A kind of process for producing photoinitiator 1173 and 184 cycle

A photoinitiator and production process technology, applied in chemical instruments and methods, preparation of carbon-based compounds, organic chemistry, etc., can solve the problems of restricting the use of chlorine gas, difficult to handle, large quantities, etc., to save freight costs and achieve good quality stability. , the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

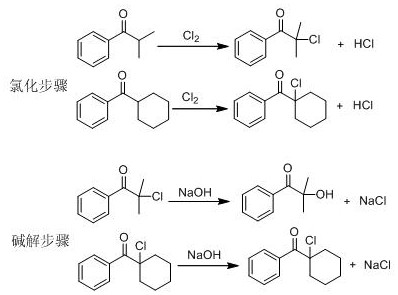

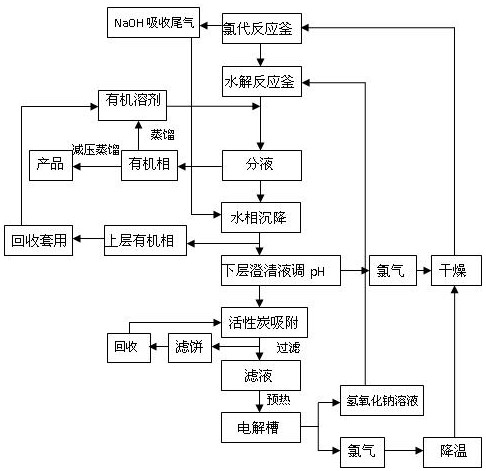

Method used

Image

Examples

Embodiment 1

[0035] The electrolysis of embodiment 1 photoinitiator 1173 waste water

[0036] 1. Pretreatment of sodium chloride solution produced in 1173 alkaline hydrolysis process

[0037] Take 2500.0g of the 1173 alkali hydrolysis sodium chloride solution that has been settled in the production workshop, and detect the sodium chloride content is 23.1%, and add 50.2g of 30% hydrochloric acid dropwise under stirring, and the pH value is 2-3. Add 40g of powdered activated carbon (400 mesh), and stir for 0.5 hours at 40°C. Activated carbon was removed by filtration under reduced pressure to obtain a colorless, clear and transparent solution with a COD value of 499 mg / L.

[0038] 2. Electrolysis of sodium chloride solution

[0039] Install and fix the anode, cathode and cation exchange membrane of the electrolytic cell. Take 2000.0 g of alkali hydrolysis sodium chloride solution after step 1 pretreatment, then preheat to 80-85 ° C, transfer to the anode chamber of the electrolytic cell, ...

Embodiment 2

[0042] The electrolysis of embodiment 2 photoinitiator 184 wastewater solutions

[0043] 1. Pretreatment of sodium chloride solution produced in the 184 alkaline hydrolysis process

[0044] Take 2500.0g of the 184 alkali hydrolysis sodium chloride solution that has been settled in the production workshop, detect the sodium chloride content of 22.5%, add 45.7g of 30% hydrochloric acid dropwise, and the pH value is 3. Add 45g of powdered activated carbon (400 mesh) and stir for 0.5 hours. Activated carbon was removed by filtration under reduced pressure to obtain a colorless, clear and transparent solution with a COD value of 425 mg / L.

[0045] 2. Electrolysis of sodium chloride solution

[0046] Install and fix the anode, cathode and cation exchange membrane of the electrolytic cell. Take 2000.0 g of alkali hydrolysis sodium chloride solution after step 1 pretreatment, then preheat to 80-85 ° C, transfer to the anode chamber of the electrolytic cell, and put 5% sodium hydrox...

Embodiment 3

[0049] The preparation of embodiment 3 photoinitiator 1173

[0050] 1. Chlorination reaction: put 100g of cuminone into a 500mL four-necked bottle, and start stirring. Feed in the chlorine gas that has been dried in step 1 or step 2. Keep the temperature of the material in the bottle at 40-45°C during the process of passing chlorine. After passing chlorine for about 10 hours, the material in the bottle began to turn yellow. Sampling was carried out for gas phase detection, and the remaining 0.12% of cuminyl ketone, the content of the product 2-chloro-2methyl-1-phenylacetone was 99.2%, and the reaction was completed.

[0051]2. Alkaline hydrolysis reaction: Put 100 g of 2-chloro-2-methyl-1-phenylacetone prepared above into a 500 mL four-necked bottle. Start stirring, and then dropwise add 100 g of 27.4% lye produced by electrolysis in the four-necked bottle. During the dropping process, the temperature of the reaction solution was controlled at 70-75°C. After adding the ly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com