Patents

Literature

35results about How to "With consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

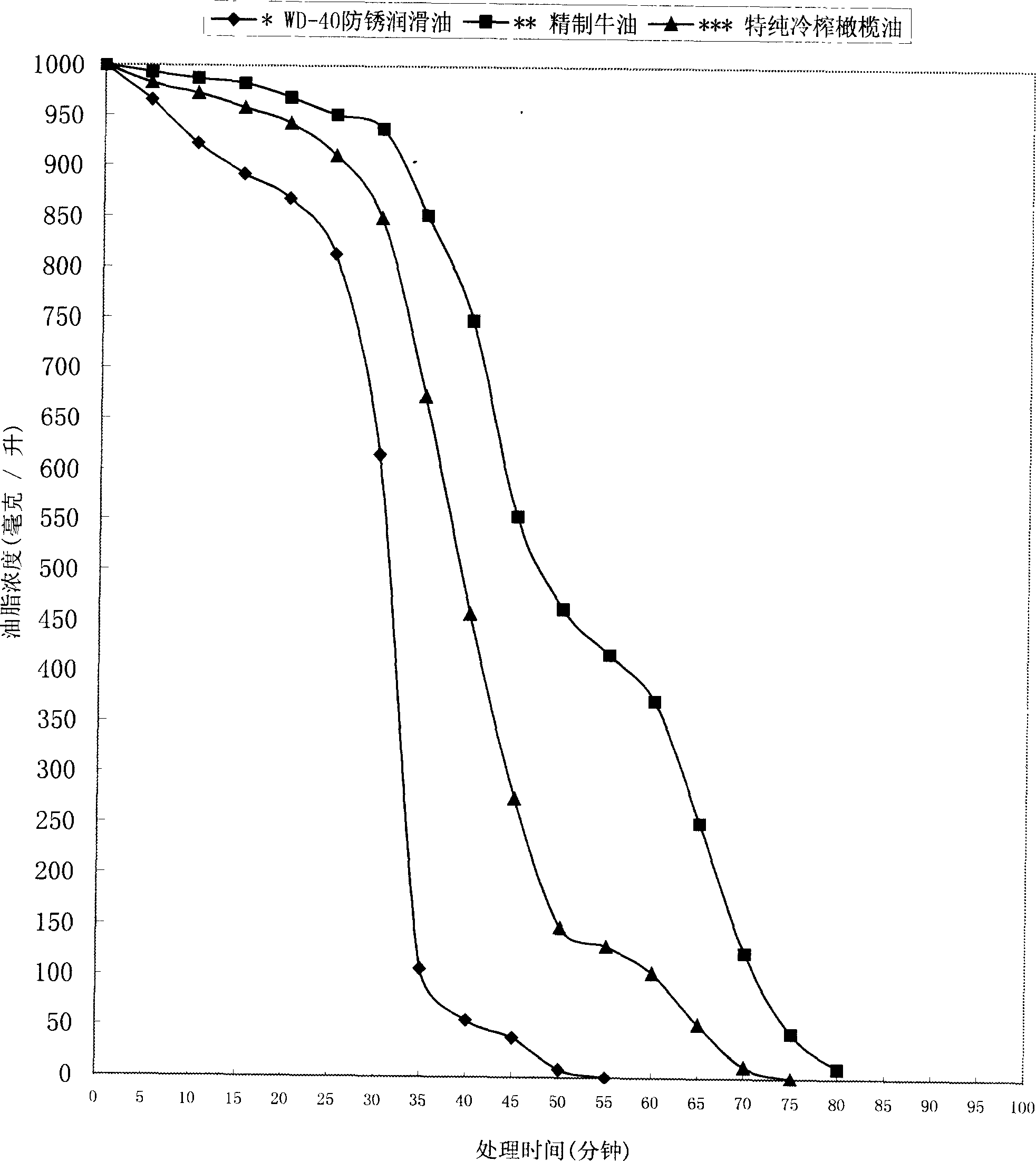

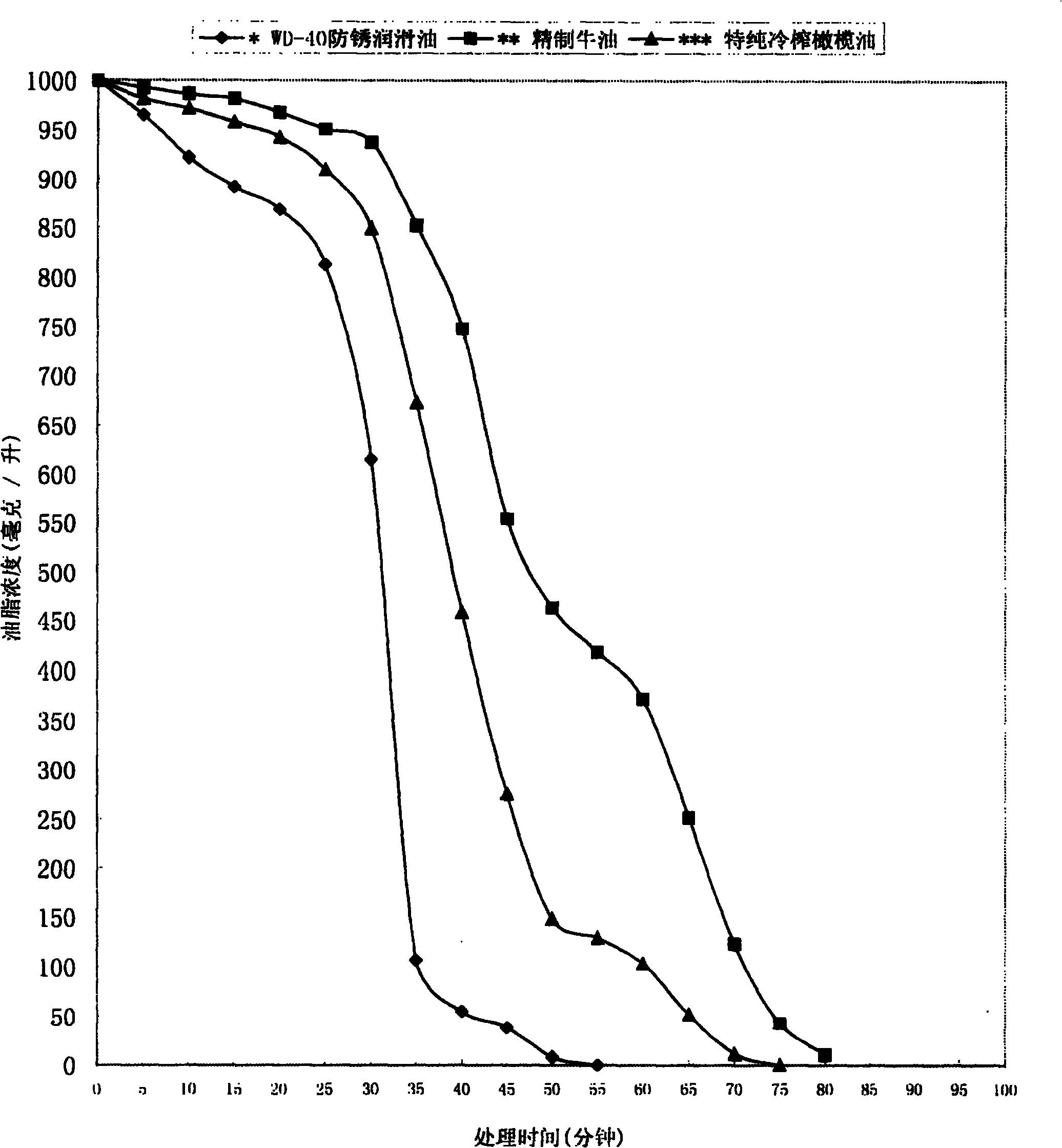

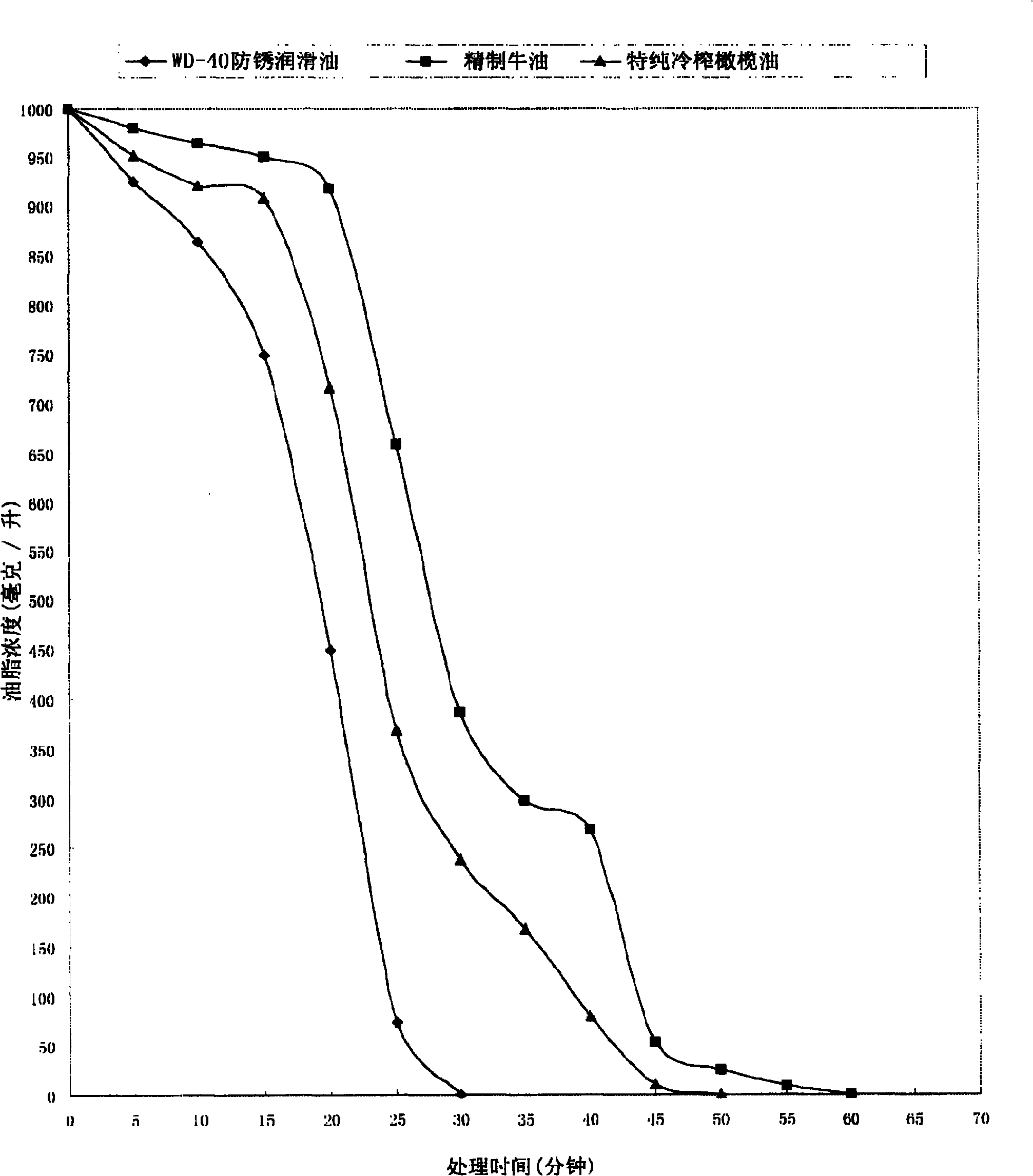

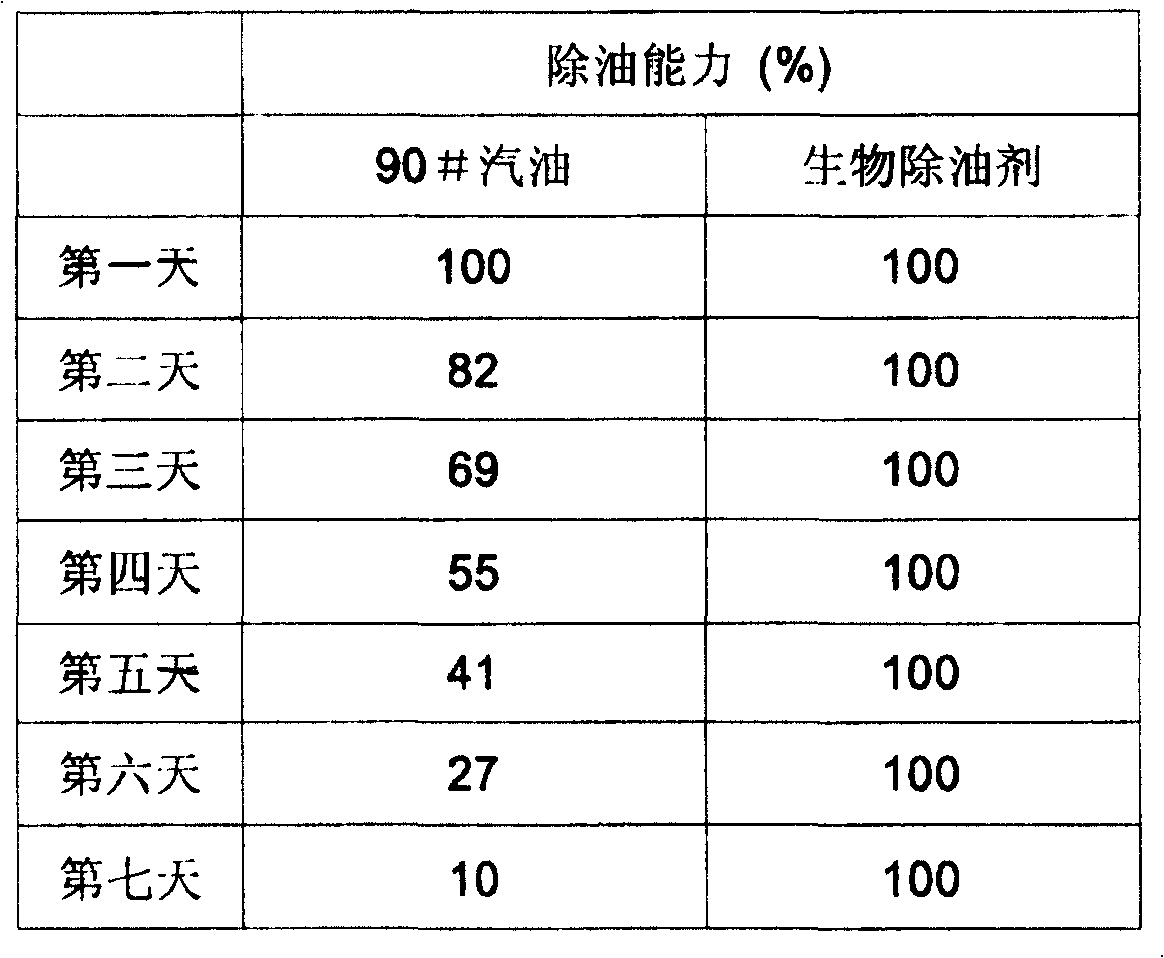

Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

The invention discloses a biological degreaser for degreasing pretreatment in metal processing industry and method for processing greasy dirt on metal surfaces, which integrates the two independent processes of grease removing and greasy dirt decomposing, the biological degreaser containing oil-degraded microorganisms can not only scale off greasy dirt from metal surfaces, but also decompose the greasy dirt simultaneously.

