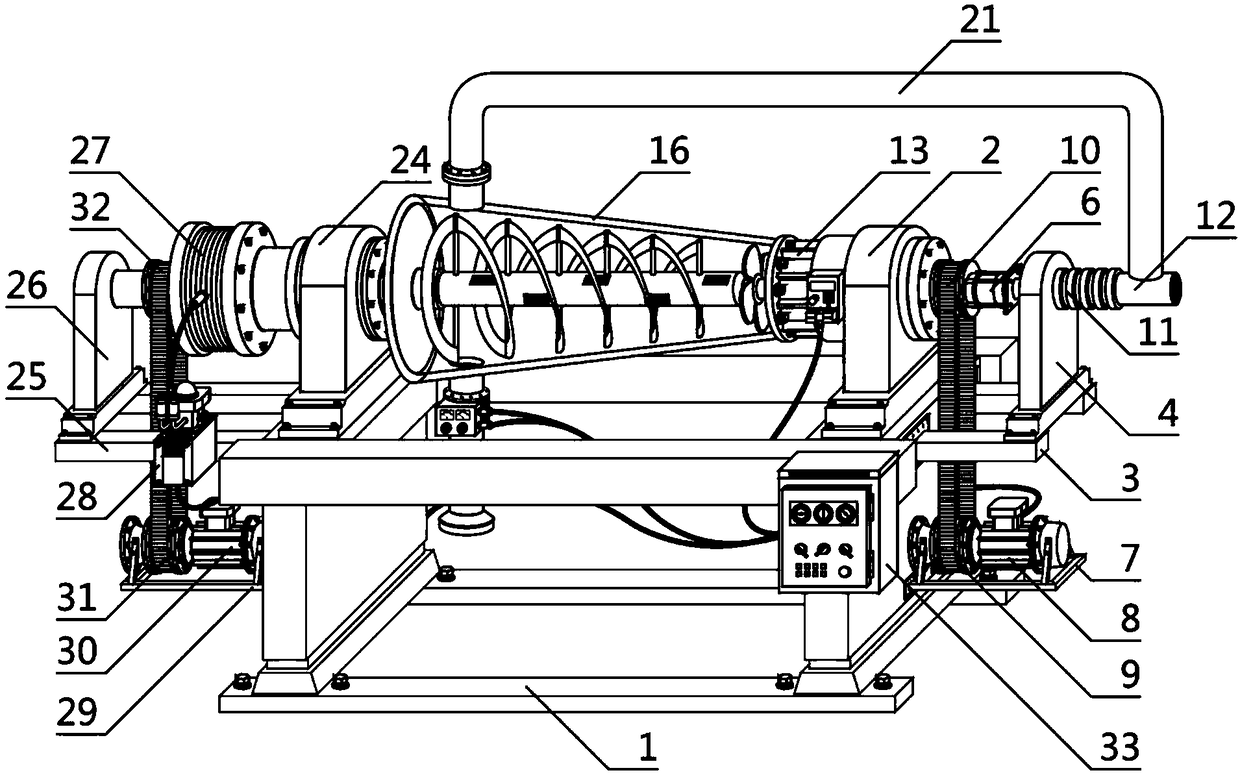

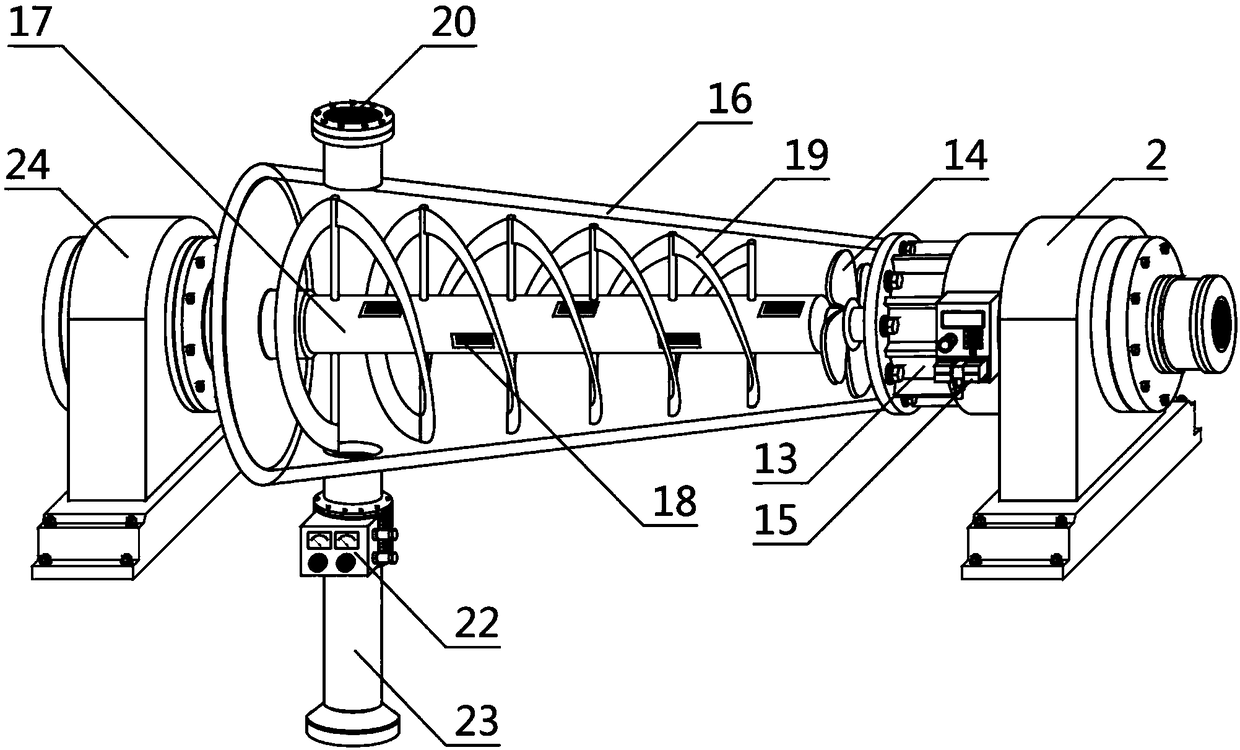

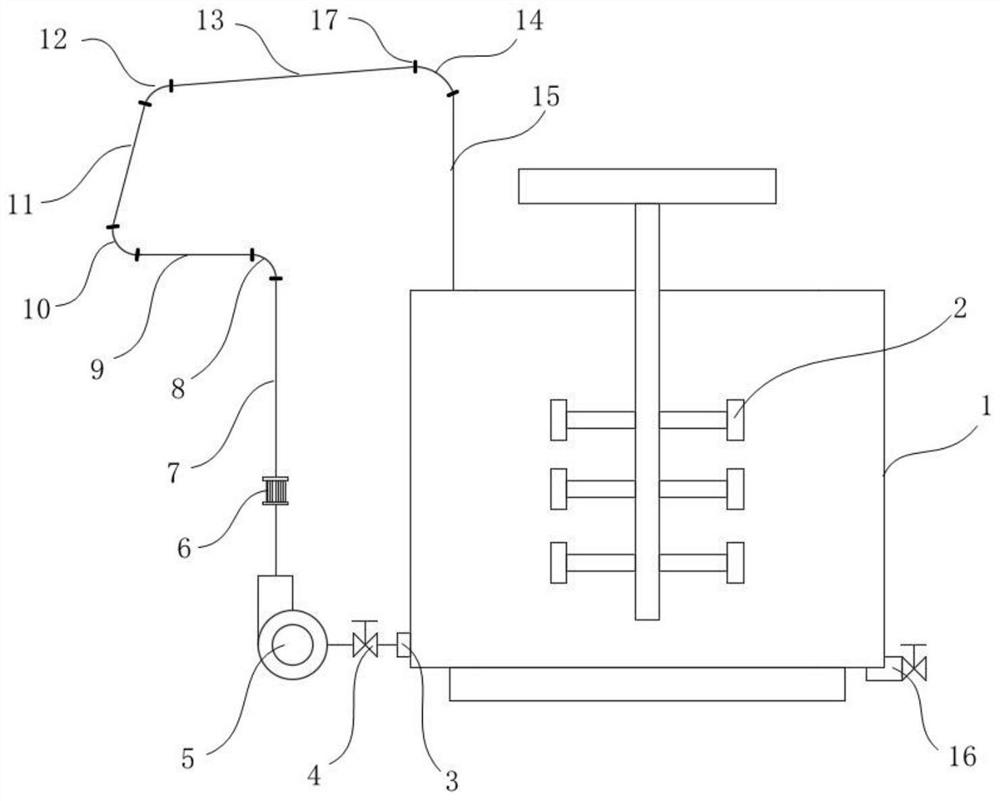

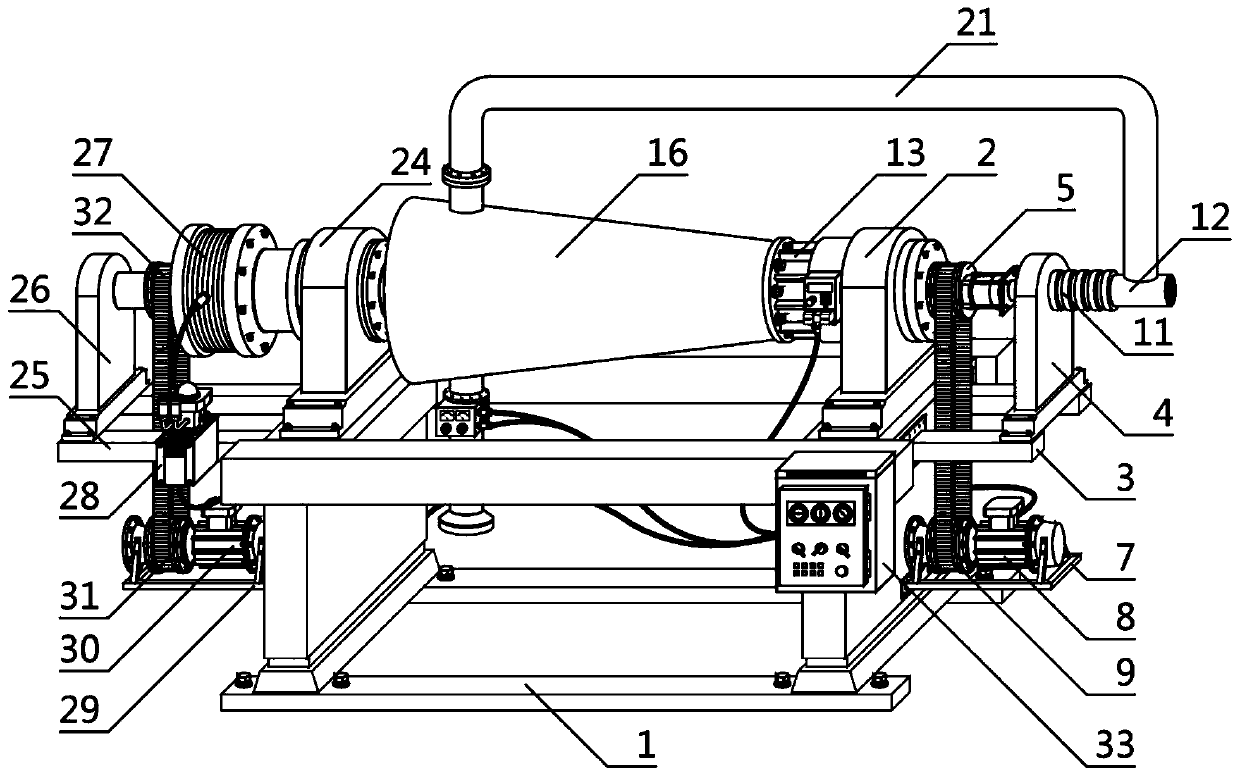

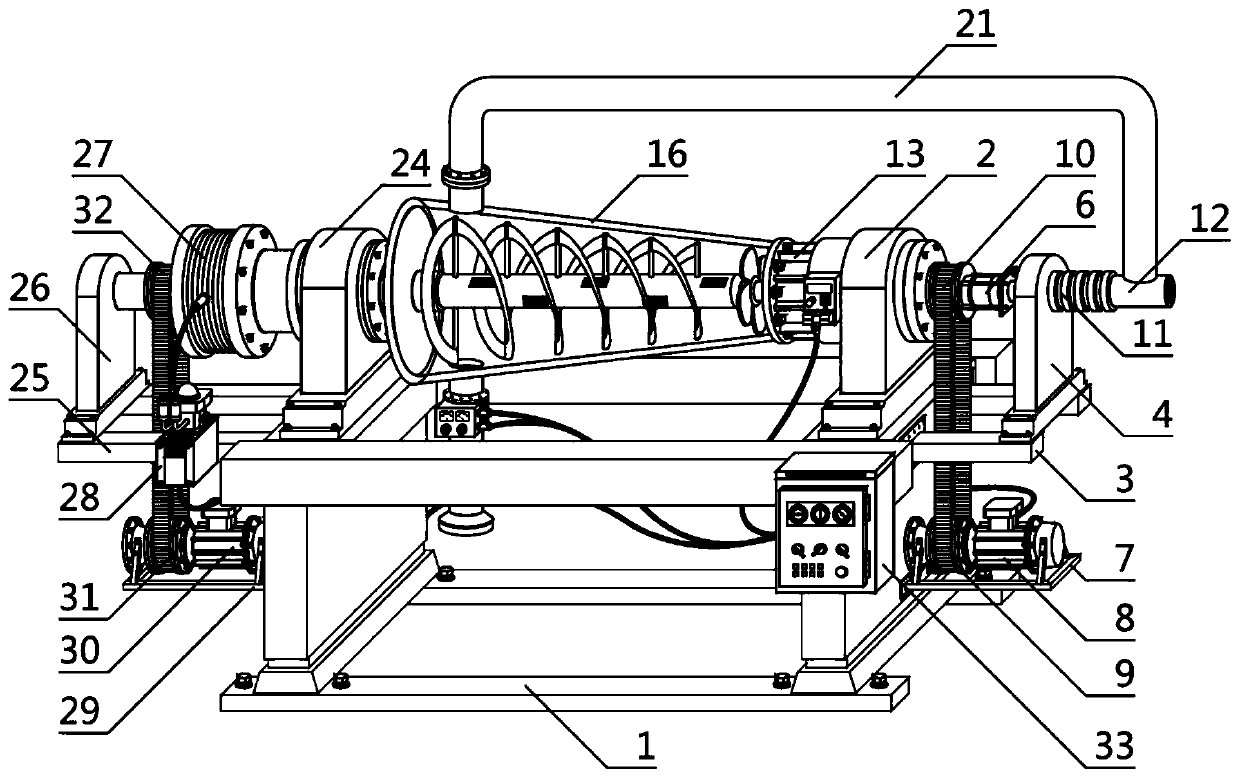

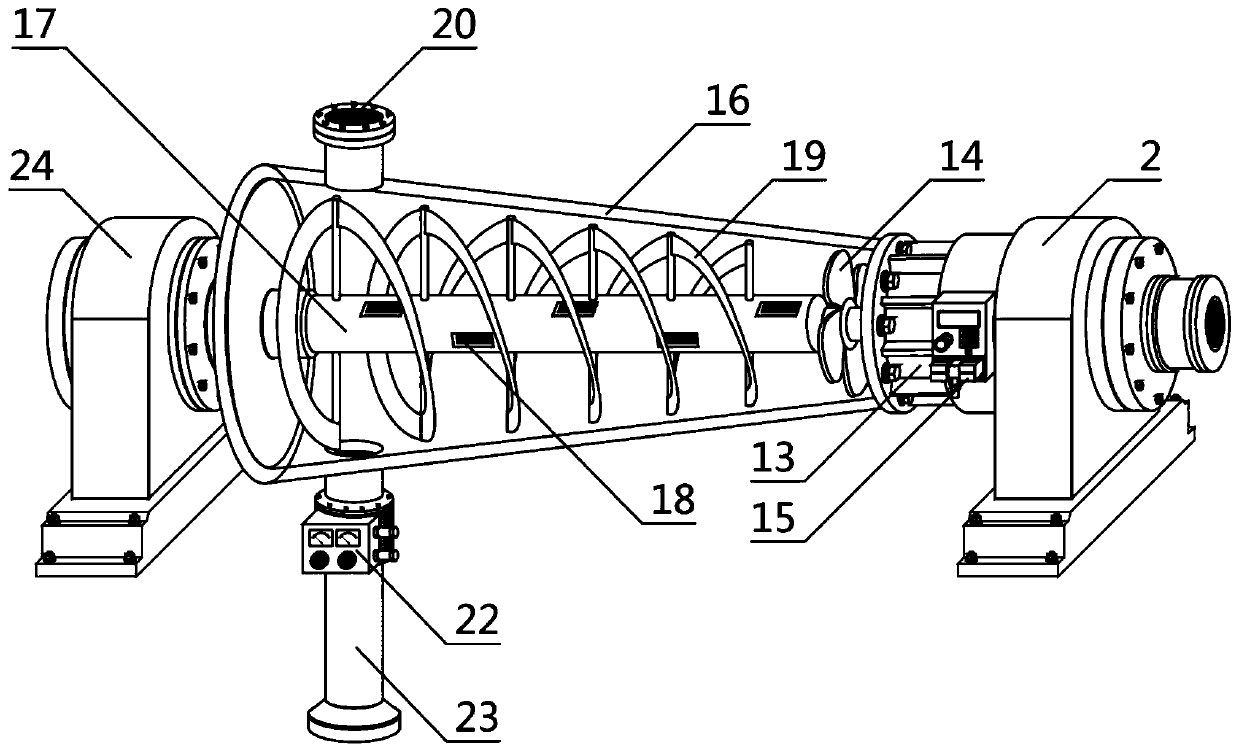

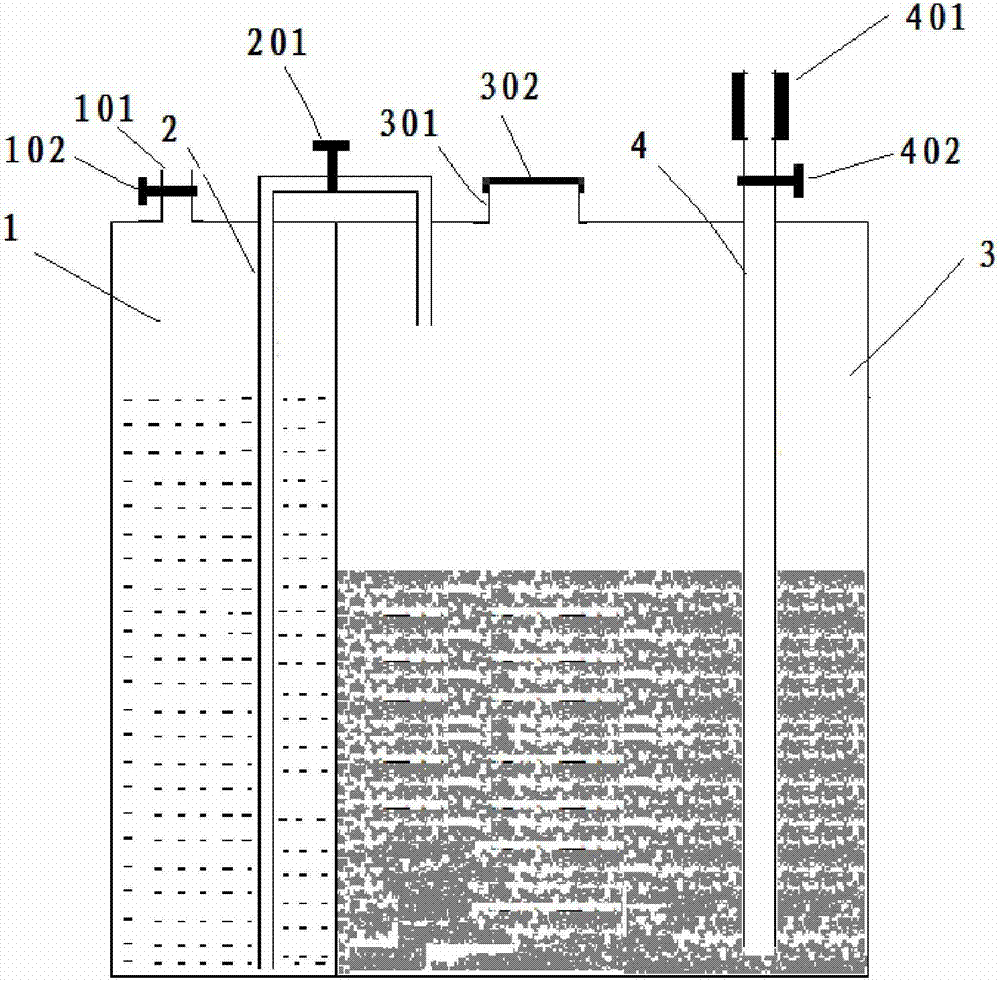

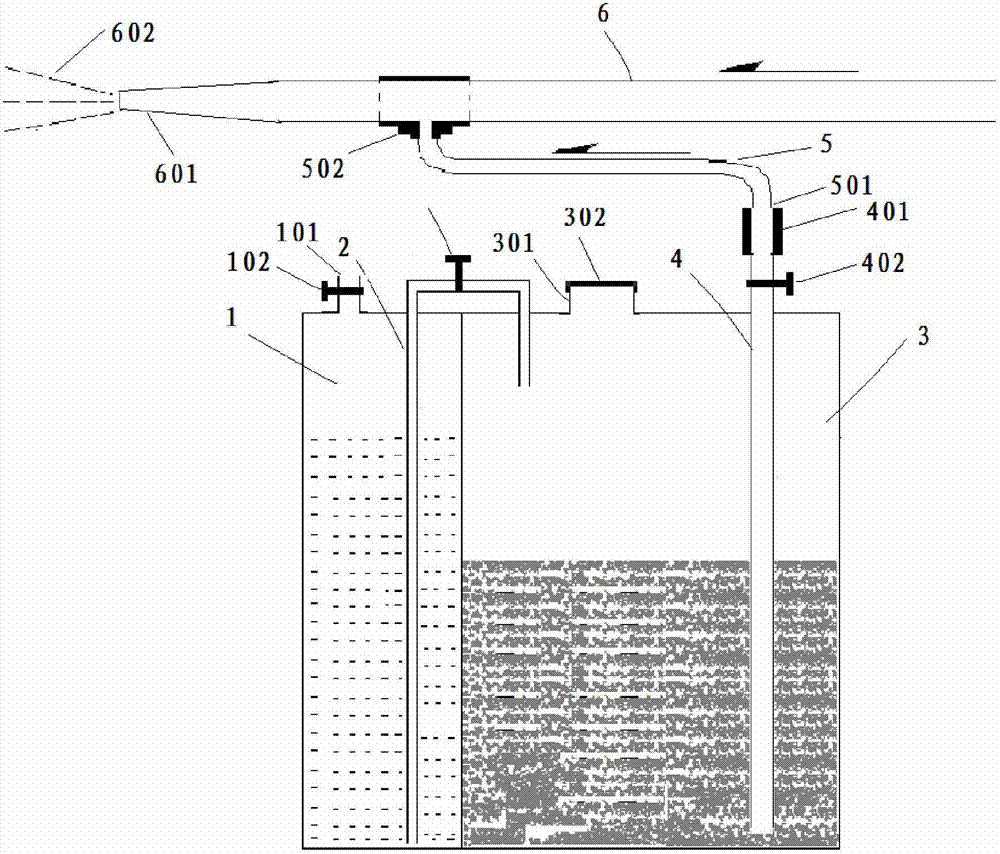

Test device and test method for wear test of filling slurry conveying pipeline

PendingCN113218801AControl flowControl flow rateInvestigating abrasion/wear resistanceWear testingStructural engineering

The invention discloses a test device and a test method for a wear test of a filling slurry conveying pipeline, and the test device comprises a stirring tank, a conveying assembly connected with the output end of the stirring tank, and a test pipeline assembly connected with the output end of the conveying assembly. The output end of the test pipeline assembly is connected with the input end of the stirring tank; and the test pipeline assembly comprises a plurality of horizontal pipelines, elbows, inclined pipelines and vertical pipelines which are connected with one another. By means of the mode, the abrasion law of filling slurry with different proportions in a horizontal pipeline, an inclined pipeline, a vertical pipeline, an elbow and the like can be studied, the flow and the flow speed of the filling slurry can be controlled so as to simulate various test environments, and the test effect is better.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Feeding equipment for cement processing

InactiveCN112518992AAchieve smashAchieving stirringCement mixing apparatusGrain treatmentsElectric machineryDrive motor

The invention discloses feeding equipment for cement processing. The feeding equipment comprises a bottom plate, hydraulic cylinders are assembled on the two sides of the top of the bottom plate, a stirring box is fixed to the tops of the two hydraulic cylinders, a smashing box is installed at the top of the stirring box, a feeding hopper is connected to the middle position of the top of the smashing box, and a driving motor is installed on one side of the outer wall of the smashing box through a locking bolt. An output shaft of the driving motor extends into the smashing box and is connectedwith a smashing mechanism, a cement filter screen is arranged under the smashing mechanism, a stirring rod is rotatably installed on the stirring box, multiple stirring blades are installed in the middle of the stirring rod in the circumferential direction at equal intervals, and a transmission mechanism is connected between the stirring mechanism and the stirring rod. According to the feeding equipment, cement blocks can be automatically smashed, screened and stirred during feeding, the labor intensity is reduced, meanwhile, stirring water can be filtered, the problem that impurities in sewage enter cement is effectively solved, the use effect is improved, the design is reasonable, and the feeding equipment is suitable for popularization.

Owner:涟源市湘中华源水泥有限公司

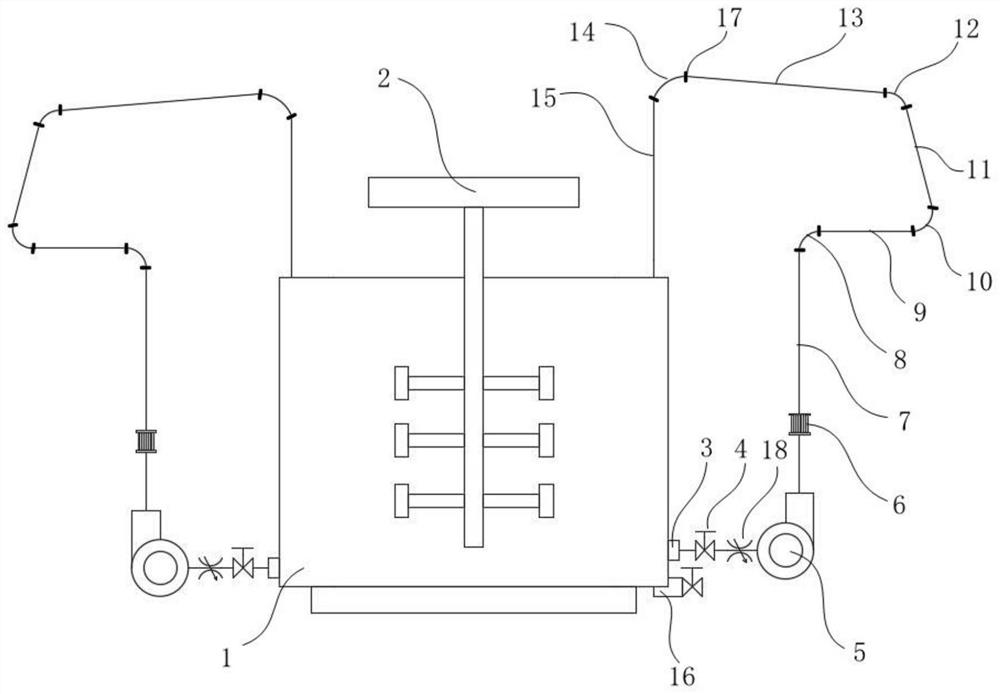

