Piezoelectric device, angular velocity sensor, and method of manufacturing a piezoelectric device

A technology of angular velocity sensors and piezoelectric elements, which is applied in the field of piezoelectric element manufacturing, can solve problems such as the degradation of piezoelectric properties of piezoelectric materials, and achieve the effects of improved heat resistance, piezoelectric characteristics and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

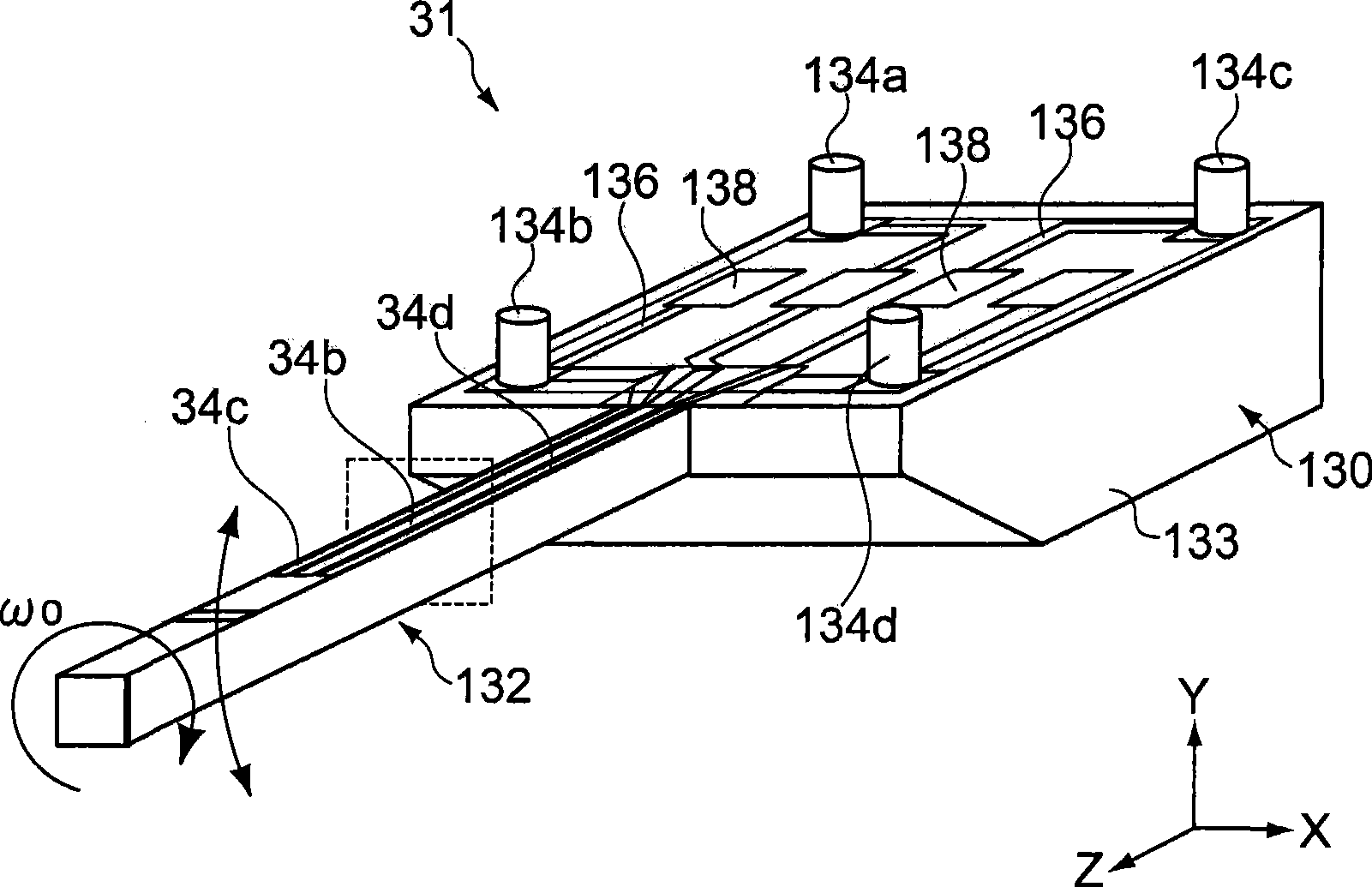

[0066] First, a first embodiment of the present invention will be described. FIG. 1 is a diagram showing a piezoelectric element and an angular velocity sensor including the piezoelectric element according to a first embodiment of the present invention.

