1:1 type plugging epoxy grouting material as well as preparation method and application thereof

A grouting material and leaking epoxy technology, which is applied in the field of waterproofing and plugging, can solve the problems of repeated leakage and high brittleness of the consolidated body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

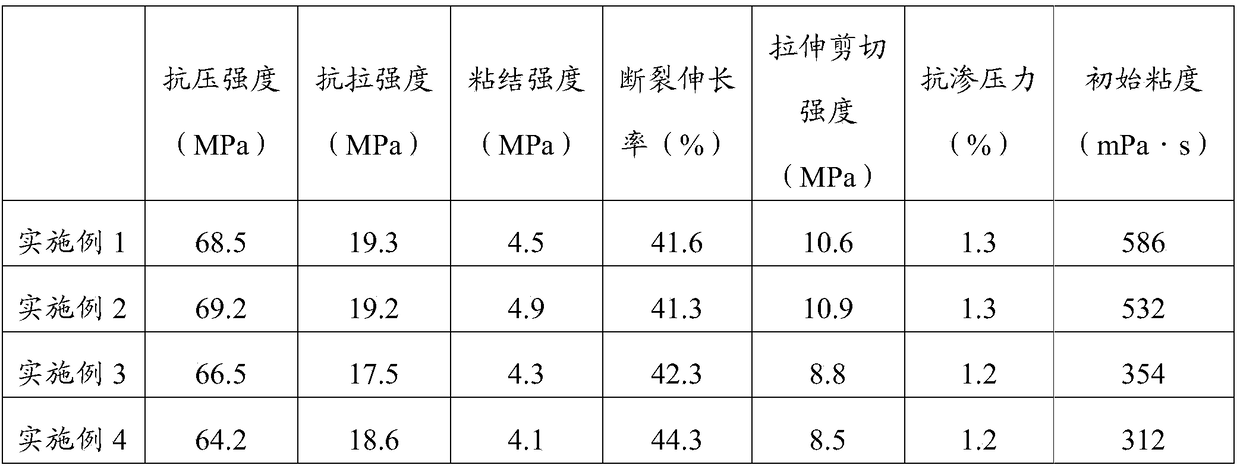

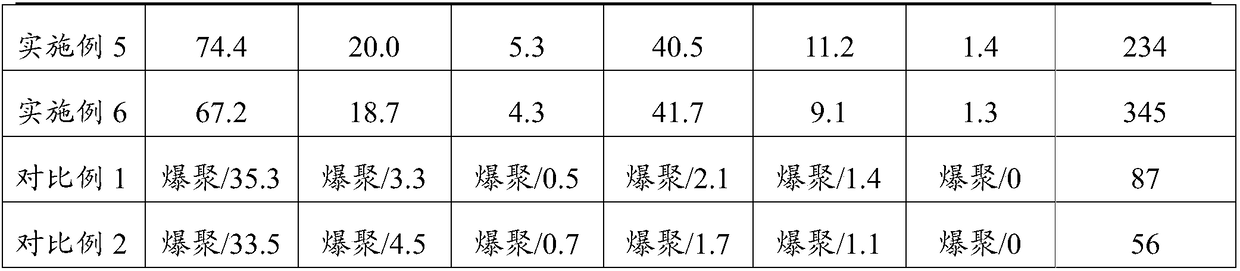

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned 1:1 type leak-stopping epoxy grouting material according to an embodiment of the present invention includes the following steps S1-S2:

[0032] S1. Mix the amine curing agent, viscosity diluent and modifier and stir evenly. After reflux reaction for 3-5 hours, add the remaining raw materials of component B and stir evenly to obtain component B.

[0033] In one embodiment, an amine curing agent is added to the reaction kettle, the modifier is slowly added dropwise under stirring, and the viscosity diluent is slowly added at the same time, and the reaction is carried out under reflux for 3 to 5 hours. After the reaction is complete, the remaining B The raw materials of components are stirred for 0.5 to 1.5 hours to obtain component B.

[0034] S2. Mix bisphenol A epoxy resin, novolac epoxy resin and additives and stir evenly to obtain component A.

[0035] The preparation method of this embodiment has a simple process and is ...

Embodiment 1

[0040] Add 100g of diethylenetriamine into a three-port reaction kettle with a condensing reflux pipe and an agitator, slowly drop in 50g of bisphenol A epoxy resin E51 and 15g of benzyl alcohol while stirring at room temperature, and reflux for 3 hours. After the kettle returned to room temperature, add 3g of 2-phenylimidazole and tris-(dimethylaminomethyl)phenol, and 3g of silane coupling agent 3-glycidyl propyl trimethoxysilane, continue to stir for 1 hour to obtain B components.

[0041] In an open reaction kettle, add 100g of bisphenol A epoxy resin E51, 15g of liquid phenol novolac epoxy resin, 30g of reactive diluent benzyl glycidyl ether and 2g of defoamer at room temperature, and stir well Obtain the A component.

[0042] When in use, mix component A and component B uniformly according to the mass ratio of 1:1, and solidify in water at room temperature for 28 days to form a consolidated body.

Embodiment 2

[0044] Add 100g of triethylenetetramine in a three-port reaction kettle with a condensing reflux pipe and an agitator, and slowly drop in 40g of bisphenol A epoxy resin E44 and 15g of benzyl alcohol while stirring at room temperature, and reflux for 5 hours. After the kettle returned to room temperature, add 3g of 2-phenylimidazole and tris-(dimethylaminomethyl)phenol, and 3g of silane coupling agent 3-glycidyl propyl trimethoxysilane, continue to stir for 1 hour to obtain B components.

[0045] In an open reaction kettle, add 100g of bisphenol A epoxy resin E51, 20g of liquid phenol novolac epoxy resin, 30g of reactive diluent benzyl glycidyl ether and 2g of defoamer at room temperature, and stir well Obtain the A component.

[0046] When in use, mix component A and component B uniformly according to the mass ratio of 1:1, and solidify in water at room temperature for 28 days to form a consolidated body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com