Owner:TANTZ ENVIRONMENTAL TECH

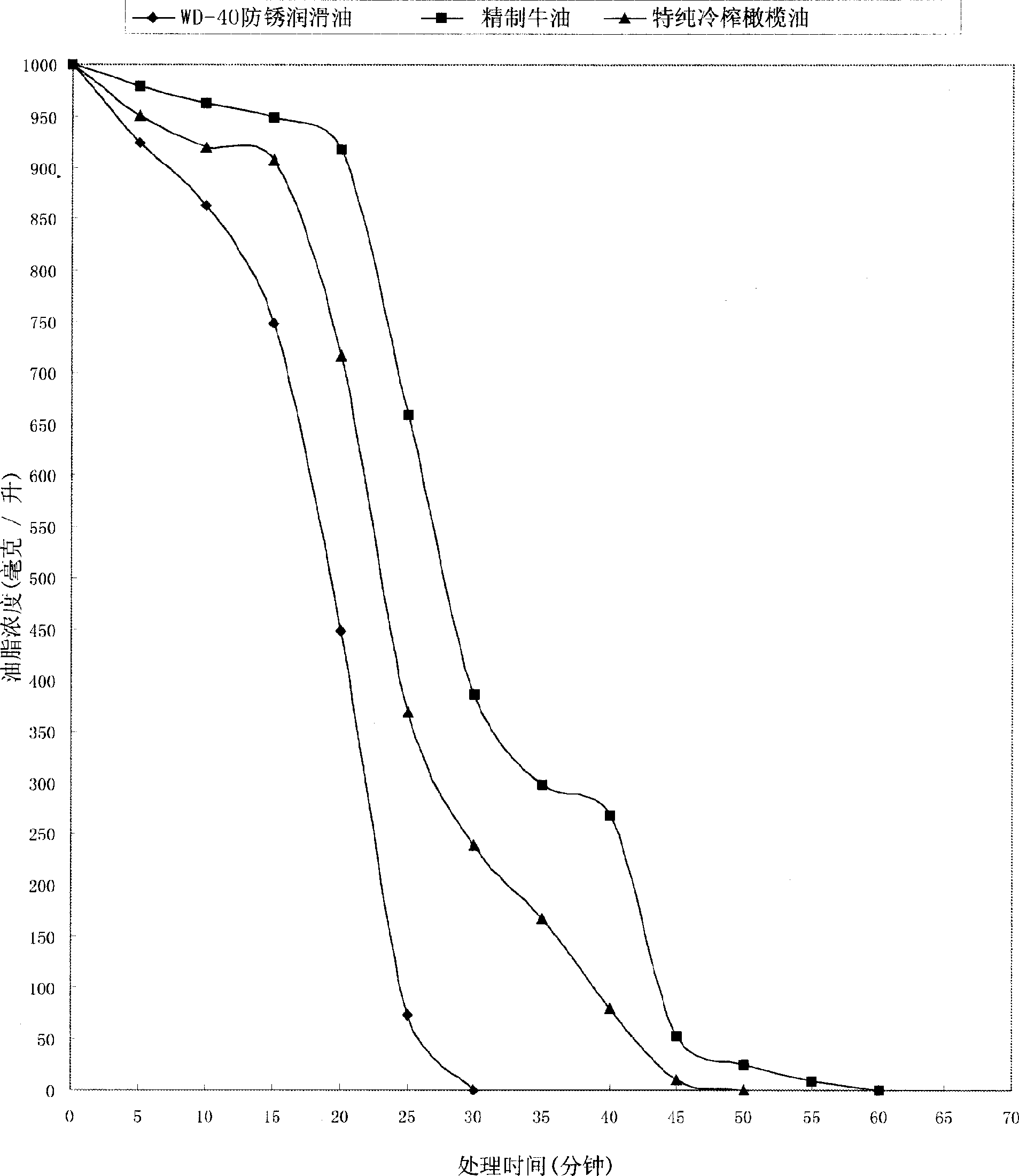

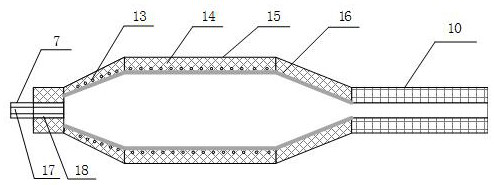

High-temperature-wear-resistant lining plate for coke pot for coke dry quenching and preparation method thereof

InactiveCN102212820ASuitable for harsh working conditionsImprove corrosion resistanceCoke quenchingMetallic material coating processesQuenchingHigh power lasers

The invention discloses a preparation method of a high-temperature-wear-resistant lining plate for a coke pot for coke dry quenching. The high-temperature-wear-resistant lining plate is prepared by cladding a metal ceramic layer on a metal lining plate. The preparation method comprises the following steps: (1) preparing uniformly mixed metal ceramic powder; (2) brushing light absorbing coatings on the surface of the metal lining plate uniformly; (3) after the coating of the light absorbing coatings is dry, feeding the powder pneumatically or feeding the powder by way of powder spreading or gravity, wherein the thickness of the powder layer is 0.5-4.0mm; and (4) scanning the metal ceramic powder which has been spread or delivered in place by virtue of a high power laser and forming the cladded high-temperature-wear-resistant metal ceramic layer on the metal lining plate. By utilizing the method to prepare the high-temperature-wear-resistant metal lining plate for the coke pot for coke dry quenching, low cost and stable production quality are ensured, and implementation is convenient; and the method is convenient for mass production and has prominent economic and social benefits.

Owner:SHIJIAZHUANG HUADING HI TECH STRENGTHEN ALLOY EQUIP MFG

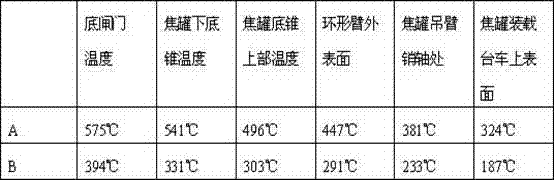

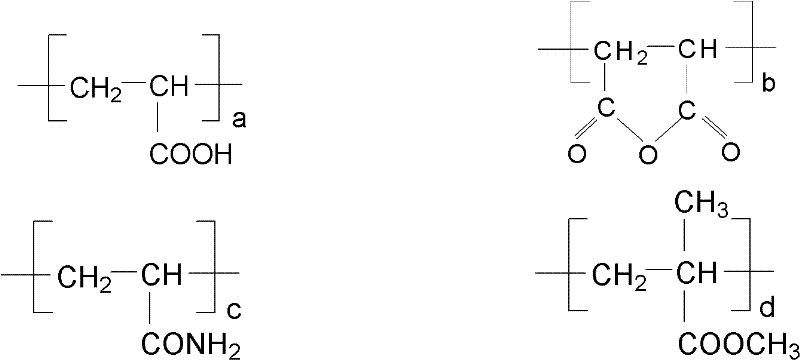

Color fixing substitution alkali for low-salt dyeing by using reactive dye pad steaming process

The invention relates to color fixing substitution alkali for low-salt dyeing by using a reactive dye pad steaming process, and the color fixing substitution alkali can be applied to low-salt color-fixing treatment on a cotton fabric dyed with a reactive dye. The color fixing substitution alkali is an organic / inorganic composite buffer system consisting of alkali metal hydroxide, alkali carbonate, a dispersing agent, an alkali-resistant penetrating agent and an accelerating agent. The traditional color-fixing alkali agent for the reactive dye is replaced and low-salt dyeing is realized under the condition of not changing the traditional technological equipment and flow. The color-fixing substitution alkali agent has the characteristics of low consumption, favorable stability, convenience for operation, and the like, meanwhile, is beneficial to reduction of production cost and environment pollution, has little influence on the equipment and meets the requirements on energy saving, emission reduction and efficiency increase.

Owner:FUJIAN QINGYUAN TECH

Coke passivator and preparation method thereof

ActiveCN101186853AReduce washoutReduced responseSolid fuelsHigh magnesiumCoke strength after reaction

The invention belongs to the technical field of ironmaking, in particular relating to a coke passivator and process for preparation. The coke passivator is produced by the raw materials at different part by weight, including 15-30 parts of boracic acid, 15-30 parts of borax, 30-50 parts of high magnesium powder, 5-15 parts of aluminum silicon powder, and 5-20 parts of calcium silicon powder. The coke passivator can uniformly form a layer of protective coating, which can reduce the erosion of the coke caused by CO2, decrease the reactivity of the coke, increase the coke strength after reaction, improve the utilization coefficient and the service life of the blast fumace and reduce the coke ratio. Utilizing the concentration of 0.3kg / t can reduce the reactivity of the coke by 5%, increase the coke strength after reaction by 7% and improve the production of the blast furnace by more than 3%-5%. The invention is an ideal product for blast furnace ironmaking which has the advantages of saving energy, reducing consumption, increasing production, improving benefits and protecting environment.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

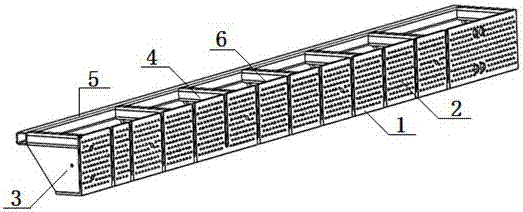

Production technology of precast concrete member rough surface

InactiveCN107283602ASave manual pulling laborSave energyMouldsMould fastening meansRough surfaceNational standard

The invention discloses a production technology of a precast concrete member rough surface. The production technology comprises the steps that 1, a precast concrete member rough surface forming template is prepared; 2, a precast member flange die is manufactured; 3, the precast member rough surface forming template prepared in the step 1 is connected and fixed to the precast concrete flange die prepared in the step 2; 4, the precast member rough surface flange die obtained in the step 3 is installed on a steel trolley or a bottom template; 5, connecting reinforcement bars are arranged based on the step 4; 6, concrete pouring, vibration, maintenance and demolding are carried out, and a precast concrete member with the rough surface is formed. Mechanical equipment and washing stations are saved, dust pollution and slurry pollution are avoided, the cost is low, the efficiency is high, the precast concrete member rough surface meets national standards, and the product quality is good.

