Cold crucible vacuum inductive smelting device having energy beam auxiliary heat source

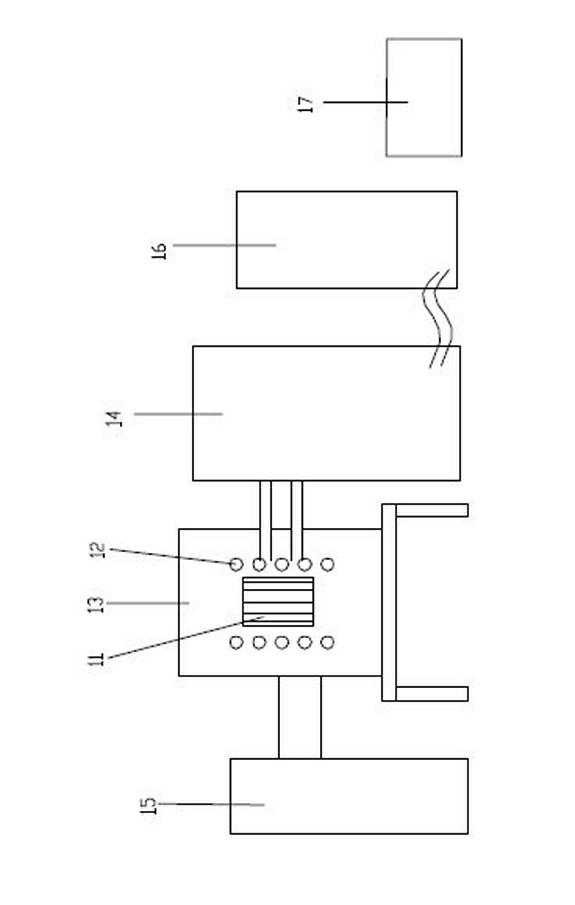

A vacuum induction melting and auxiliary heat source technology, applied in lighting and heating equipment, crucible furnaces, furnaces, etc., can solve problems such as inability to melt refractory metals and alloys, and achieve uniform structure, favorable compactness and consistency, and accurate composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