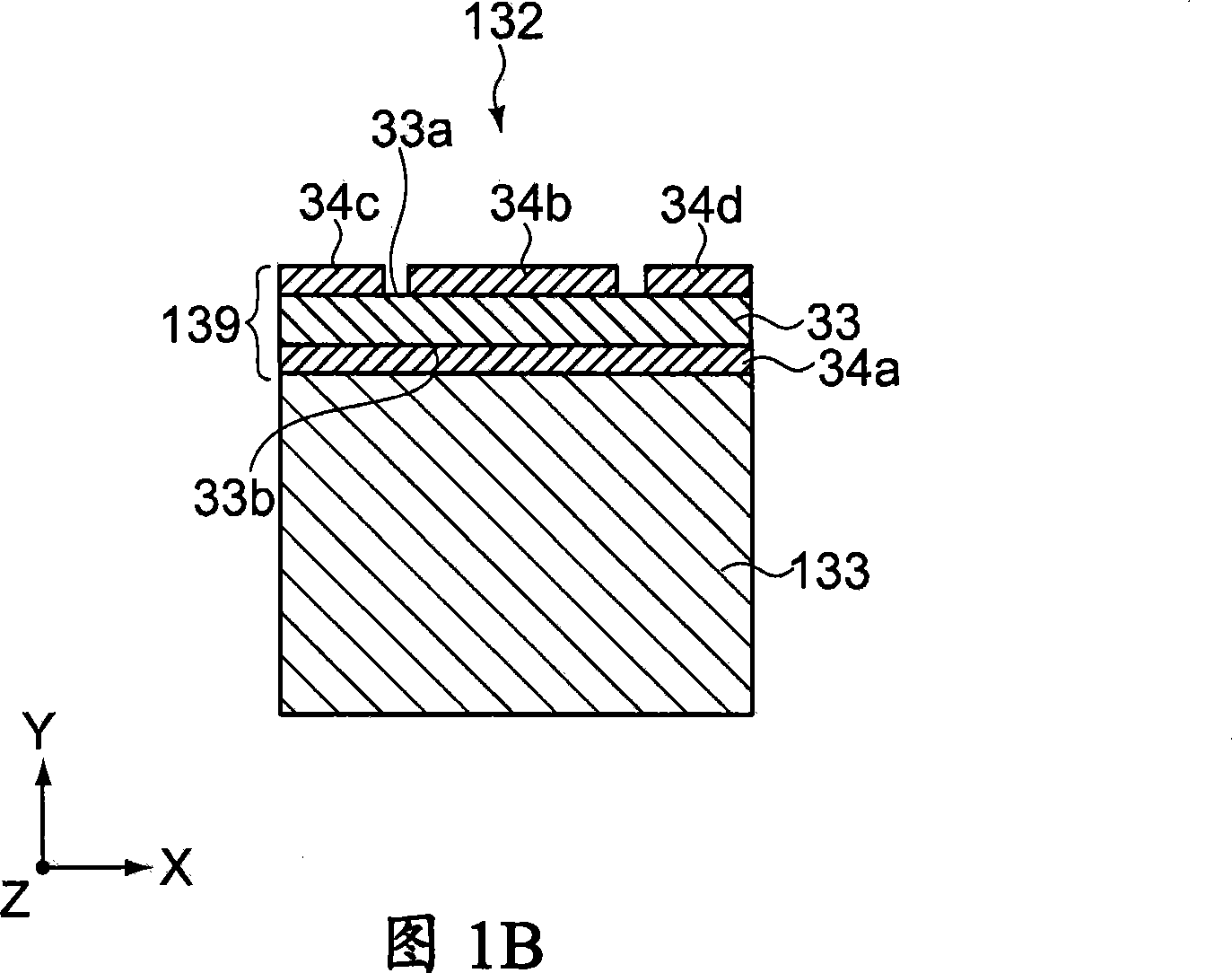

[0067] The angular velocity sensor 31 includes a base body 130 and a vibrating arm 132 extending from the base body 130 and capable of vibrating. FIG. 1B is a cross-sectional view of a surface perpendicular to the longitudinal axis (Z-axis) of the vibrating arm 132 .

[0068] The angular velocity sensor 31 includes, for example, a semiconductor arm substrate 133 made of silicon, and a piezoelectric element 139 provided on the arm substrate 133 . As shown in FIG. 1B , for example, a first electrode film 34 a as a common electrode is laminated on a silicon substrate, and a piezoelectric film 33 is laminated on the first electrode film 34 a. On the first surface 33a that is the upper surface of the piezoelectric film 33, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com