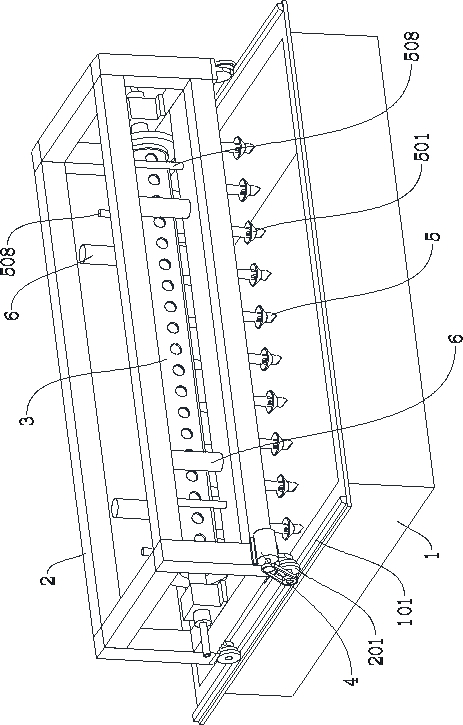

Automatic water metering system

PendingCN114350465AFully automatedNo manual mixingAlcoholic beverage preparationReciprocating motionControl engineering

The invention provides an automatic water metering system, which belongs to the technical field of wine brewing equipment and comprises a grain tank hopper, a frame body, a water metering assembly, a first driving part, a lifting rod and a second driving part. According to the automatic water metering system, the first driving part drives the walking wheel to move on the linear guide rail, so that the water metering assembly is driven to reciprocate on the grain tank hopper, the water metering assembly sprays metering water to grain tanks in the grain tank hopper in the moving process, and therefore automation of the water metering procedure is achieved; and the water can be uniformly scattered on the surface of the grain tank. A lifting rod is further mounted on the frame body, the lifting rod reciprocates in the vertical direction under the driving action of a second driving part, a material overturning part is mounted on the lifting rod, the lifting rod moves downwards to be inserted into the grain residues, and then the grain residues are overturned by the material overturning part in the upward moving process, so that the grain residues located at the bottom are overturned upwards, manual stirring is not needed, and the labor intensity of workers is reduced. The labor intensity is reduced, and meanwhile the production efficiency is improved.

Owner:河北凤来仪酒业有限公司

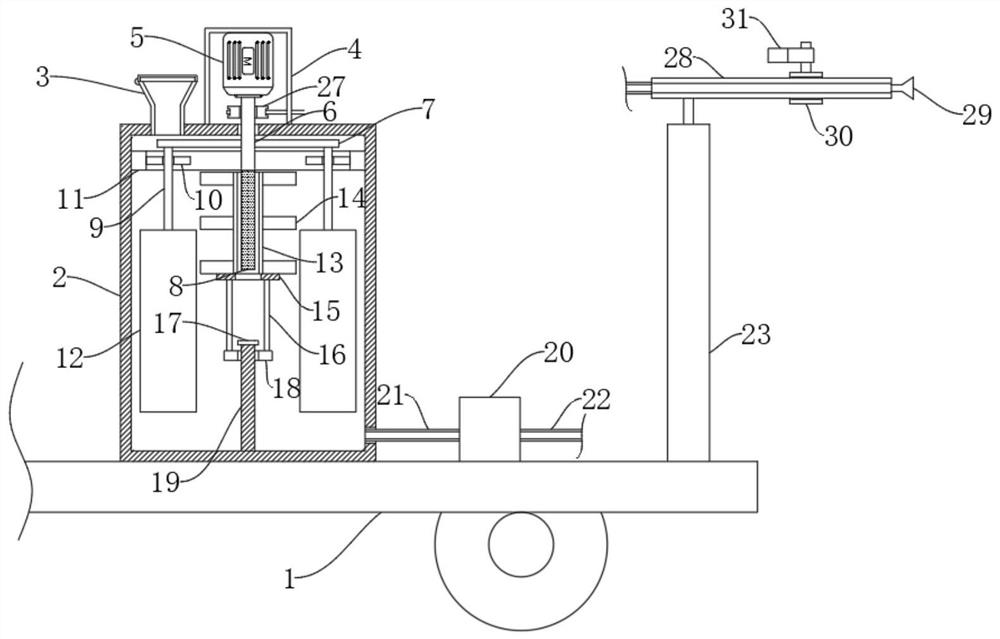

Multifunctional water and fertilizer integrated irrigation and fertilization device

InactiveCN112470663AIncrease dissolution rateNo manual mixingWatering devicesPressurised distribution of liquid fertiliserAgricultural scienceElectric machine

The invention discloses a multifunctional water and fertilizer integrated irrigation and fertilization device. The multifunctional water and fertilizer integrated irrigation and fertilization device comprises a vehicle body, wherein a stirring box is fixedly connected to the upper wall of the vehicle body, a feeding pipe is arranged on the upper wall of the stirring box in a communicating mode, acover is rotatably connected to the side wall of the feeding pipe through a hinge, and a fixing shell is fixedly connected to the upper wall of the stirring box; and a motor is fixedly connected to the top in the fixing shell, a rotating shaft is fixedly connected to an output shaft of the motor, and the rotating shaft extends into the stirring box. The device is reasonable in structural design, the operation steps of people is simplified, the working efficiency of people is improved, a fertilizer can fully dissolve, the dissolution rate of the fertilizer can be increased, the fertilizer can be prevented from precipitating, the fertilizer can be fully utilized, the irrigation and fertilization cost can be reduced, and the irrigation range of the device can also be improved.

