Combustor started regenerative catalytic oxidation device with a plurality of reaction chambers for coal mine ventilation air methane (VAM)

A technology with multiple reaction chambers and oxidation devices, applied in the fields of greenhouse gas capture, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increasing the cost and floor area of the oxidation device, the limitation of heat recovery efficiency, and the limited efficiency, etc. Achieve the effects of easy modular design and manufacture, fast start-up, and high heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

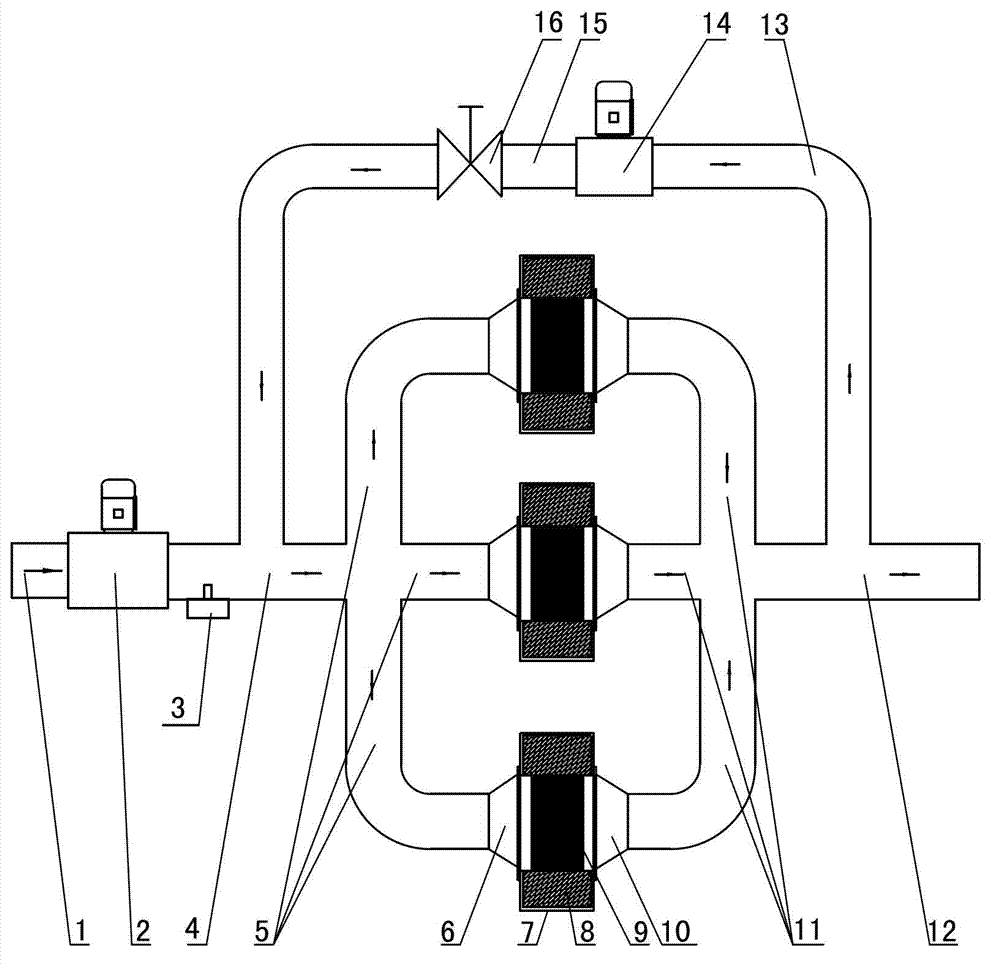

[0014] exist figure 1 In the shown embodiment: it includes 3 reaction chambers, the exhaust air delivery pipe 1 is connected to the exhaust air intake main pipe 4 through the blower 2, and the burner 3 is arranged on the exhaust air intake main pipe 4; each reaction chamber is equipped with The reaction chamber housing 7 of the insulation layer 8 is enclosed, and the catalyst ceramic layer 9 is arranged in the reaction chamber; the entrance of each reaction chamber is connected to the exhaust air intake main pipe 4 through the expansion pipe 6 and the exhaust air intake branch pipe 5 in turn, each The outlets of the reaction chamber are all sequentially connected to the main exhaust pipe 12 through the shrinkage tube 10 and the exhaust branch pipe 11, and the other end of the main exhaust pipe 12 is connected to the atmosphere; the heat recovery system includes a heat recovery inlet pipe 13, The heat recovery blower 14 and the heat recovery connection pipe 15 provided with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com