Pre-dispersed masterbatch of scorch-resistant comprehensive accelerator for rubber as well as preparation method

A technology of pre-dispersing masterbatches and accelerators, which is applied in the field of rubber additives. It can solve the problems that the broken crosslinks cannot be replenished, the rubber is prone to scorching, and the vulcanization flattening period is shortened, so as to improve the scorching phenomenon. , to ensure fluidity, to avoid the effect of lack of material and less glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The anti-scorch integrated accelerator pre-dispersed masterbatch for rubber in Example 1 consists of 13 parts of rubber matrix, 60 parts of thiazole accelerator, 15 parts of anti-scorch agent, 10 parts of softener and 2 parts of processing aid.

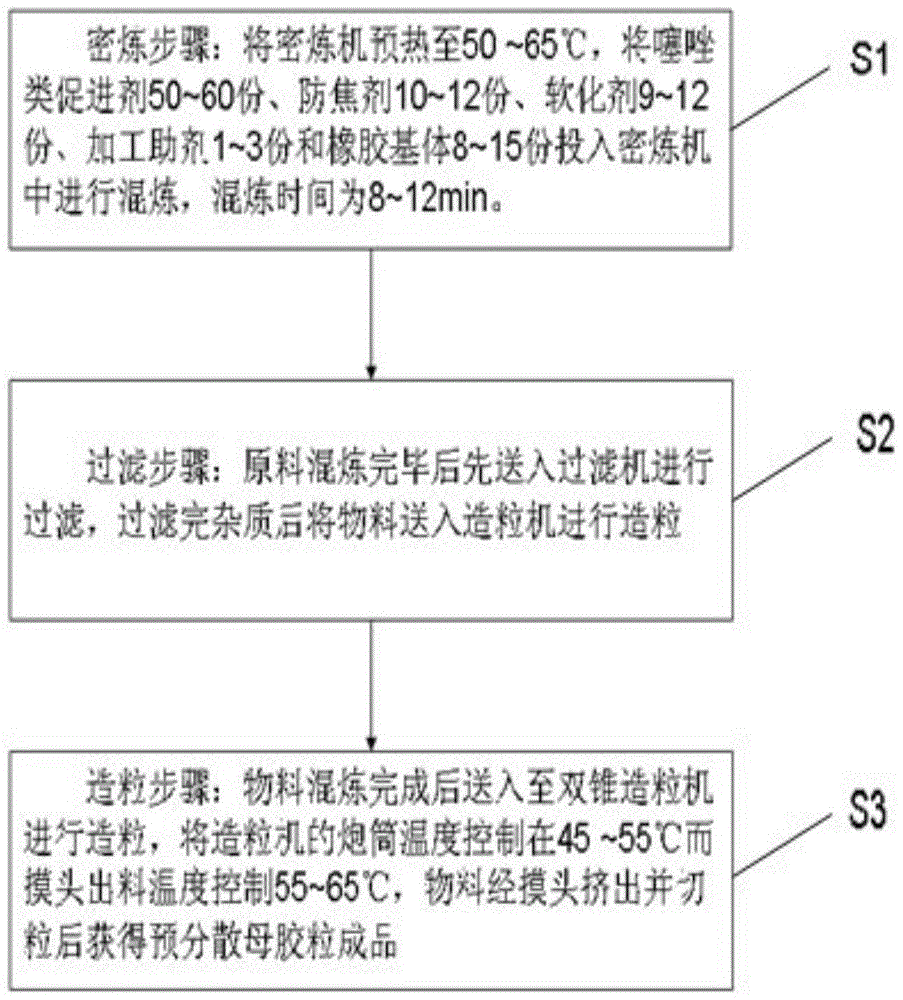

[0020] The preparation method of this pre-dispersed masterbatch is as follows figure 1 shown, including the following steps:

[0021] S1 Internal mixing step: Preheat the internal mixer to 50-65°C, accurately weigh the rubber matrix, thiazole accelerator, anti-scorch agent, softener and processing aid according to the proportion and put them into the internal mixer for mixing , the mixing time is about 8 to 12 minutes;

[0022] S2 Filtration step: After the raw materials are mixed, they are first sent to a filter for filtration. The filter uses a screen with a mesh size of 120 or more to filter large particles of impurities in the colloidal material, and then the material is sent to a granulator for granulation;

[0023] S3 g...

Embodiment 2

[0024] The composition of the anti-scorch comprehensive accelerator pre-dispersed masterbatch for rubber in Example 2: 15 parts of rubber matrix, 55 parts of thiazole accelerator, 20 parts of anti-scorch agent, 9 parts of softener and 1 part of processing aid; The preparation method of the micelle is the same as that of Example 1; the anti-scorch comprehensive accelerator pre-dispersed masterbatch of Example 2 is obtained. After testing, the Mooney value of the masterbatch is ML(1+4)min, 9.86 at 50°C, and the density at 20°C is 1.44g / cm 3 .

Embodiment 3

[0025] The composition of the anti-scorch comprehensive accelerator predispersed masterbatch for rubber in Example 3: 15 parts of rubber matrix, 60 parts of thiazole accelerator, 10 parts of anti-scorch agent, 12 parts of softener and 3 parts of processing aid; The preparation method of the micelle is the same as that of Example 1; the anti-scorch comprehensive accelerator pre-dispersed masterbatch of Example 3 is obtained. After testing, the Mooney value of the masterbatch is ML(1+4)min, 57.12 at 50°C, and the density at 20°C is 1.45g / cm 3 .

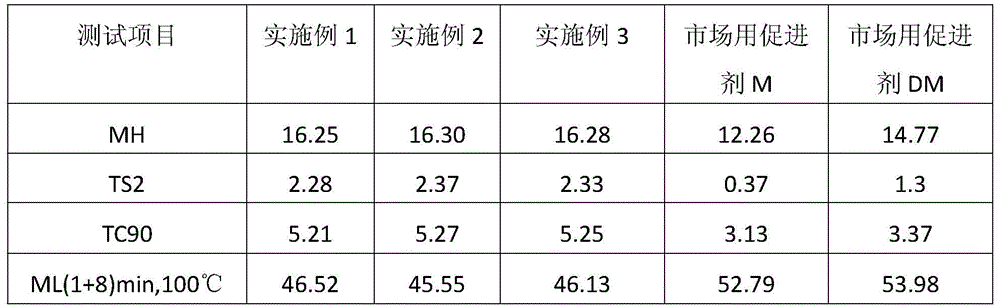

[0026] Anti-scorch comprehensive accelerator pre-dispersed masterbatch particles for rubber provided by the invention, through accelerator M (MBT) (2-thiol benzothiazole) and accelerator DM (MBTS) (dibenzothiazole disulfide) The experimental comparison of the two kinds of accelerators shows that the comprehensive accelerator for rubber of the present invention has a very long scorch period according to the test data of the rheometer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com