Owner:张春林

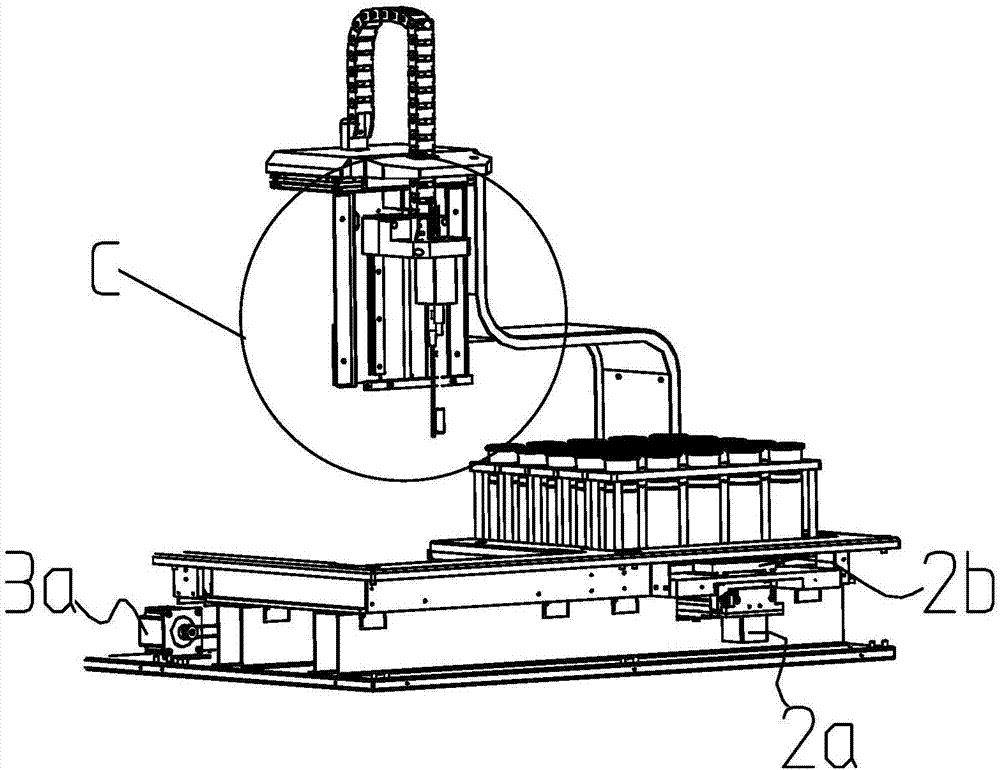

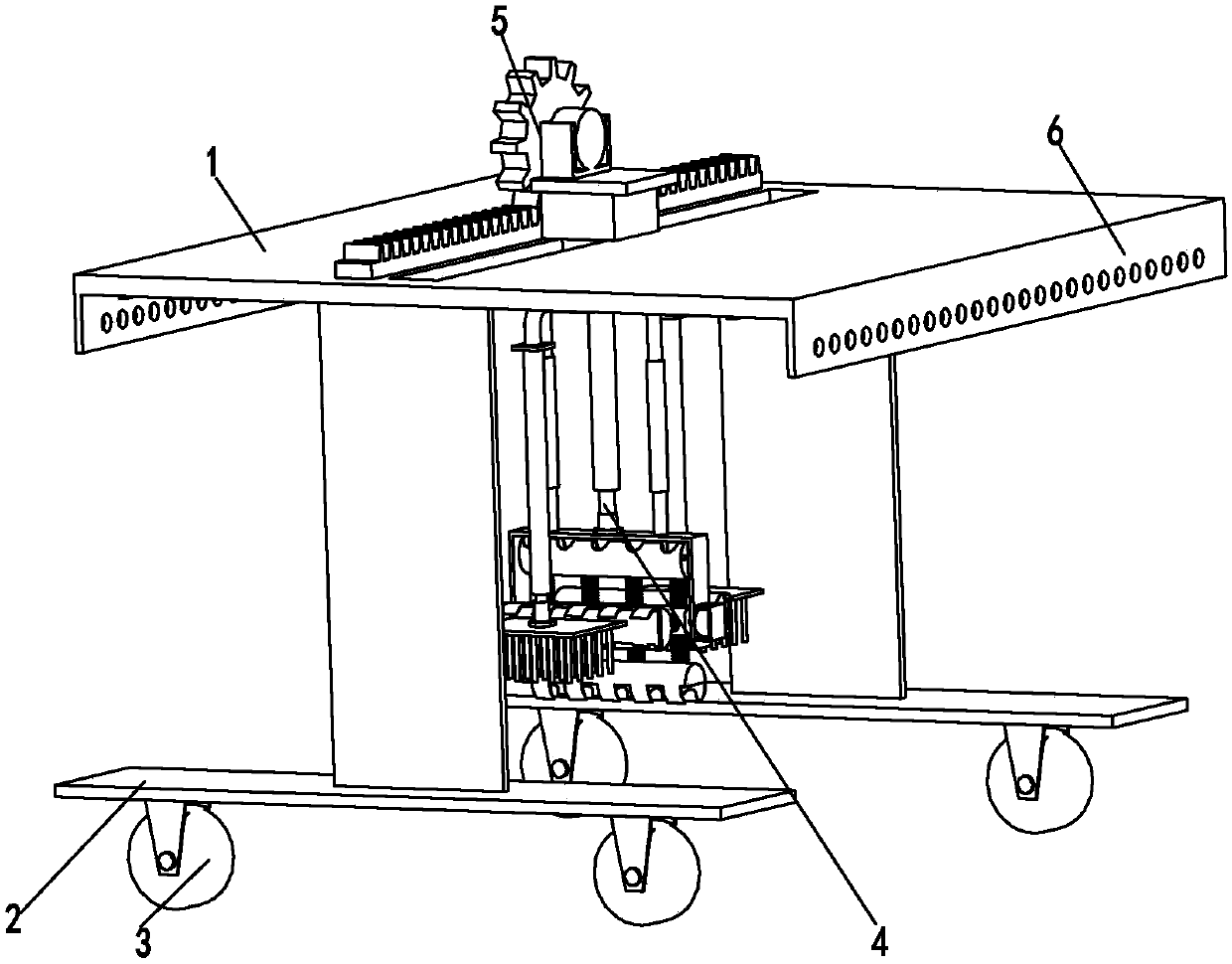

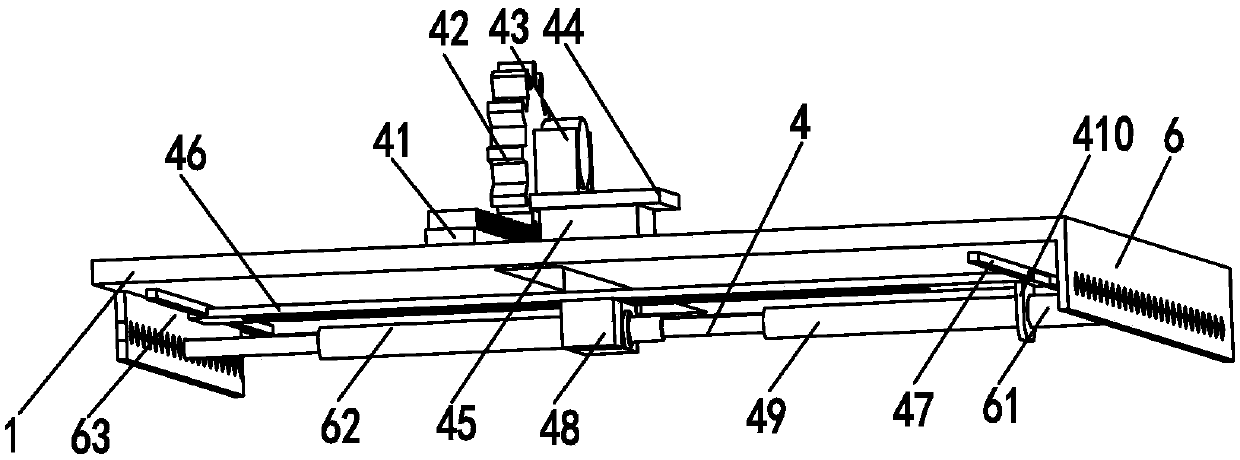

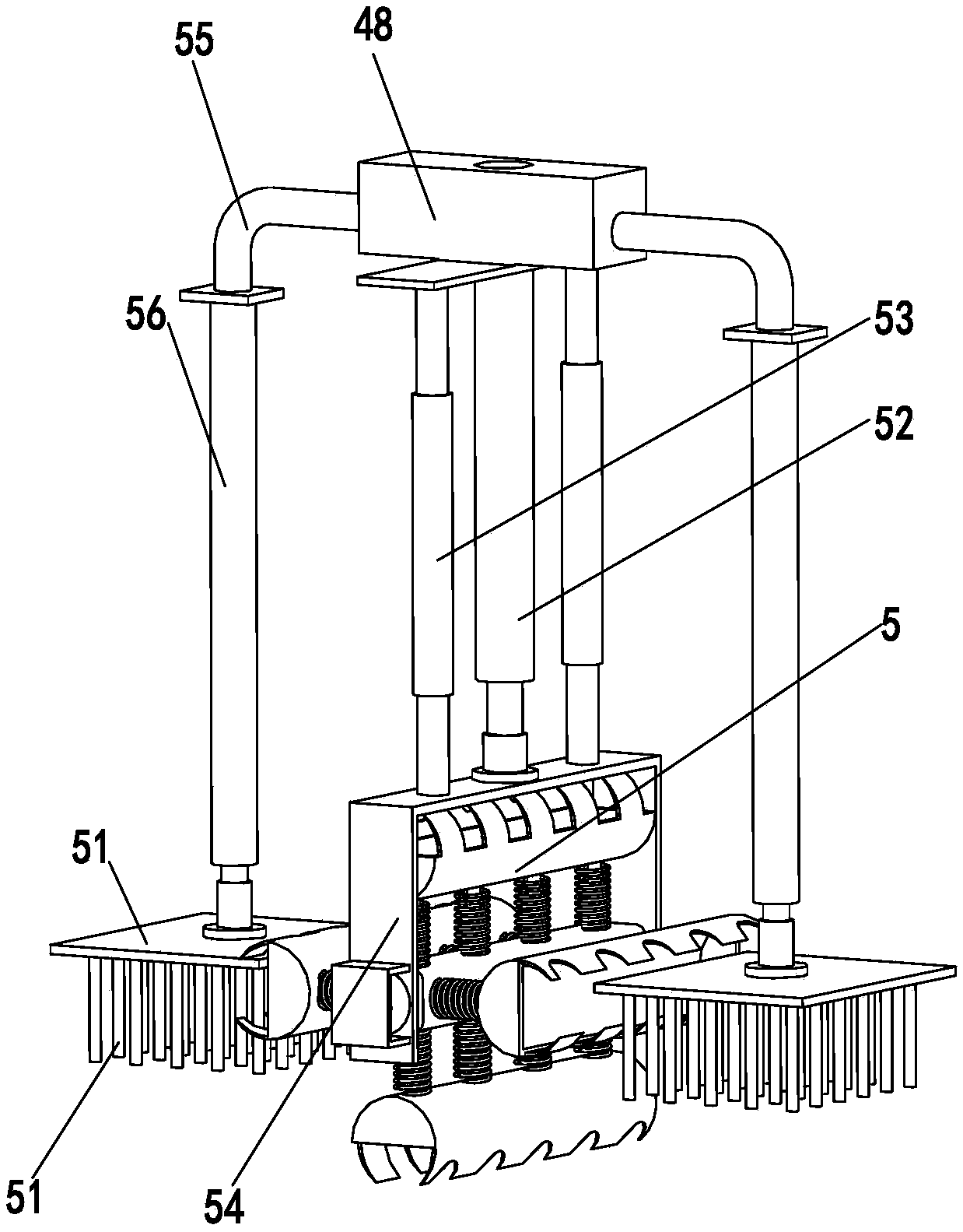

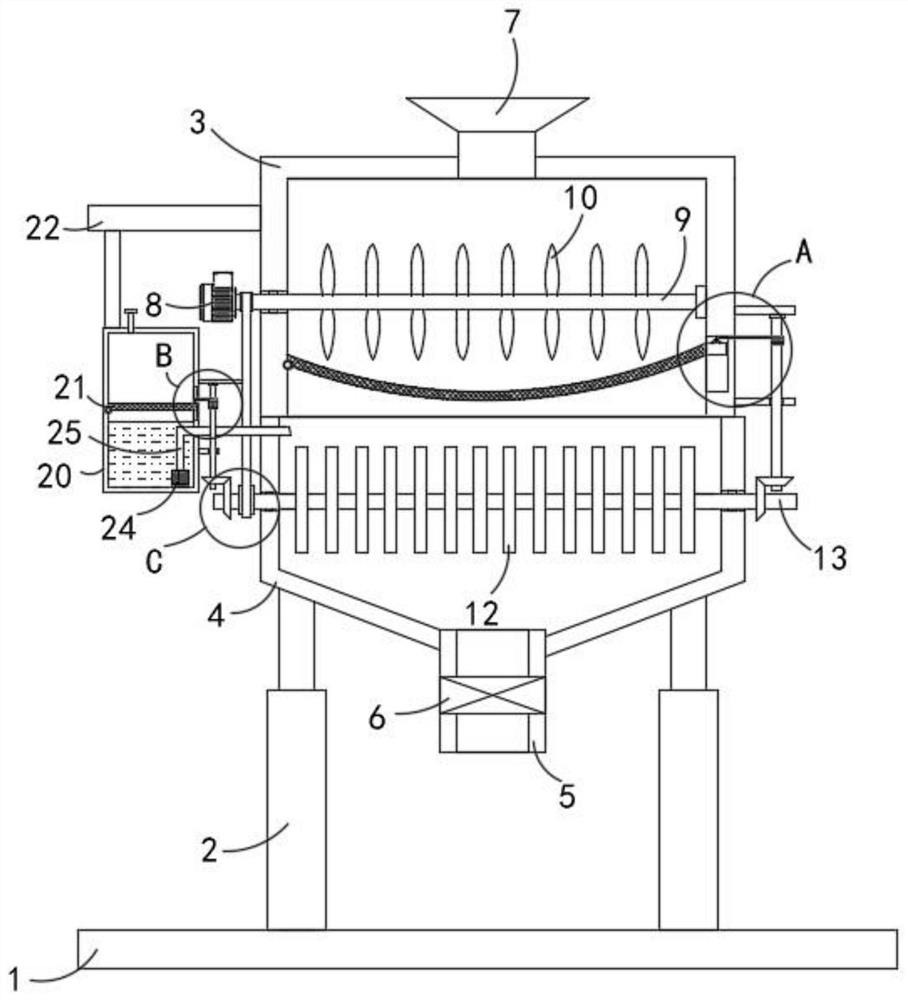

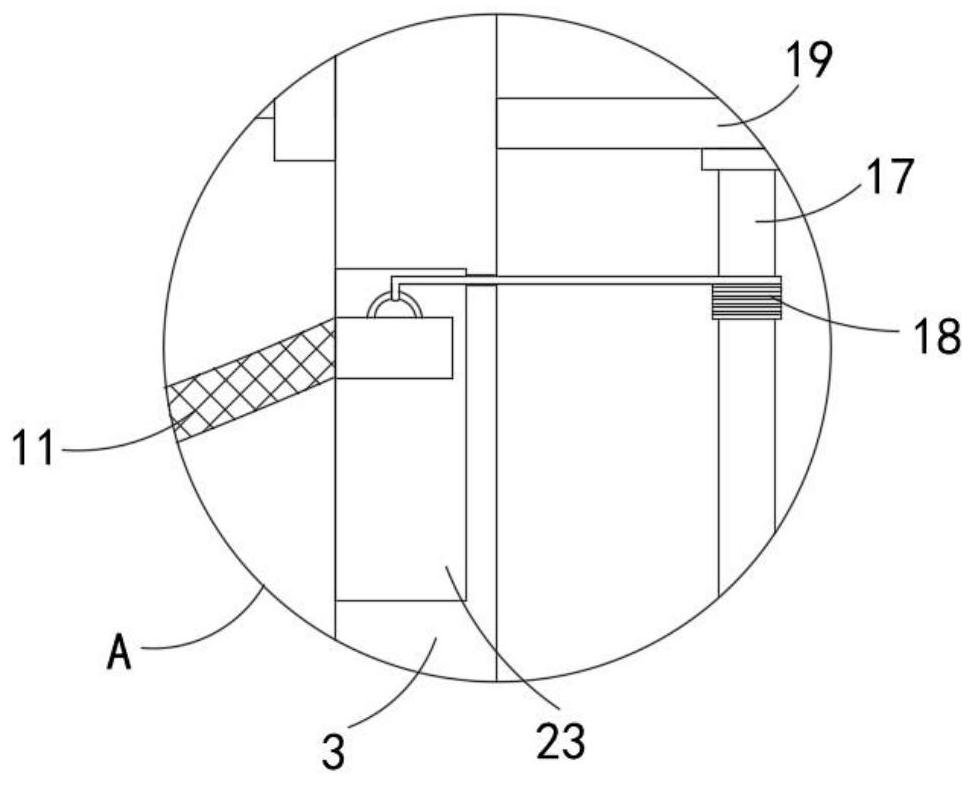

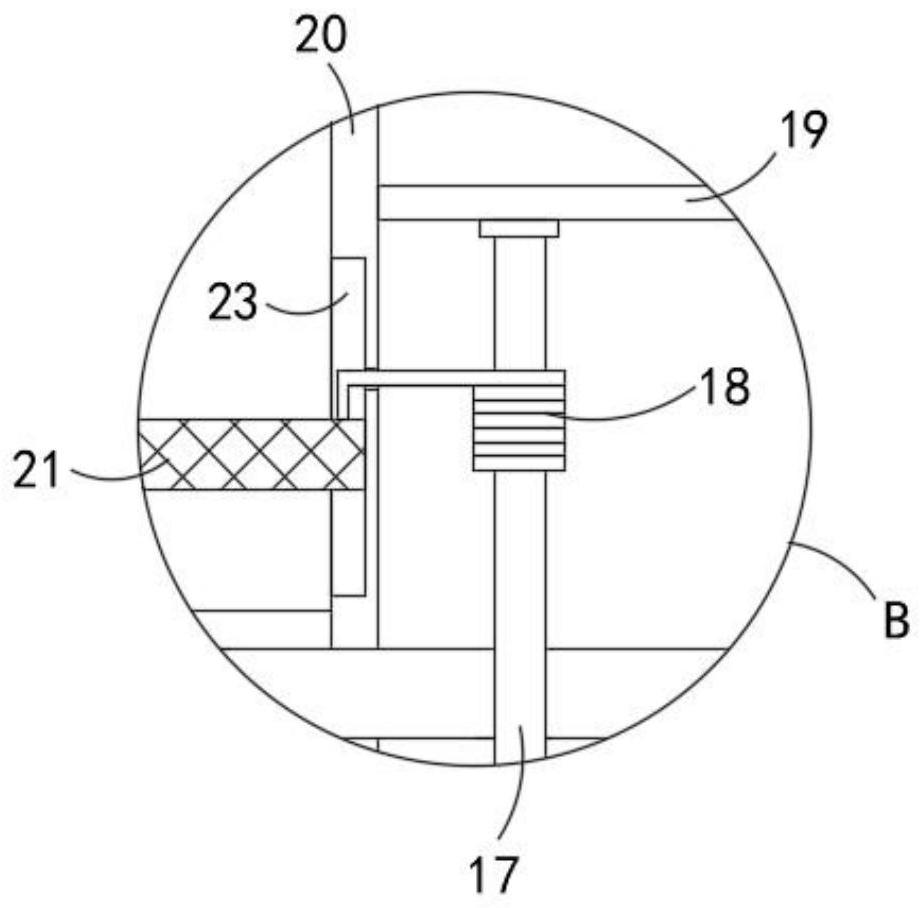

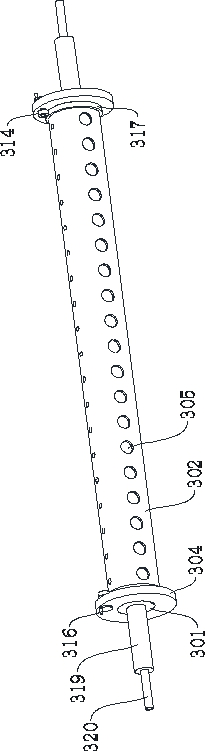

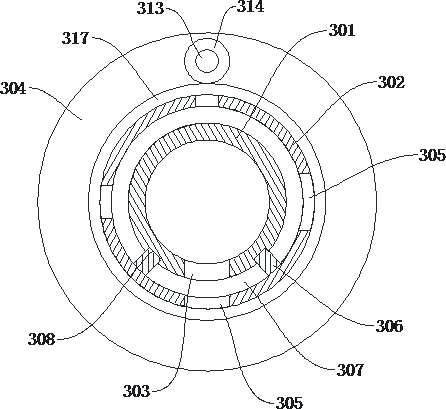

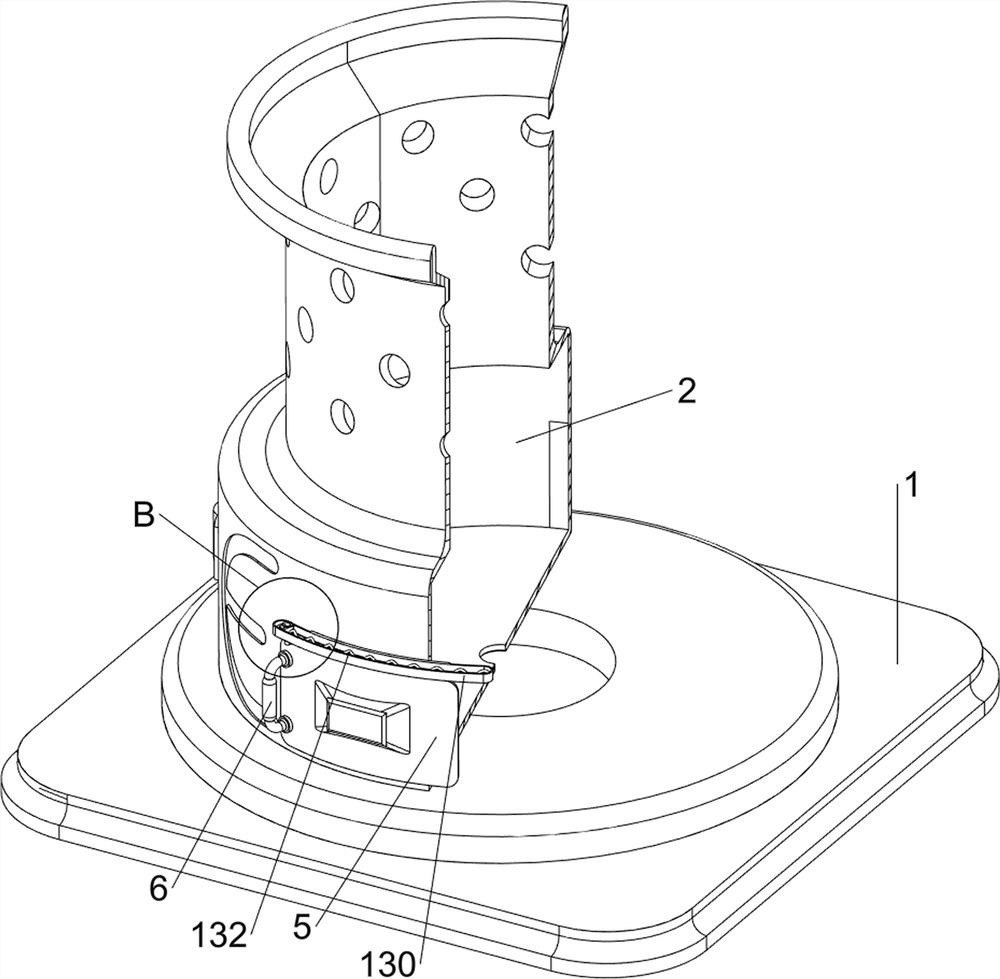

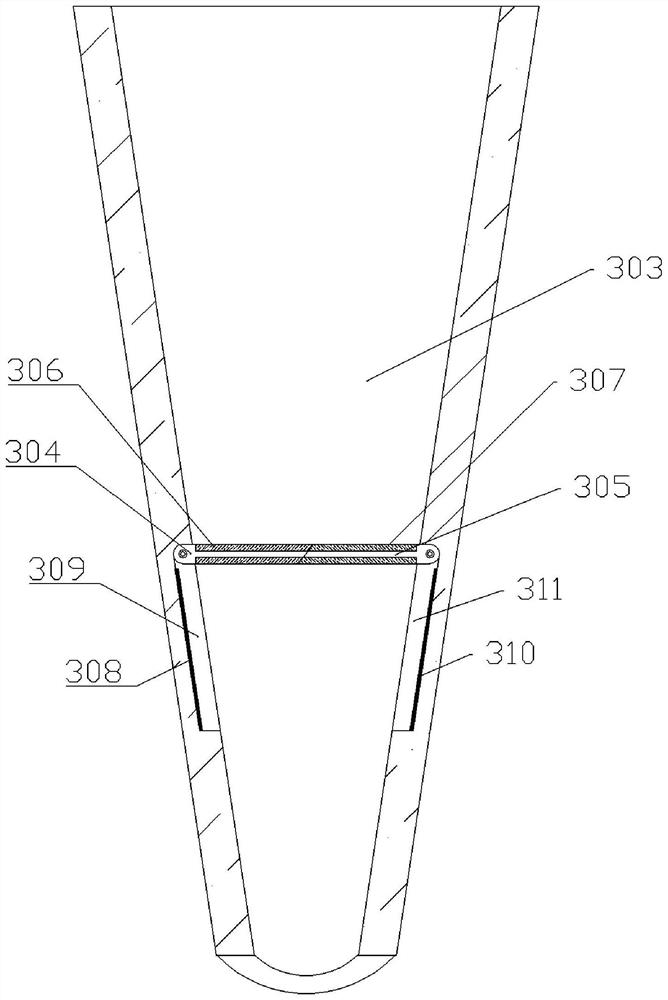

Sectional proportioning apparatus of brake pad raw material

PendingCN109046092ANo manual mixingRaw materials are accurateRotary stirring mixersTransportation and packagingMechanical engineeringBrake pad

The invention discloses a sectional proportioning apparatus of a brake pad raw material. The sectional proportioning apparatus comprises a base, a slide rail fixedly arranged on the base, and a stirring drum connected with the slide rail in a rolling manner; and the stirring drum is in a cylindrical hollow thin-wall shape, a cover of the stirring drum is fixedly provided with a motor, a rotating shaft of the motor is provided with a stirring apparatus arranged in the stirring drum, the side wall of the stirring drum is also provided with a receiving apparatus, the lower end of the stirring drum is provided with a discharging apparatus, a proportioning supporting frame is also arranged above the base, the proportioning supporting frame is provided with a first raw material drum and a secondraw material drum in a hanging manner, the base is also provided with a proportioning drum, and the proportioning drum is located below the slide rail. The movable stirring apparatus performs the sectional feeding operation among different raw material drums, so that the manual stirring is not required, time and labor can be saved, precision in proportioning can be achieved, and the production efficiency is high.

Owner:盐城加申汽车制动部件有限公司

Grinding system convenient to feed and discharge

InactiveCN108555767AChange volumeHelp cuttingEdge grinding machinesPolishing machinesDischarge efficiencyEngineering

The invention discloses a grinding system convenient to feed and discharge. The grinding system comprises a grinding machine which is connected with a feeding device through a conveying pipe, a discharging device is arranged in the grinding machine, the grinding machine comprises a lower base, an upper base is arranged above the lower base and is connected with a first rotating motor, the first rotating motor is connected with an