Recovery method and device of enamelling technique tail-gas

A technology of enameling process and recovery method, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve the problems of increasing greenhouse gas emissions, difficult equipment, and restricting promotion and use, and achieve the effect of preventing black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

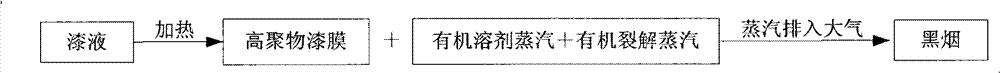

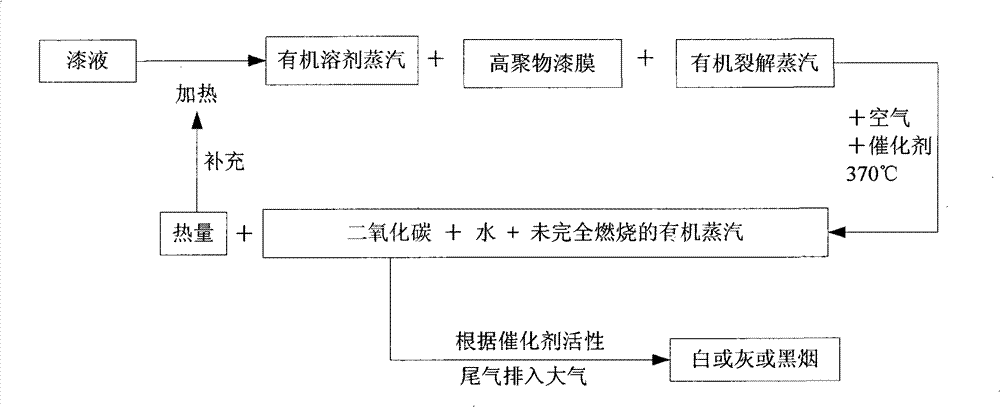

Problems solved by technology

Method used

Image

Examples

Embodiment 1

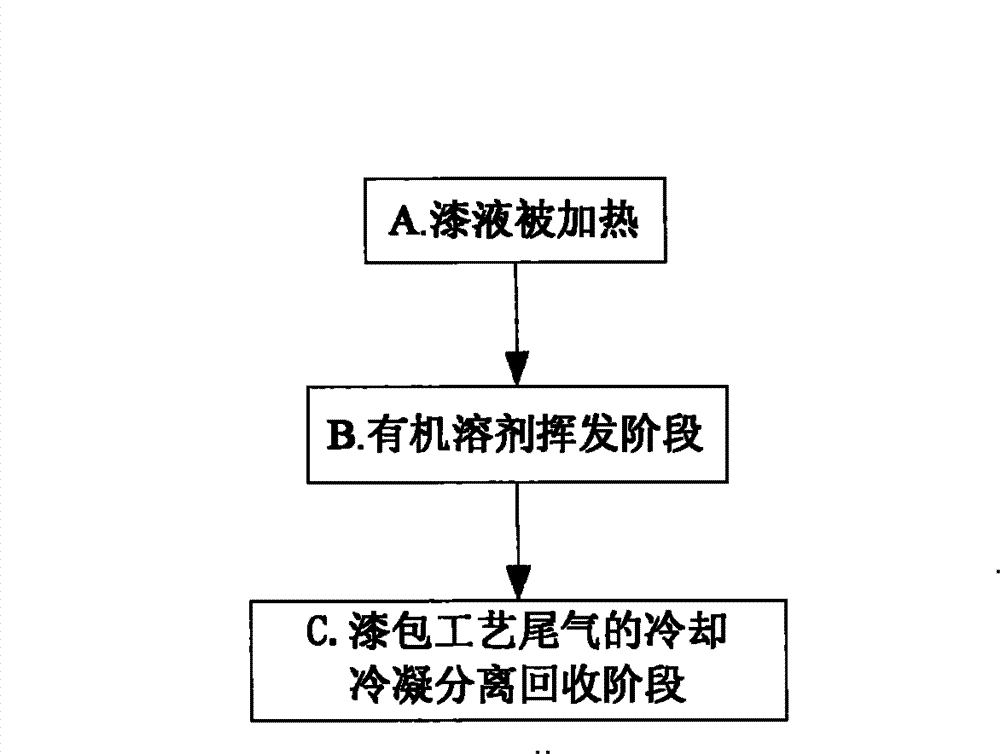

[0045] Example 1: Figure 4 The flow chart of recovering tail gas from enamelling process to condenser in the present invention; Figure 5 The flow chart of the recovery method of enamelling process tail gas in the first embodiment of the present invention. Such as Figure 4 with Figure 5 As shown, when the paint liquid enters the furnace together with the air and is heated, when the temperature of the paint liquid reaches the distillation range of solvent A (distillation range refers to a certain temperature range, 90% of a certain liquid in this temperature range is converted into Gas) A type of solvent begins to volatilize gradually and becomes solvent vapor. At this time, the fan sends A solvent vapor through the air outlet and A solvent vapor out of the air duct to continuously inject the freshly volatilized organic solvent vapor A into the type A solvent cooling condenser ( In order to prevent the overheating and deterioration of the organic solvent vapor and reduce ...

Embodiment 2

[0052] Embodiment 2: The following is a detailed description of the device and its recovery method by taking the wire enamel prepared by a mixed solvent composed of two organic solvents as an example.

[0053] Image 6 The recovery device of the tail gas of the enamelling process of the present invention-condensing enamelling oven; Figure 7 It is the process flow diagram of the recovery method of the enamelling process tail gas in the second embodiment of the present invention.

[0054] Such as Image 6 with Figure 7 As shown, the typical structure of the condensing enamelling oven and the enamelling organic solvent vapor are illustrated by taking a typical vertical enamelling oven and a typical mixed solvent composed of trimixed cresol and xylene in the wire enamel industry as an example. Separation and recovery methods.

[0055] After the conductor is coated with the paint liquid, it is pulled into the furnace 5 arranged in the oven frame 6 (due to the effect of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com