Production technology of precast concrete member rough surface

A technology of prefabricated concrete and prefabricated components, which is applied in the direction of manufacturing tools, mold auxiliary parts, ceramic molding machines, etc., and can solve problems such as unfavorable industrial production, low efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

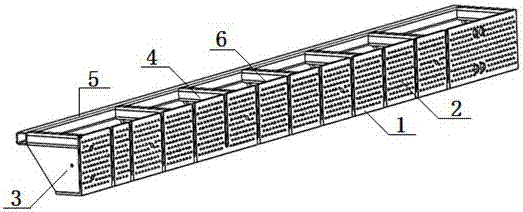

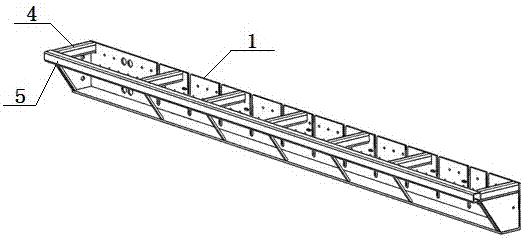

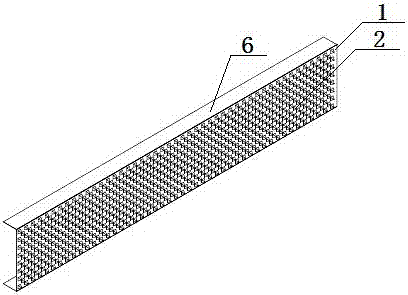

[0046] see Figure 1~Figure 6 , the prefabricated concrete component rough surface production process of the present invention comprises:

[0047] 1) Provide rough surface forming templates for prefabricated components: multiple grooves or protrusions that meet the national standards for rough surfaces of prefabricated components are formed on PE material templates or metal templates;

[0048] 2) Provide prefabricated component rib molds: provide rib templates according to the design dimensions of prefabricated components, and install supporting components on the back of the rib templates;

[0049] 3) Connect and fix the PE material formwork or metal formwork with multiple grooves or protrusions prepared in the above 1) on the front side of the rib formwork produced in the above 2), and compound it into a mold with multiple grooves or multiple a raised prefabricated component rough side rib mold;

[0050] 4) Install the prefabricated component rough side rib mold with multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com