uncovered grinding cavity through a rotating shaft, the grinding cavity is provided with a workpiece inlet and a flowing abrasive material inlet, a grinding cover body is arranged on one side of the grinding cavity and is symmetrically provided with a first stretchable rod and a second stretchable rod, the first stretchable rod is connected with a first push rod motor, the second stretchable rod is connected with a second push rod motor, the inner surface of the grinding cavity and the grinding cover body are provided with fixed abrasive materials in an embedded manner, and a first electric-hydraulic push rod and a second electric-hydraulic push rod are arranged on the two sides of the upper base. The grinding system has the advantages that the size of thegrinding cavity can be adjusted according to the machining workpiece quantity, the workpiece grinding effect is good, the workpiece grinding efficiency is high, the feeding efficiency is high, and the discharging efficiency is high.

Owner:湖州铭之远研磨科技有限公司

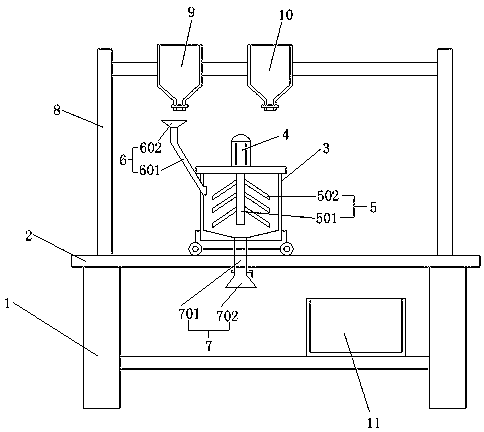

Electric knapsack sprayer

InactiveCN105057138AAchieve cycleImprove uniformityLiquid spraying apparatusDiaphragm pumpEngineering

The invention discloses an electric knapsack sprayer and belongs to the field of agricultural machinery. The electric knapsack sprayer comprises a pesticide storage box, a spraying device box arranged at the lower part of the storage box and a sprinkler, wherein a liquid inlet is formed in the pesticide storage box; a box cover is arranged at the liquid inlet; a diaphragm pump, a storage battery and an electric reversing valve are arranged in the spraying device box, an inlet of the diaphragm pump is communicated with the pesticide storage box, an outlet of the diaphragm pump is connected with the electric reversing valve, the electric reversing valve are communicated with the sprinkler and a circulating pipe, and an outlet of the circulating pipe is located at the upper part of the pesticide storage box; a speed regulator and a controller are arranged on the spraying device box, and the diaphragm pump, the storage battery, the electric reversing valve and the speed regulator are connected with the controller. According to the electric knapsack sprayer, pesticide circulation in the pesticide storage box can be realized rapidly, the pesticide uniformity is good, manual mixing is not needed, and the work efficiency is improved; pesticide can circulate in a spraying process, and pesticide precipitation is avoided.

