Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

A technology of metal surface and degreaser, which is applied in the field of biological degreaser, can solve the problem of non-decomposed oil pollution, and achieve the effect of reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The biological degreasing agent in the present embodiment is made up of main agent, and its proportioning is as follows:

[0034] Phosphatidylglycerol 4.00%, alkyl glycoside 11.00%, alkyl ether carboxylate 7.00%, Bacillus subtilis, Bacillus polymyxa and Xanthophylla 6.00%, water 72.00%.

[0035] 1. According to this ratio, mix evenly in a test tank with a volume of 3 liters, and prepare 2 liters of main ingredients.

[0036] 2. Add 2 liters of 90# gasoline to another experimental tank with the same volume.

[0037] 3. The experimental oil used in this experiment is Purelube SAE 30 Non-detergent Oil (manufactured by HAJ Inc.).

[0038] 4. In this experiment, whether 80% of the experimental oil on the Hastelloy sheet can be removed within 5 minutes is used as a sign to measure whether the degreaser has good oil removal ability: within 5 minutes, if the experimental oil removed from the Hastelloy sheet More than 80%, the degreaser is defined as having good degreasing ...

Embodiment 2

[0049] The biological degreasing agent in the present embodiment is made up of main agent, and its proportioning is as follows:

[0050] Phosphatidylglycerol 9.00%, alkyl glycoside 15.00%, alkyl ether carboxylate 20.00%, Bacillus licheniformis, Bacillus megaterium and Xanthobacter 4.00%, potassium chloride 0.3%, sodium sulfate 0.2%, water 51.50%.

[0051] 1. Based on the formulations in Example 1 and Example 2, respectively prepare 20 liters of main ingredients. Then store in a 20-liter airtight container in a cool, dry place.

[0052] 2. The experimental oil used in this experiment is Purelube SAE 30 Non-detergent Oil (manufactured by HAJ Inc.).

[0053] 3. On the day when the main ingredient is prepared, dilute the main ingredient with water at a ratio of 1:20. Then use exactly the same degreasing ability test method in embodiment 1, test the degreasing ability of two formulas respectively, test continuously for 7 days.

[0054] 4. After storage for 2 weeks, 4 weeks an...

Embodiment 3

[0063] The biological degreasing agent in the present embodiment is made up of main agent, and its proportioning is as follows:

[0064] Main ingredients: rhamnolipid 10.00%, polyoxyethylene ether 15.00%, Bacillus subtilis 5.00%, sodium sulfate 0.10%, sodium chloride 0.40%, lipase 0.20%, water 69.30%; in the degreasing tank, mix well .

