Stirring apparatus of silicon wafer grinding liquid

A technology of stirring device and grinding liquid, applied in mixers with rotary stirring device, transportation, packaging, dissolving, etc., can solve the problems of uneven force, unqualified silicon wafer quality, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

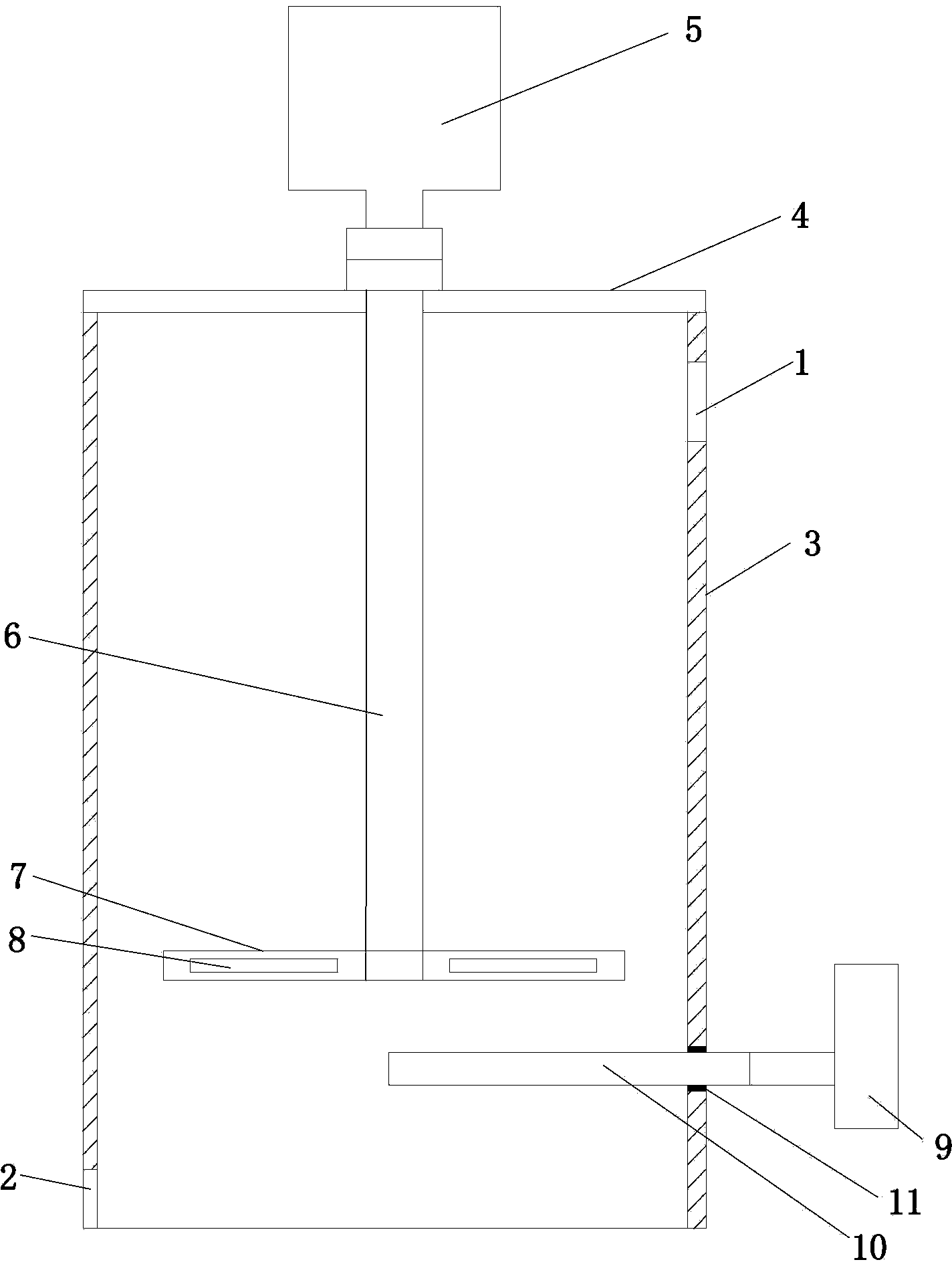

[0012] see figure 1 , a stirring device for silicon wafer grinding fluid, comprising a mixing tank body 3 with a liquid inlet 1 and a liquid outlet 2, the silicon wafer grinding fluid to be ground is added into the mixing tank body from the liquid inlet, and can be fed from the outlet The liquid flows out from the mouth, and a connection cover 4 is provided at the upper end of the mixing barrel body. The connection cover 4 is fixedly connected to the mixing barrel body through bolts, and the stirring motor 5 is fixedly arranged on the connection cover 4, so that the connection cover forms a support for the stirring motor. Regardless of whether the stirring motor is working or stopped, it is very firm; the output shaft of the stirring motor is connected to the stirring main shaft 6 through a coupling, so that the power of the stirring motor can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com