Owner:NANTONG GUANGYI ELECTROMECHANICAL CO LTD

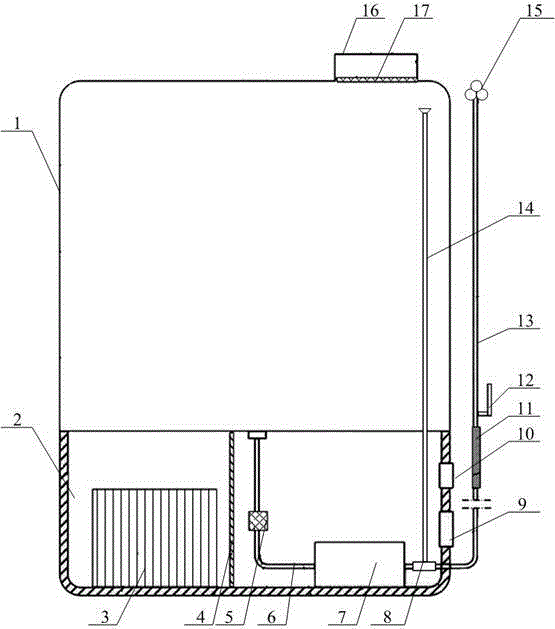

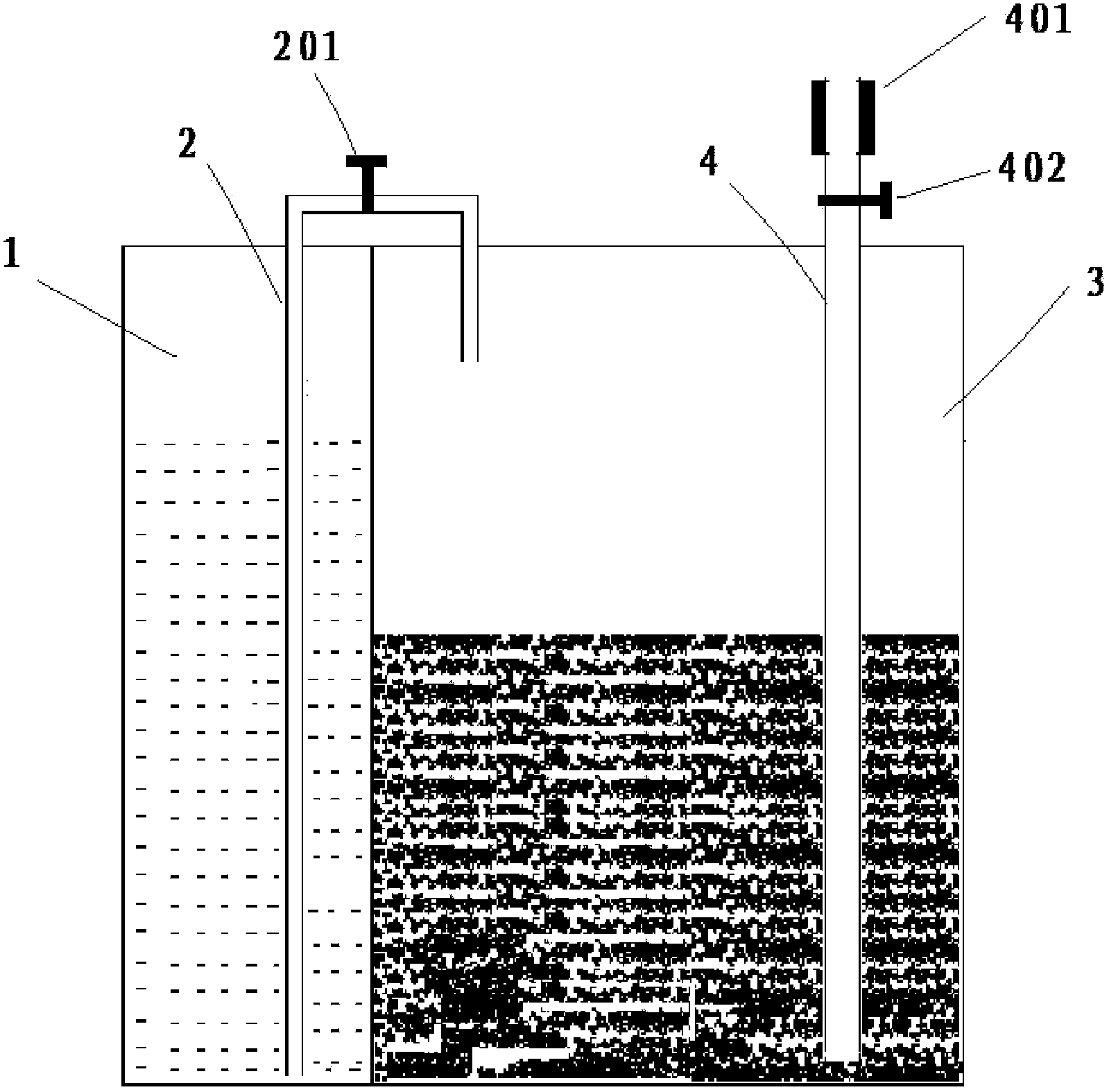

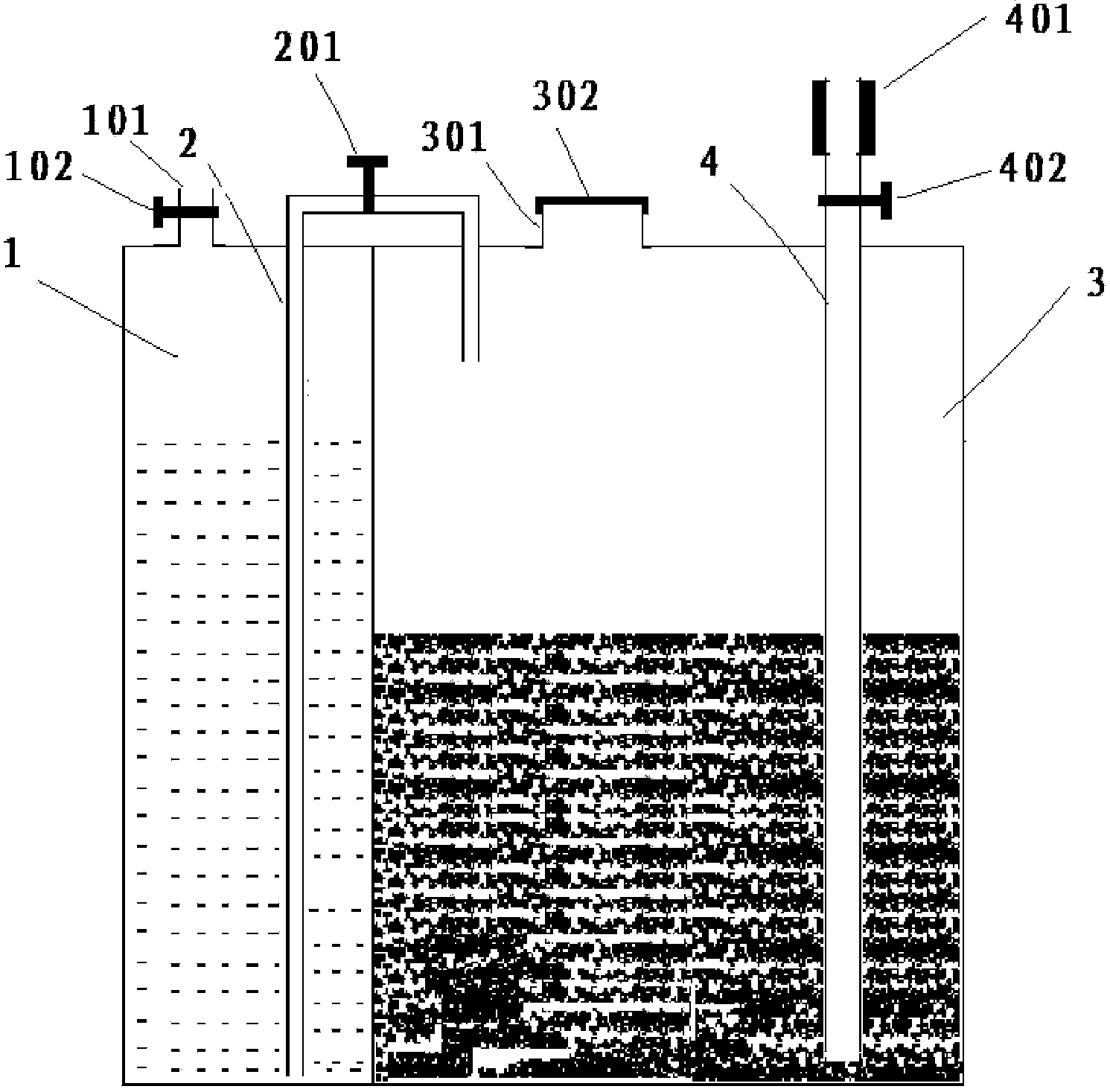

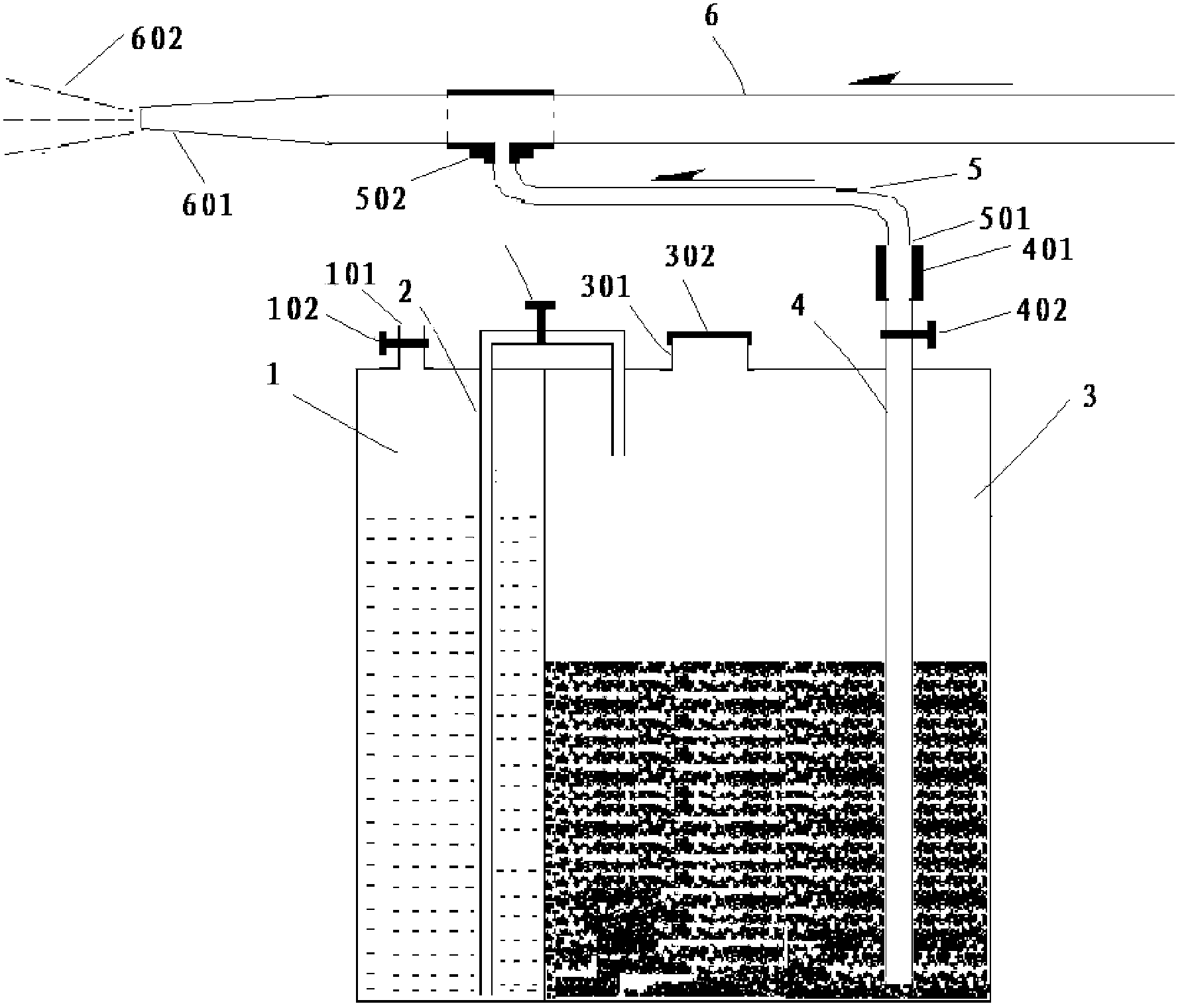

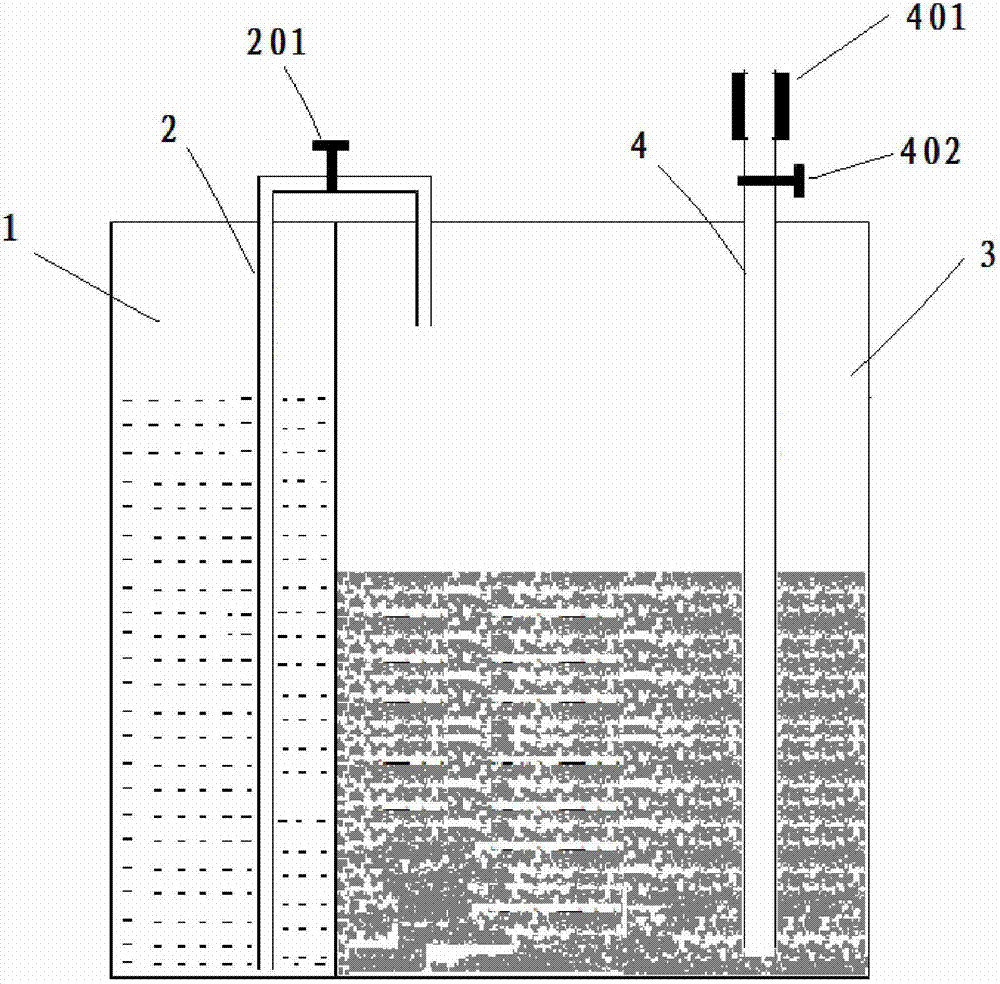

Stirring apparatus of silicon wafer grinding liquid

InactiveCN104248925AMeet production requirementsIncreases chances of thorough agitationRotary stirring mixersTransportation and packagingEngineeringUltimate tensile strength

The present invention belongs to the technical field of silicon wafer processing, and specifically relates to a stirring apparatus of a silicon wafer grinding liquid. The stirring apparatus comprises a stirring barrel provided with a liquid inlet and a liquid outlet, and a stirring mechanism arranged on the stirring barrel and provided for stirring inside the stirring barrel, wherein the stirring mechanism comprises a stirring motor arranged on the stirring barrel, a stirring main shaft connected with the stirring motor output shaft, and a plurality of stirring blades arranged on the stirring main shaft, and the side walls of every stirring blade are provided with concave grooves. The stirring apparatus of the present invention has characteristics of no requirement of manual stirring, labor intensity reducing, uniform stirring and complete meeting of the silicon wafer production requirement.

Owner:CHANGZHOU LIWEI KNIFE

Novel pollution treatment device for waste gas

InactiveCN107998837AEvenly mixedProtect healthGas treatmentRotary stirring mixersHazardous substanceEngineering

The invention discloses a novel pollution treatment device for waste gas. The novel pollution treatment device comprises a walking trolley body and an agitating barrel, wherein the agitating barrel isfixedly arranged on the left side of a top end surface of the walking trolley body; the right side of the top end surface of the walking trolley body is provided with a concave platform; the upper end surface of the concave platform is provided with an absorption barrel; a wall body of the interior of the walking trolley body is provided with a driving cavity; the bottom of the outer wall of theright side of the driving cavity is fixedly provided with a first driving motor; an end surface of the left side of the first driving motor is connected with a driving threaded rod in a power fit manner; the external surface of the driving threaded rod is connected with a guide slide block in a thread fit manner; the guide slide block is connected with the driving cavity in a slide fit manner; theupper part of the guide slide block is provided with a second driving motor in a left-right through embedment manner. The novel pollution treatment device has a simple structure and is convenient touse; a liquid medicine is uniformly prepared and mixed; the manual agitation is not needed; the health of a human body is protected; meanwhile, an absorption component is automatically lifted to effectively and sufficiently collect the waste gas; toxic and harmful substances in the waste gas are absorbed through the liquid medicine, and the pollution of the waste gas is reduced.