Owner:HUNAN YUANDA ENG DESIGN CO LTD

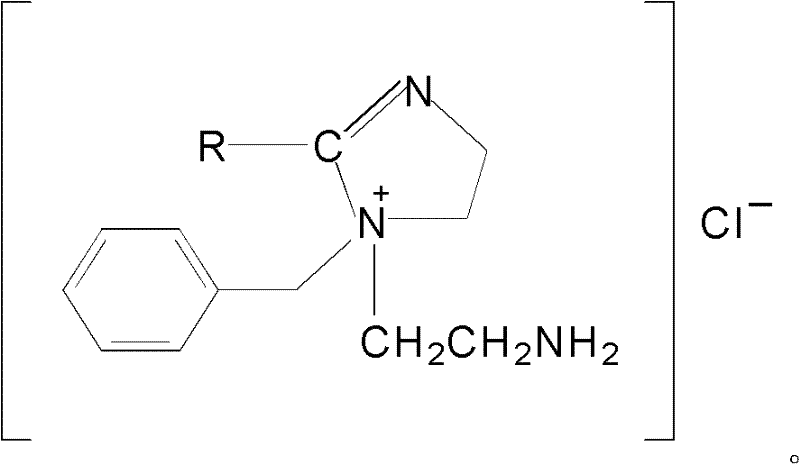

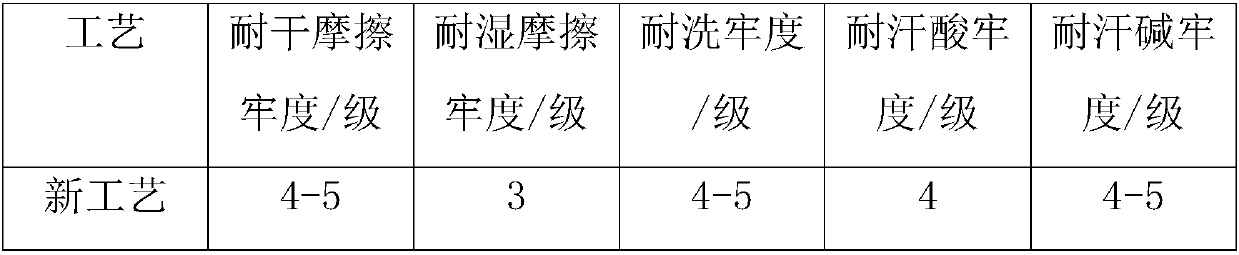

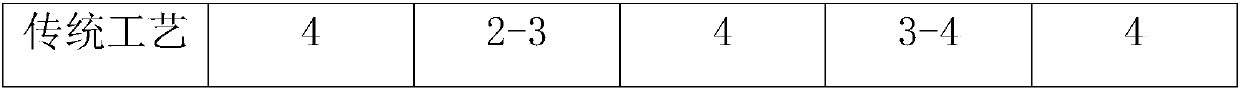

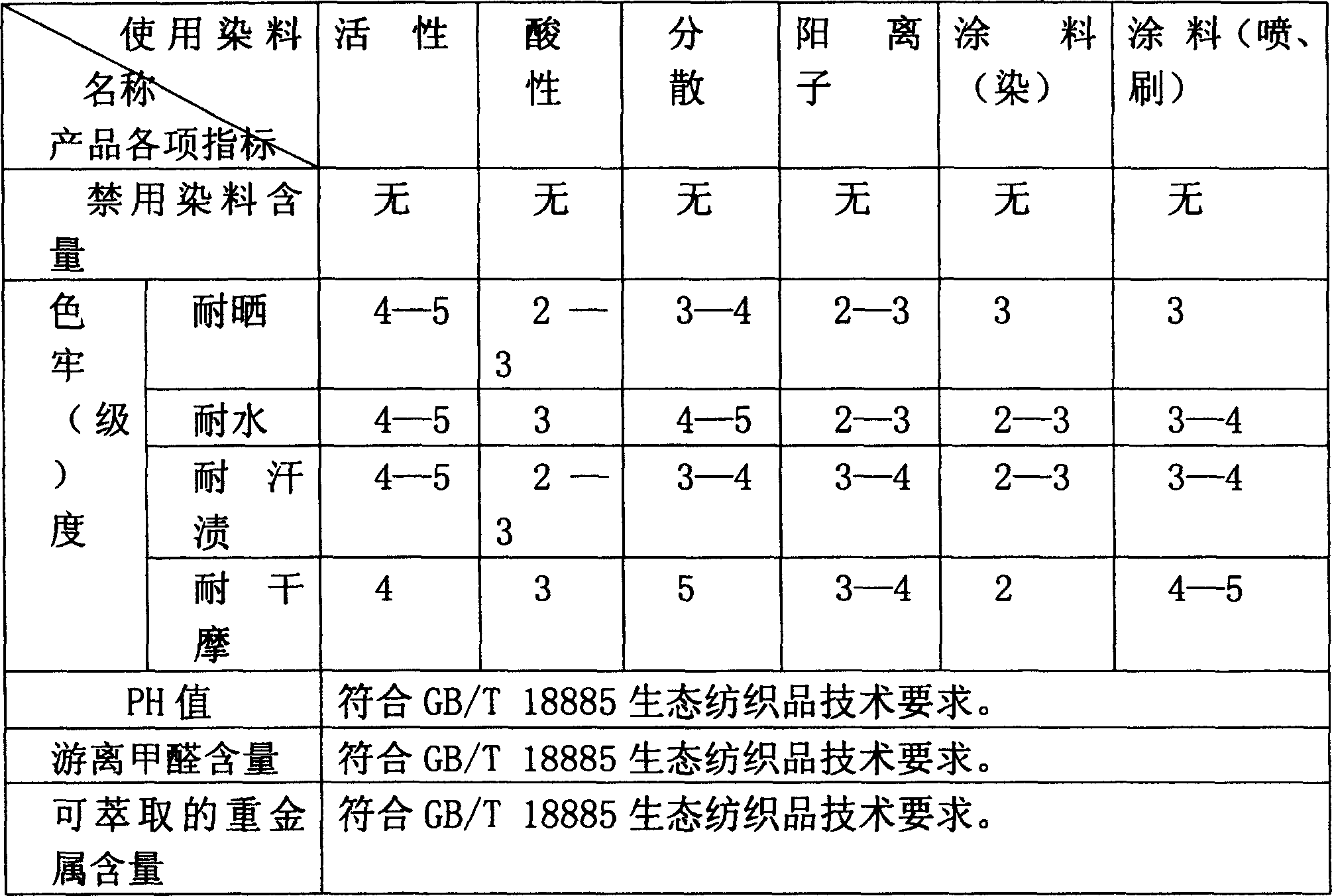

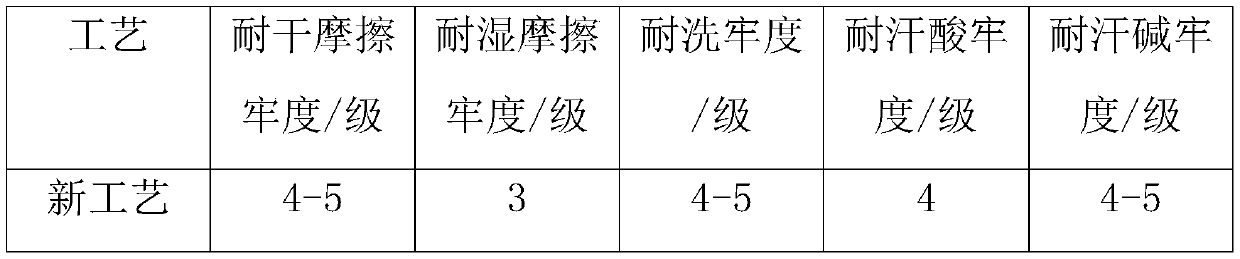

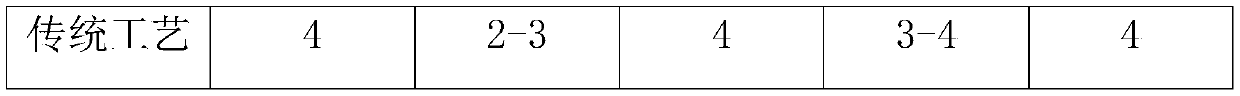

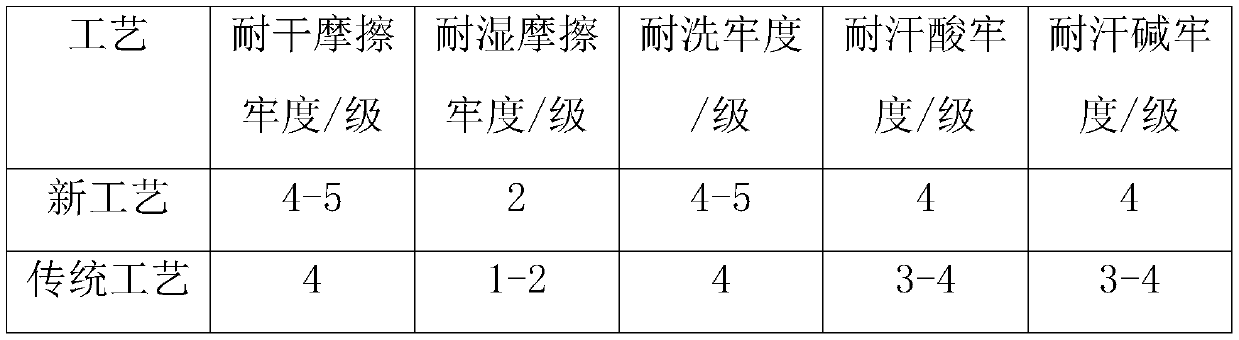

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

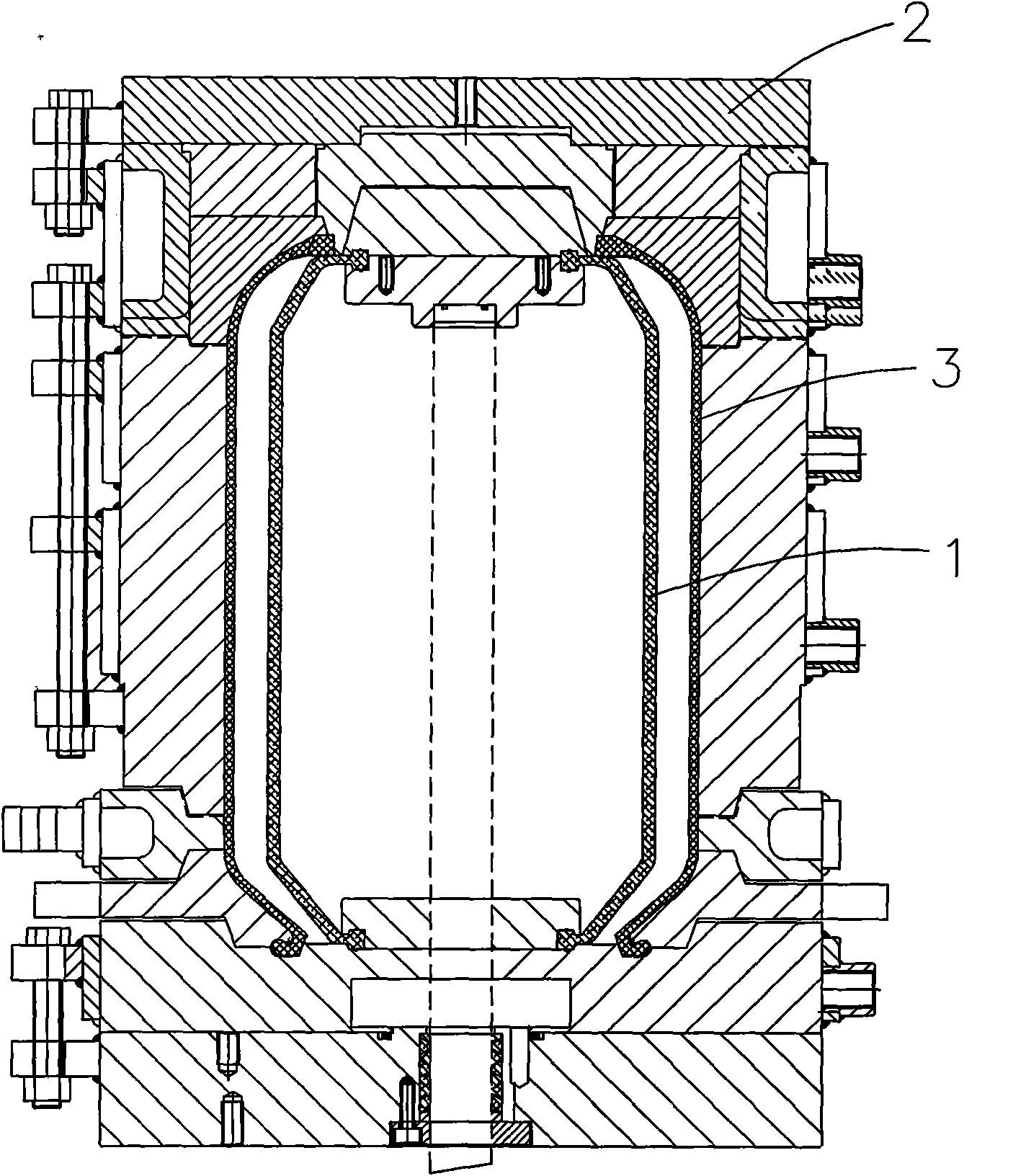

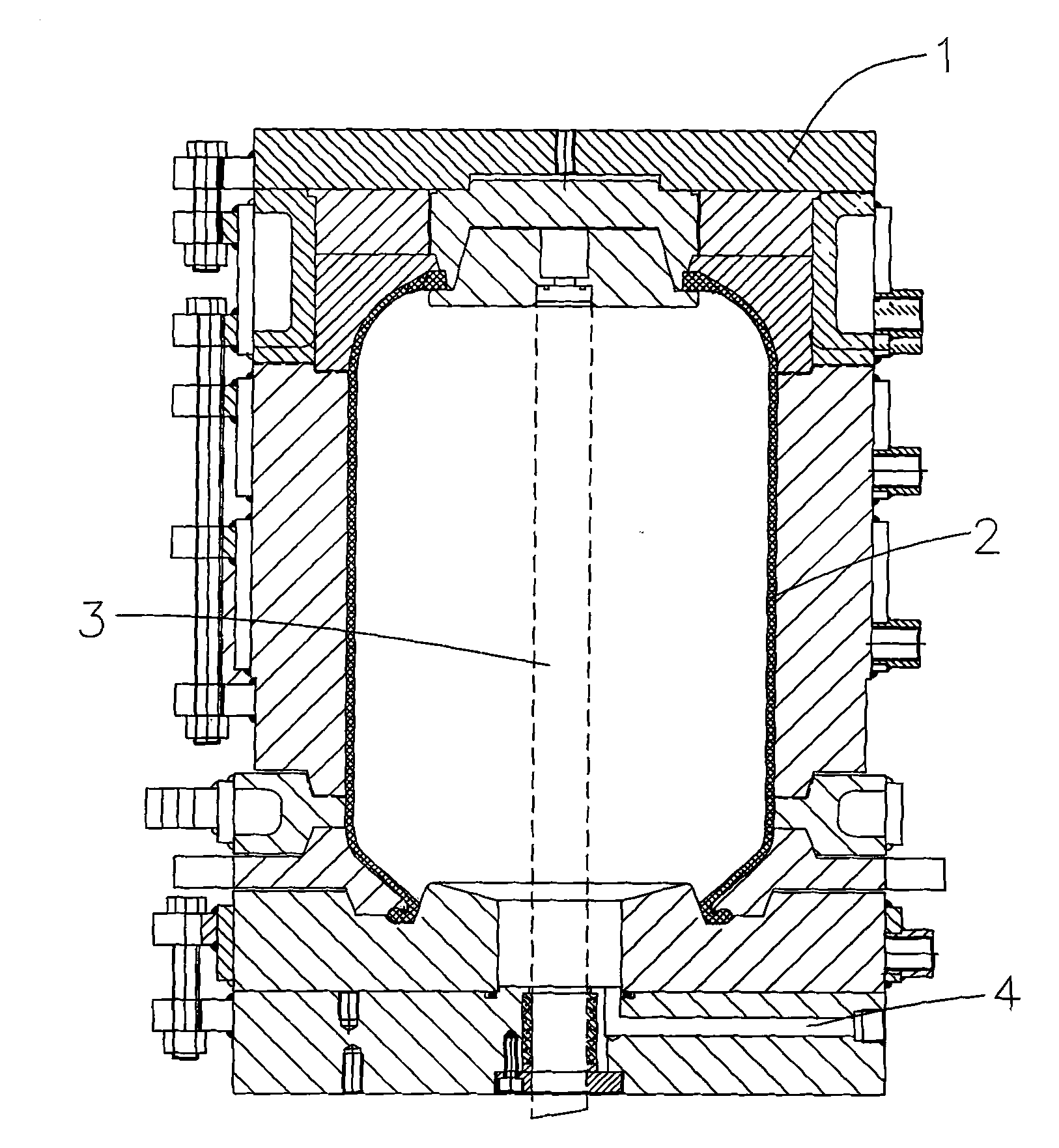

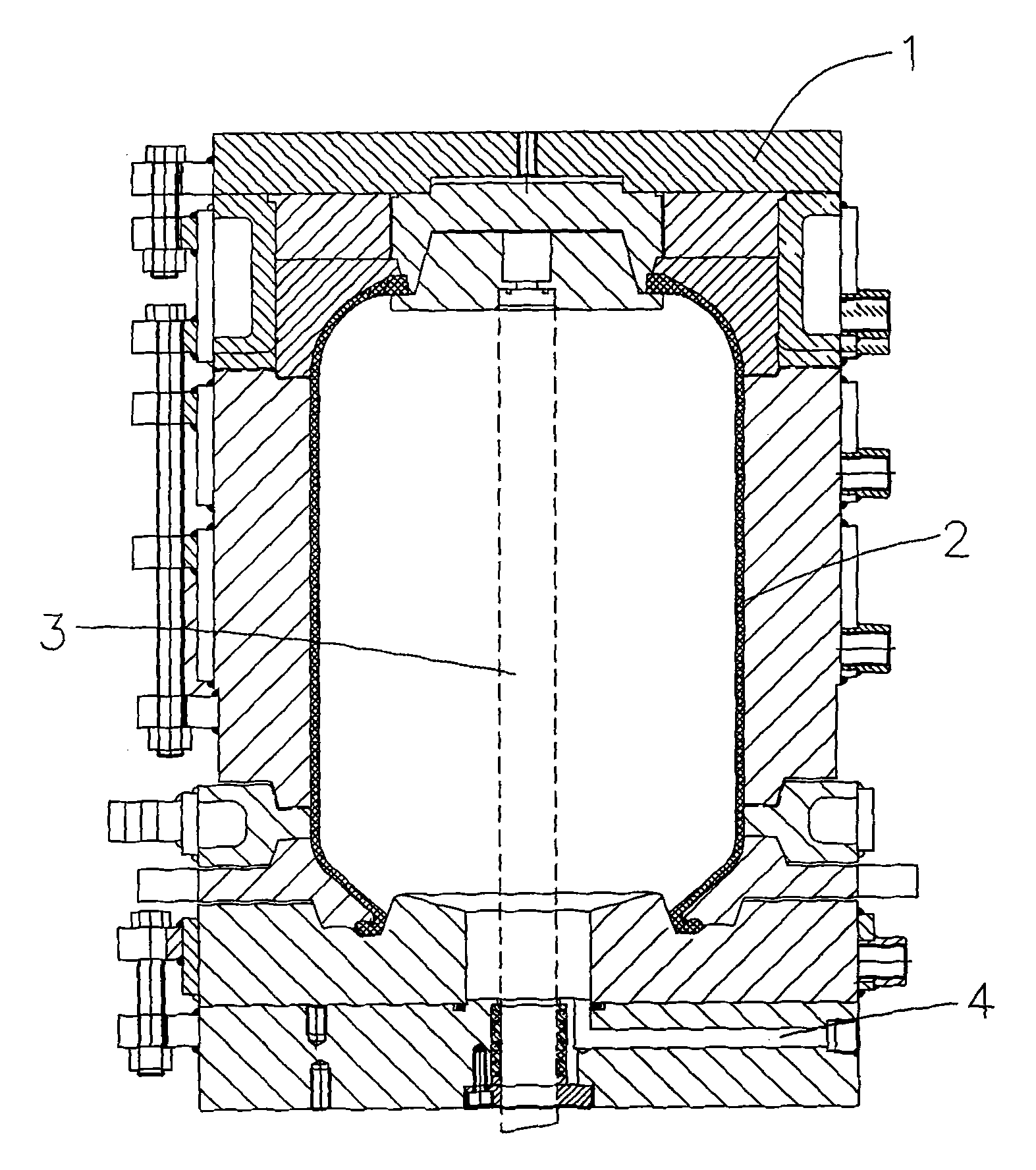

Rubber air spring capsule-free vulcanization production method

The invention discloses a rubber air spring capsule-free vulcanization production method, which comprises: removing a capsule holder structure from a vulcanization mold; directly filling a preformed rubber air spring blank into the molding cavity of the vulcanization mold; sizing the rubber air spring blank in the presence of air or nitrogen under a pressure of 0.1 to 1bar; closing the mold, and charging steam under a pressure of 6 to 15bar to provide heat for the rubber air spring blank; and quickly charging nitrogen serving as an internal pressure medium under a pressure of 18 to 35bar for vulcanization. In the invention, by applying a capsule-free vulcanization technical process, the method has the advantages of energy conservation, reduction in energy consumption, environmental friendliness, improvement on efficiency and the like and improves the uniformity and service life of products.

Owner:李文庆

Biological degreasing agent used in metal processing pretreatment of oil removing and degreasing, and method for processing metal surface greasy dirt

The invention discloses a biological degreaser for degreasing pretreatment in metal processing industry and method for processing greasy dirt on metal surfaces, which integrates the two independent processes of grease removing and greasy dirt decomposing, the biological degreaser containing oil-degraded microorganisms can not only scale off greasy dirt from metal surfaces, but also decompose the greasy dirt simultaneously.

Owner:TANTZ ENVIRONMENTAL TECH

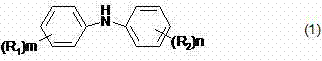

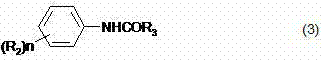

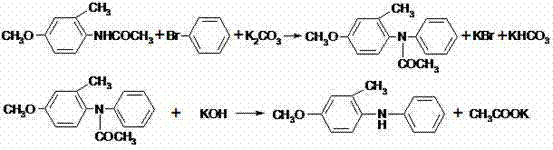

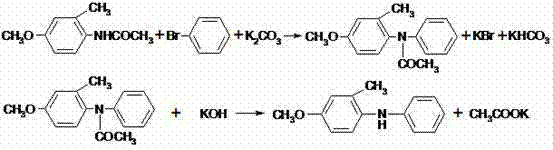

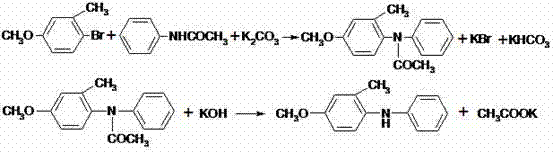

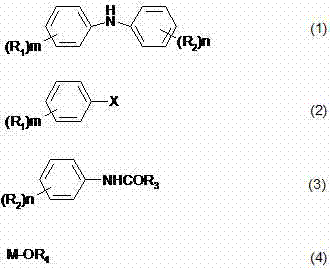

Preparation method of diphenylamine or ring-substituted derivative thereof

ActiveCN103086898ASave energySimple production processOrganic compound preparationAmino-hyroxy compound preparationPtru catalystAcyl group

The invention relates to a preparation method of diphenylamine or a ring-substituted derivative thereof. The method comprises the following steps: utilizing an alkali metal alkoxide as an alkaline reagent, and performing reaction on halogenobenzene or the ring-substituted derivative thereof and N-acylated aniline or the ring-substituted derivative thereof in the presence of a catalyst to prepare the diphenylamine or the ring-substituted derivative thereof and simultaneously produce a second product, namely carboxylic acid ester. The molar ratio of the halogenobenzene or the ring-substituted derivative thereof, the N-acylated aniline or the ring-substituted derivative thereof and the alkali metal alkoxide is generally selected at 1.0:(1.0-1.1):(1.1-1.3). The method is utilized for producing the diphenylamine or the ring-substituted derivative thereof, and the method has the advantages of simple production process, short reaction period, high utilization rate of equipment, low energy consumption and a small quantity of three wastes.

