Glue coating unit of coiling glass fiber cloth

A technology of glass fiber cloth and gluing, which is applied to the device and coating of the surface coating liquid, which can solve the problems of large investment in equipment, complicated production process procedures, and many personnel in the production process, so as to save production area , The effect of convenient production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

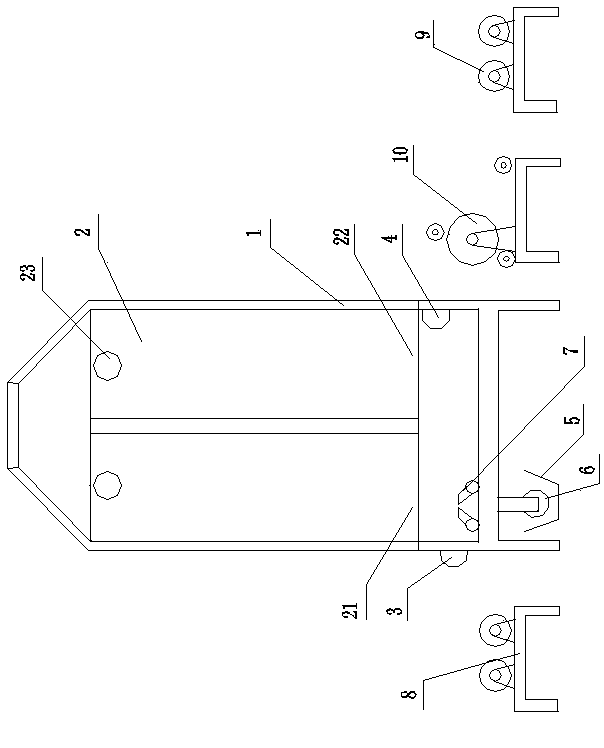

[0009] like figure 1 As shown, an electric heating oven 2 is arranged above the frame 1, a feed inlet 21 and a discharge outlet 22 are respectively arranged below the oven 2, a cloth guide roller 23 is arranged in the oven 2, and the bottom of the oven 2 corresponds to the inlet , The outlets 21 and 22 are also provided with a cloth feed roller 3 and a cloth discharge roller 4 .

[0010] A glue tank 5 is arranged on the frame 1 below the feed port 21 of the oven 2 , and an impregnating roller 6 is arranged cooperatively in the glue tank 5 .

[0011] A pair of scrapers 7 for controlling the amount of gluing is arranged between the impregnation roll 6 and the feed port 21 of the oven 2 .

[0012] A discharge rack 8 is set on the front side of the oven 2, a stacker 9 is set on the rear side, and a calender 10 can also be set between the oven 2 and the stacker 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com