Owner:郭超杰

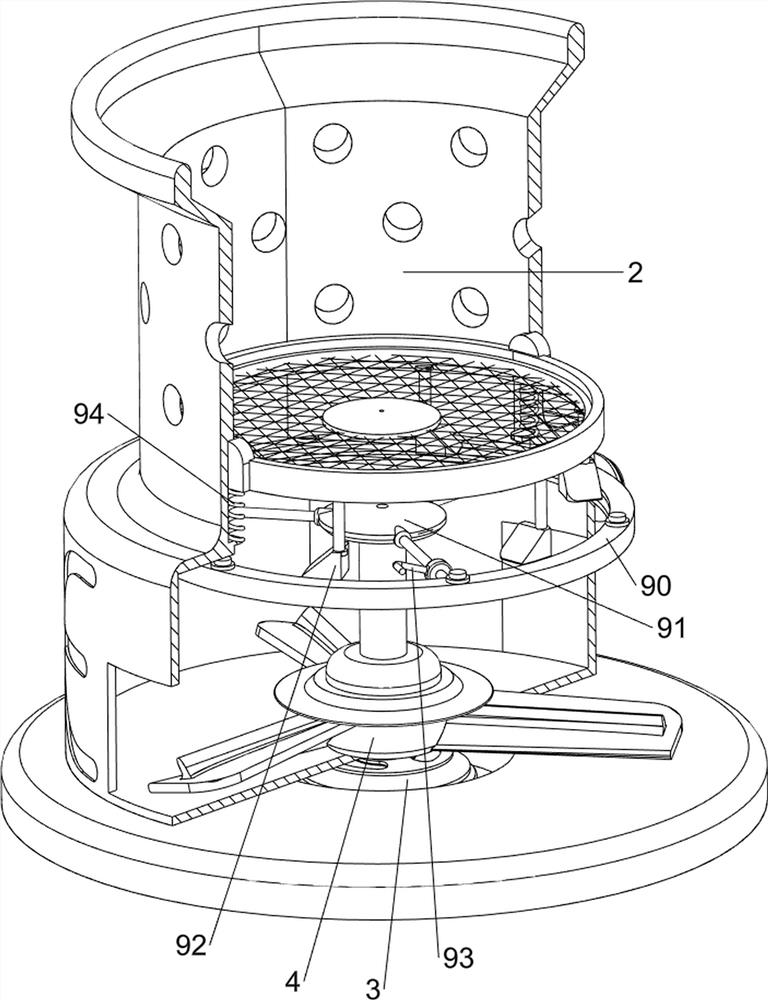

An intelligent cement mixing and processing equipment

InactiveCN108501204BPrevent many disadvantages such as uneven fillingReduce stirring speedDischarging apparatusMixing operation control apparatusDrive shaftDrive motor

The invention aims at providing intelligent cement stirring treatment equipment. According to the technical scheme provided by the invention, the intelligent cement stirring treatment equipment is composed of an operation platform, a first bearing seat, a first driving supporting platform, a first driving auxiliary bracket, a first driving transmission shaft, a first driving motor bracket, a firstdriving motor, a feeding buffering cabin, a feeding opening, an induction triggering device, a stirring tank, a stirring rotary shaft, a second bearing seat, a second driving supporting platform, a second driving auxiliary bracket, a rotary speed regulation motor, a second driving motor bracket, a second driving motor and a master control cabinet. The equipment has better sealing performance andis more environmentally friendly and more reliable; automatic monitoring is realized; the intelligent cement treatment equipment is used for stirring a series of building solvent solid materials including cement, concrete and the like and can realize gradual condensation of the materials when the materials are not stirred for a long time, so that the stirring speed is reduced to carry out data analysis and the rotary speed power is improved; a stirring rotary speed also can be controlled so that output cement materials can be directly ensured.

Owner:杨金梅 +4

Device for manufacturing mortar by using waste concrete

PendingCN114393707AFully filteredMeet construction needsSievingDischarging apparatusArchitectural engineeringElectric machinery

The invention relates to a device for manufacturing mortar, in particular to a device for manufacturing mortar by using waste concrete. The invention provides a device for manufacturing mortar by using waste concrete, which is simple to operate and can be used for further filtering crushed sand and stones. The invention discloses a device for manufacturing mortar by using waste concrete. The loading frame is arranged in the middle of the top of the bottom plate, and a discharge port is formed in one side of the lower part of the loading frame; the first motor is arranged in the middle of the interior of the bottom plate; the stirring rod used for stirring the crushed concrete is arranged on the lower side of an output shaft of the first motor, the stirring rod is located in the loading frame, and the output shaft of the first motor is rotationally connected with the loading frame. The motor works to enable the connecting rod to intermittently make contact with the wedge-shaped block, then the filter screen intermittently moves up and down to shake, the smashed sandy soil can be further filtered, the sandy soil filtering is more sufficient, and the manufactured mortar can meet the construction requirement.

Owner:周连花

Agricultural intelligent regular spraying device

InactiveCN110663665ATo achieve timingSolve the problem that the single function is not practicalTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention discloses an agricultural intelligent regular spraying device which comprises a supporting rod. A first water pipe is mounted inside the supporting rod, the lower end of the first waterpipe is fixedly connected with the upper end of the water pump, the lower end of the water pump is fixedly connected with the right end of a spray tank through a second water pipe, a servo motor is placed inside a motor box inside the spray tank, the output end of the servo motor is rotatably connected with a rotating shaft, a spiral blade is fixed on the rotating shaft, the outer wall of the rotating shaft is rotatably connected with a bearing, the right end of the supporting rod is in welding connection with a control box, a storage battery and a timer are mounted inside the control box, andthe storage battery is serially connected with the timer through a lead. By arranging the spiral blade, the servo motor and the timer, the problems that no timing function is provided, function is unitary, practicability is low, pesticide cannot be uniformly dispersed in water and resources are wasted due to the fact that the pesticide accumulates at the bottom end of the water tank for a long time due to gravity action are solved.