Owner:SHANDONG DOCRIS CHEM

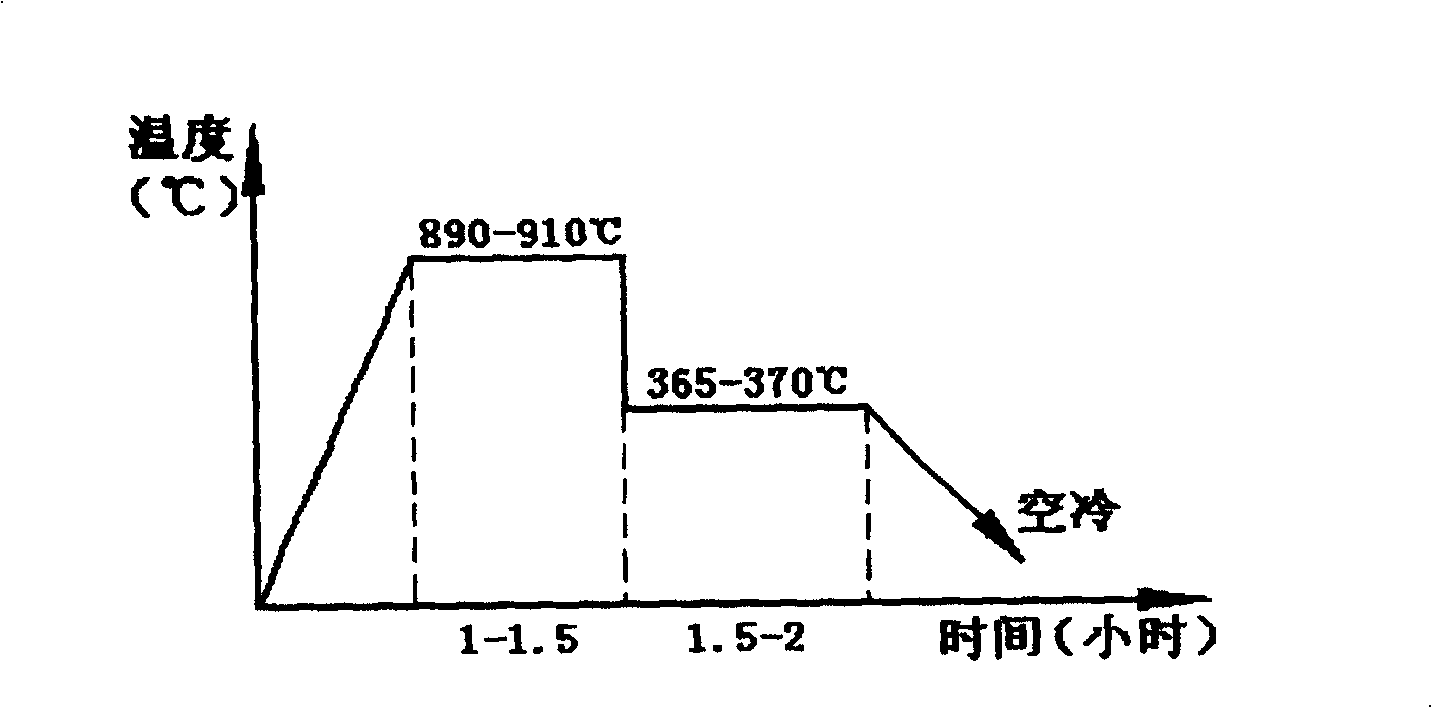

Crankshaft of automobile engine

An engine crankshaft of automobile is prepared from cast iron material. It features that material intensifying process is applied on said cast iron material i.e. utilizing isothermal hardening heat treatment to process normal graphite cast iron to be austenit-bainite graphite cast iron and making cast-state blank bailing grade be 1-2 grade as well as making graphite ball diameter be above 6grade.

Owner:CHERY AUTOMOBILE CO LTD

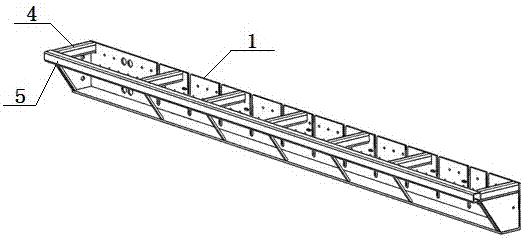

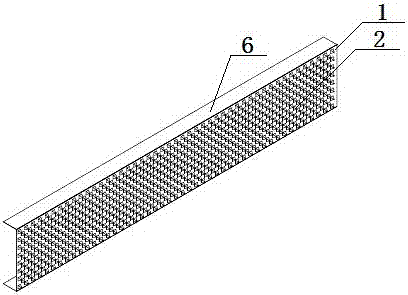

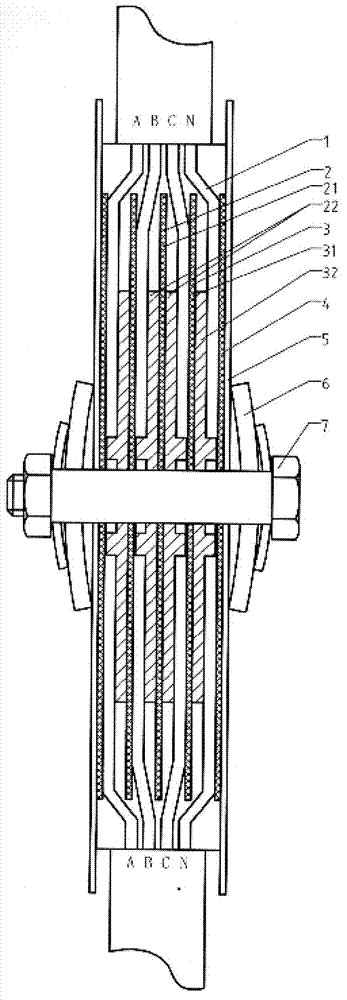

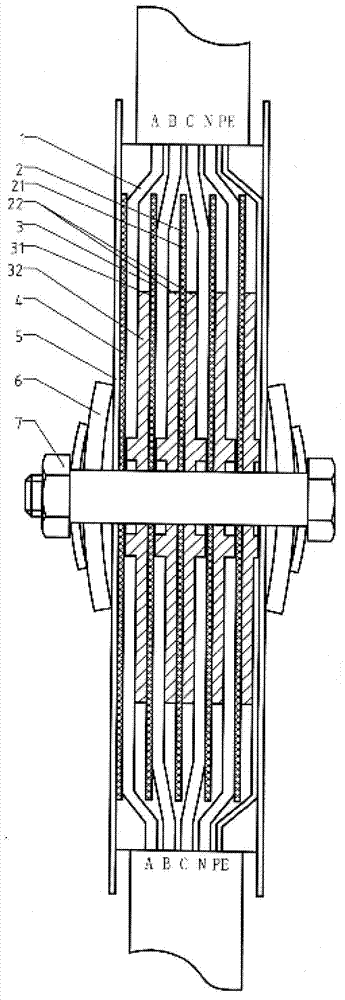

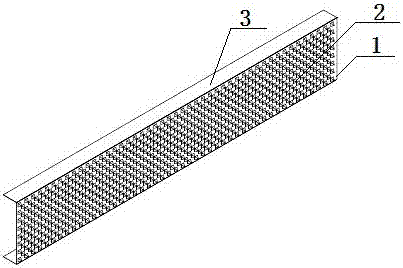

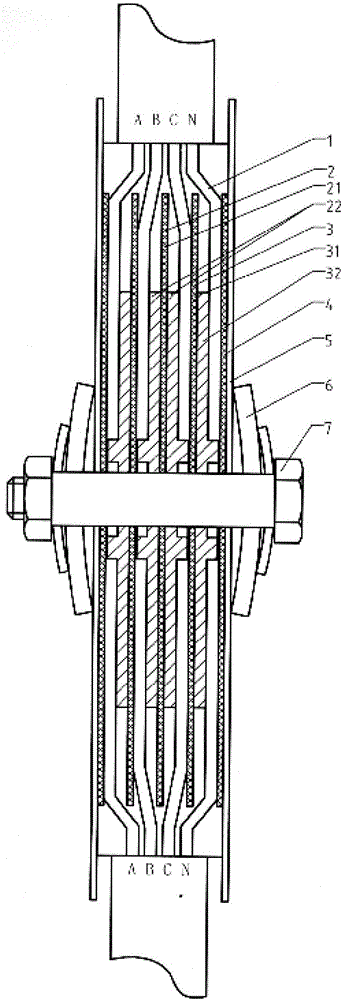

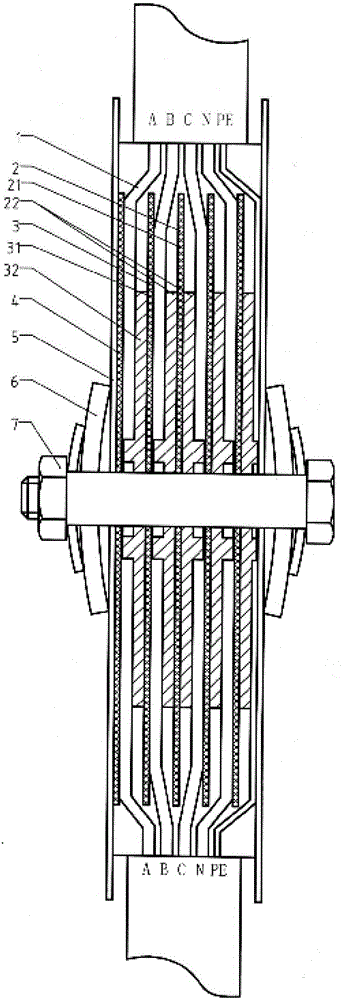

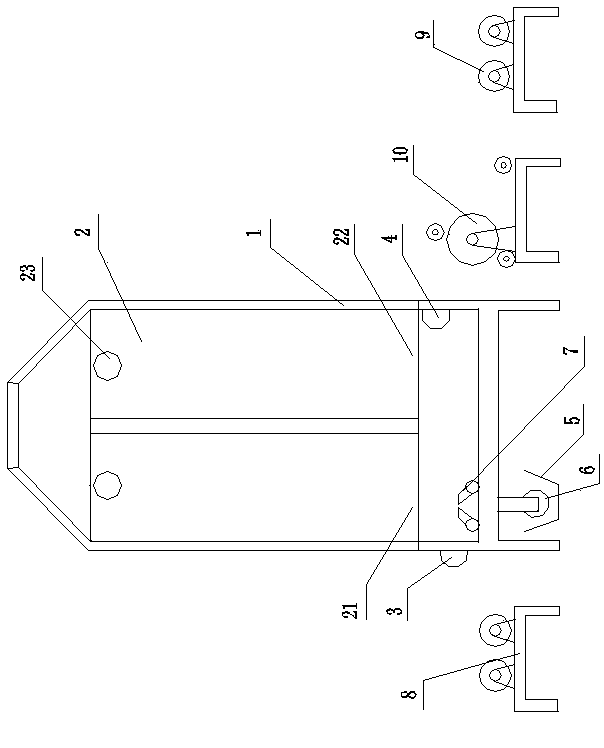

Device and method for butting single-phase single-sheet transition conductor of bus duct connector

ActiveCN102820560ALarge carrying capacityReduce temperature riseLine/current collector detailsElectric connection structural associationsSingle phaseEngineering

The invention relates to a device and method for butting a single-phase single-sheet transition conductor of a bus duct connector. The device comprises double-insertion-sheet type bus duct connectors (2) and single-insertion-sheet type bus duct connectors (3) which are arrayed in sequence, and when the power supply is of a three-phase four-wire system, one single-insertion-sheet type bus duct connector (3), the double-insertion-sheet type bus duct connector (2) and another single-insertion-sheet type bus duct connector (3) are arrayed in sequence. Each double-insertion-sheet type bus duct connector (2) comprises a two-phase insulating sheet (21) and a transition conductor (22). The connection method is as follows: dividing the end of a bus duct into branches with prestress, inserting the B-phase branch and C-phase branch of the power supply into the double-insertion-sheet type bus duct connectors (2) respectively, and inserting the single-insertion-sheet type bus duct connectors (3) between the A-phase branch and the B-phase branch, between the C-phase branch and the N-phase branch and between the N-phase branch and the PE-phase branch respectively. Due to the clamping function of the prestressed branches of a bus duct conductor bar (1), the conductor of the connector can be matched tightly before being fastened by insulating bolts (7).

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

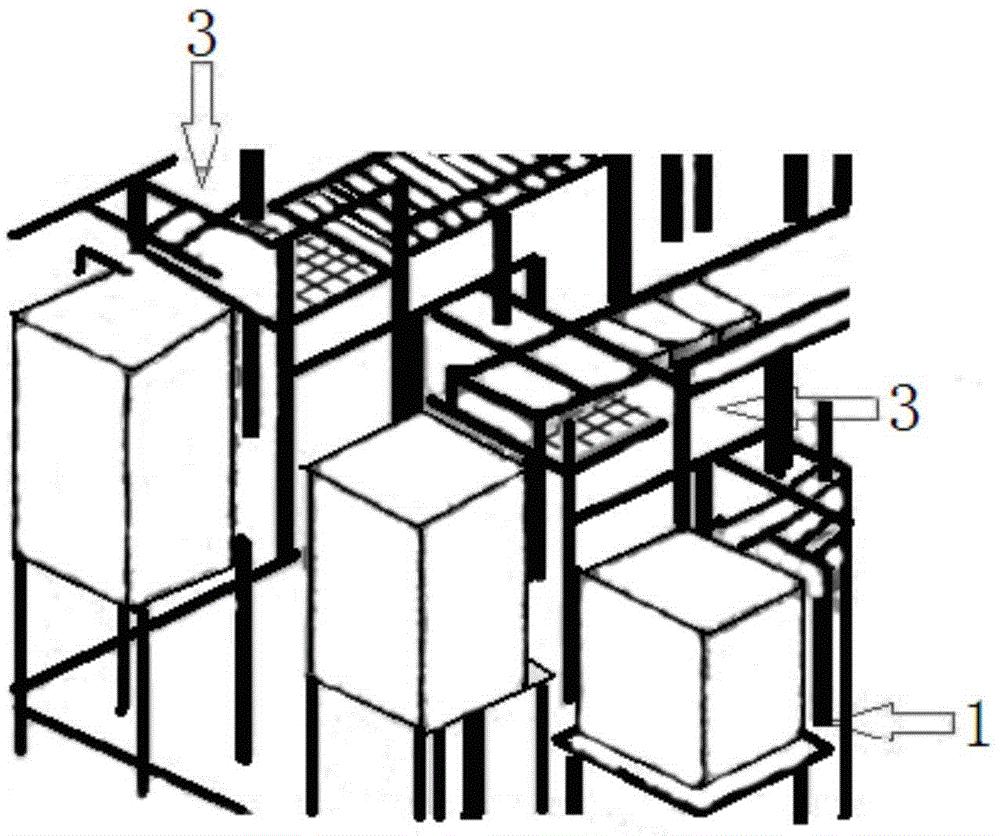

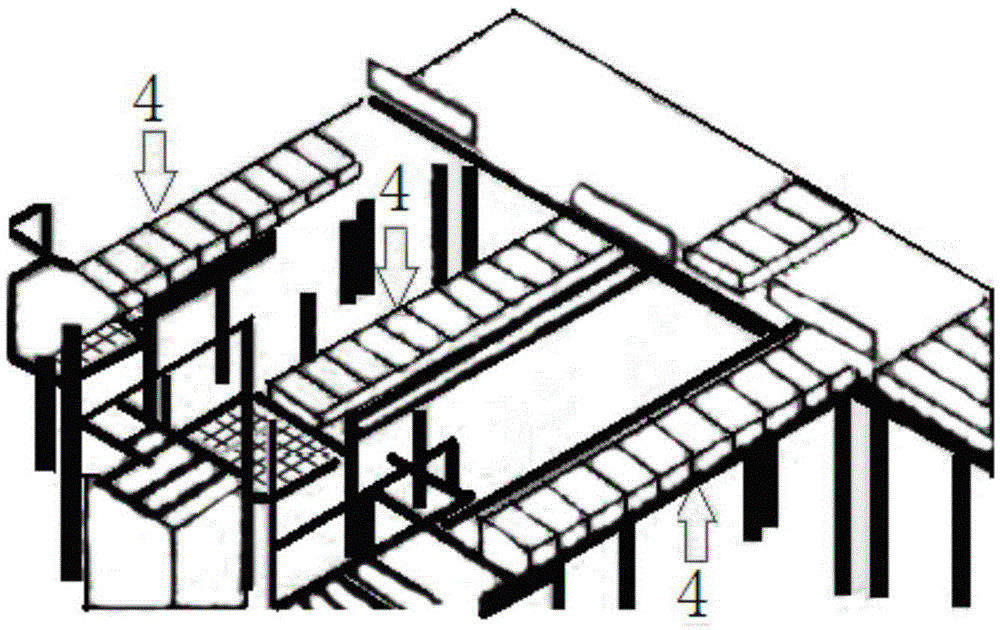

Full-automatic destacking, stacking and packaging system

InactiveCN104691813AGive full play to the advantagesEnvironmentally friendlyShock-sensitive articlesEngineeringTruck

The invention discloses a full-automatic destacking, stacking and packaging system. The full-automatic destacking, stacking and packaging system comprises the following steps: the first step, performing the intelligent positioning to a single stack brick on a kiln car, automatically conveying the positioned single stack brick to the appointed destacking position through holding the stack; the second step, performing the automatic hierarchy clamping to multiple layers of the loosely stacked bricks in the single stack of the brick kiln through several parallel destacking devices, and conveying to a grouping system, and synchronously performing by several sets of destacking devices; the third step, performing the intelligent grouping shaping to the width and length of the brick type of several destacking devices; and the fourth step, stacking the grouped bricks, and reserving the operation reserving hole of a fork truck. The full-automatic destacking, stacking and packaging system is capable of using the method of holding bricks in the single stack, parallelly destacking in several sets, and flexibly grouping shaping, and avoiding the phenomenon that the process is not stable and the collapse rate of the brick stack is high in the wet brick stacking and brick kiln burning processes because of the deformation and adhesion.

