Preparation method of Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline/amorphous composite material

A fe66co10mo4p4c4b4si3, amorphous composite material technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of annealing brittleness and stress sensitivity, long processing time, complicated equipment, etc., and achieve excellent soft magnetic properties and short processing process , The effect of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A kind of Fe 66 co 10 Mo 4 P 4 C 4 B 4 Si 3 A method for preparing bulk soft magnetic nanocrystal / amorphous composite material gold, comprising the following steps:

[0027] (1) The design composition is Fe 66 co 10 Mo 4 P 4 C 4 B 4 Si 3 The Fe-based bulk amorphous alloy is made of pure metal with a purity of more than 99.9% and an intermediate alloy as the raw material ratio. The master alloy with uniform composition is obtained by repeated melting by arc melting, and the master alloy is melted again by induction melting. A bulk amorphous alloy with a diameter of 2mm was produced by copper mold casting.

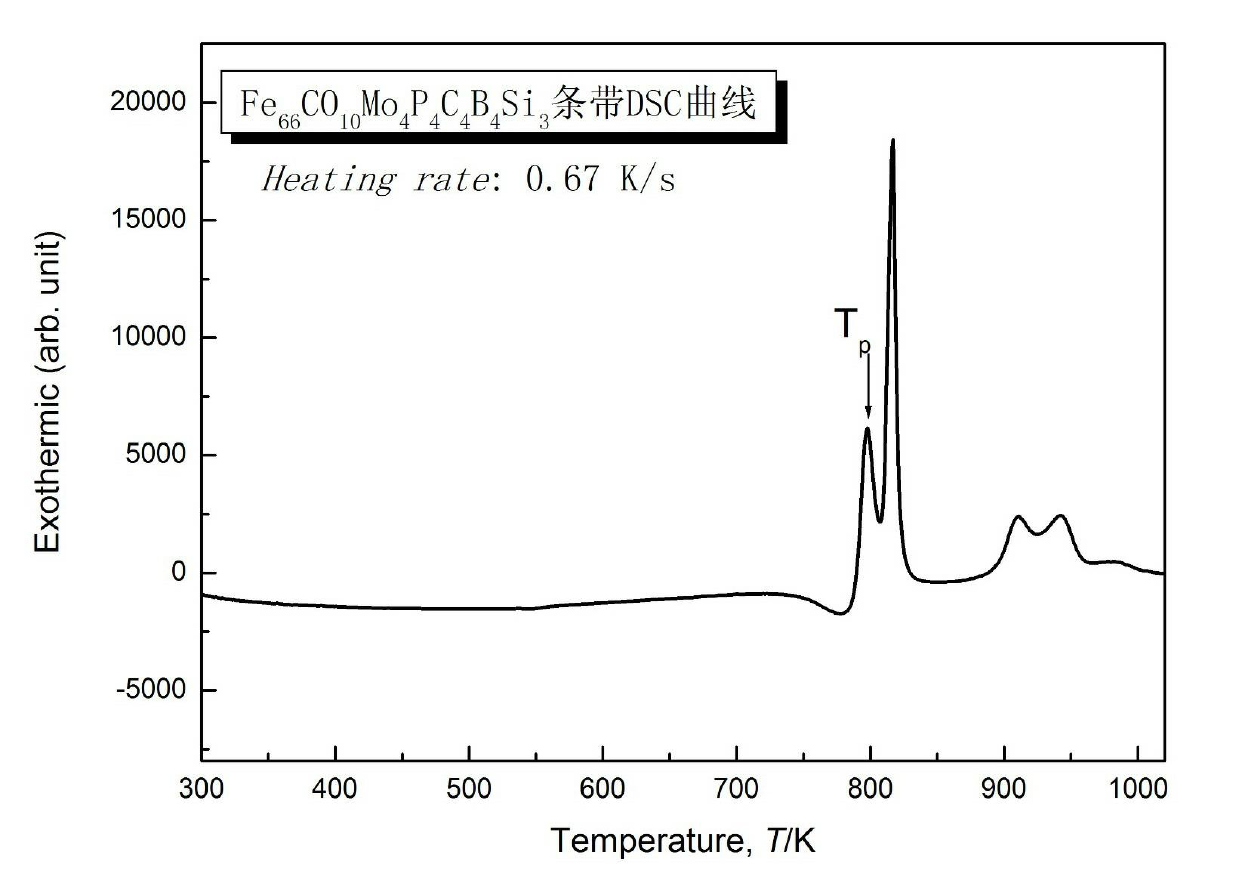

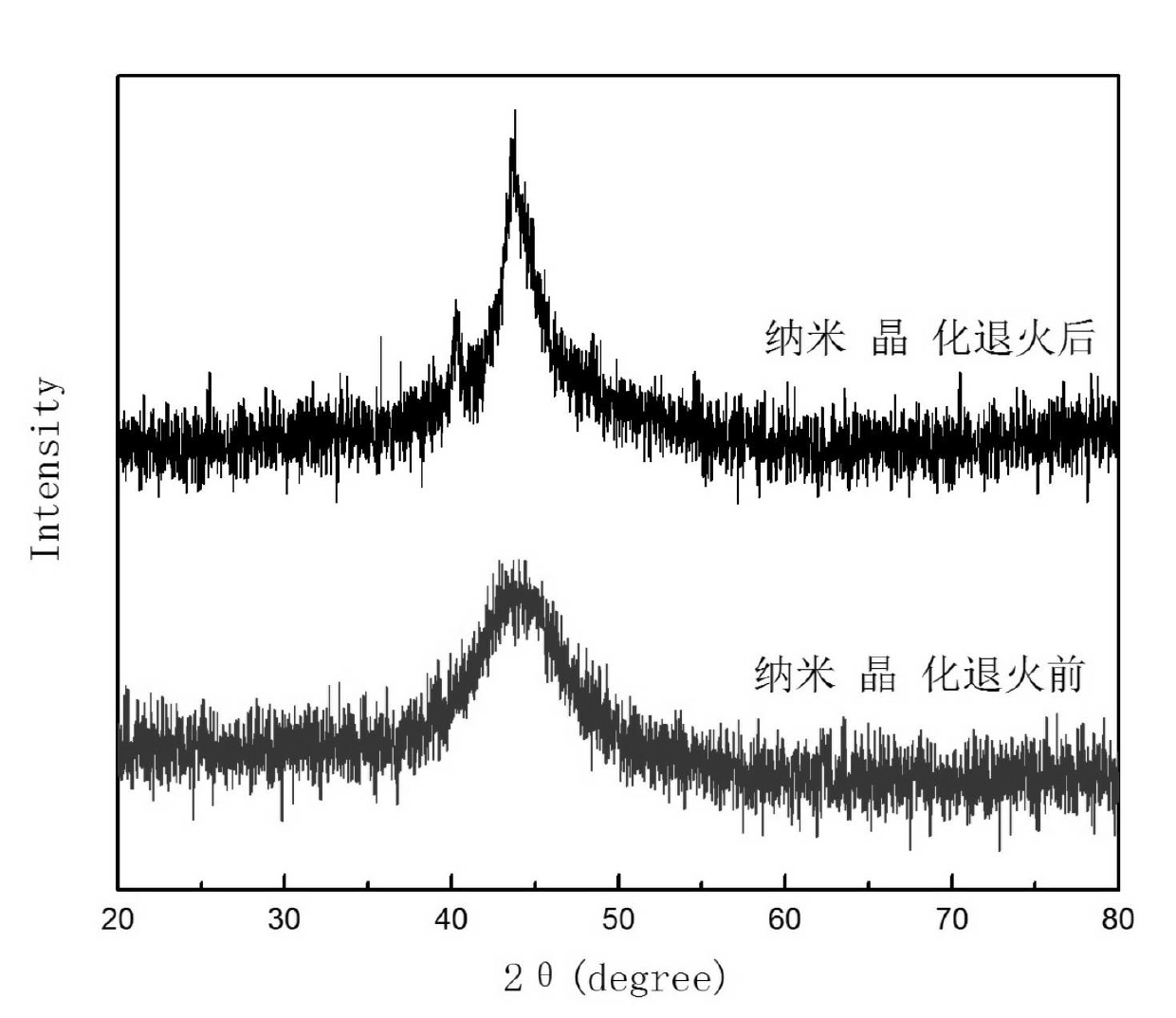

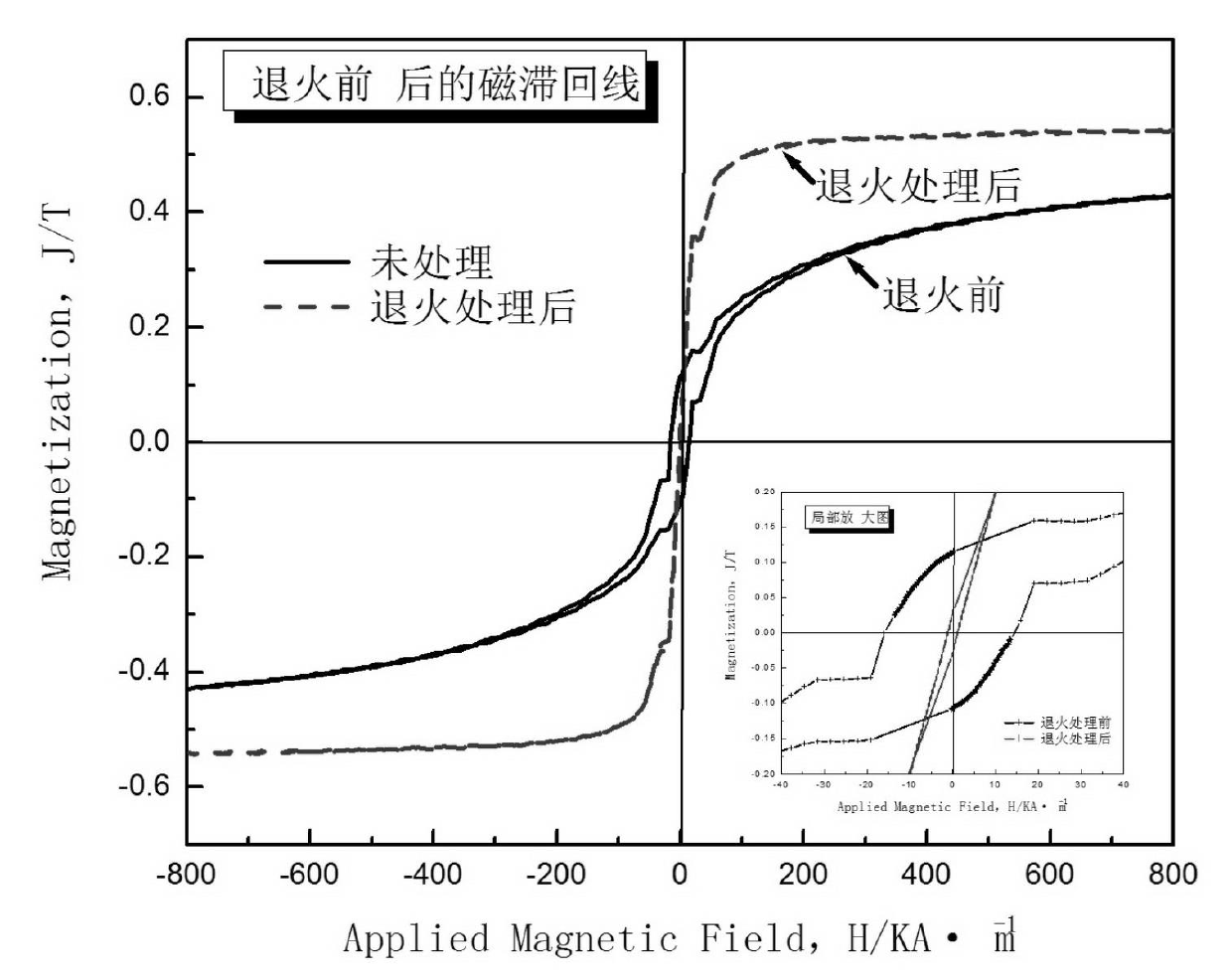

[0028] (2) For the Fe obtained in the previous step 66 co 10 Mo 4 P 4 C 4 B 4 Si 3 For DSC analysis of amorphous samples, see figure 1 , to obtain the crystallization peak temperature T of the composition alloy p The temperature was 522°C, and the sample was vacuum annealed at this temperature for 10 minutes.

[0029] (3) The temperatu...

Embodiment 2

[0034] Example 2 A kind of Fe 66 co 10 Mo 4 P 4 C 4 B 4 Si 3 A method for preparing bulk soft magnetic nanocrystal / amorphous composite material gold, comprising the following steps:

[0035] (1) The design composition is Fe 66 co 10 Mo 4 P 4 C 4 B 4 Si 3 The Fe-based bulk amorphous alloy is made of pure metal with a purity of more than 99.9% and an intermediate alloy as the raw material ratio. The master alloy with uniform composition is obtained by repeated melting by arc melting, and the master alloy is melted again by induction melting. A bulk amorphous alloy with a diameter of 2mm was produced by copper mold casting.

[0036] (2) Carry out DSC analysis (same as Example 1) to the amorphous sample, and obtain the crystallization peak temperature T of the composition alloy p It is 522°C. The samples were vacuum annealed at this temperature for 5 minutes.

[0037] (3) The temperature of the high-temperature resistance furnace is raised to 522°C, and after the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com