Owner:安徽鑫科禾科技有限公司

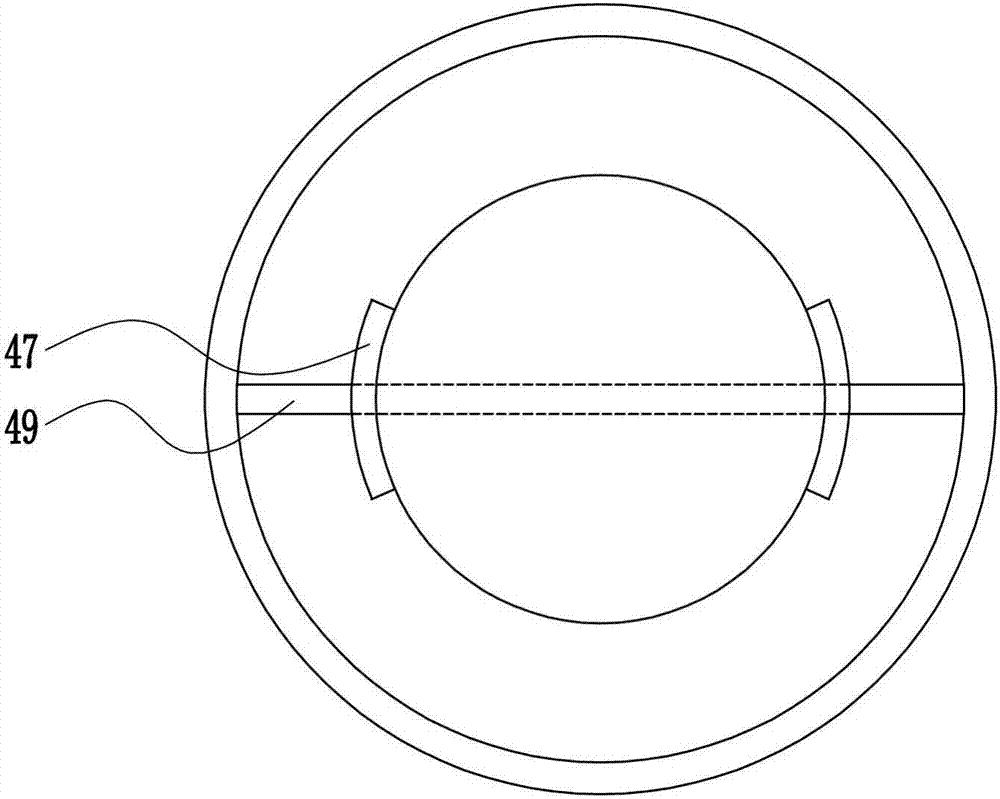

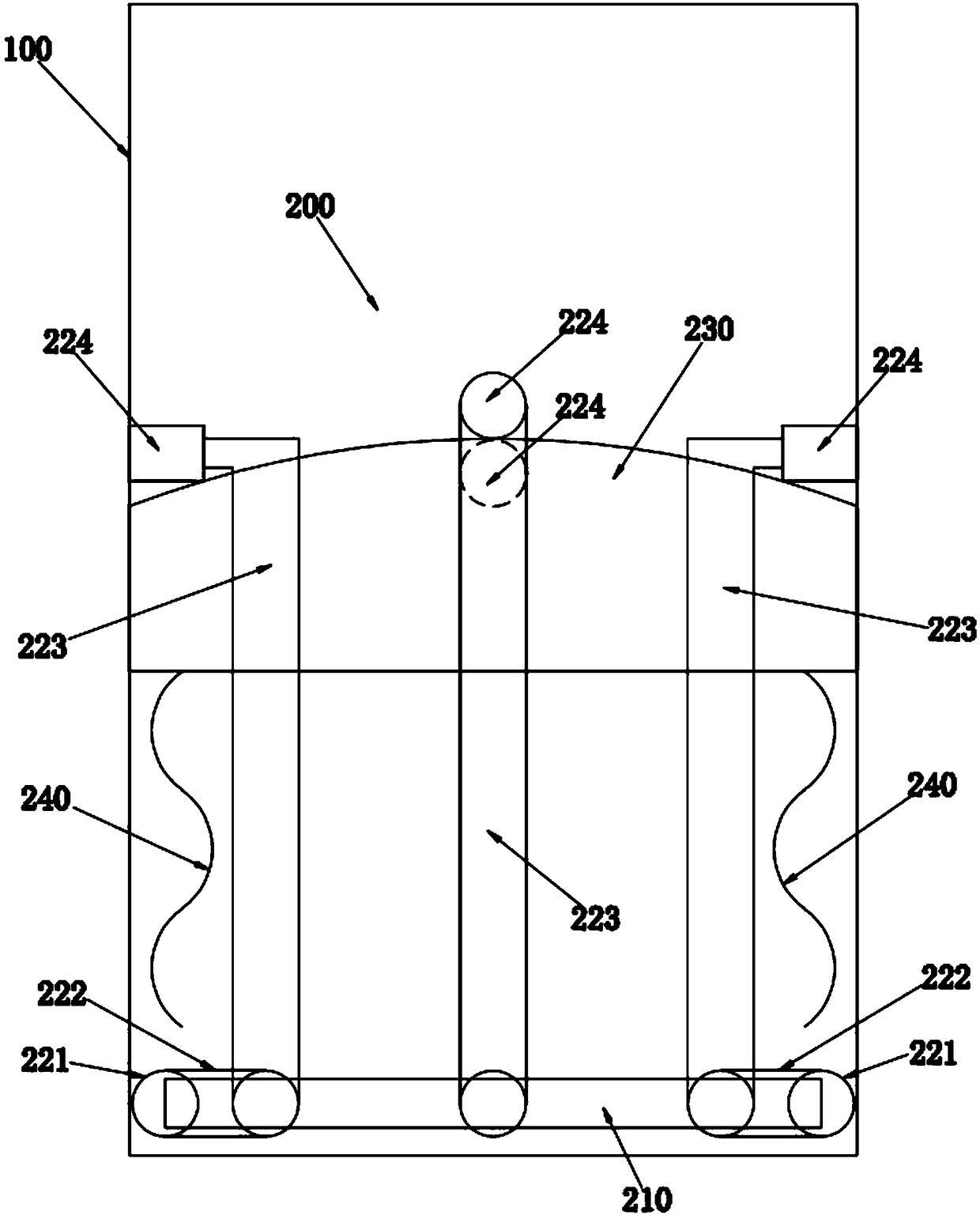

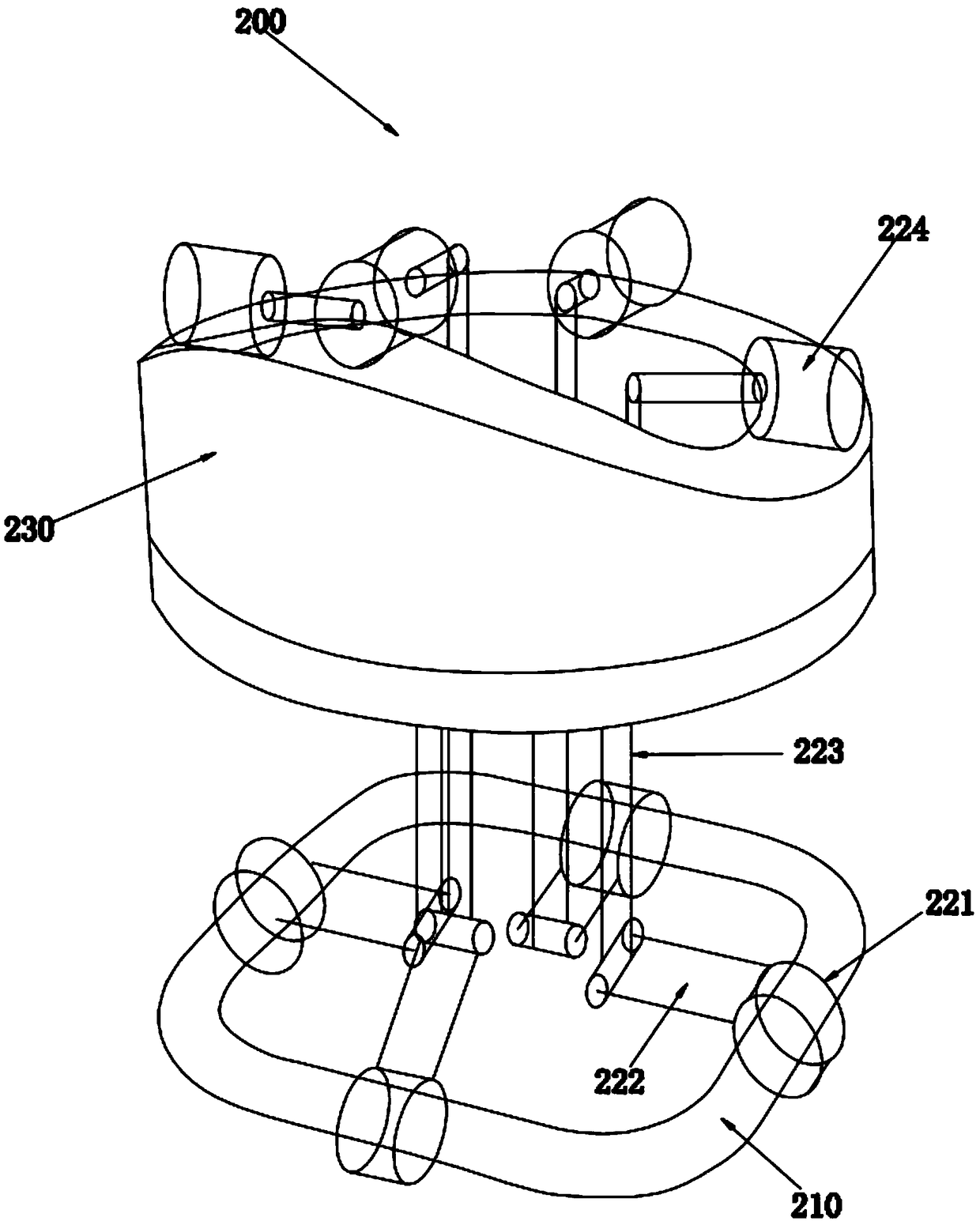

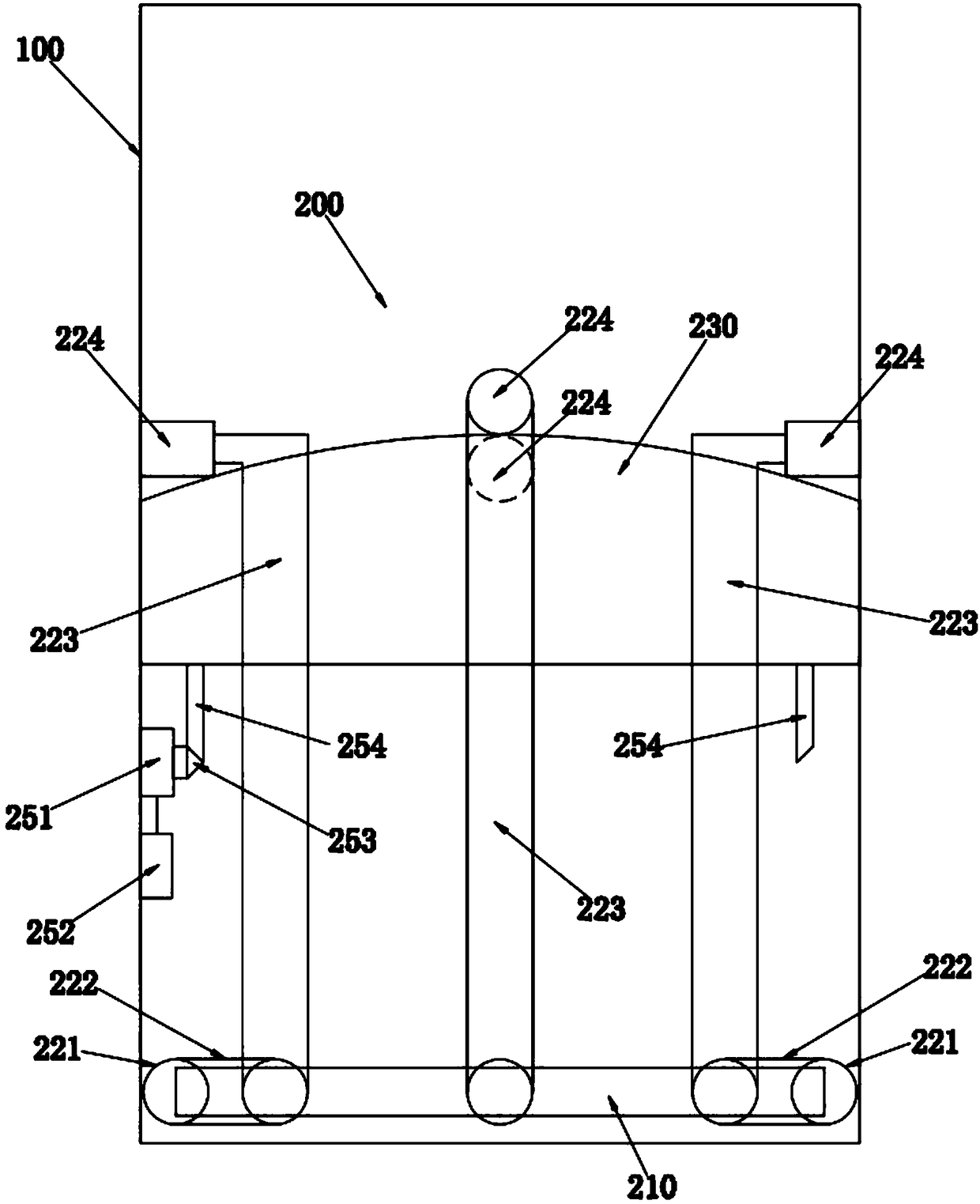

Medical powder mixing cup

The invention discloses a medical granule stirring cup. The medical granule stirring cup comprises a cup body (100) and a stirring part (200), wherein the stirring part (200) comprises a support ring (210), a first hinge ring (221), a beating rod (222), a first connecting rod (223), a roller (224), a waved ring (230) and a driving part; the roller (224) is in lap joint with the upper surface of the waved ring (230); the driving part drives the waved ring (230) to rotate. The roller (224) is lifted or lowered by the aid of the rotating waved ring (230), and caking is reduced. The medical granule stirring cup is particularly applicable to making of western medicine powder, traditional Chinese medicine powder, protein powder, juice powder and drink powder, requires no manual stirring and is low in caking rate.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

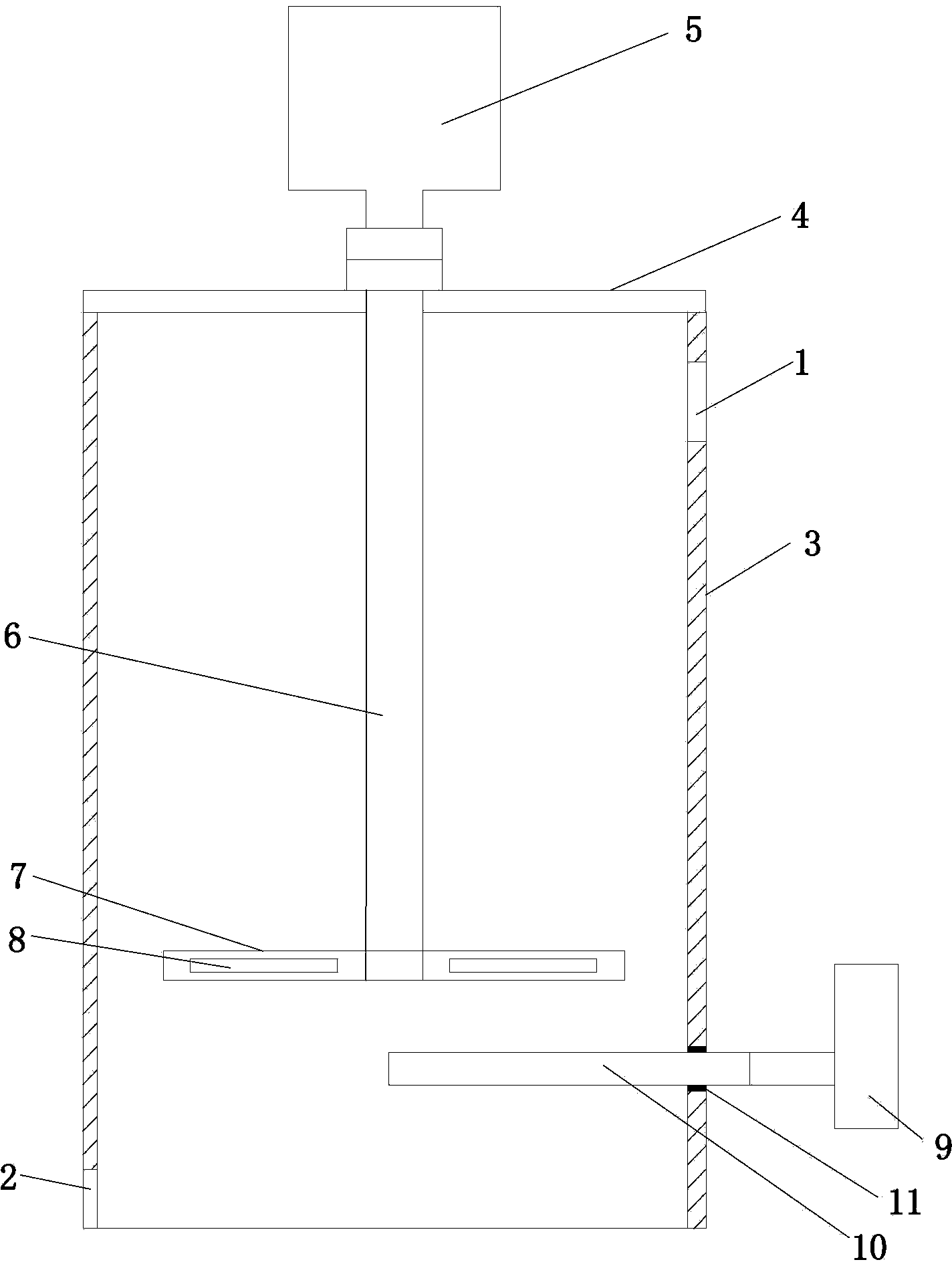

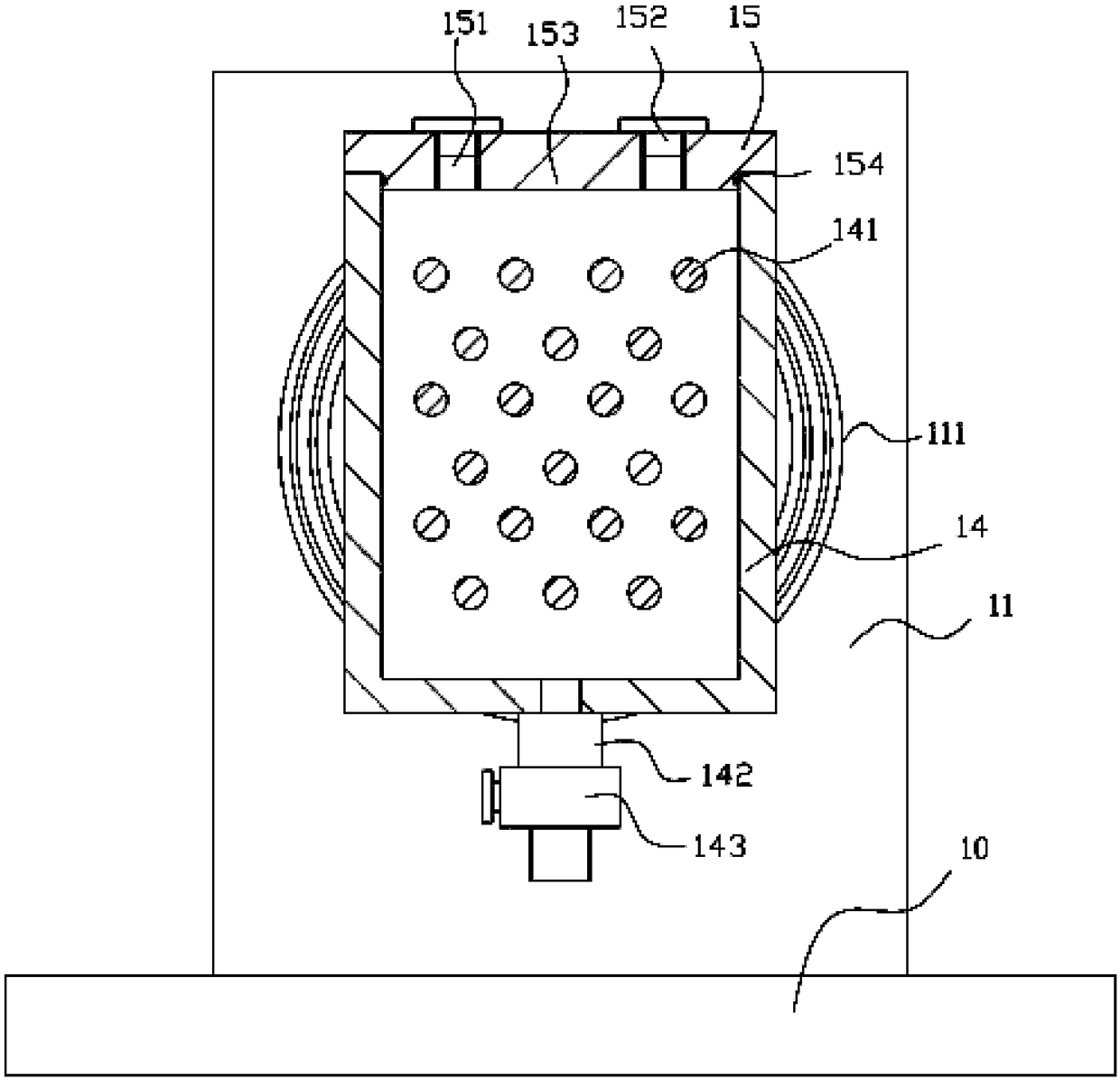

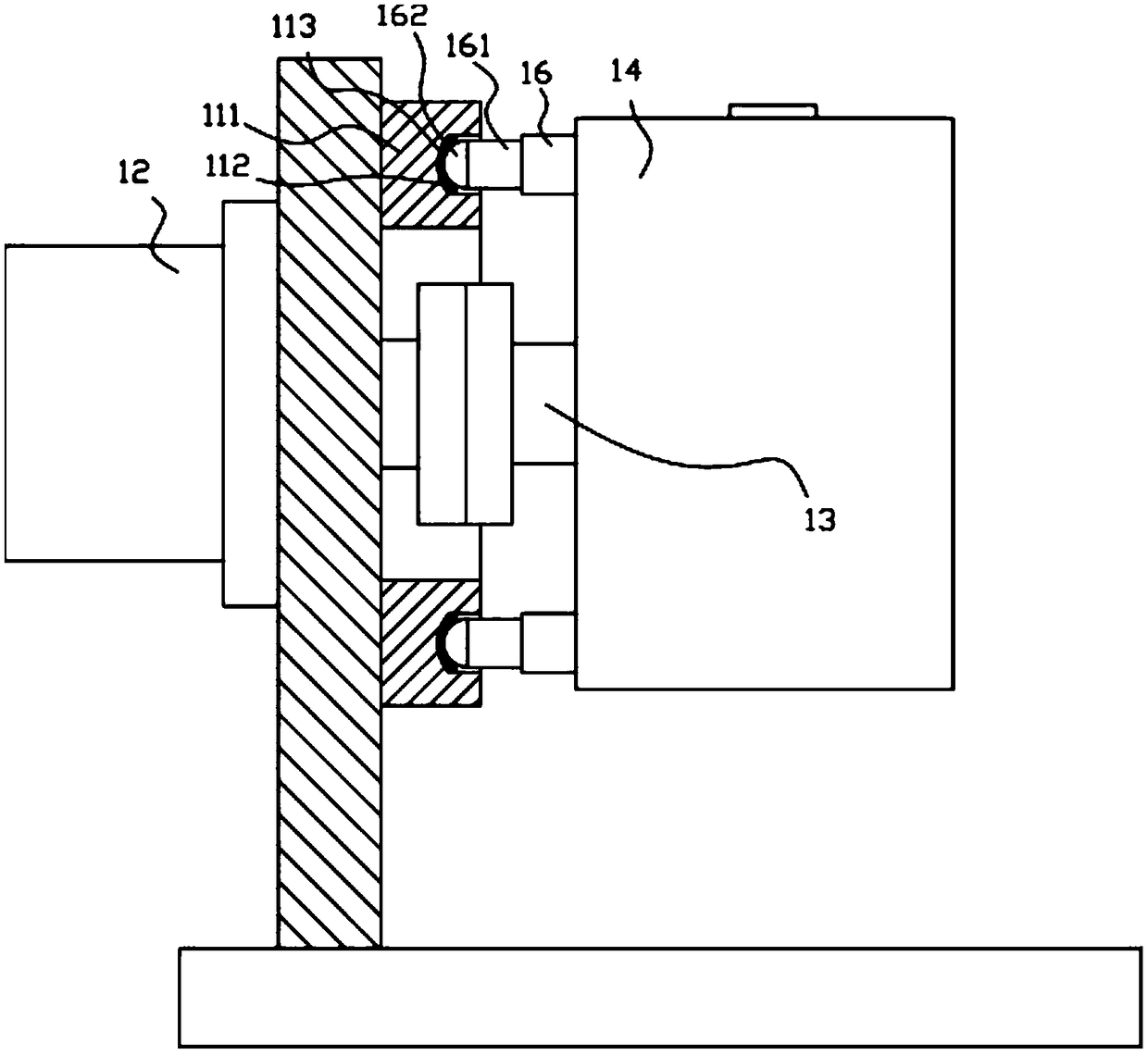

Vertical rotary chemical reagent mixing device

InactiveCN109173842AImprove the mixing effectImprove efficiencyRotating receptacle mixersTransportation and packagingCouplingCompound (substance)

The invention discloses a vertical rotary chemical reagent mixing device. The device comprises a fixed bottom plate, a main vertical plate is fixed to a rear portion of the top surface of the fixed bottom plate, the middle of the rear wall of the main vertical plate is fixedly provided with a rotating servo motor, an output shaft of the rotary servo motor passes through the main vertical plate andis connected to a rotation shaft through a coupling device, the front end of the rotation shaft is fixedly provided with a mixing tank, the top of the mixing tank is fixedly provided with a cover, atop plate of the cover is provided with a plurality of feeding screw-connecting through holes, the top of the feeding screw-connecting through hole is connected to a plug through a screw, a pluralityof stirring columns are arranged in the mixing tank, two ends of the stirring column are fixed to inner side walls of the mixing tank, the stirring columns have multiple layers, each layer comprises the multiple stirring columns and the stirring columns in upper and lower layers are staggered from each other. The device can automatically rotate and mix two mixing reagents, has good mixing effects,has high efficiency, is free of manual stirring or shaking and greatly reduces the labor.

