Rubber air spring capsule-free vulcanization production method

A technology of rubber air spring and production method, applied in the field of vulcanization, can solve the problems of long vulcanization time, time delay and damage of rubber air spring, and achieve the effects of removing heat transfer loss, improving service life and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

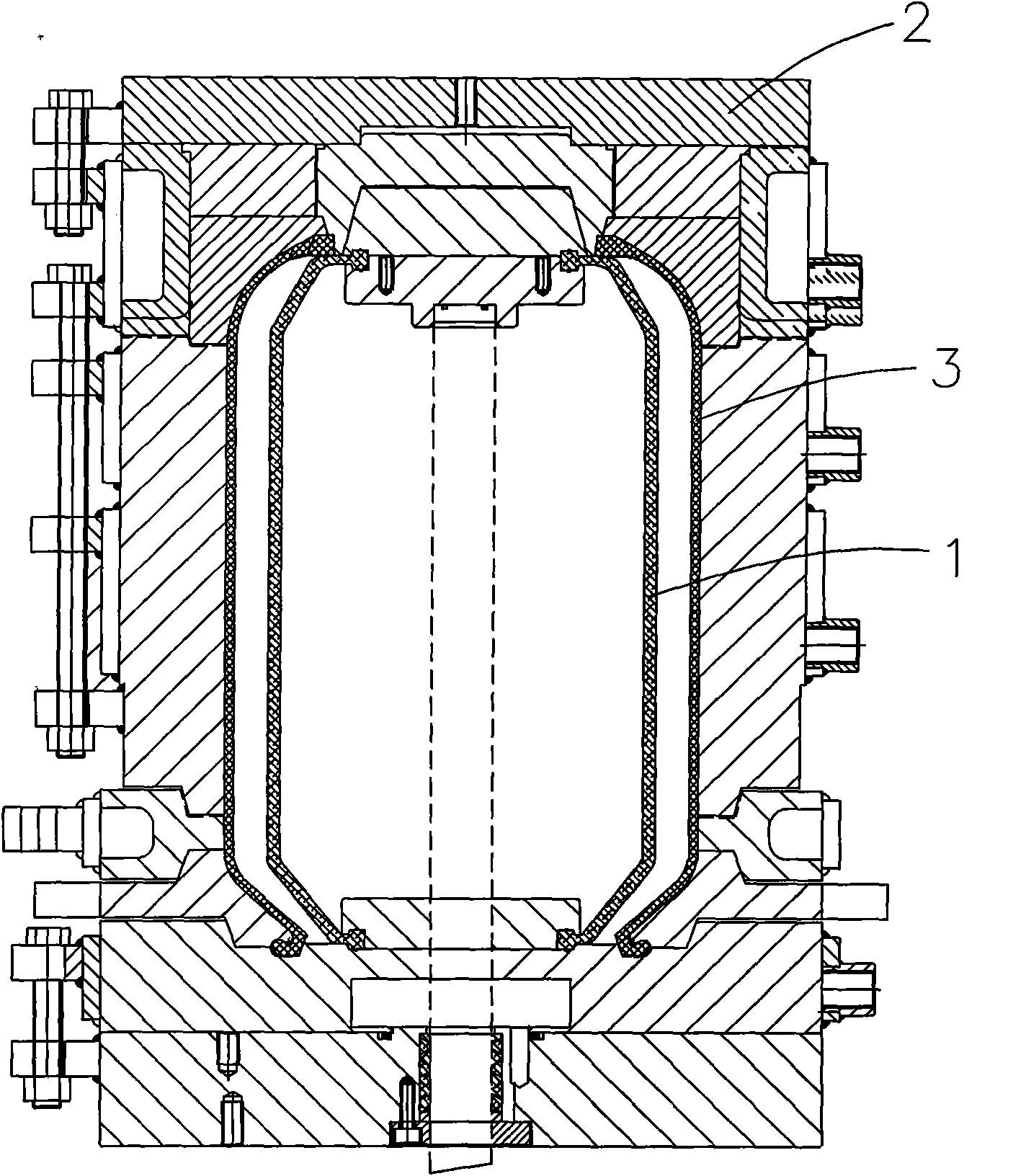

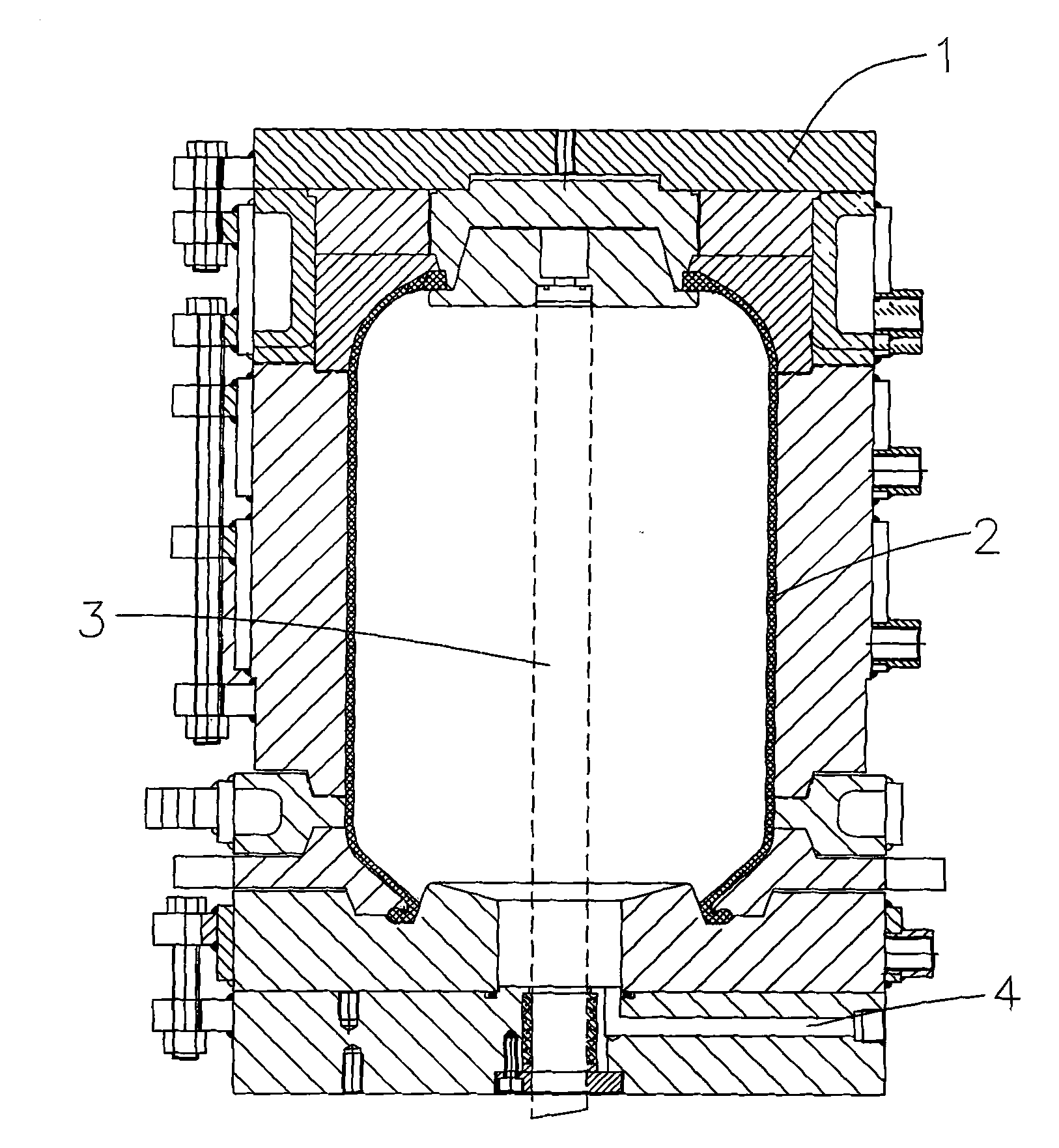

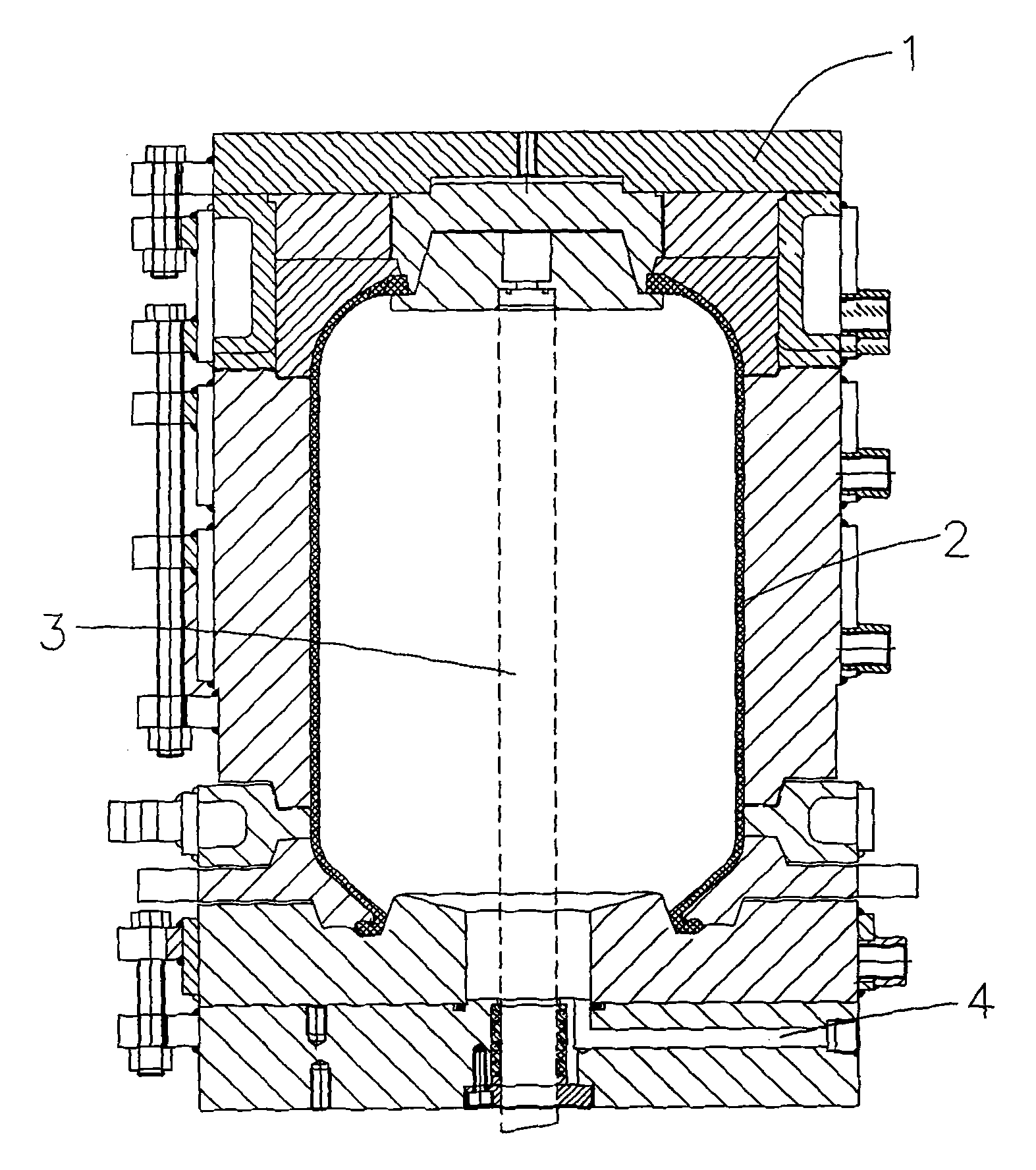

[0015] refer to figure 2 According to the bladder-free vulcanization production method of rubber air spring provided by the present invention, it specifically includes: canceling the bladder holder structure on the vulcanization mold 1, and directly loading the preformed rubber air spring tire blank 2 into the cavity of the vulcanization mold 1 , Use 0.1-1bar low-pressure air or nitrogen to shape the rubber air spring blank. After the mold is closed, fill in 6-15bar steam to provide heat for the rubber air spring blank, and then quickly fill in 18-35bar high-pressure nitrogen as the internal pressure medium Vulcanize.

[0016] As mentioned above, after the mold is closed, the interval between filling with steam and filling with nitrogen is 1min. An internal pressure medium circulation hole 4 is opened on the vulcanization mold 1 or the central rod 3 , and the air, nitrogen and steam are all filled into the vulcanization mold 1 through the internal pressure medium circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com