Tool for molding rough surface of precast concrete unit

A technology of prefabricated concrete and prefabricated components, applied in the field of construction engineering, can solve the problems of polluting the environment, unfavorable industrial production, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

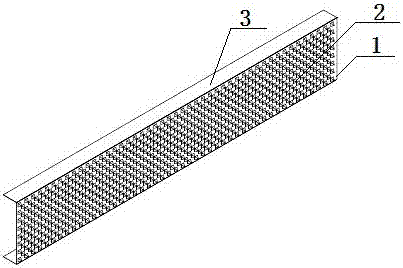

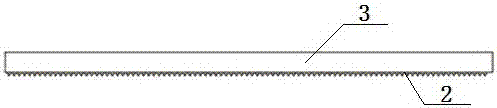

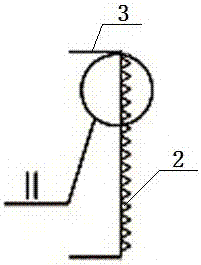

[0035] See Figure 1~Figure 6 , The rough surface forming tool of the precast concrete member of the present invention includes a forming template, and the forming template also includes a PE material template or a metal membrane plate. The PE material or metal membrane plate is processed and manufactured with a plurality of grooves that meet the national standards. Or a plurality of protrusions; the prefabricated component includes a prefabricated plate, a prefabricated beam, a prefabricated column or a prefabricated wall; the PE material diaphragm is processed with multiple grooves or a plurality of protrusions integrally molded by injection molding; the metal diaphragm Processed and manufactured with a plurality of grooves or a plurality of protrusions integrally stamped and formed; the plurality of grooves or a plurality of protrusions can be arranged on a PE material template or a metal template at equal intervals or at random intervals; the grooves are preferably inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com