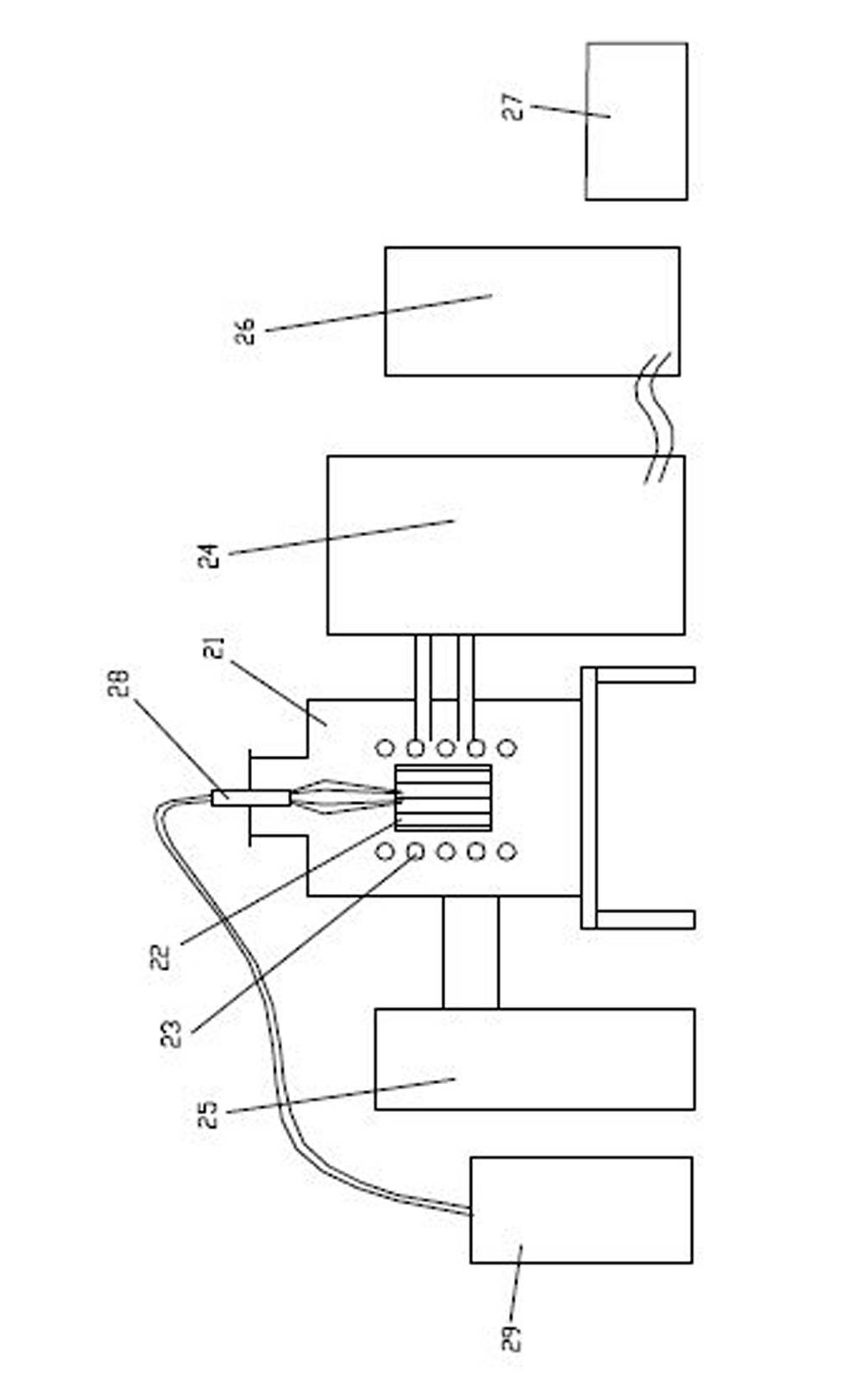

[0059] Preparation Example 1: Smelting of Metal Tungsten

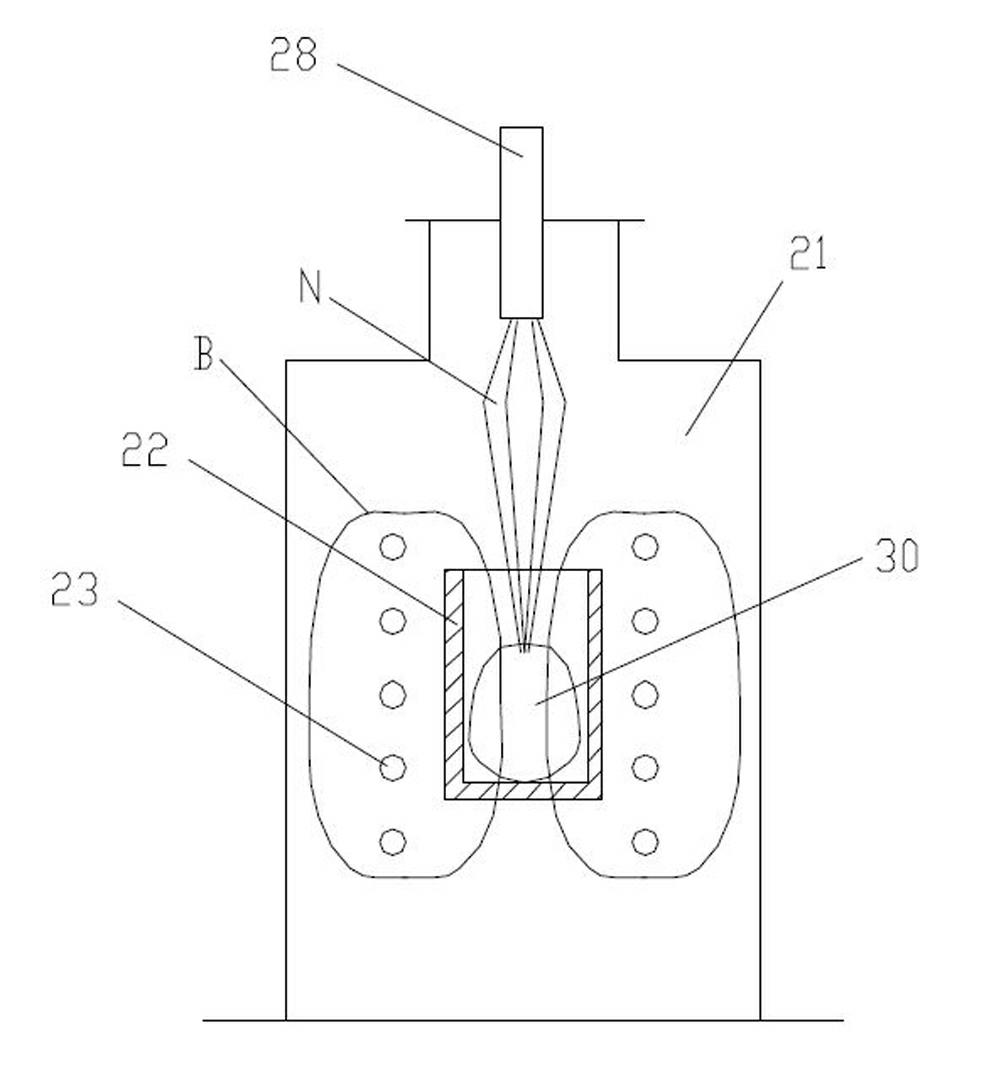

[0060] Put 10kg compacted tungsten powder billet into figure 2 In the cold crucible 22 of the shown cold crucible vacuum induction melting furnace, the power of the intermediate frequency power supply is 250kw, and the frequency is 15kHz. In this smelting furnace, the energy beam emitting head 28 and the energy beam generator 29 as the auxiliary heat source adopt an arc beam—the tungsten electrode is installed above the cold crucible 22, and the power of the DC power supply supplying the electrode is 100kw.

[0061] After the equipment is started, vacuumize first, and the vacuum degree reaches 5×10 -3 Pa is filled with 0.05MPa high-purity argon, and then the intermediate frequency power supply 24 is started to heat the charge to 1200°C. At this time, start the DC power supply to supply power to the electrode, and form a molten pool with a temperature exceeding 3600°C in the charge. Increase the power delivered by t...

preparation Embodiment 2

[0063] see Figure 4 , this embodiment adds a tilting pouring mechanism on the basis of the first embodiment. At the end of smelting, the energy beam emission is stopped, but the electromagnetic field continues to work, while the cold crucible 22 is tilted, and the melt 30 is poured into the casting mold 31 .

preparation Embodiment 3

[0065] see Figure 5 , this embodiment adds a bottom injection mechanism on the basis of the first embodiment. At the end of smelting, both the energy beam N and the electromagnetic field B continue to work, and at the same time, the injection port 32 at the bottom of the cold crucible 22 is opened, so that the melt 30 is injected into the casting mold 31 through the injection port 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com