Liquid specific heat capacity measuring device capable of realizing self-balanced pressurization and measuring method

A measuring device and technology of specific heat capacity, applied in the direction of thermal development of materials, etc., can solve the problems of inability to accurately measure the specific heat capacity of volatile liquids, and achieve the effect of saving experimental time and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

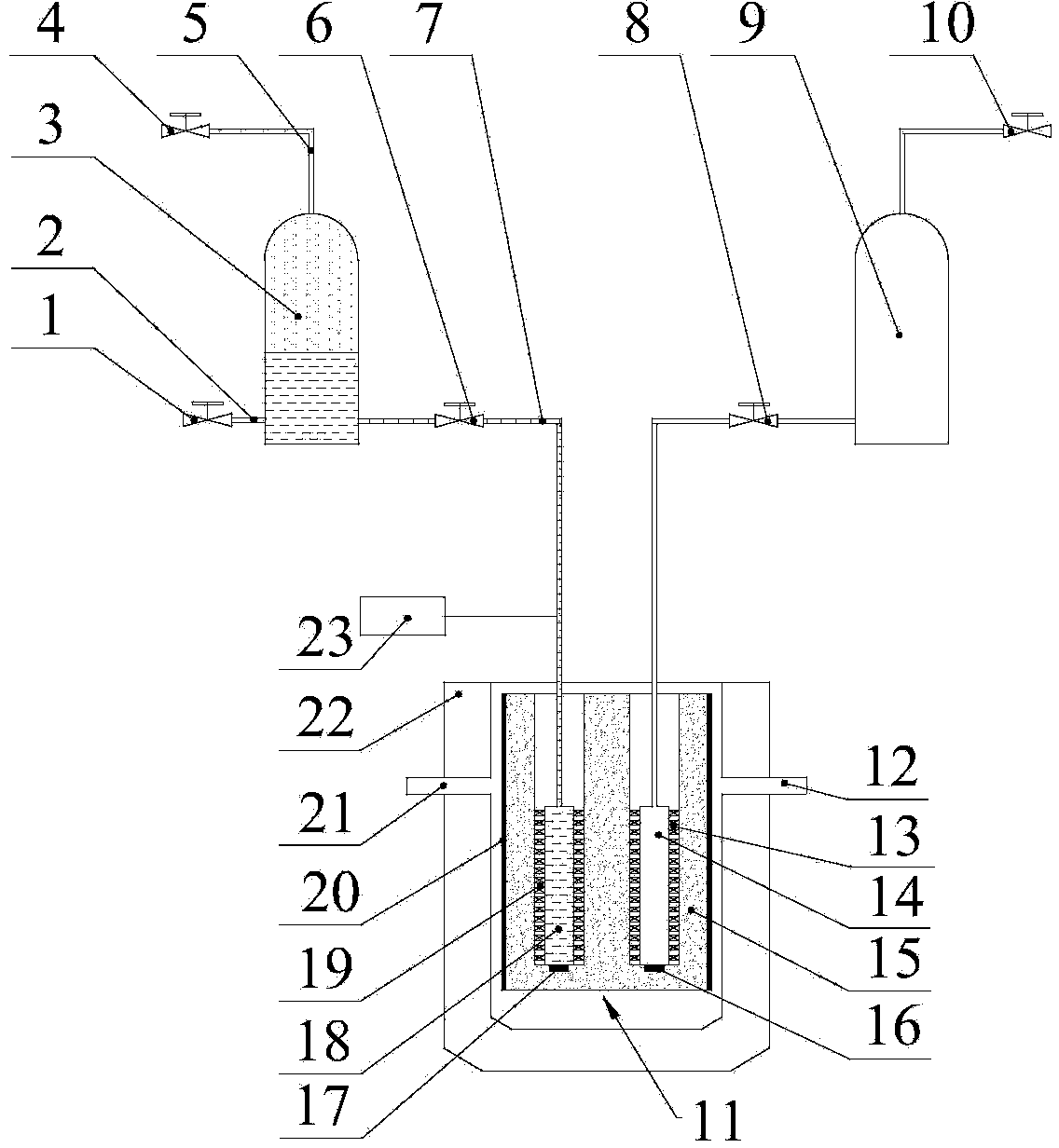

[0065] Such as figure 1 As shown, a liquid specific heat capacity measuring device capable of self-balanced pressurization includes interconnected pressure balance mechanism and measurement mechanism, and the pressure balance mechanism includes:

[0066] Liquid storage tank 3;

[0067] The liquid inlet pipe 5 is located on the outside of the liquid storage tank, the liquid inlet pipe is provided with a first valve 4, and one end of the liquid inlet pipe is connected with the liquid storage tank;

[0068] The liquid outlet pipe 7 is located on the outside of the liquid storage tank, and the second valve 6 is arranged on the liquid outlet pipe, and one end is fixed with the liquid storage tank, and the other end is fixed with the measuring mechanism;

[0069] The sampling pipe 2 is located at the middle and lower part of the liquid storage tank, and the fifth valve 1 is arranged on the sampling pipe.

