Beneficiation method of veinlet disseminated low-grade porphyry type copper ore

A mineral processing method and low-grade technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of copper and associated metals, large amount of mineral processing agents, and unstable process, so as to improve the quality of concentrate and recovery of mineral processing The effect of improving the efficiency, improving the hydrophobicity and reducing the energy consumption of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] A method for beneficiating veinlet disseminated low-grade porphyry copper ore, comprising the following steps:

[0029] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness of -0.074mm particle size grade accounts for 70% of the total weight of the ore. During the grinding process, add 1000g / t of lime, add water to adjust the slurry until the pH of the ore is 10. Obtain the ore grinding slurry for use;

[0030] Step 2. Add regulator sodium sulfide 30g / t, collector 60g / t, and foaming agent 2# oil 30g / t to the grinding pulp obtained in step 1 in order to carry out copper rapid flotation, copper rapid flotation Time 3min, get copper fast floating coarse concentrate and copper fast floating tailings, stand-by;

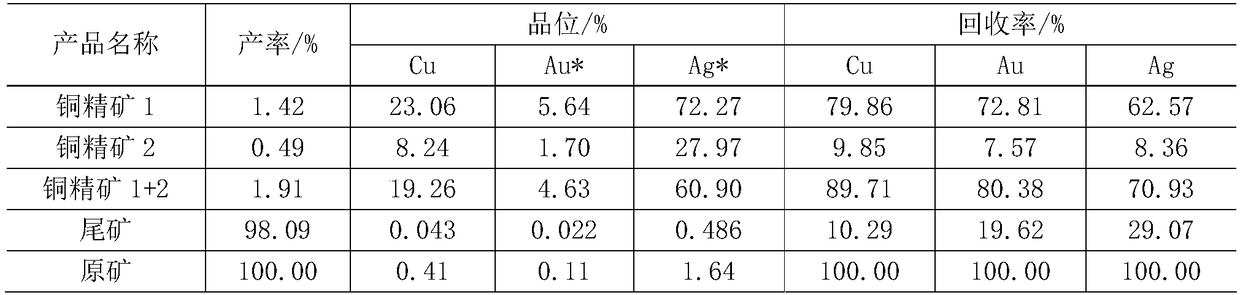

[0031] Step 3. The copper fast floating coarse concentrate obtained in step 2 is subjected to 2 times of beneficiation, which are respectively the 1st beneficiation and the 2nd beneficiation, and the final copper conc...

specific Embodiment approach 2

[0047] A method for beneficiating veinlet disseminated low-grade porphyry copper ore, comprising the following steps:

[0048] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness -0.074mm particle size grade accounts for 80% of the total weight of the ore. During the grinding process, add lime 1500g / t, add water to adjust the slurry until the pH of the ore is 11. Obtain the ore grinding slurry for use;

[0049] Step 2. Add regulator sodium sulfide 60g / t, collector 100g / t, foaming agent 2# oil 20g / t in order to the grinding pulp obtained in step 1, and perform copper rapid flotation, copper rapid flotation Time 2min, get copper fast floating coarse concentrate and copper fast floating tailings, stand-by;

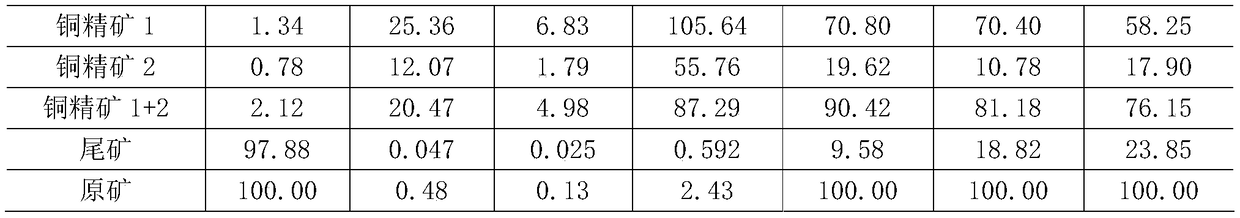

[0050] Step 3. The copper fast floating coarse concentrate obtained in step 2 is subjected to 2 times of beneficiation, which are respectively the 1st beneficiation and the 2nd beneficiation, and the final copper concentrate A...

specific Embodiment approach 3

[0066] A method for beneficiating veinlet disseminated low-grade porphyry copper ore, comprising the following steps:

[0067] Step 1. Crush the raw ore and grind it finely with a ball mill. The content of the grinding fineness -0.074mm particle size grade accounts for 70-80% of the total weight of the ore. During the grinding process, add lime 1000-1500g / t, add water to adjust the slurry Until the pH of the pulp is 10-11, the ore grinding pulp is obtained for use;

[0068] Step 2. Add regulator sodium sulfide 30-60g / t, collector 60-100g / t, foaming agent 2# oil 20-30g / t in sequence to the grinding pulp obtained in step 1 to carry out rapid copper flotation Selection, copper fast flotation time 2 ~ 3min, get copper fast floating coarse concentrate and copper fast floating tailings, stand-by;

[0069] Step 3. The copper fast floating coarse concentrate obtained in step 2 is subjected to 2 times of beneficiation, which are respectively the 1st beneficiation and the 2nd beneficia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com