Building concrete preparation equipment

A technology for concrete and equipment, applied in the field of construction concrete configuration equipment, can solve the problems of waste of concrete and the easy adhesion of concrete to the ground, and achieve the effects of reducing the amount of waste, reducing the amount of waste, and accelerating the spraying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

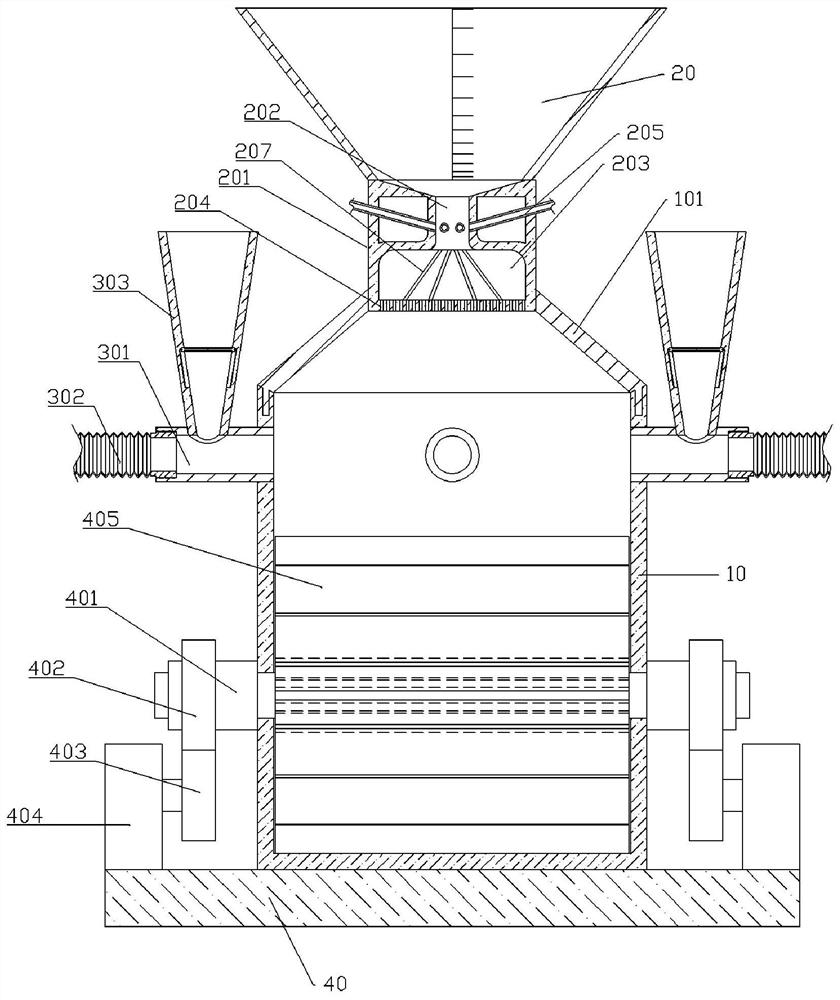

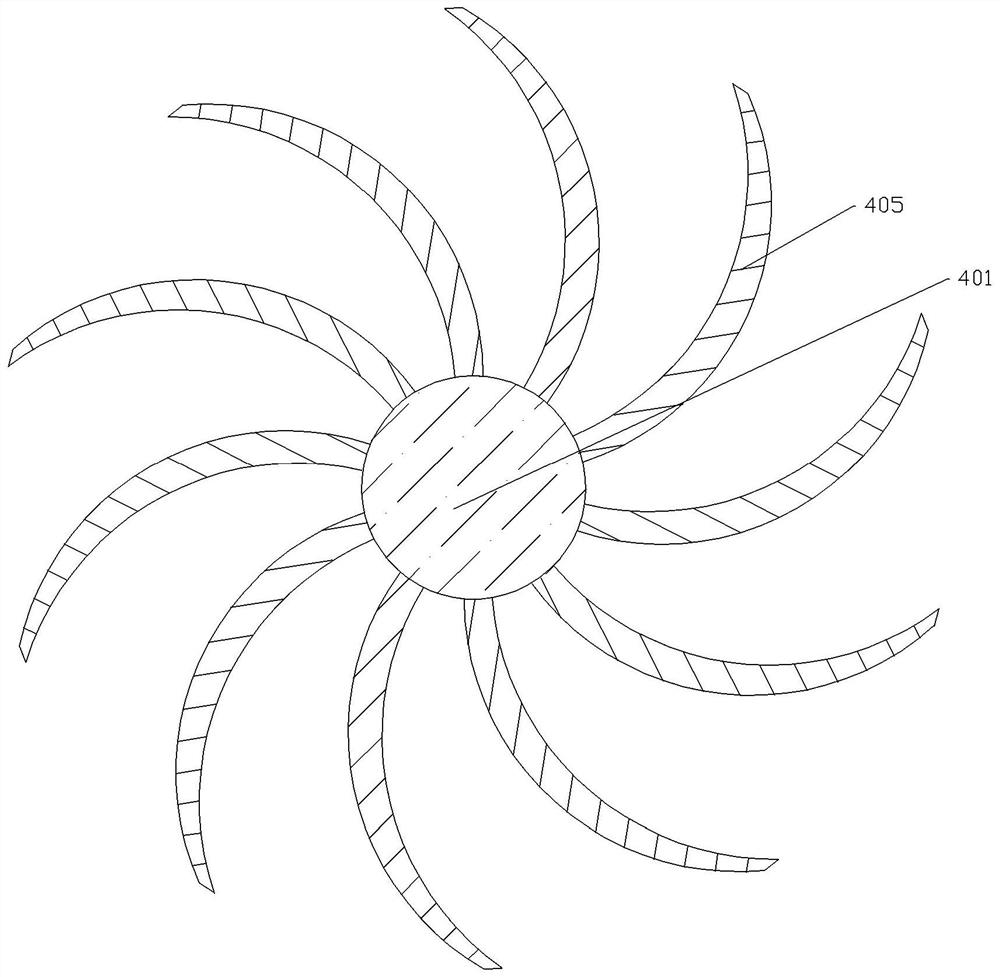

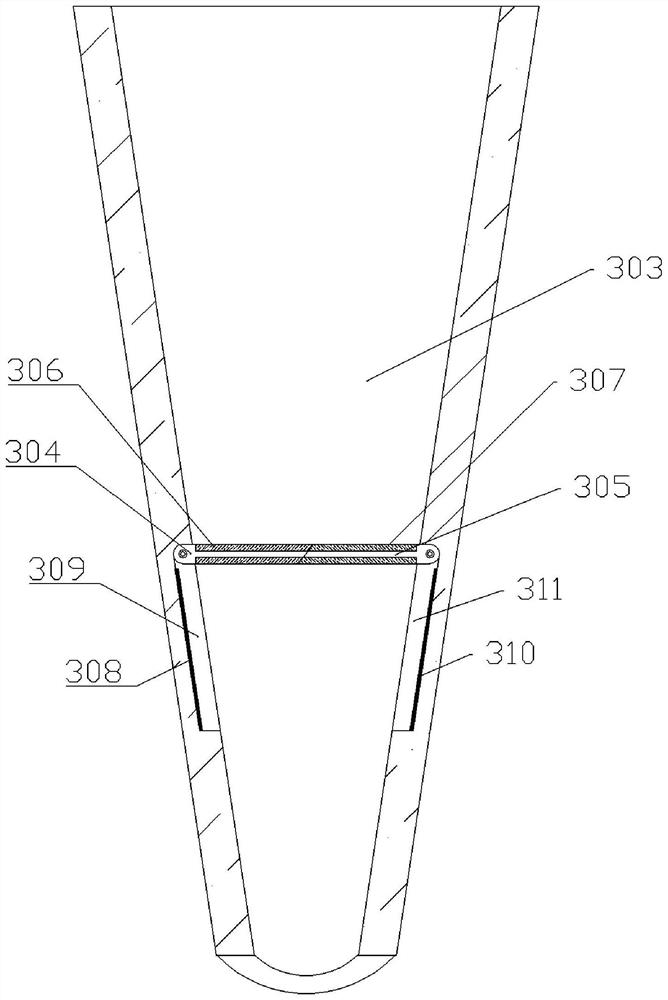

[0035] Embodiment 1 is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: construction concrete configuration equipment, including mixing tank 10, six air intake pipes 205, air intake pump (not shown), receiving part, mixing unit installed in mixing tank 10 and feeding unit, the upper end of mixing tank 10 is an open mouth, and the upper end of the mixing bucket 10 is inserted with a bucket cover 101.

[0036] Such as figure 1As shown, the feeding unit includes a water inlet part that can add water into the mixing bucket 10 and four feeding parts that can add cement or sand into the mixing bucket 10. The water inlet box 201 welded at the lower end of the water box 20 is provided with a scale 206 for marking the amount of water on the water box 20, and the water inlet box 201 is sequentially provided with a water inlet 202, a water inlet chamber 203 and several The water spray hole 204 connected to the water inlet chamber 203, the upper end of ...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is that embodiment 2 is basically as attached Figure 4 , attached Figure 5 And attached Figure 6 As shown, the bottom surface of the mixing tank 10 is provided with a discharge hole 102, the discharge hole 102 is provided with a switch valve 103, the discharge hole 102 of the mixing tank 10 is coaxially glued with a discharge pipe 50, and the mixing tank 10 It is communicated with the discharge pipe 50, and the discharge pipe 50 is a bellows; as Figure 4 As shown, the right end of the discharge pipe 50 is glued with a discharge box 501 , and the right end of the discharge box 501 is provided with a discharge port 502 communicating with the discharge pipe 50 .

[0047] Such as Figure 6 As shown, four slots 503 are arranged on the inner wall of the left side and the right side of the discharge box 501, and the four slots 503 on the left side and the right side are opposite in turn, and inserting pieces can be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com