Owner:SHANGHAI JIXIN METAL COATING

Preparation method of fontanesia fortunei Carr. scented tea

InactiveCN106070918AImprove nutritional value and medicinal valueHigh nutritional valueTea substituesBudCell budding

The invention relates to a preparation method of fontanesia fortunei Carr. scented tea. The preparation method comprises the following steps: air-drying and picking, airing for withering, raising the temperature for deactivating enzyme, sun-drying, picking and choosing, and packaging and storing. According to the preparation method provided by the invention, fontanesia fortunei Carr. flower buds are mainly used as a raw material, the efficacy of pollen is made full use, and the prepared fontanesia fortunei Carr. scented tea has the effects of losing weight, sterilizing and eliminating inflammation, nursing intestines and the stomach, promoting metabolism, enhancing the immunity and the like. Through the preparation method provided by the invention, which is free of stir-frying, kneading and twisting, loss of the pollen in the fontanesia fortunei Carr. flower buds can be reduced and the nutritional value of the pollen is maximized; fontanesia fortunei Carr. flowers have unique fragrance, so that the fontanesia fortunei Carr. scented tea is good in mouth feel and pleasant in fragrance; the fontanesia fortunei Carr. scented tea is safe to drink and simple in process, and is suitable for large-scale production.

Owner:盐城市盐都区盐龙蟒南农家苑

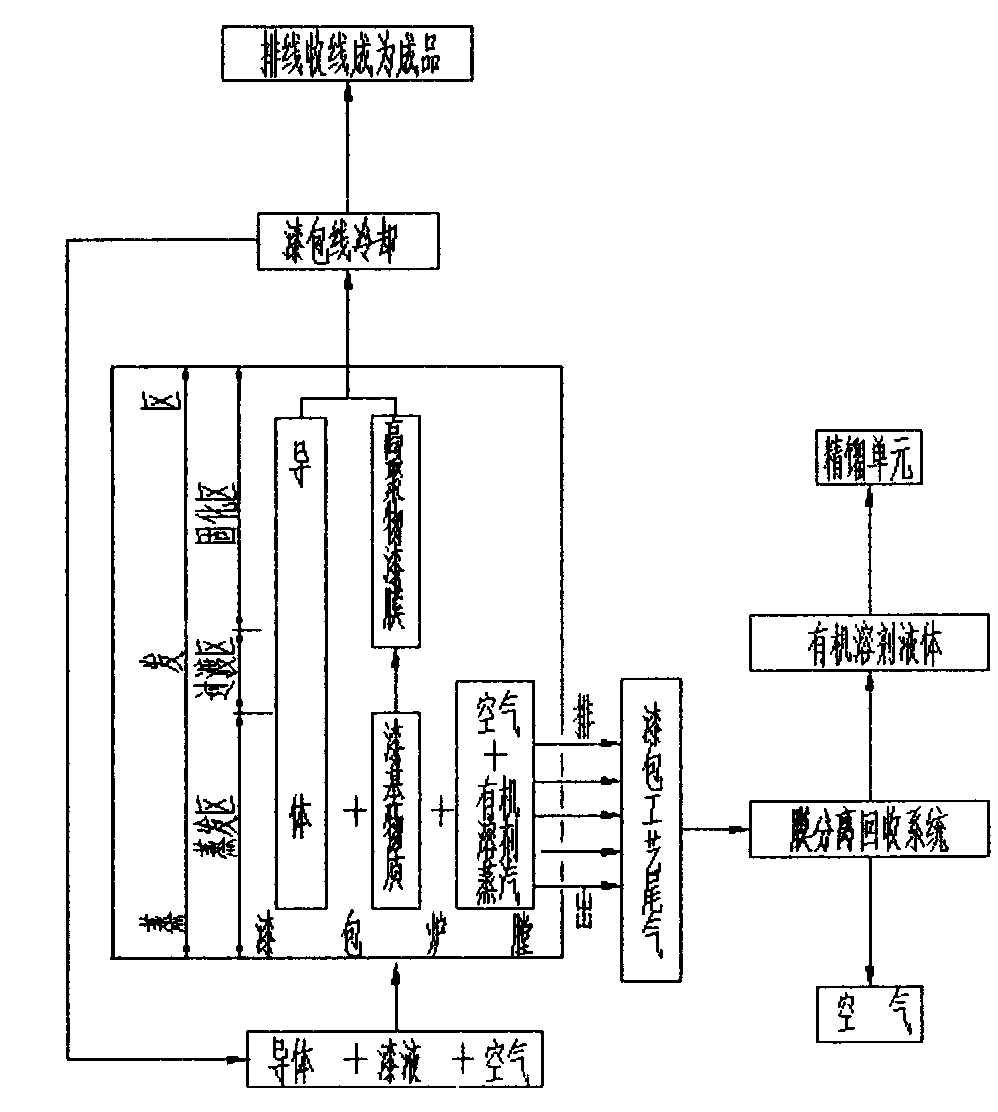

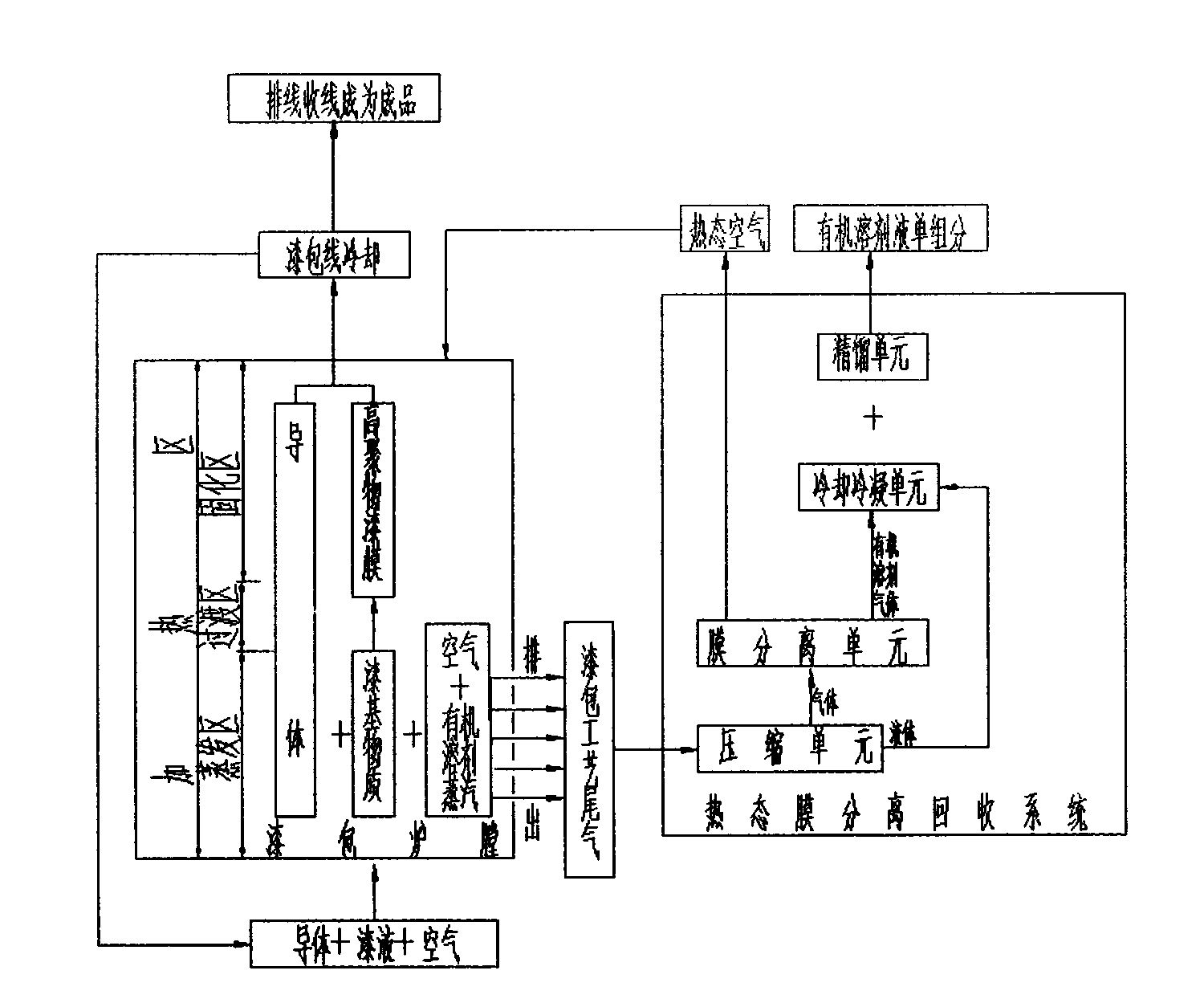

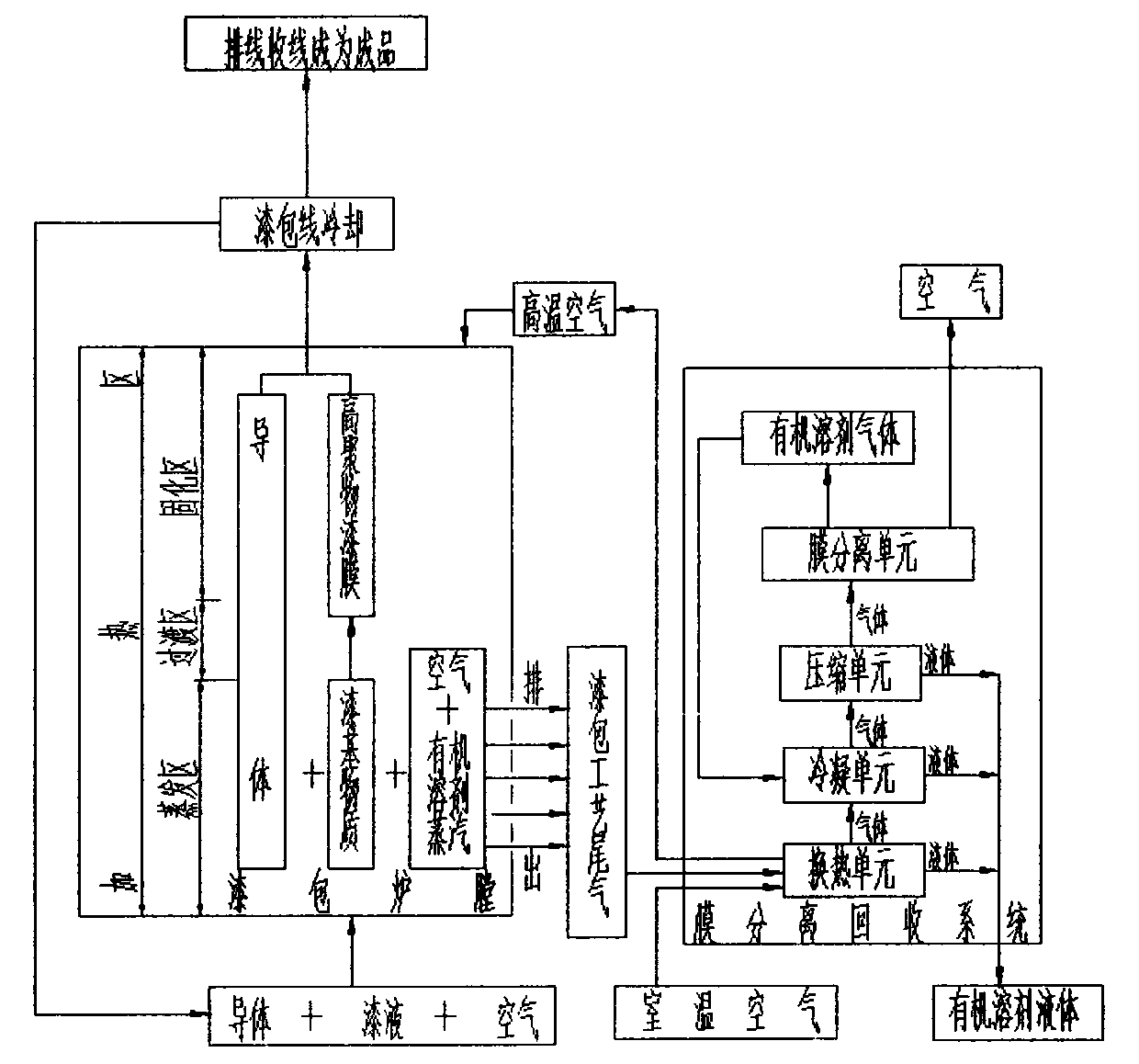

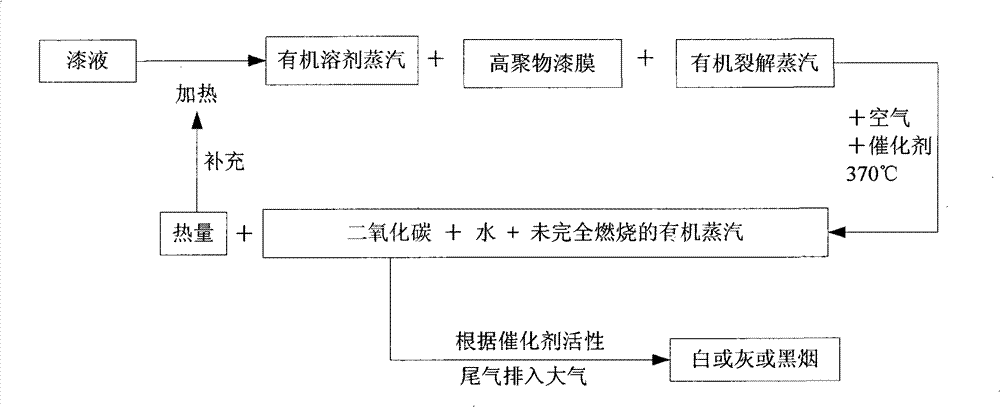

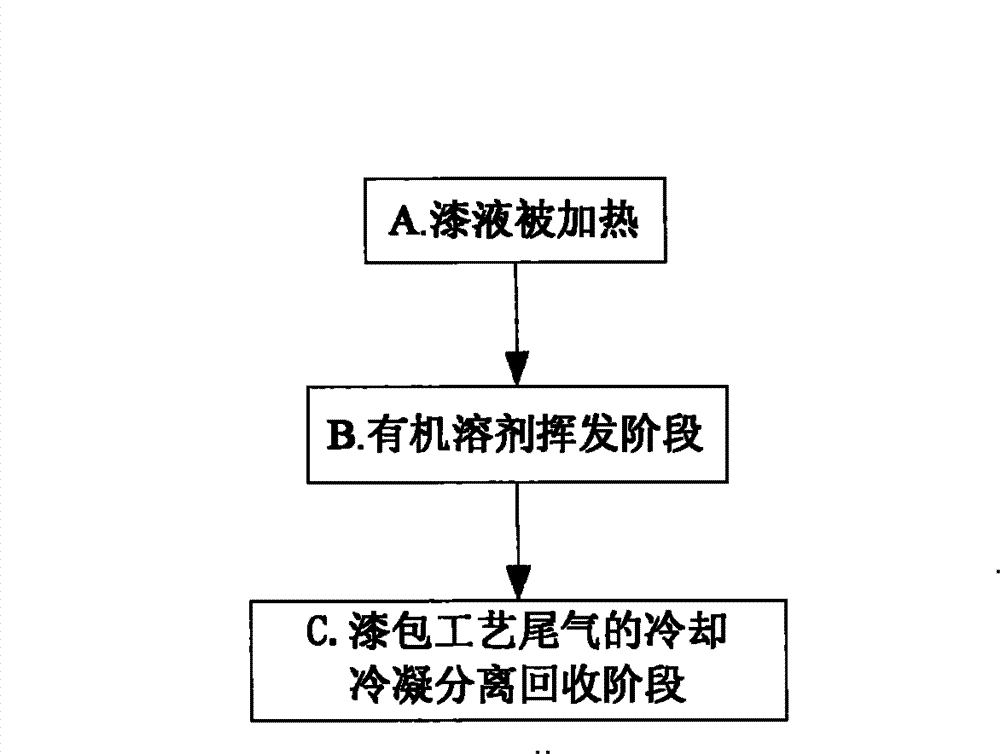

Separation recovery method of enameling technique exhaust

InactiveCN103506007AWith consumption reductionAvoid black smokeSemi-permeable membranesVapor condensationRecovery methodOrganic solvent

The invention discloses a separation recovery method of enameling technique exhaust, which comprises the following steps: A. after a conductor is enameled, the conductor enters the inside of an enameling hearth together with air; B. in the evaporation region, an organic solvent is volatilized into enameling technique exhaust; C. the enamel-base substance is continuously heated to generate a high polymer enamel film, and enters a room temperature space to be cooled; D. after repeated circulations, the wire is taken up by a winding; D. the recovery method also comprises the step of discharging the enameling technique exhaust out of the hearth in time between the step B and the step C; and F. the enameling exhaust is continuously injected into a membrane separation recovery system on line. The method has the following advantages: the solvent which is catalytically burnt up and stilled used in the existing enameled wire industry is subjected to organic solvent vapor-air separation through a membrane component, and recovered to obtain an organic solvent liquid; and the organic solvent liquid is rectified to obtain the organic solvent. Compared with other modes for treating enameling technique exhaust, the membrane separation recovery of enameling technique exhaust has the advantages of no toxicity, no emission, energy saving, consumption reduction and effect enhancement.