[0070] Measuring agencies include:

[0071] The heating box 11 has heating...

Embodiment 2

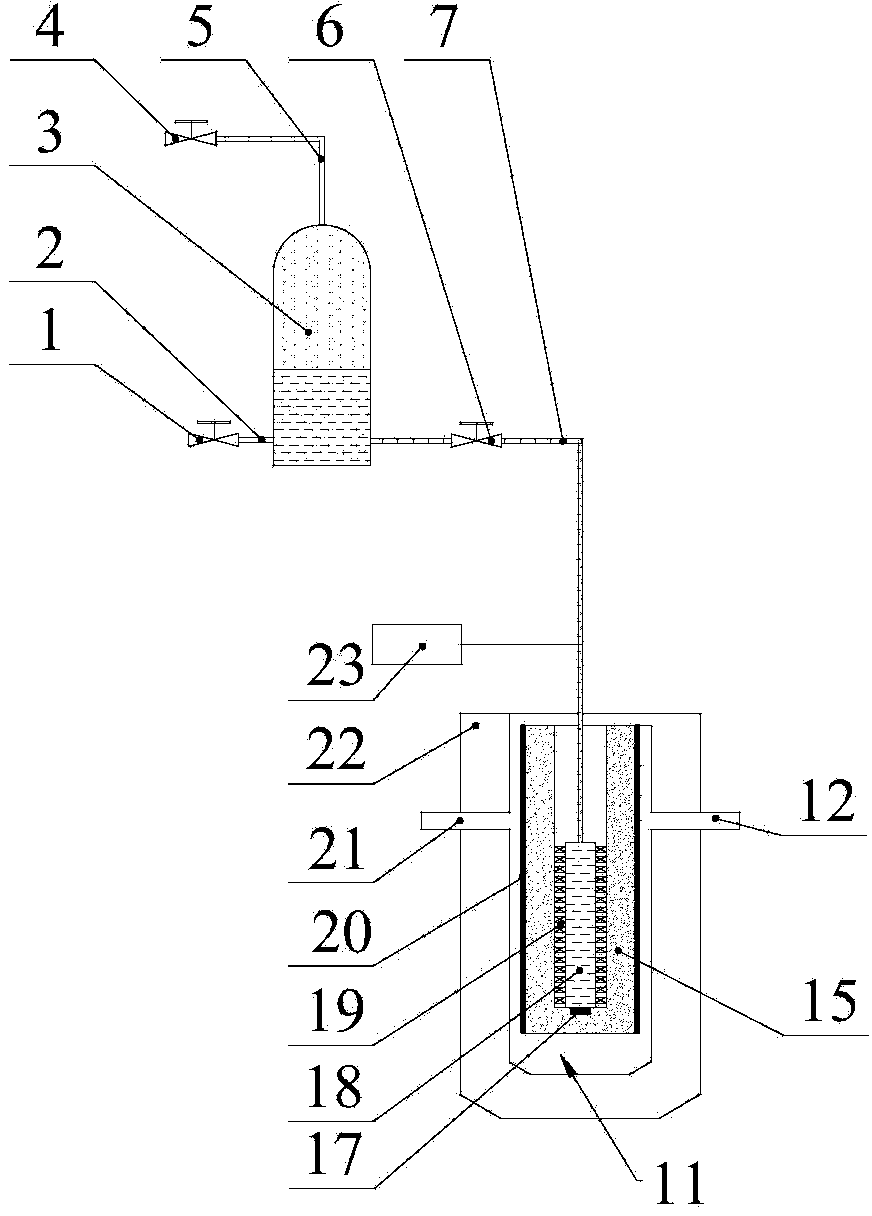

[0093] Such as figure 2 As shown, in this implementation, on the basis of Embodiment 1, the comparison tank, the comparison pool, the second temperature sensor and the second heat flow measurement element are removed.

[0094] The method for measuring the specific heat capacity of the refrigerant difluorochloromethane (R22) using the device of this embodiment comprises the following steps:

[0095] 1) Open the first valve 4 and the second valve 6, vacuumize the liquid storage tank 3 and the measuring pool 18, close the first valve 4 after vacuuming, so that the liquid storage tank and the measuring pool form a closed cavity, heat The element 20 works to uniformly heat the heating measuring pool, and measure the temperature signal T' of the outer wall of the measuring pool and the heat flow signal HF of the outer wall of the measuring pool when the inside of the measuring pool is in a vacuum state blank ;

[0096] 2) Fill the cooling medium inlet 21 with cold water or air to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com