Method and device for producing bunker coal with sludge

A coal-burning device and sludge technology, which is applied to fuels, solid fuels, biofuels, etc., can solve the problems of immaturity, low sludge content in sludge and coal slurry, and large amount of stabilizer, and achieve low cost and coal saving. The effect of good effect, saving resources and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

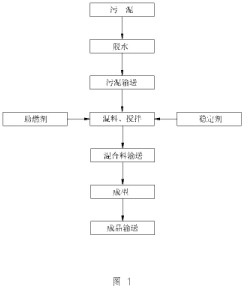

[0027] Such as figure 1 As shown, a kind of sludge utilization includes the steps of:

[0028] 1) Dehydration, the sludge is dehydrated, and the water content in the sludge after the sludge dehydration treatment is 45wt%;

[0029] 2) Mixing, the dehydrated sludge is conveyed and mixed, and a combustion aid and a stabilizer are added to the dehydrated sludge for mixing. The amount of the mixture of fly ash, limestone powder and gypsum powder is 8% of the weight of the dehydrated sludge, and the weight ratio of fly ash, limestone powder and gypsum powder in the mixture is 2:1:1;

[0030] 3) Stirring, stirring and mixing the mixed sludge;

[0031] 4) Molding and drying, the mixed material is transported for molding after stirring and mixing, and then dried to obtain briquettes.

Embodiment 2

[0033] A method for utilizing sludge to produce coal, comprising the steps of:

[0034] 1) Dehydration, the sludge is dehydrated, and the water content in the sludge after the sludge dehydration treatment is 40wt%;

[0035] 2) Mixing, the dehydrated sludge is conveyed and mixed, and a combustion aid and a stabilizer are added to the dehydrated sludge for mixing. The amount of fly ash added is 10% of the weight of the sludge after dehydration, and the binder humic acid binder is also added, and the amount of humic acid binder is 5% of the weight of the sludge after dehydration;

[0036] 3) Stirring, stirring and mixing the mixed sludge;

[0037] 4) Molding and drying, the mixed material is transported for molding after stirring and mixing, and then dried to obtain briquettes.

Embodiment 3

[0039] A method for utilizing sludge to produce coal, comprising the steps of:

[0040] 1) Dehydration, the sludge is dehydrated, and the water content in the sludge after the sludge dehydration treatment is 50wt%;

[0041] 2) Mixing, the dehydrated sludge is transported and mixed, and a combustion aid and a stabilizer are added to the dehydrated sludge for mixing. The amount of the combustion aid is 30% of the weight of the dehydrated sludge, and the combustion aid is made of coal The powder weight content is 75% and the rest is composed of wood chips; the added amount of stabilizer limestone powder is 15% of the weight of the sludge after dehydration, and the binder humic acid binder is also added, and the amount of humic acid binder is after dehydration. 9% of the weight of the sludge, add foaming agent sodium lauryl sulfate, the amount of sodium lauryl sulfate added is 0.5% of the weight of the sludge after dehydration

[0042] 3) Stirring, stirring and mixing the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com