Gel preparation sprinkler fire extinguishing equipment, its manufacturing method and method of spraying gel

A kind of fire extinguishing equipment and gel technology, which is applied in the field of coal seam fire prevention and control, can solve the problems of automatic fire extinguishing device without polymer gel, difficulty in extinguishing fire with glue injection, power supply interruption, etc., achieves improved fire extinguishing effect, has explosion-proof performance, and prolongs storage The effect of deadlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will now be described in detail in accordance with the accompanying drawings. Note that the relative arrangement of the components and the shape of the device in the embodiments are only described as examples, and it is not intended to limit the scope of the present invention to these examples. In addition, similar reference numerals and letters refer to similar items in the figures, and thus, as long as one item is defined in one figure, there is no need to discuss the item for subsequent figures.

[0020] First, the first embodiment of the gel preparation spray fire extinguishing equipment according to the present invention will be described.

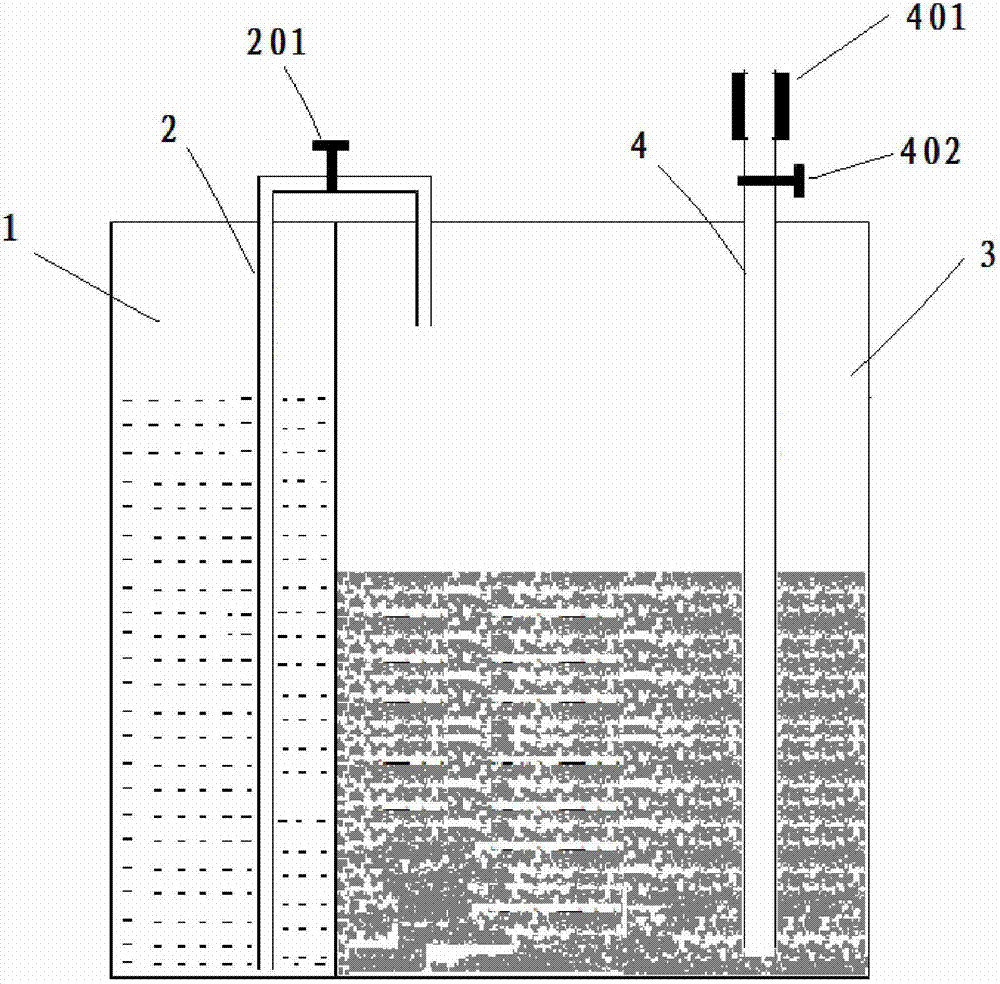

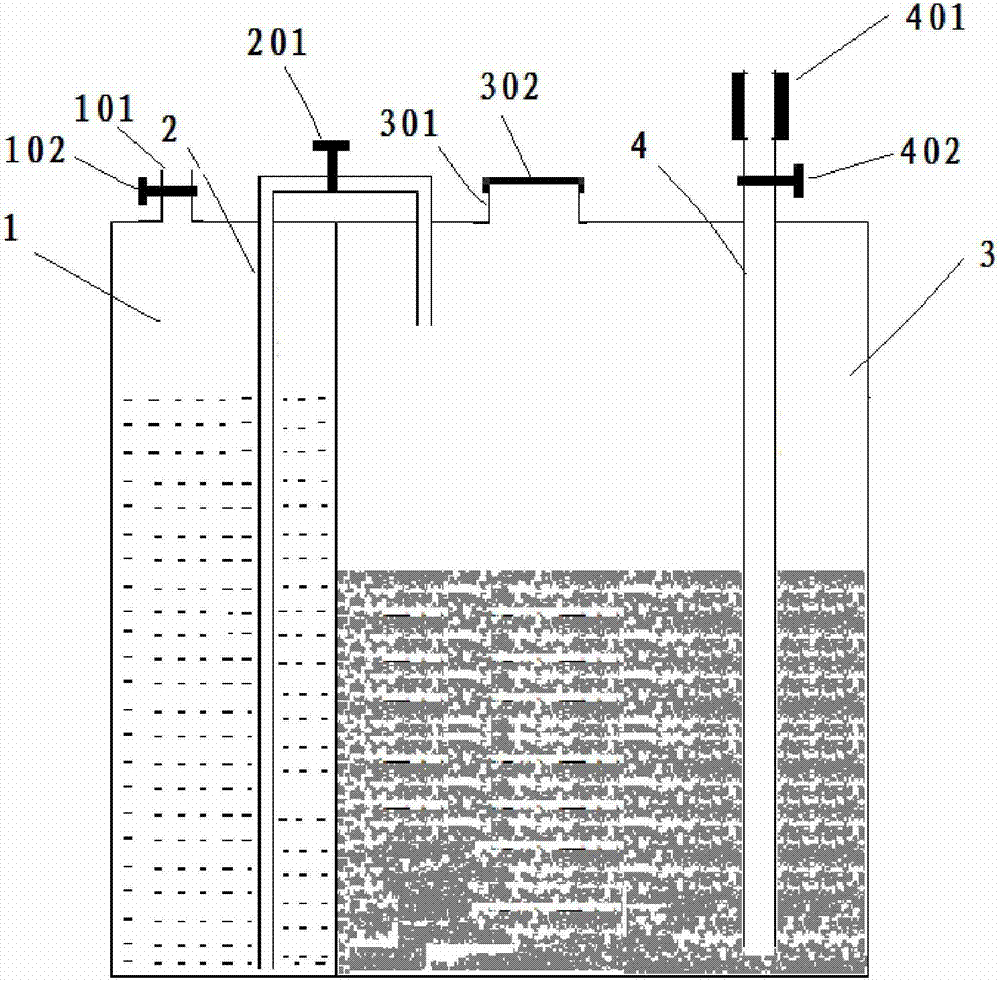

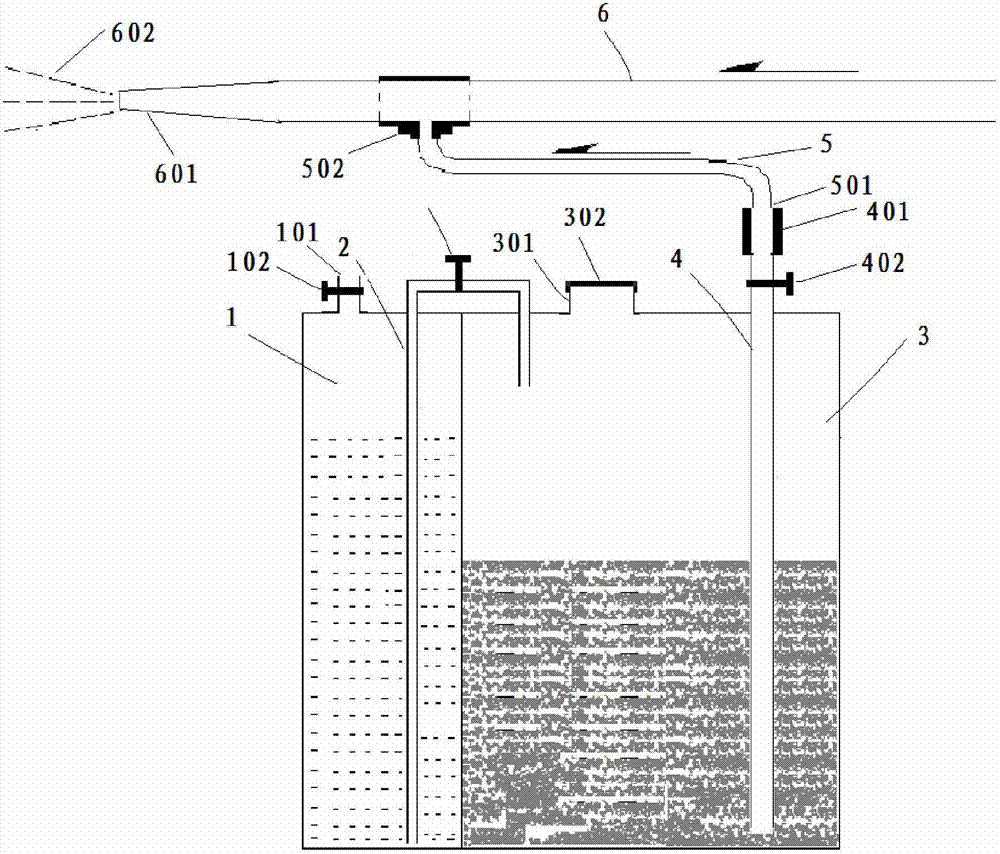

[0021] figure 1 It is a schematic diagram of a gel preparation spray fire extinguishing device according to the first embodiment of the present invention. Such as figure 1 As shown, the gel preparation spraying fire extinguishing equipment according to the first embodiment includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com