Heat energy device for preparing superheated steam with waste heat steam

A technology of superheated steam and hot steam, which is applied in the direction of steam superheating, steam generation, lighting and heating equipment, etc. It can solve the problems of uneconomical heat sources, achieve the effects of reducing one-time investment, reducing operating costs, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

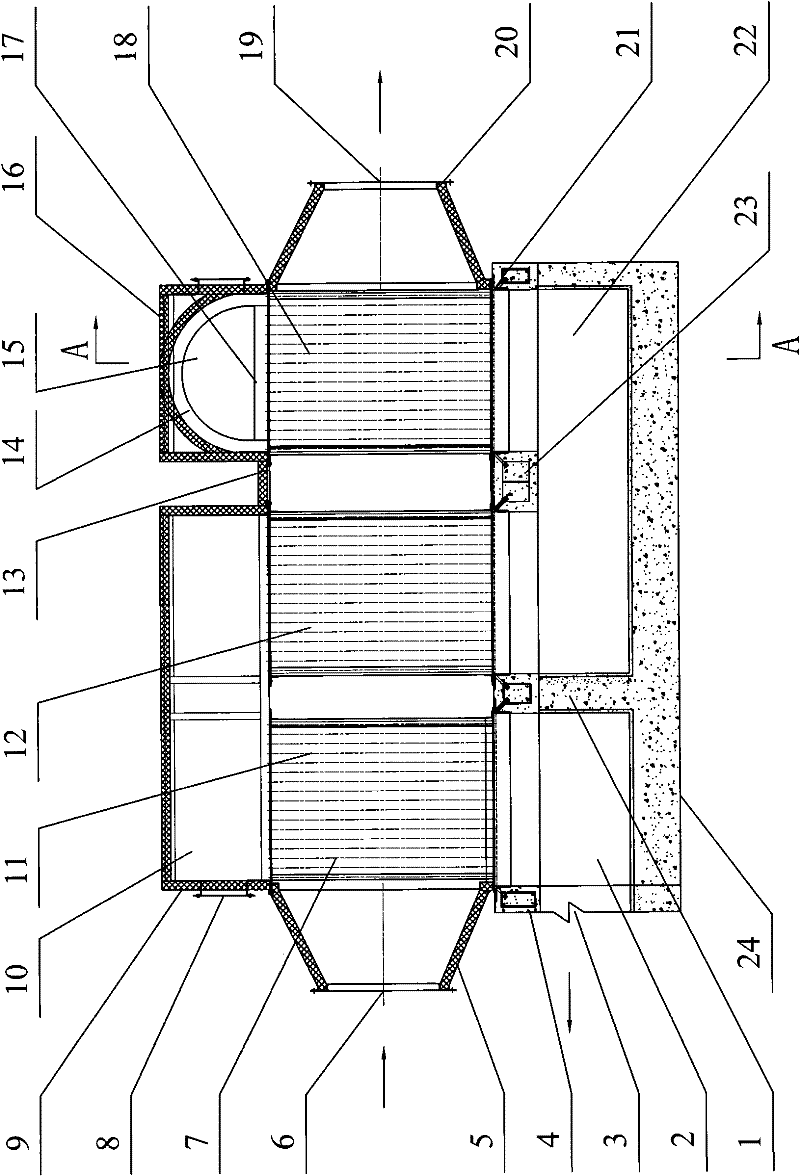

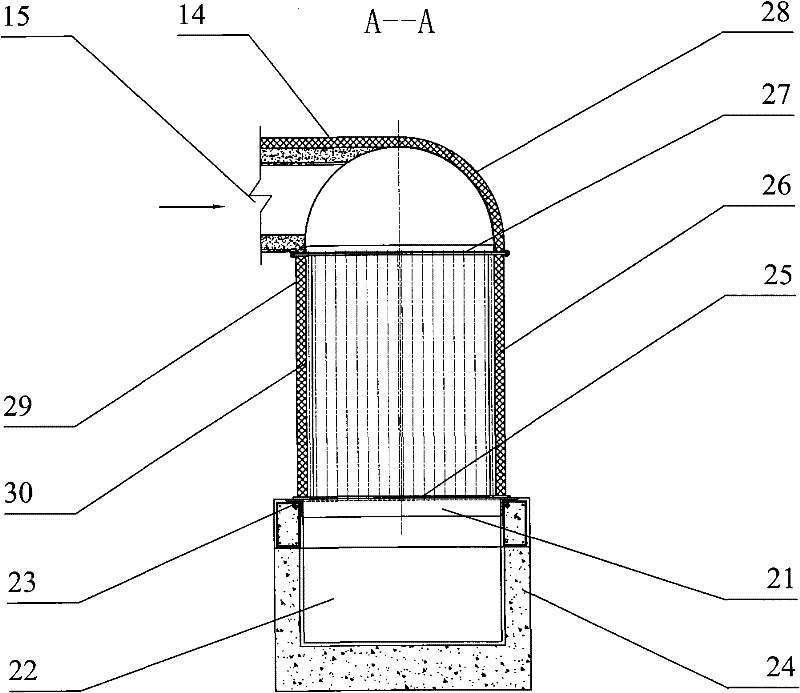

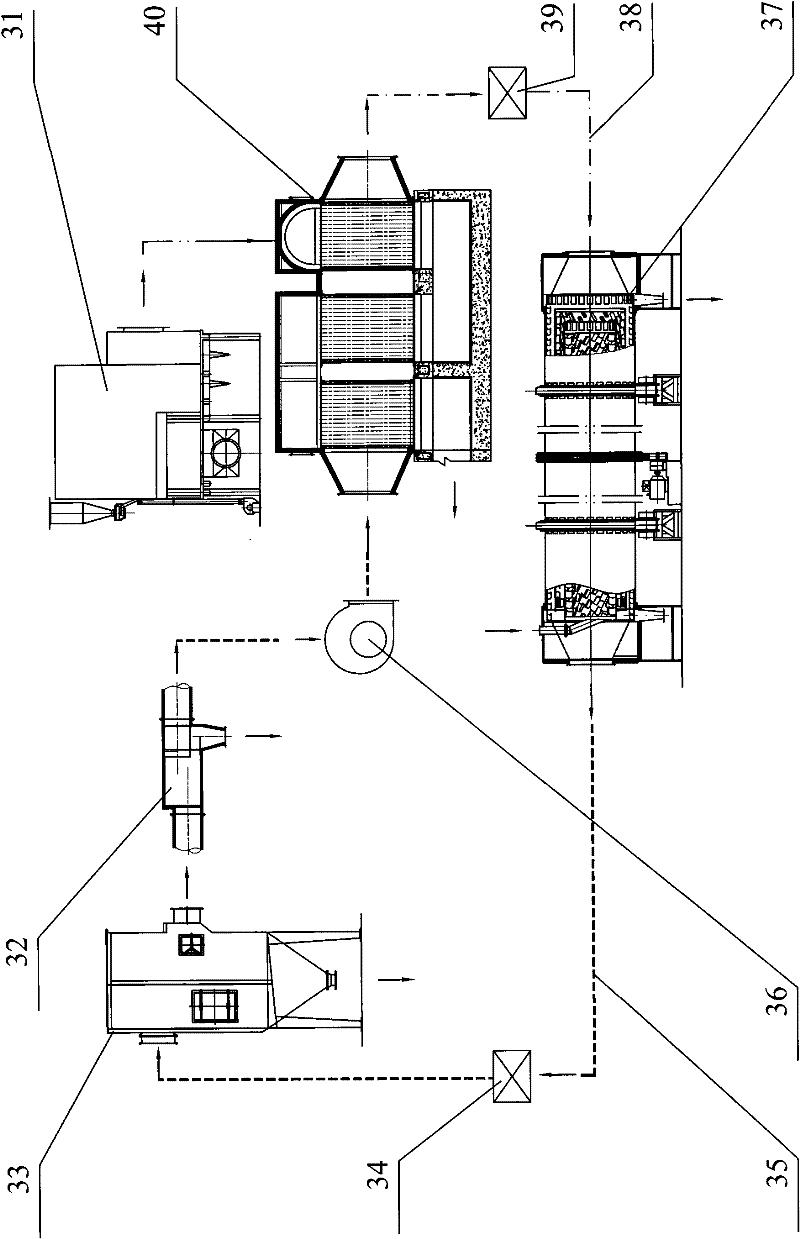

[0020] according to Figure 1~3 The specific structure of the present invention will be described in detail. The thermal energy device 40 for preparing superheated steam 38 from waste heat gas 35 includes: a base 24 with a partition wall 1, a lower single-body smoke box 2 with a waste gas outlet 3, and a lower connected smoke box 22 fixed on the base The heat exchange part above the seat 24 is provided with flue gas inlets 15 and the upper single-body smoke box 16 of the arched flue 14, the upper conjoined smoke box 10 and other components. Among them, a low-temperature heat exchange zone 11 , a medium-temperature heat exchange zone 12 and a high-temperature heat exchange zone 18 formed by tube-bundle heat-mass exchangers 7 are arranged between the heat-insulation walls 26 on both sides of the heat exchange part. Thermal insulation wall 26 is made of inner wall plate 30, outer wall plate 29 and the high thermal insulation material 28 between interior and outer wall plates 30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com