Owner:韩富生

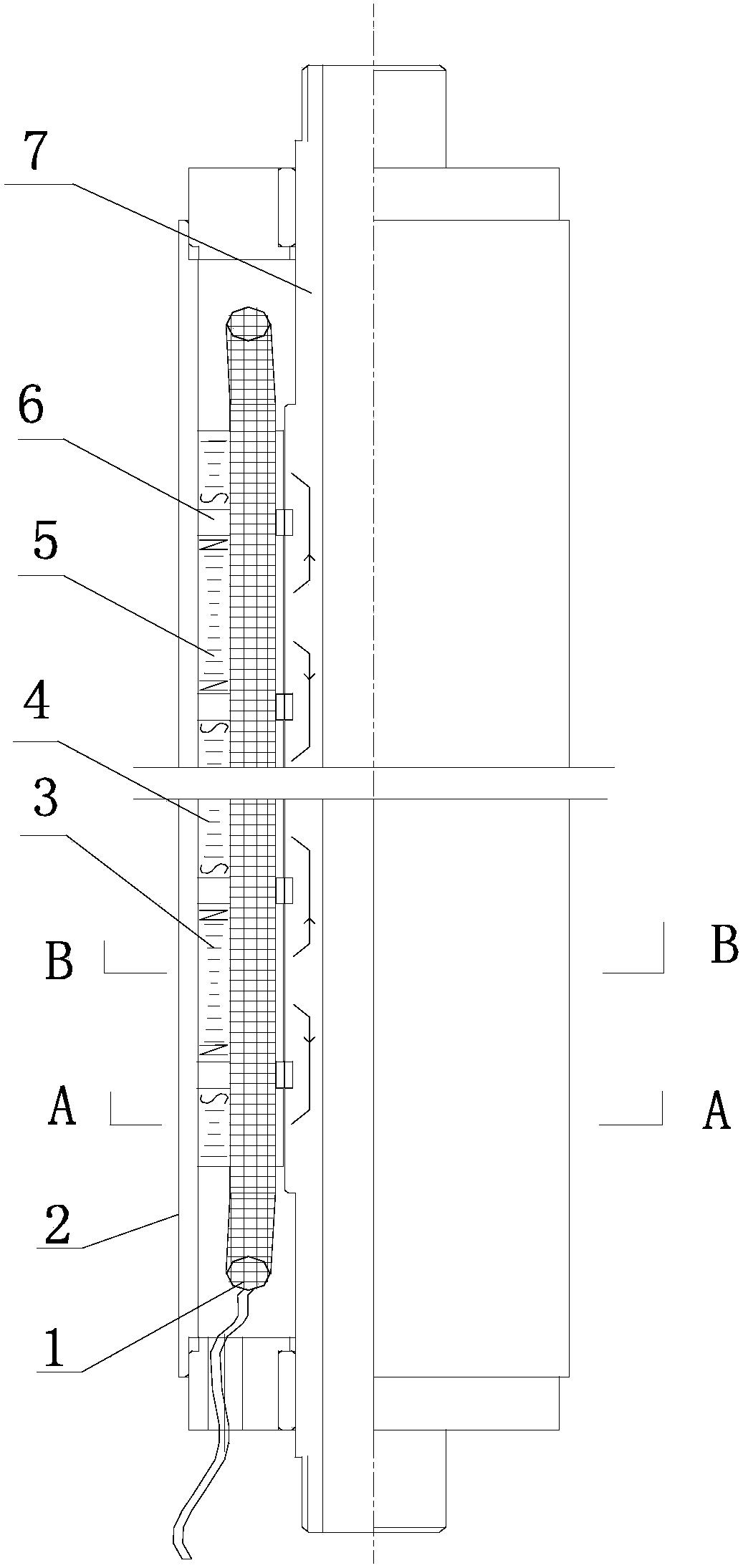

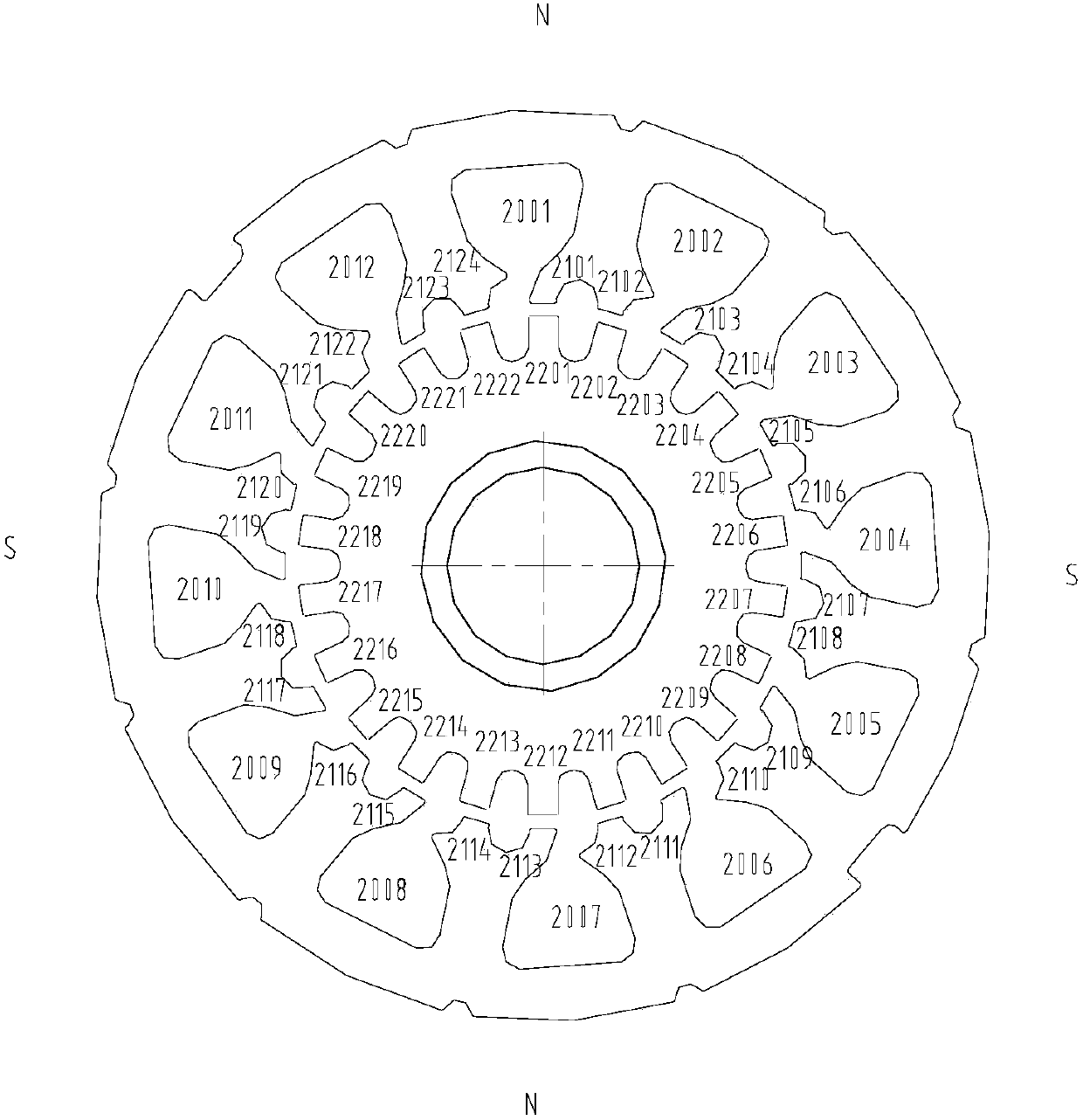

Axial excitation low-speed synchronous motor with axial straight-through tooth integral rotor

InactiveCN107623423AHigh mechanical strengthIncrease torqueMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorLow speed

The present invention relates to an axial excitation low-speed synchronous motor with an axial straight-through tooth integral rotor. An S-polarity segment sectionalized stator core 3 and N-polarity segment sectionalized stator core 4 are separately formed by stacking large and small tooth circumferential offset tooth slot stator core punched sheets 5; the S-polarity segment sectionalized stator core 3, the N-polarity segment sectionalized stator core 4 and an annular excitation coil 6 are axially mounted in a case 2 co-axially and sequentially in a forward direction and reverse direction alternate manner; an axial through tooth overall hollow rotor 7 is coaxially mounted in the inner cavities of the S-polarity segment sectionalized stator core 3 and the N-polarity segment sectionalized stator core 4; and 0.2-mm electromagnetic air gaps are left between the axial through tooth overall hollow rotor 7 and the S-polarity segment sectionalized stator core 3 and the N-polarity segment sectionalized stator core 4.

Owner:哈尔滨森特能源科技有限公司

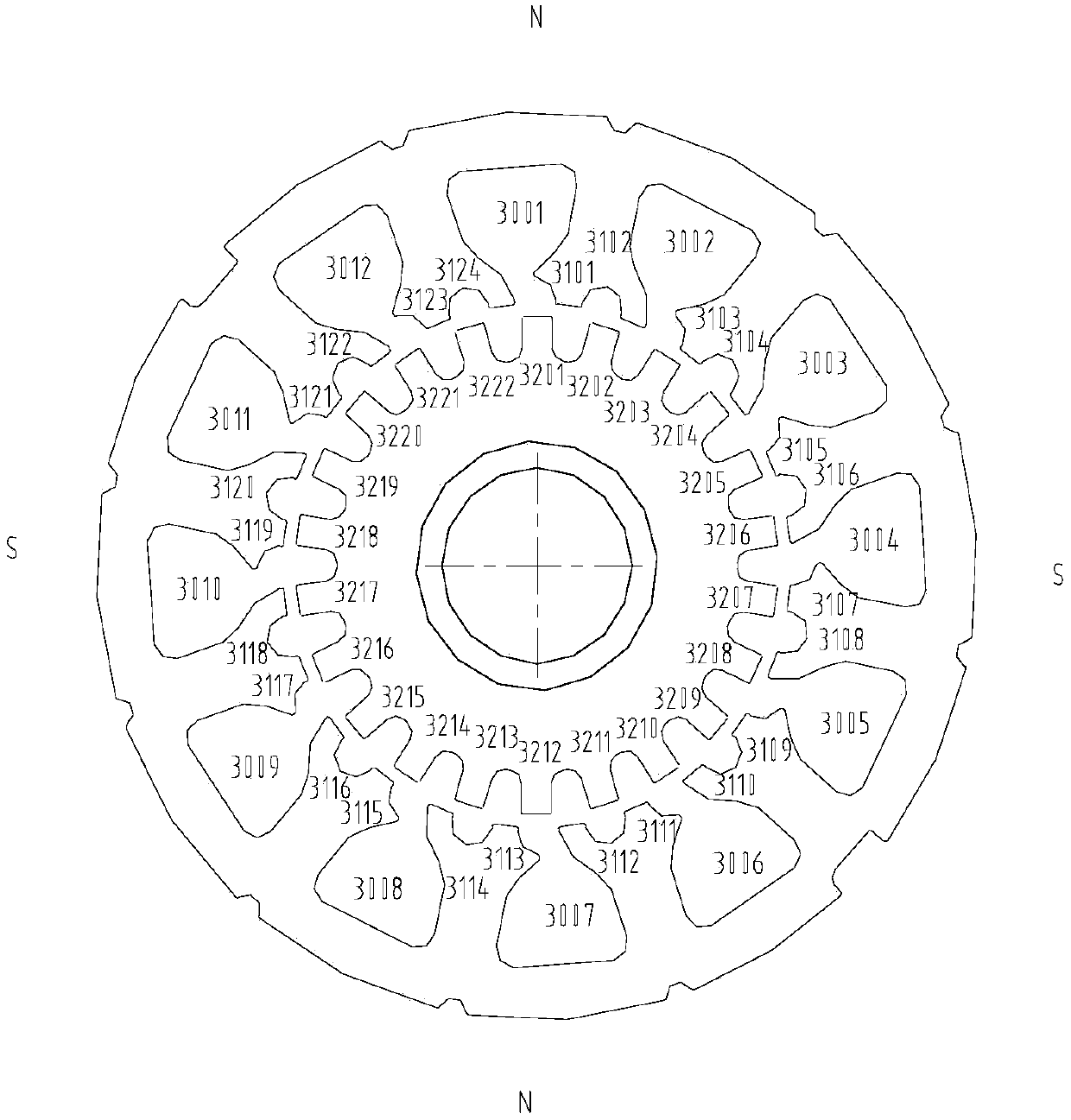

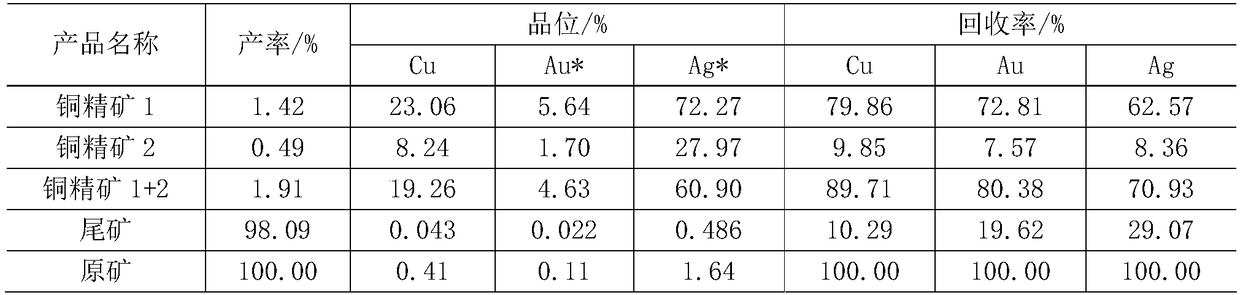

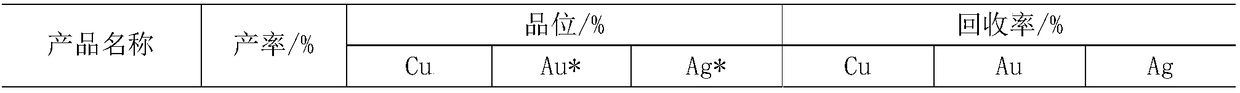

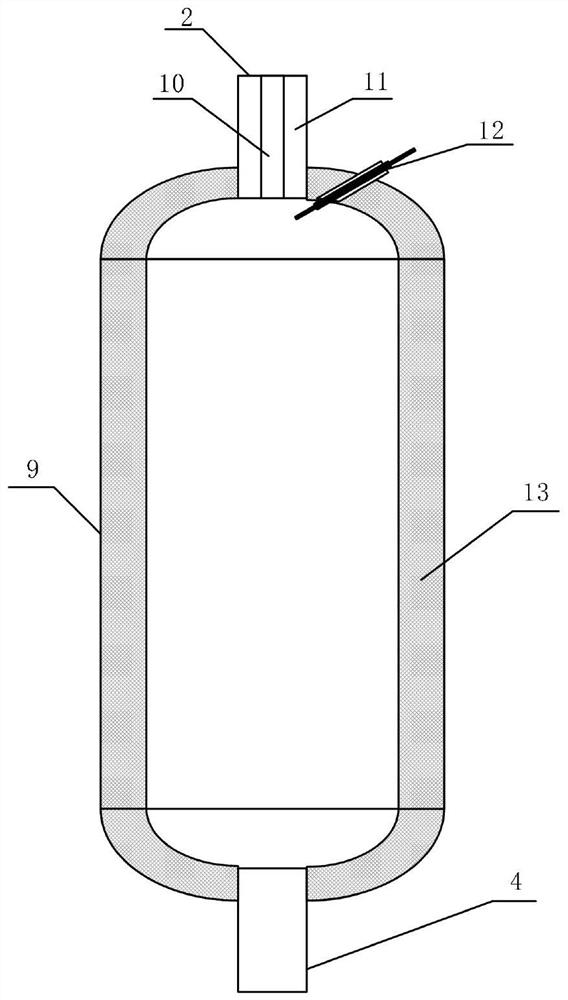

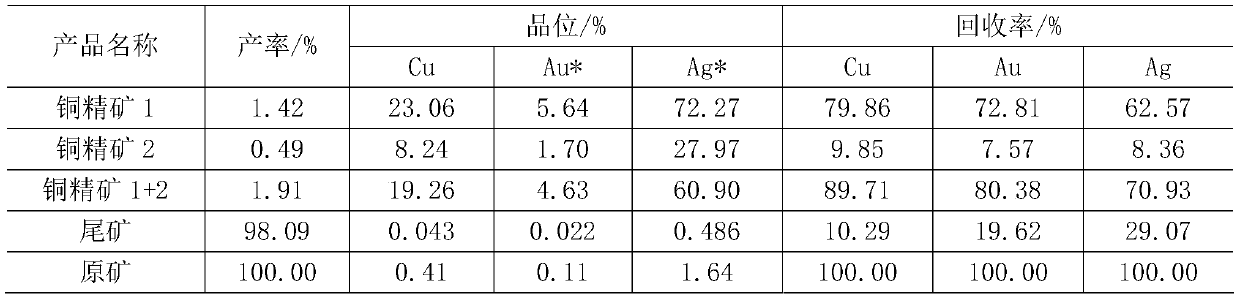

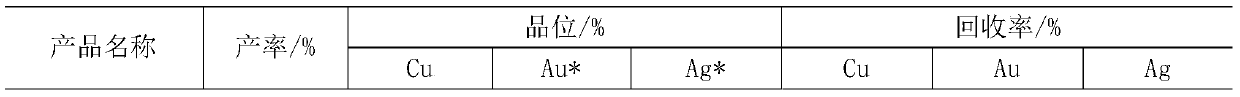

Beneficiation method of veinlet disseminated low-grade porphyry type copper ore

ActiveCN109465115AHigh mechanical strengthGood mineralization effectFlotationCopper sulfideMaterials science

