Crankshaft of automobile engine

An automobile engine and crankshaft technology, applied in the crankshaft and other directions, can solve the problem of not being able to adapt to the load of a large-displacement automobile engine, and achieve the effects of good mechanical properties, high toughness and fatigue strength, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0014] In order to achieve the above object, the technical solution taken by the present invention and its corresponding specific implementation are as follows:

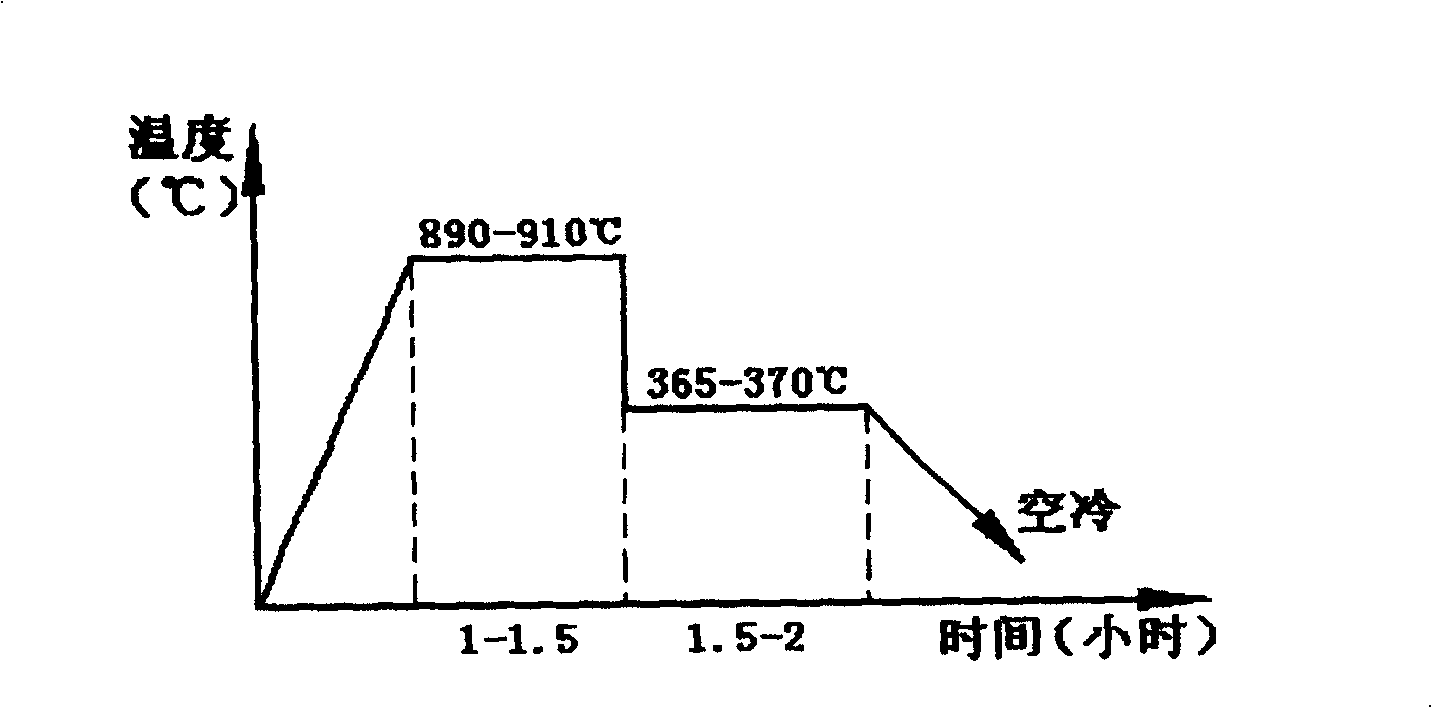

[0015] The automobile engine crankshaft provided by the present invention adopts cast iron material, and the key is that the cast iron material adopts a material strengthening process. The method is that ordinary nodular cast iron becomes Aube nodular cast iron through austempering heat treatment, and its matrix structure is upper bainite and residual austenitic Tensile body, the spheroidization grade of the as-cast rough is 1 to 2 grades, and the diameter of graphite balls is above 6 grades.

[0016] High-strength, high-toughness Aubeite nodular cast iron has superior comprehensive mechanical properties, and at the same time, the cost is lower than steel, and the blank manufacturing and cutting are convenient. Its material performance index is: tensile strength σ b >1050MPa, yield strength σ s ≥750MPa, elongation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com