Owner:SUZHOU AORAN COMMODITY

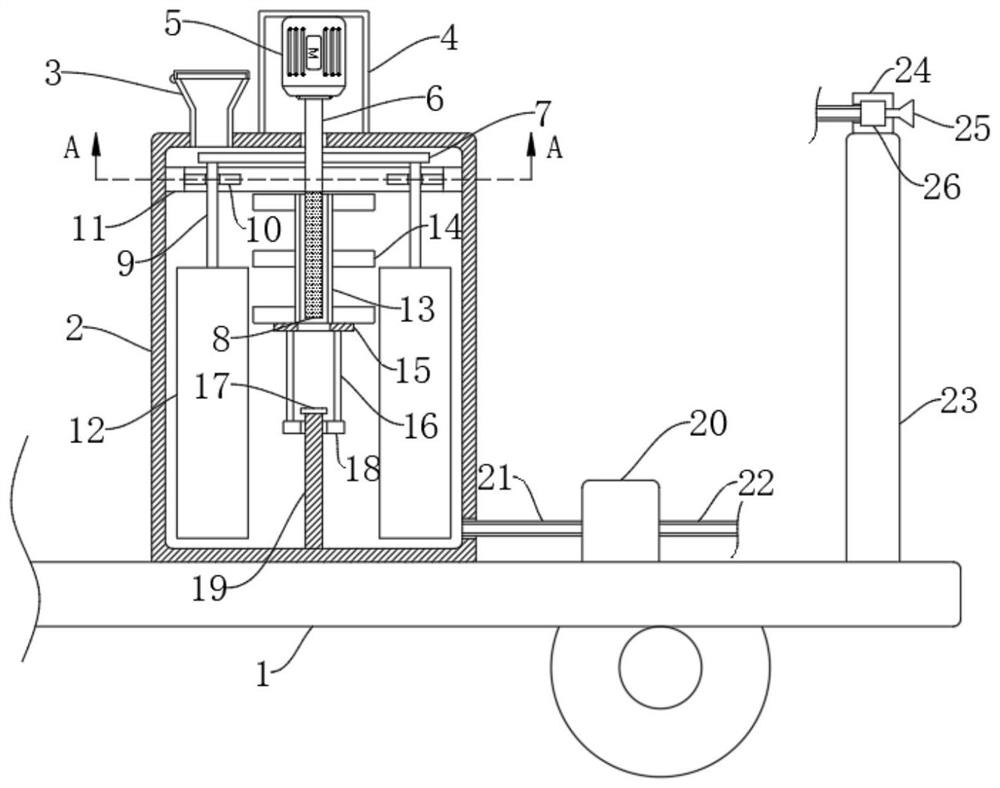

Spraying fire extinguishing equipment prepared through gel, manufacturing method thereof and gel spraying method

InactiveCN103352715AEasy to useConducive to emergency fire fightingDust removalFire preventionBiochemical engineeringStationary state

The invention relates to spraying fire extinguishing equipment prepared through gel, a manufacturing method for the spraying fire extinguishing equipment and a gel spraying method. The spraying fire extinguishing equipment prepared through the gel comprises a solvent tank, a gel raw material box, a solvent conveying pipe and a discharging pipe, wherein non-polar solvent is accommodated in the solvent tank; gel raw materials are accommodated in the gel raw material box; one end of the solvent conveying pipe stretches to the bottom of the solvent tank, the other end of the solvent conveying pipe stretches inside the gel raw material box, the solvent conveying pipe comprises a conveying pipe valve, and the conveying pipe valve is located between the solvent tank and the gel raw material box and is used for controlling the non-polar solvent to flow into the gel raw material box from the solvent tank; one end of the discharging pipe stretches to the bottom of the gel raw material box, the other end of the discharging pipe is a discharging outlet used for discharging a mixture of the gel raw materials and the non-polar solvent, the discharging pipe is provided with a discharging pipe valve, and the discharging pipe valve is used for controlling discharging of the mixture and is close to the discharging outlet. In a stationary state, the conveying pipe valve and the discharging pipe valve are in closed states, the pressure P1 of gas in the gel raw material box is larger than external pressure, and the pressure P2 of gas in the solvent tank is larger than P1.

Owner:XIAN UNIV OF SCI & TECH +1

Gel preparation sprinkler fire extinguishing equipment, its manufacturing method and method of spraying gel

InactiveCN103352715BEasy to useConducive to emergency fire fightingDust removalFire preventionGel preparationSolvent

The present application relates to a gel preparation sprinkler fire extinguishing equipment, a manufacturing method thereof and a method for spraying the gel. The spray fire extinguishing equipment for gel preparation comprises: a solvent box, in which a non-polar agent solvent is contained; a gel raw material box, in which a gel raw material is contained; a solvent delivery pipe, one end of which extends into the bottom of the solvent box, and the other One end stretches into the gel raw material box, and the solvent delivery pipe includes a delivery pipe valve for controlling non-polar agent solvent flowing into the gel raw material box from the solvent box at the part between the solvent box and the gel raw material box; And the discharge pipe, one end of which extends into the bottom of the gel raw material box, and the other end is a discharge outlet for discharging the mixture of the gel raw material and the non-polar agent solvent. There is a discharge pipe valve for controlling the discharge of the mixture at the pipe, wherein, in a static state, the delivery pipe valve and the discharge pipe valve are in a closed state, and the pressure P1 of the gas in the gel raw material box is greater than the external pressure, The pressure of the gas in the solvent tank is P2>P1.

Owner:XIAN UNIV OF SCI & TECH +1

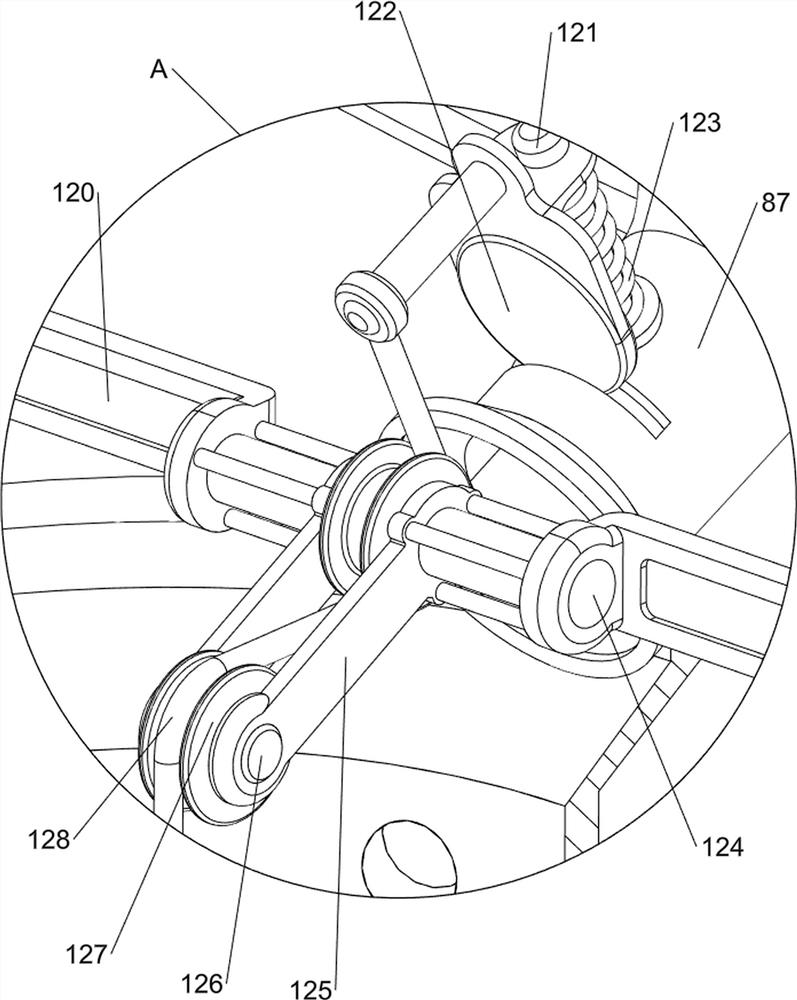

An asphalt heating and mixing system for civil engineering and its processing technology

ActiveCN108772012BStir wellRealize the function of automatic intelligent control of self-heating stirringShaking/oscillating/vibrating mixersTransportation and packagingGas releaseMachining process

The invention relates to an asphalt heating and stirring system for civil engineering and its processing technology, comprising a bottom plate, a rotation adjustment device is installed on the bottom plate, a stirring device is installed on the outside of the bottom plate, and the stirring device is located directly above the rotation adjustment device. The stirring device includes a stirring installation frame installed on the bottom plate, and a stirring telescopic rod is installed at the lower end of the stirring mounting frame. The sleeve is equipped with a stirring buffer spring. The present invention can solve the existing problems in the existing asphalt heating process that the heated asphalt needs to be manually stirred, and the asphalt cannot be heated evenly during heating, and the irritating gas released after the asphalt is heated is seriously harmful to the human body, and the artificially stirred asphalt is uneven , the proportion of asphalt is relatively heavy, it is easy to deposit at the bottom and it is not easy to stir, and manual stirring takes a long time, labor intensity is high and work efficiency is low.

Owner:安徽省路恒建设科技有限公司

Building concrete preparation equipment

InactiveCN111958823AReduce wasteIncrease ejection speedMixing operation control apparatusCement mixing apparatusEnvironmental geologyMechanical engineering

The invention relates to the field of building construction, and particularly discloses building concrete preparation equipment. The building concrete preparation equipment comprises a stirring barreland a stirring unit which is mounted in the stirring barrel and further comprises a feeding unit, the feeding unit comprises a water inlet part capable of adding water into the stirring barrel and aplurality of feeding parts capable of adding cement or sand into the stirring barrel, the water inlet part and the feeding parts are fixed to the stirring barrel correspondingly, and the water inlet part and the feeding parts communicate with the stirring barrel correspondingly. According to the scheme, the stirring unit in the stirring barrel can stir and mix water, cement and sand in the stirring barrel, and the waste amount of concrete can be effectively reduced.

Owner:CHONGQING VOCATIONAL INST OF ENG

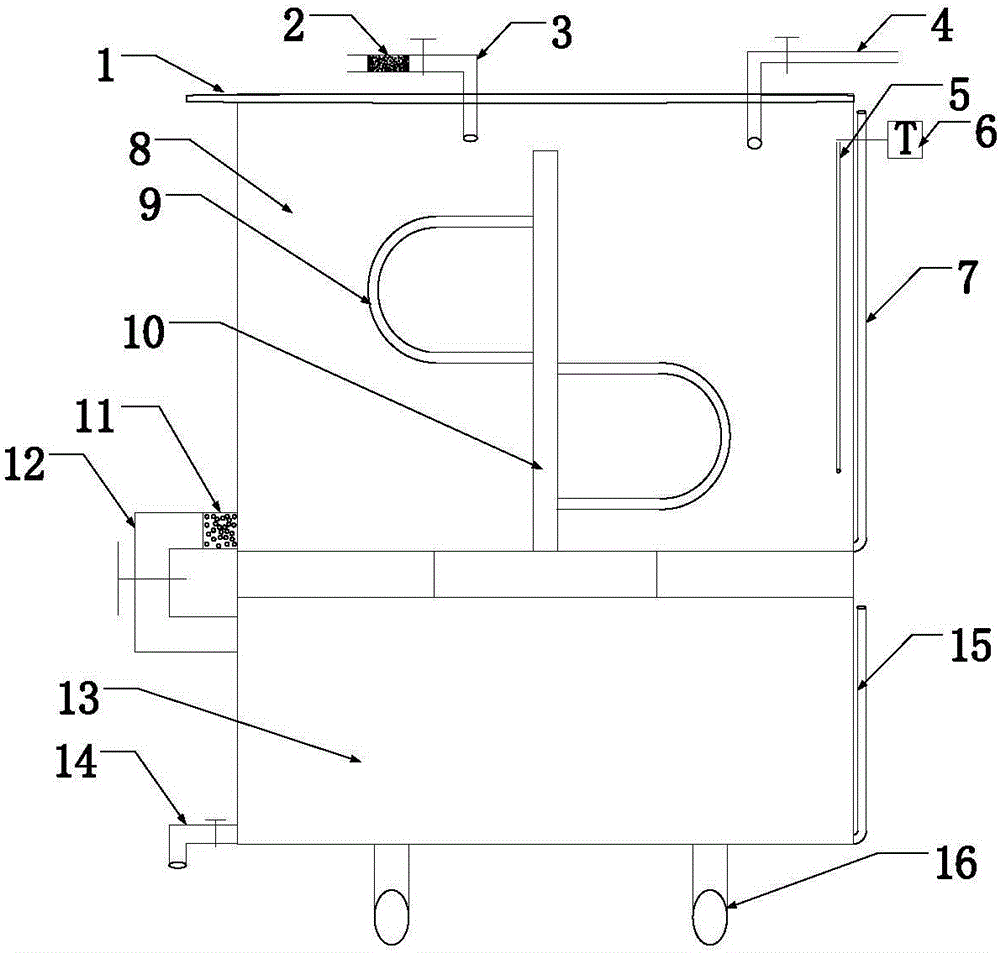

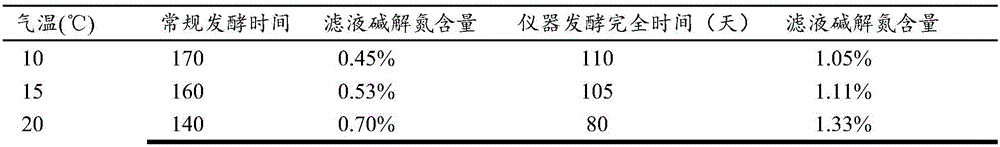

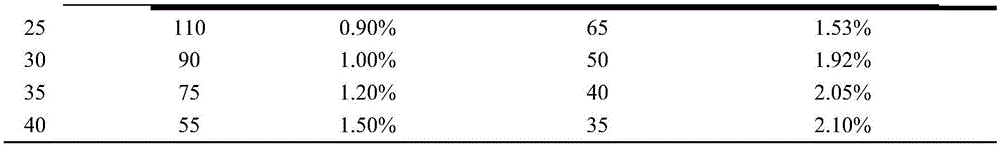

Oil cake fermentation device

InactiveCN105819908AReduce pollutionAvoid emissionsClimate change adaptationBioloigcal waste fertilisersDisplay deviceAgricultural engineering

The invention discloses an oil cake fermentation device. The oil cake fermentation device is provided with a gas outlet, a fermentation tank, and a liquid storage tank. A deodorizing adsorber is arranged in the gas outlet. A temperature display is arranged next to the external side of the fermentation tank. A first water level meter is arranged next to the temperature display. A stirrer is arranged in the middle part of the fermentation tank. The liquid storage tank and the fermentation tank are connected through a fluid director, a filter is arranged in the fluid director close to the bottom side of the fermentation tank, a second water level meter is arranged on the right side of the external end of the liquid storage tank; and a moving wheel is arranged on the lower end of the external side of the liquid storage tank. The oil cake fermentation device has the advantages that the fermentation place of the fermentation device is not limited, the fermentation device can be moved, the fermentation efficiency is high, the fermentation process can be monitored effectively, no environmental pollution is generated; the solid and liquid can be easily separated, artificial operation is reduced; the oil cake fermentation efficiency is high, the fermentation is radical, the solid and liquid can be radically separated; and the fermentation device is used to produce base fertilizer and additional fertilizer for organic plant production, and has the functions of fermentation and separation.

Owner:CHENGDU FANSHANG AGRI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com