The invention relates to a beneficiation method of veinlet disseminated low-grade porphyry type copper ore, belonging to the technical field of mineral metallurgy processing. The technical problem tobe solved by the invention is the difficulty of low copper ore grade and various copper minerals in mineral processing. A technology for introducing a copper and associated gold and silver mineral high-efficiency combined collector, adding lime and sodium sulfide for pulp blending in roughing process and introducing sodium silicate and sodium hexametaphosphate in the fine screening process is adopted. The problems that the recovery rate of useful minerals is low, the fine screening process is long and the concentrate grade is not high in beneficiation of the veinlet disseminated low-grade porphyry type copper ore are solved. The recovery of main metal copper and associated gold and silver is effectively increased, the quality of copper concentrate is improved, the stability of beneficiation is improved, the adverse effect of seasonal temperature difference on mineral beneficiation indexes is overcome, the circulating reuse of mineral beneficiation wastewater is realized, and the mineral beneficiation cost and energy consumption are reduced. The invention is used for beneficiation of copper sulfide ores in high-cold seasonal frozen areas.

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD

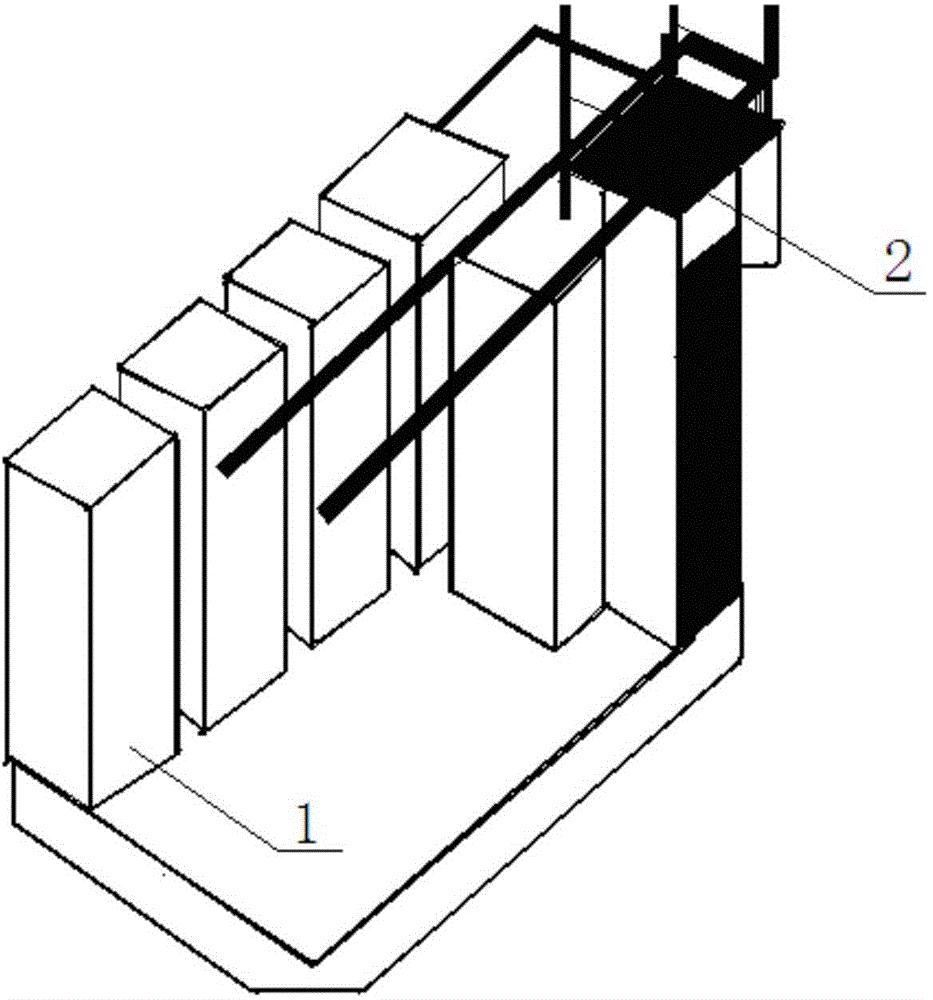

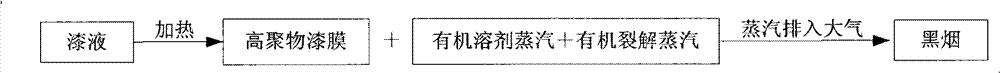

Recovery method and device of enamelling technique tail-gas

InactiveCN101337134BDischarge in timeAvoid black smokeVapor condensationRecovery methodOrganic solvent

The present invention discloses an end gas reclaiming method for a lacquering process including the steps of: A. lacquer liquid being heated; B: organic solvent being heated to volatilizate; C: end gas of lacquer coating process being cooled, condensated, separated and reclaimed. Advantages of this invention are as follows: the organic solvent steam and high temperature air are reclaimed separately from the catalyzed and burnt solvent which is still in use today in lacquer-coating industry by the method of cooling, condensation and separation. The reclaimed liquid turns into reusable organic solvent after a rectifying process while the reclaimed sub-high temperature air is sent back into the hearth to supplement the required energy for heating the lacquer liquid. In the circumferential surface of the inner hearth of the lacquering oven, a plurality of air outlets are arranged in the organic solvent volatilization section,which makes the solvent steam be discharged in time and preventsthe black smoke from being formed due to the metamorphism of solvent steam under overheated condition. Compared with the end gas of lacquering process reclaimed by traditional electrothermal and catalysis-burning process, the end gas reclaimed by the process of cooling, condensation and separation has advantages of innocuity, no-exhaust, energy saving, consume reducing and efficiency increasing.

Owner:韩富生

Tool for molding rough surface of precast concrete unit

PendingCN107529485ANo pollution in the processSave energyCeramic shaping apparatusRough surfaceEngineering

The invention relates to a tool for molding the rough surface of a precast concrete unit. The tool comprises multiple grooves or multiple bumps which are molded and processed on a molding template andaccord with standards of the rough surface of a precast unit in China. The tool provided by the invention has the advantages that mechanical equipment and washing stations are greatly eliminated, nodust pollution or mud pollution is produced, cost is low, efficiency is high, and the rough surface of the molded precast unit accords with the standards in China, so that product quality is good.

Owner:惠州远大住宅工业有限公司

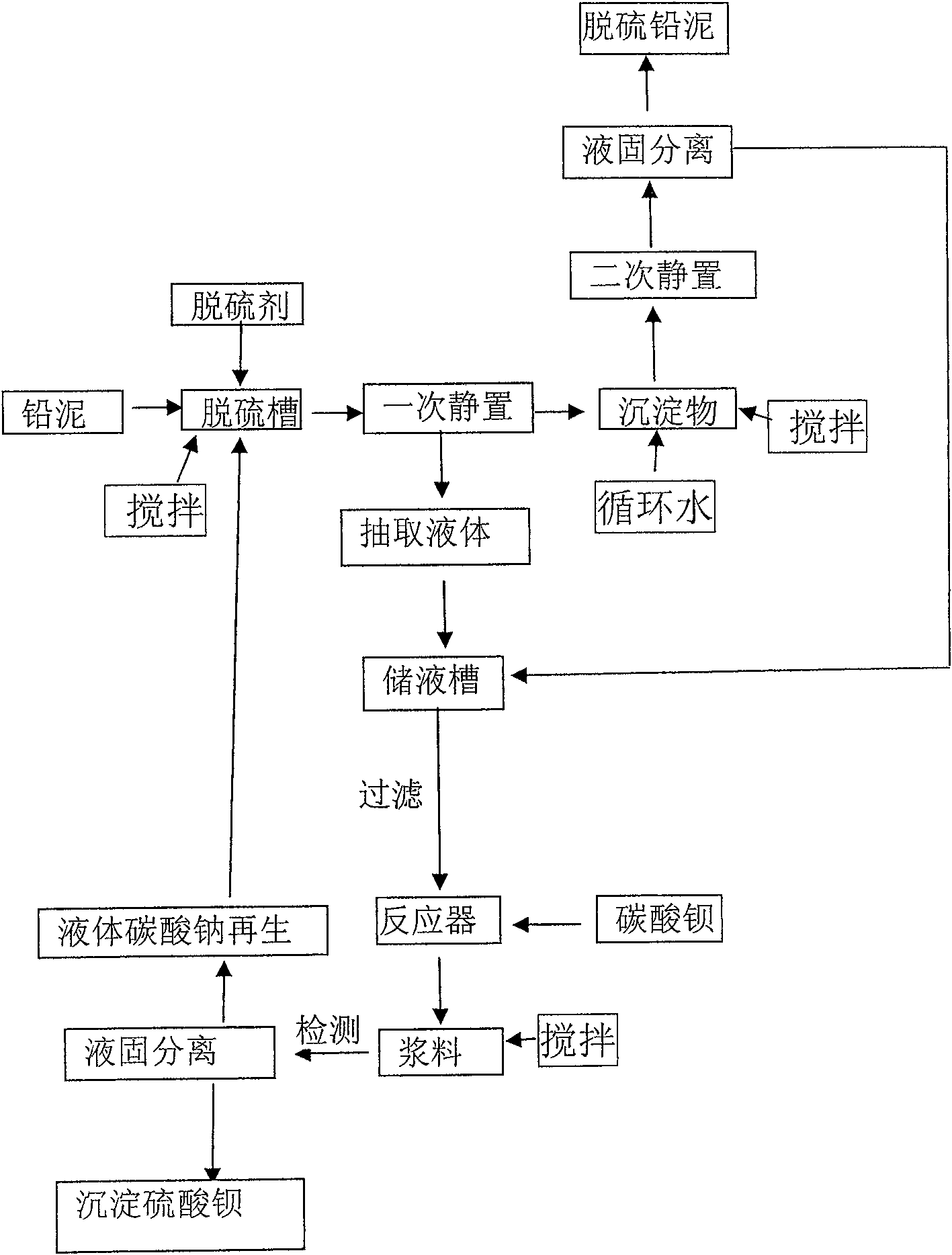

Desulfurization and transformation method for waste lead accumulator regenerative lead

InactiveCN100569967CSolve the real problemThe effect is positive and obviousProcess efficiency improvementCarbonate preparationLead carbonateChloride

Owner:上海飞轮有色冶炼厂

Assembled integrated process of 3D memory and spray painting and lithograph

ActiveCN1268805CShort processTo meet the objective requirements of the ever-changing fashionHeating/cooling textile fabricsDyeing processSlurryEngineering

This is a complex arrangement technology of three dimensions recall and inject drawing and printing for ready-to-wear clothes. It contains following steps: To do the arrangement for the ready-to-wear clothes: To arrange of polymerization and skein for them. Be arranged them in three dimensions in finished form by thermo-compression or to spur paint paste on their surface. To cure them on fire to fix colors, then to arrange them in their dimensions and pack them.

Owner:JIANGSU HUAYI GARMENT CO LTD

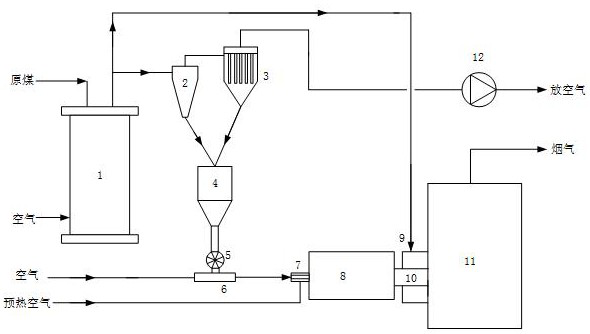

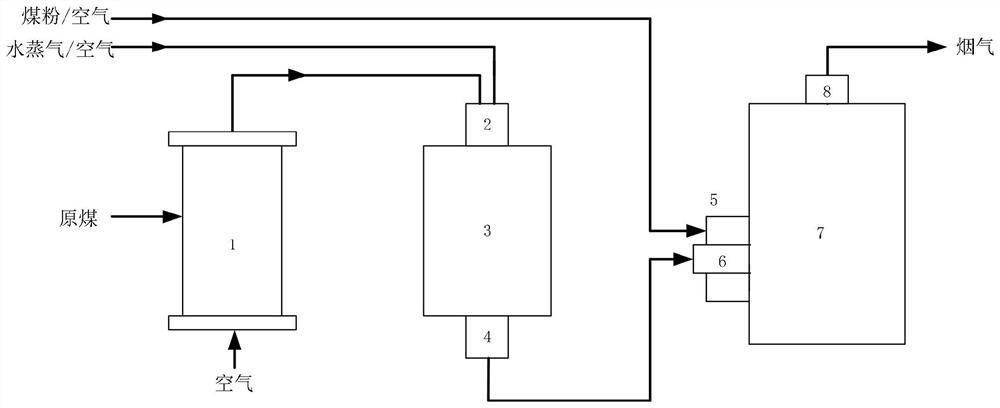

Method and device for ultralow-load stable combustion of pulverized coal fired boiler in power plant

ActiveCN113719831AImprove adaptabilityImprove burnout rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelPower gridProcess engineering

The invention discloses a method and a device for ultralow-load stable combustion of a pulverized coal fired boiler in a power plant, belongs to the field of power generation of coal-fired boilers, and aims to realize stable operation of the pulverized coal fired boiler under ultralow load and meet the requirement of flexible peak regulation of a power grid. The method comprises the steps that raw coal is made into pulverized coal with the particle size smaller than 200 micrometers through a coal mill, wherein 1%-5% of the pulverized coal is carried by airflow to enter a combustion stabilizer; the temperature of the combustion stabilizer is controlled to be 800-1,100 DEG C by adjusting the air amount, and the pulverized coal is subjected to oxygen-deficient combustion and gasification reaction to generate high-temperature fuel gas; and the high-temperature fuel gas with unburnt pulverized coal is sprayed into the boiler through an ignition pipe, and the effect of stabilizing combustion of the pulverized coal in the boiler is achieved. The combustion stabilizer is composed of a nozzle, an electric heater, the ignition pipe, a heat-insulation fire-resistant lining and a shell. The method has the advantages of being simple in system, flexible to operate, good in coal type adaptability, high in response speed, low in operation cost and small in investment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

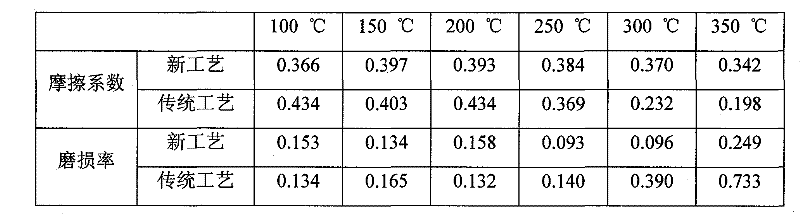

Novel composite powder of rubber substituent FA for substituting rubber to produce wound clutch facing

InactiveCN102127248BWith sustainable developmentHigh and smooth coefficient of frictionStarch adhesivesAldehyde/ketone condensation polymer adhesivesSocial benefitsBLENDER/MIXER

The invention discloses a novel composite powder of rubber substituent FA for substituting rubber to produce a wound clutch facing, which aims to solve the problems of consumption of disposable resource of petroleum, complex process, high production cost, hidden danger of safety and environment, 'three hot' of products and the like in the conventional method of producing the wound clutch facing by using rubber. The novel composite powder of rubber substituent FA is prepared by mixing polysaccharide powder, a stabilizing material, a coloring agent and an isolation material in a blender mixer according to a certain ratio, dosing sequence and dosage for a certain period of time. The novel composite powder of rubber substituent FA for producing the wound clutch facing has the characteristics of energy conservation, consumption reduction, environmental protection, sustainable development and the like, and has obvious economic and social benefits.