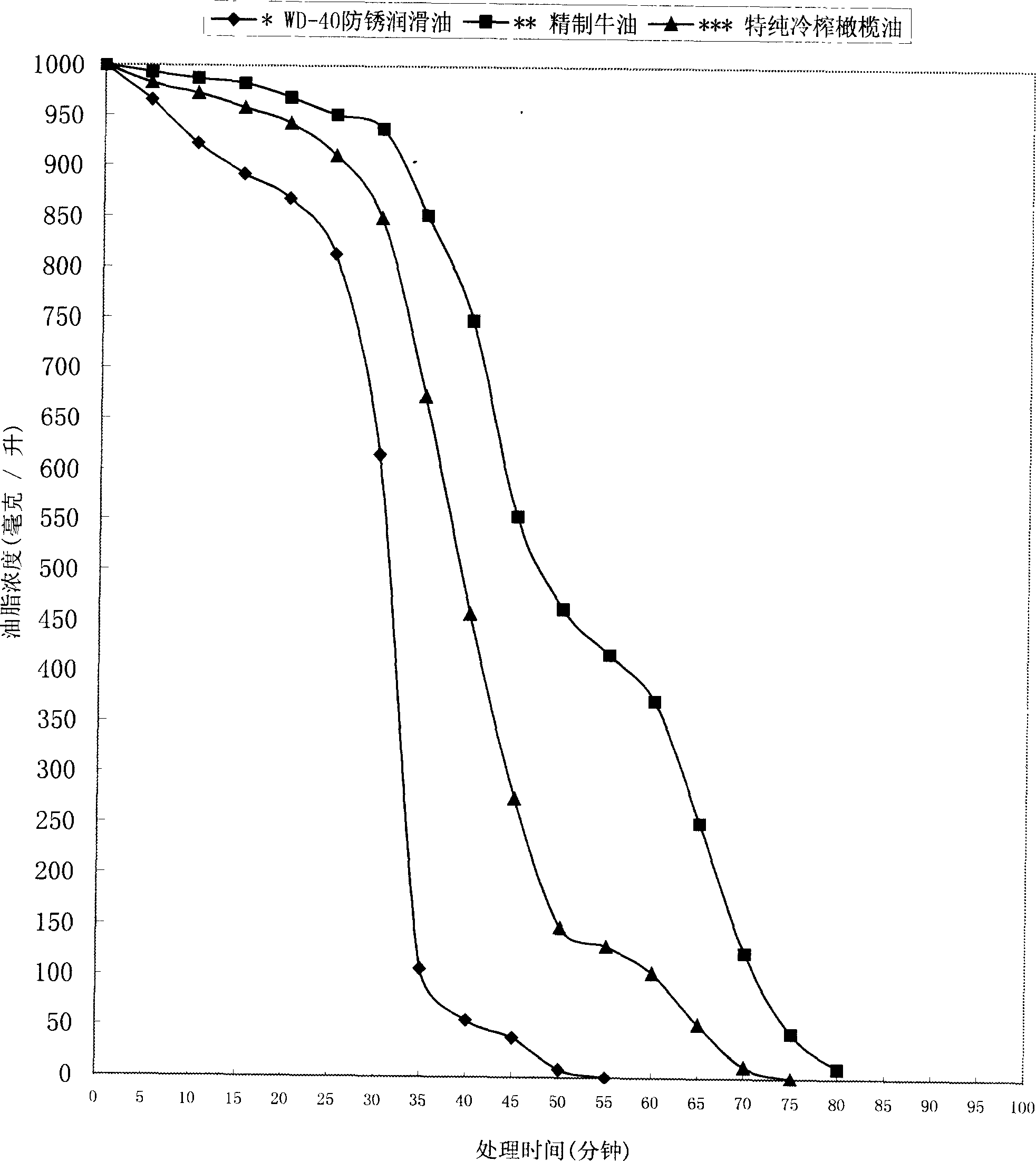

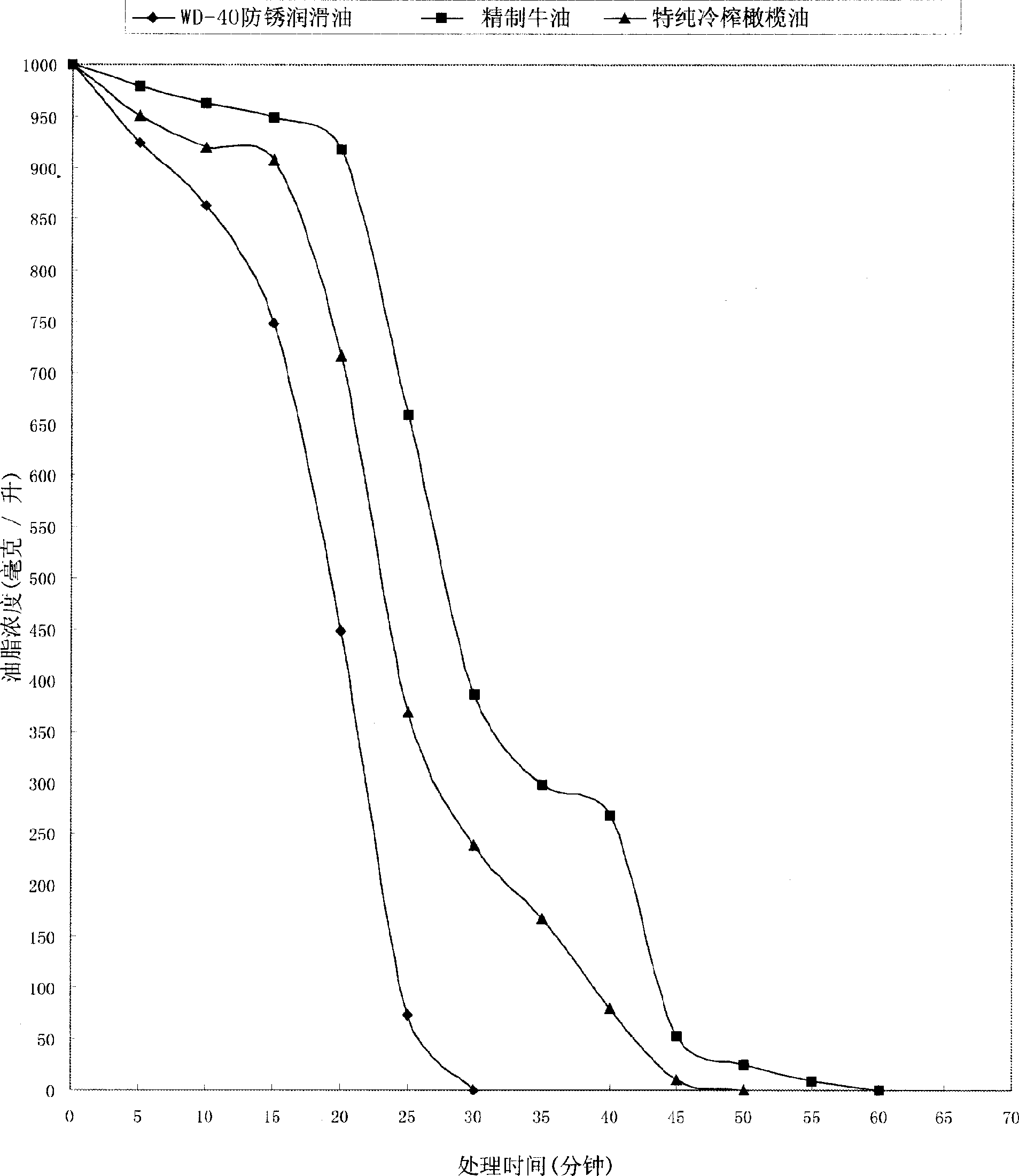

[0065] 1. Degreasing test: The following is a comparison of the degreasing speed of the biological degreasing agent formula for different oils stripped from the standard Hastelloy sheet under static and dynamic conditions.

[0066] 2. The specific experimental steps of the static test are as follows:

[0067] (1) Take 2 liters of the main agent, dilute it with water at a ratio of 1:30 in the experimental tank, and prepare 60 liters of working solution.

[0068] (2) Add 10 grams of auxiliary agent to the diluted main agent, and stir evenly to prepare a biological degreasing agent.

[0069] (3) Take 15 Hastelloy tablets of standard specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com