Test device and test method for wear test of filling slurry conveying pipeline

A technology for conveying pipelines and filling slurry, which is applied in the directions of measuring devices, testing wear resistance, and analyzing materials, etc. It can solve the problems of inability to carry out pipeline wear tests, inapplicability, and easy wear of pipelines, so as to achieve efficient and high-quality preparation, prevent Segregation and sedimentation, good test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

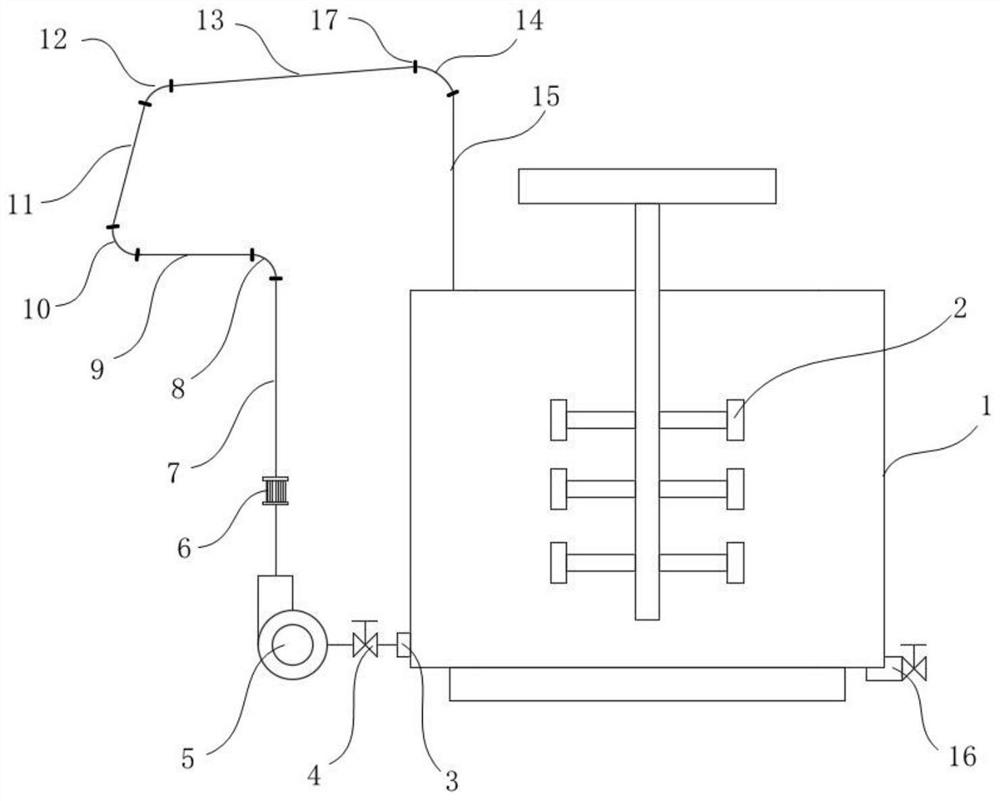

[0038] like figure 1 As shown, a test device for the wear test of the filling slurry conveying pipeline includes a stirring tank 1, a conveying assembly connected to the output end of the stirring tank 1, and a test pipe assembly connected to the output end of the conveying assembly. The test pipe The output end of the assembly is connected to the input end of the stirring tank 1 to recycle the filling slurry, so as to study the wear law of the test pipe assembly with less test material. The conveying component is preferably a frequency conversion slurry pump 5, by controlling the pumping frequency of the frequency conversion slurry pump 5, the research on the pipeline wear of the filling slurry at different flow rates can be realized. The test pipeline assembly includes several interconnected horizontal pipelines 9, elbows, inclined pipelines and vertical pipelines, which can simulate various slurry transportation conditions.

[0039] With such a setting, the research on the...

Embodiment 2

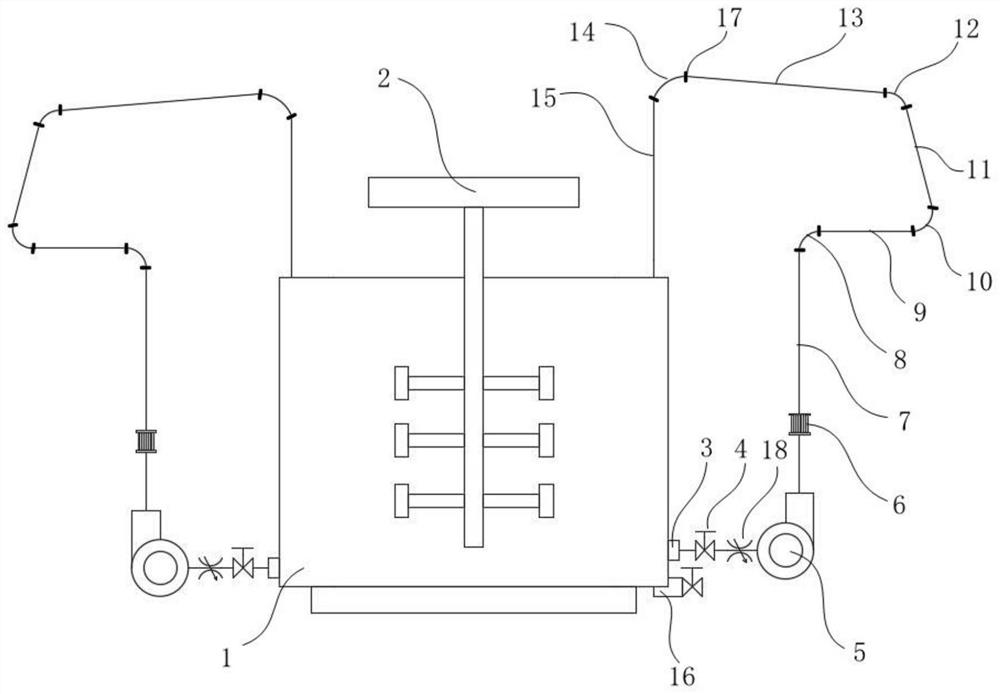

[0062] like figure 2 As shown, in this embodiment, the bottom of the stirring tank 1 is provided with a plurality of outlets 3 . The conveying assembly includes a plurality of frequency conversion slurry pumps 5 respectively connected to the outlet 3 of the stirring tank 1 . Moreover, on-off valves 4 and flow valves 18 are provided on the connecting pipelines between each frequency conversion slurry pump 5 and the stirring tank 1 .

[0063] In this embodiment, the test pipeline assembly includes multiple sets of test pipelines respectively connected to multiple frequency conversion slurry pumps 5 , and each set of test pipelines includes multiple types of delivery pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com