Owner:NANTONG XINYUAN SPECIAL FIBER

Ultra-low load stable combustion method and device for coal-fired boiler

PendingCN114777116AImprove burnout rateReduce loadPulverulent fuel combustion burnersCombustion regulationBoiler furnaceWater vapor

The invention discloses an ultralow-load stable combustion method and device for a coal-fired boiler, and belongs to the technical field of power generation of coal-fired boilers. In order to solve the problem that stable combustion is difficult to maintain during deep peak-shaving low-load operation of a coal-fired unit at present, raw coal is ground into superfine pulverized coal, and the air amount is adjusted, so that the air carries the superfine pulverized coal and then is sprayed into a gasification furnace from a central channel of a burner at the top of the gasification furnace; igniting the superfine pulverized coal through a high-energy igniter in the gasification furnace; introducing mixed gas of high-temperature water vapor and air; adjusting the proportion of the pulverized coal, air and water vapor, and controlling the temperature of the gasification furnace, so that the pulverized coal, oxygen and water vapor are subjected to partial gasification reaction to generate high-temperature fuel gas rich in CO; the high-temperature fuel gas carrying the non-burnt superfine pulverized coal is sprayed into a boiler hearth through the ignition pipe, and stable pulverized coal burning in the boiler is completed. The operation cost is low, the load of the pulverized coal boiler can be reduced to 20% or below, the burn-off rate of pulverized coal is high, and the requirement for ultralow load peak regulation is met.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of beneficiation method of veinlet disseminated low-grade porphyry copper ore

Owner:HEILONGJIANG DUOBAOSHAN COPPER LTD

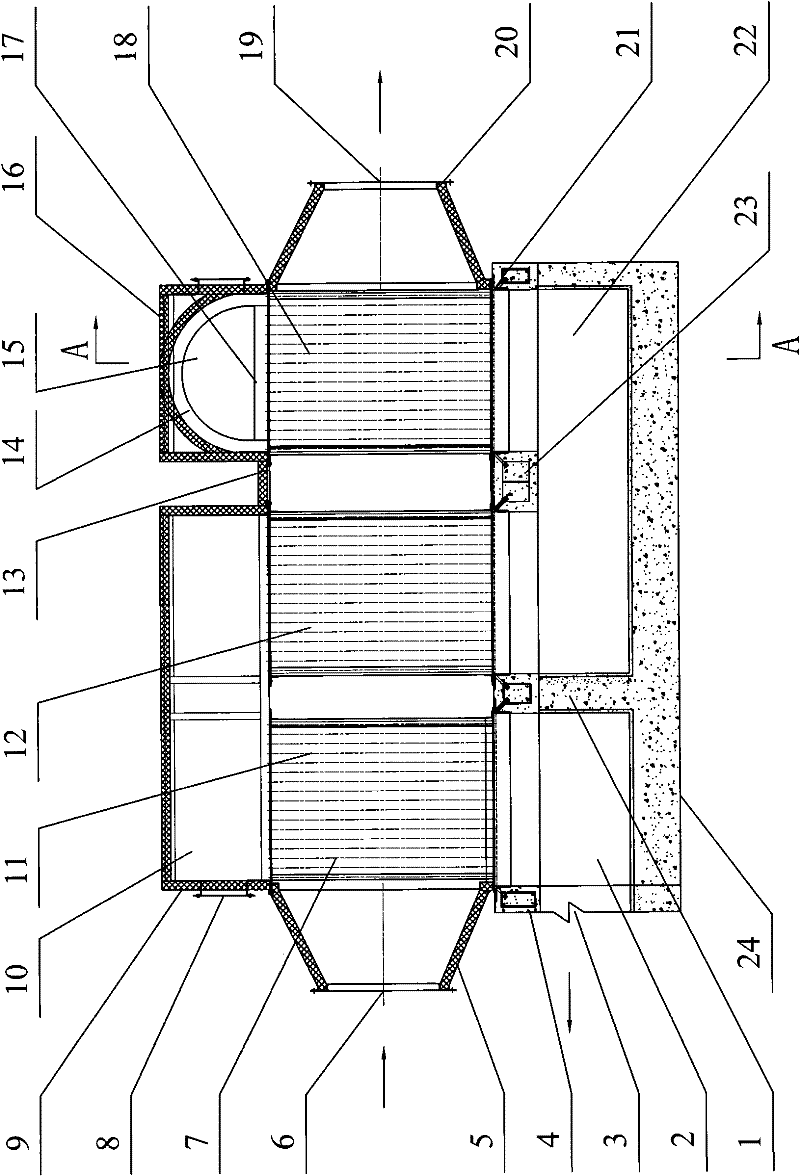

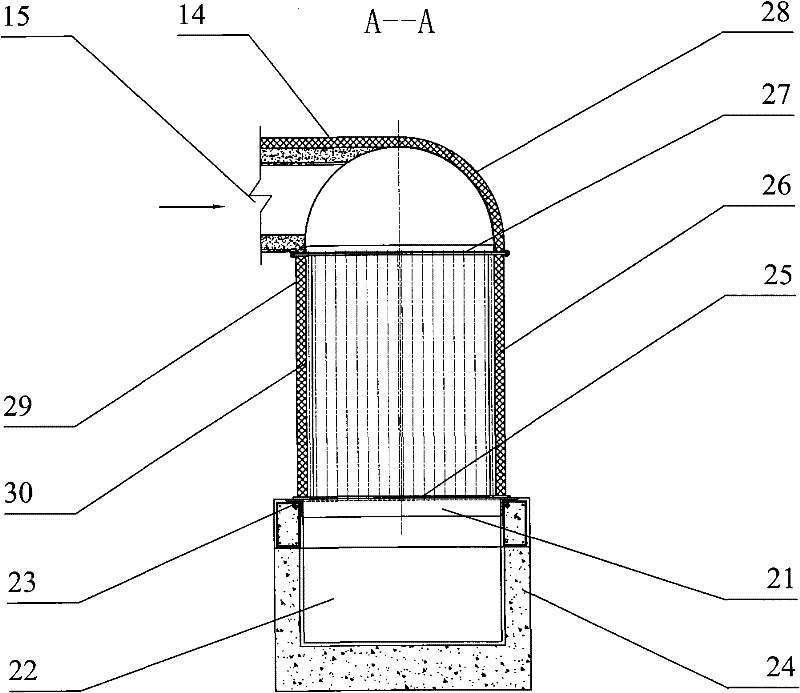

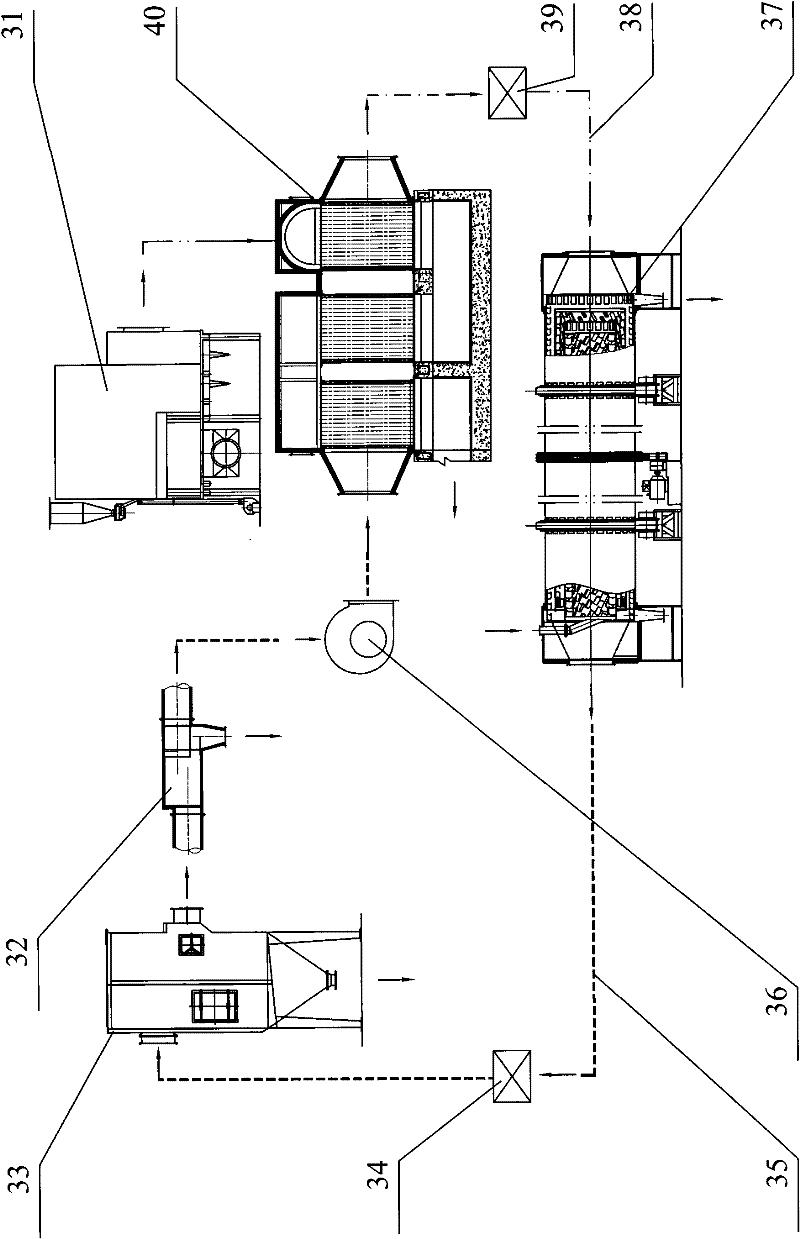

Heat energy device for preparing superheated steam with waste heat steam

The invention discloses a heat energy device for preparing superheated steam with waste heat steam, which effectively solves the problem that conventional heat sources for drying brown coal are uneconomic and have the hidden troubles of ignition and explosion. The device comprises a partition wall, a base, a heat exchange part, an upper independent smoke box, a lower independent smoke box and upper and lower integrated smoke boxes. Key points are that: the heat exchange part is provided with a low temperature heat exchange region, a medium temperature heat exchange region and a high temperature heat exchange region which are formed by a tube bundle heat medium exchanger respectively; tube cavities of the tube bundle heat medium exchangers at each heat exchange region are communicated withthe cavities of the upper independent smoke box, the lower independent smoke box and the upper and lower integrated smoke boxes respectively; staggered tube gaps between an upper tube plate and a lower tube plate of each tube bundle heat medium exchanger at the heat exchange part form a communicated cavity; the communicated cavity of the low temperature heat exchange region is connected with a waste heat steam conveying tube; and the communicated cavity of the high temperature heat exchange region is connected with a superheated steam supply tube. The device has the characteristics of rational structural design, stable performance, easy maintenance, low operating cost, energy conservation, consumption reduction, emission reduction and wide application range and can reduce the one-time investment when used for drying the brown coal.

Owner:沈阳清井环保机械工程有限公司

A process for improving the wet rubbing fastness of woven dark-colored cloth

ActiveCN107916518BFeel goodIncrease elasticityTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentPolymer scienceEngineering

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

Culture medium cold-filling preparation process

InactiveCN102774800BShort manufacturing timeIncrease productivityBottle-handling machinesHydrogenCulture mediums

The invention discloses a culture medium cold-filling preparation process. The preparation process includes following steps: weighing solid or liquid components of reagents needed for culture medium, dissolving and mixing the weighed culture medium components, adding pure water 30%-50% of the volume into a filling machine, adding the dissolved culture medium components while stirring, subjecting the culture medium mixture to constant dissolving, adjusting PH (potential of hydrogen) value, adjusting the rotation speed of the filling machine to be 150-270r / min for stirring, adjusting the pneumatic pressure of the filling machine to be 0.01-0.02MPa, filling at the normal temperature, and covering and sealing the filled culture medium for steam moist heat sterilization. Preparation of the culture medium can be completed only by weighing instrument equipment and packaging sterilization equipment without constant-dissolving and heating equipment, so that preparation time of the culture medium is shortened, production efficiency is improved, production cost is lowered, energy is saved and emission is reduced, excessive degradation of nutritional components is avoided, and various nutritional components of the culture medium are protected from being damaged.

Owner:TAIZHOU QIANYUAN BIO TECH

A butt joint connection device and method for a single-phase single-piece transition conductor of a bus duct joint

ActiveCN102820560BLarge carrying capacityReduce temperature riseLine/current collector detailsElectric connection structural associationsElectrical conductorStructural engineering

The invention relates to a device and method for butting a single-phase single-sheet transition conductor of a bus duct connector. The device comprises double-insertion-sheet type bus duct connectors (2) and single-insertion-sheet type bus duct connectors (3) which are arrayed in sequence, and when the power supply is of a three-phase four-wire system, one single-insertion-sheet type bus duct connector (3), the double-insertion-sheet type bus duct connector (2) and another single-insertion-sheet type bus duct connector (3) are arrayed in sequence. Each double-insertion-sheet type bus duct connector (2) comprises a two-phase insulating sheet (21) and a transition conductor (22). The connection method is as follows: dividing the end of a bus duct into branches with prestress, inserting the B-phase branch and C-phase branch of the power supply into the double-insertion-sheet type bus duct connectors (2) respectively, and inserting the single-insertion-sheet type bus duct connectors (3) between the A-phase branch and the B-phase branch, between the C-phase branch and the N-phase branch and between the N-phase branch and the PE-phase branch respectively. Due to the clamping function of the prestressed branches of a bus duct conductor bar (1), the conductor of the connector can be matched tightly before being fastened by insulating bolts (7).

Owner:JIANGSU ONEQ ELECTRICAL APPLIANCE GRP

Glue coating unit of coiling glass fiber cloth

InactiveCN104338654AEasy production controlSave production areaLiquid surface applicatorsCoatingsGlass fiberEngineering

The invention relates to the technical field of production of materials for food processing, particularly relates to the production technology of a food-grade baking pad used in an oven, and particularly discloses a glue coating unit of coiling glass fiber cloth. A drying oven is arranged above a rack. A feeding opening and a discharging opening are respectively formed below the drying oven. A cloth guiding roller is arranged in the drying oven. A glue groove is formed in the position, below the feeding opening of the drying oven, of the rack. A dipping roller is disposed in the glue groove. A scraper for controlling the coating amount is arranged between the dipping roller and the feeding opening of the drying oven. A material feeding frame is arranged on the front side of the drying oven, and a material receiving frame is arranged on the back side of the drying oven. The glue coating unit integrates coating, drying and vulcanizing, brings convenience to production control, saves production land occupation, greatly reduces energy consumption for unrolling and rolling equipment required in all processes of equipment, and is characterized by saving energy and reducing consumption.

Owner:YANGZHOU CITY JIANGDU DISTRICT CHENGUANG SPECIAL EQUIP FACTORY

Preparation method of diphenylamine or ring-substituted derivative thereof

ActiveCN103086898BSave energySimple production processOrganic compound preparationAmino-hyroxy compound preparationPtru catalystAcyl group

The invention relates to a preparation method of diphenylamine or a ring-substituted derivative thereof. The method comprises the following steps: utilizing an alkali metal alkoxide as an alkaline reagent, and performing reaction on halogenobenzene or the ring-substituted derivative thereof and N-acylated aniline or the ring-substituted derivative thereof in the presence of a catalyst to prepare the diphenylamine or the ring-substituted derivative thereof and simultaneously produce a second product, namely carboxylic acid ester. The molar ratio of the halogenobenzene or the ring-substituted derivative thereof, the N-acylated aniline or the ring-substituted derivative thereof and the alkali metal alkoxide is generally selected at 1.0:(1.0-1.1):(1.1-1.3). The method is utilized for producing the diphenylamine or the ring-substituted derivative thereof, and the method has the advantages of simple production process, short reaction period, high utilization rate of equipment, low energy consumption and a small quantity of three wastes.

Owner:SHANDONG DOCRIS CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com